Photovoltaic module

A technology of photovoltaic modules and reflected light, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as inability to dissipate temperature of components, decline in output power and service life, and affect heat dissipation performance of components, so as to improve output power and use Effect of life, balanced temperature and light receiving uniformity, and improvement of cumulative power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

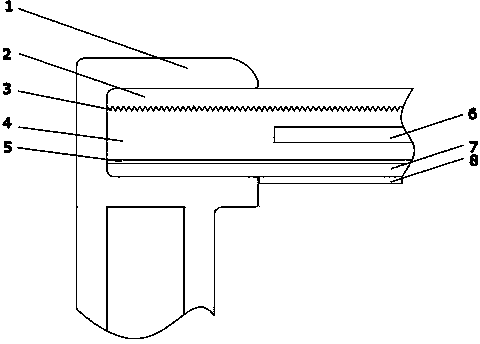

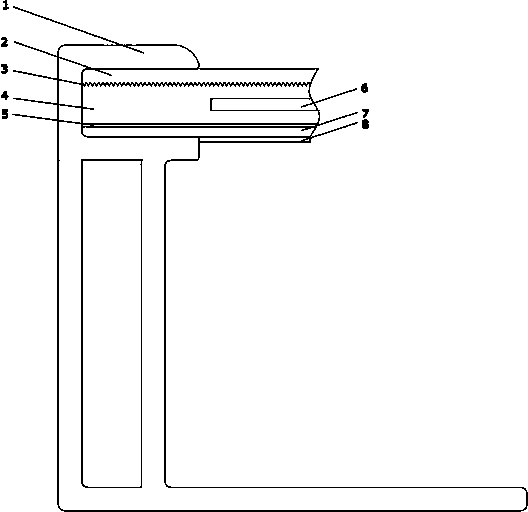

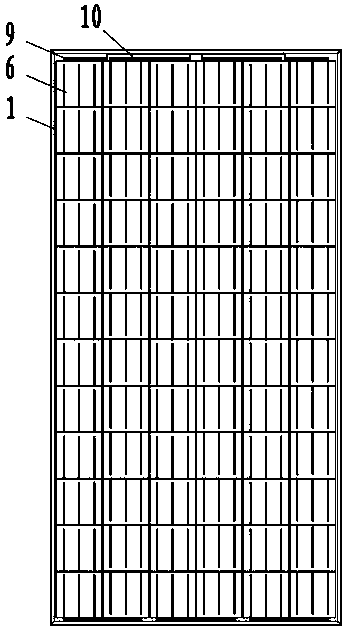

[0018] The new photovoltaic module involved in the present invention includes a junction box and a laminate, and is characterized in that: the laminated structure includes functions of absorbing infrared and ultraviolet light or other wavelengths of light or reflecting infrared light with a thickness of 2mm from top to bottom. The front panel with the function of ultraviolet light or other wavelengths of light is rolled tempered glass 2, the PVB encapsulation layer with UV absorption or transmission function 4, crystalline silicon battery (single crystal, polycrystalline, similar to single crystal battery) 6, 2mm thick The inner surface of the backboard float tempered glass substrate 7 coated with a highly reflective ceramic film, the backlight surface of the front glass substrate 2 is provided with a textured suede surface 3, and the inner surface of the backplane glass substrate 7 is coated with a high reflective ceramic film 5, The outer surface of the backