Thermal balance control method for modular multilevel converter

A modular multi-level, control method technology, applied in the field of power system, can solve problems such as sub-module capacitance deviation, and achieve the effect of simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

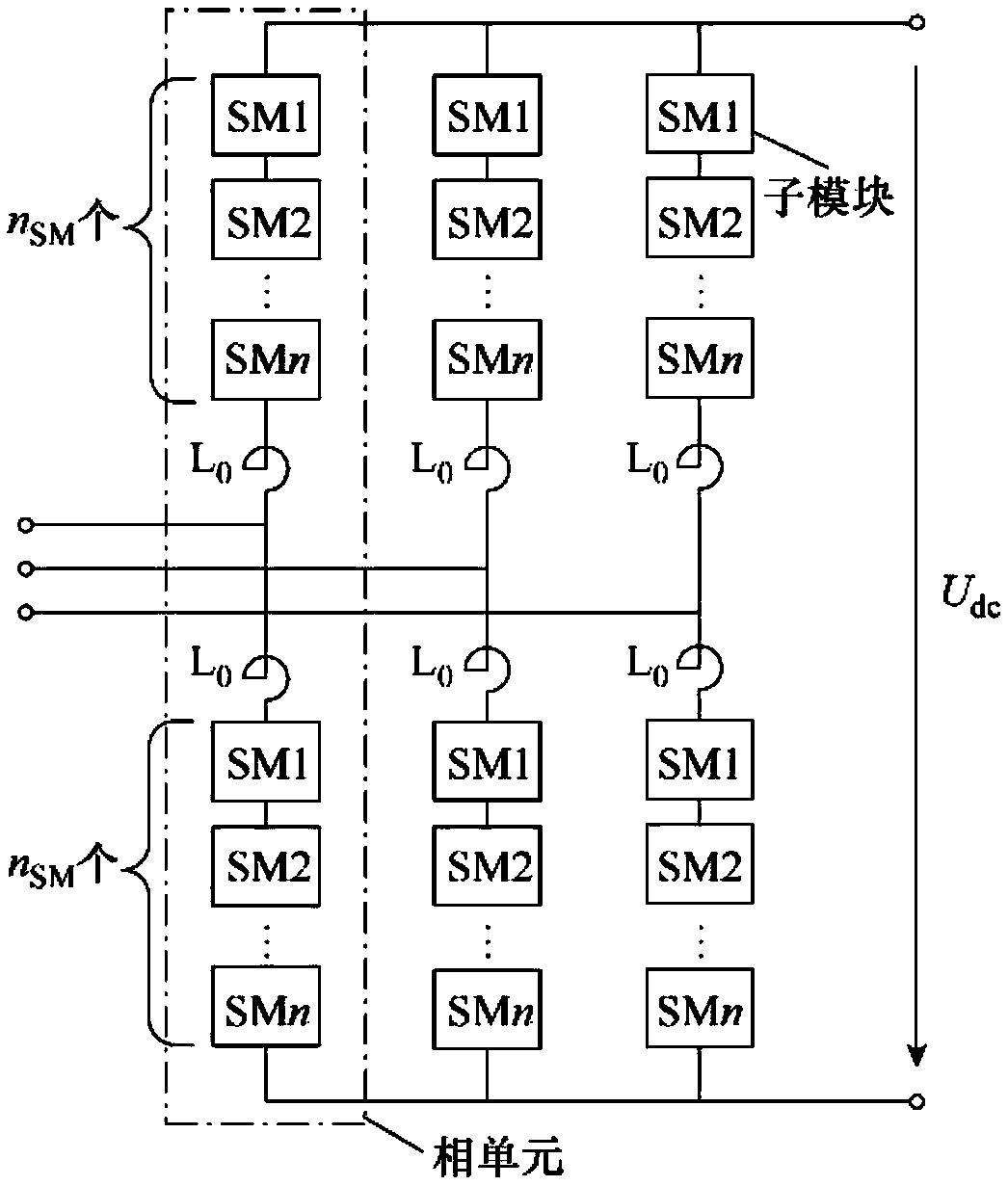

[0035] figure 1 is a typical topology diagram of a modular multilevel converter MMC. figure 1 In the topology of the modular multilevel voltage source converter (MMC), each phase has two upper and lower bridge arms, and each bridge arm is composed of n half-bridge sub-modules and a bridge arm reactor L. where U dc is the DC side voltage.

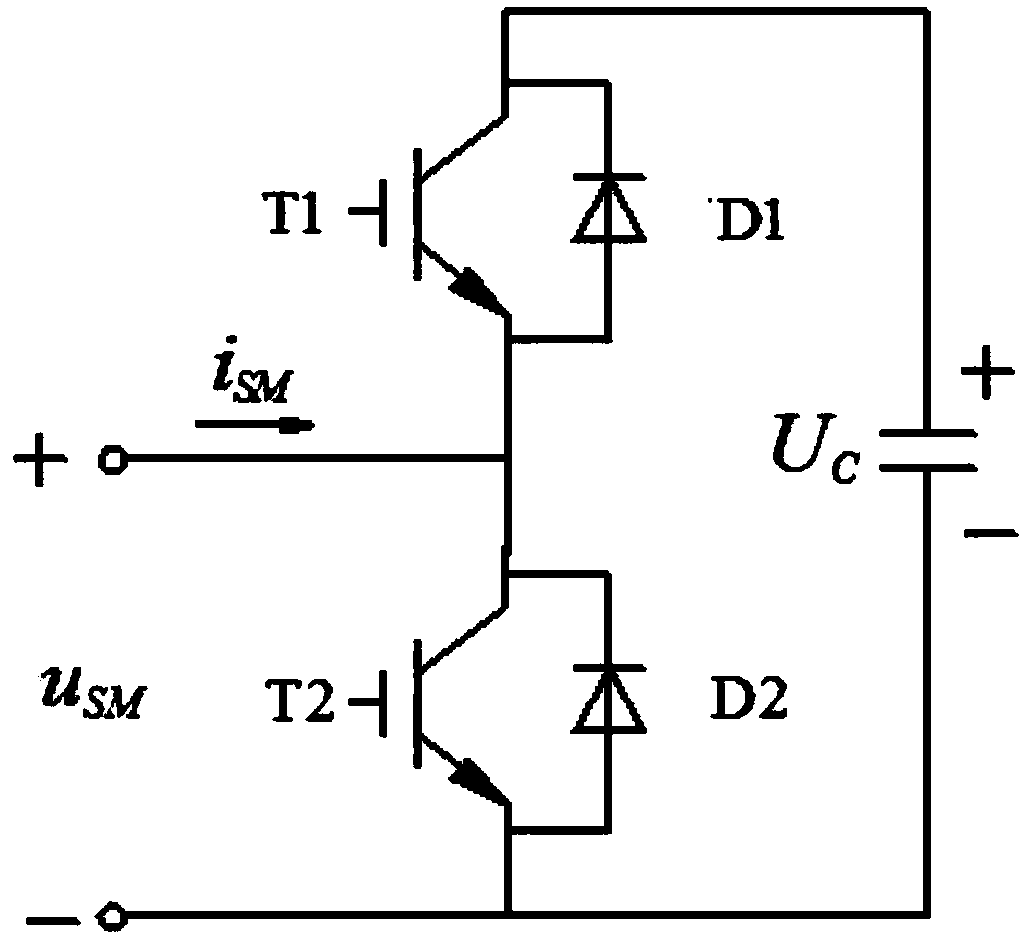

[0036] figure 2 is the block diagram of the half-bridge sub-module. figure 2 , the half-bridge sub-module is composed of two IGBTs T 1 , T 2 , two antiparallel diodes D 1 、D 2 And a capacitor, the output voltage of a single half-bridge sub-module is the capacitor voltage U SM Or it is 0, so it can output two levels of 1 and 0.

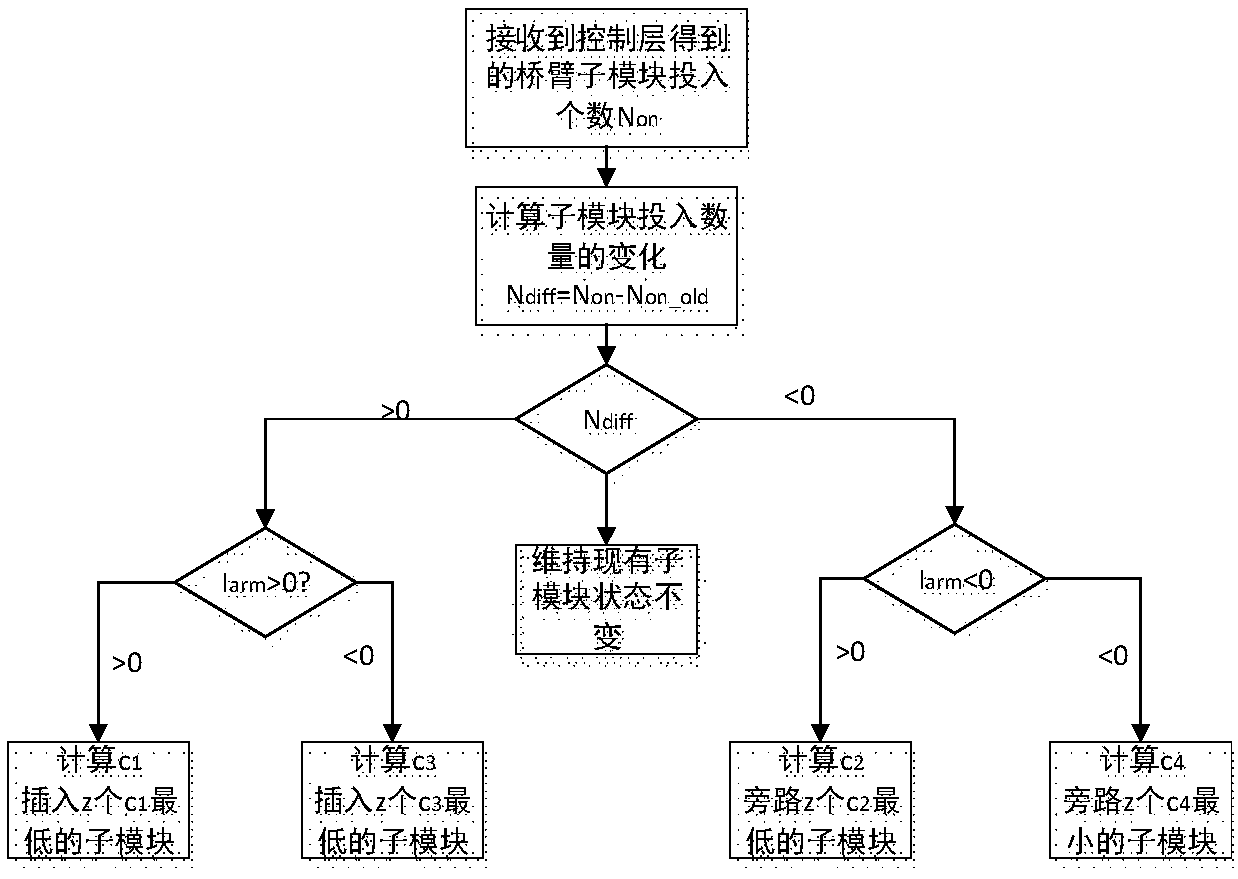

[0037] image 3 It is a flow chart suitable for the heat balance control of the modularized multilevel converter provided by the present invention:

[0038] (1) First accept the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com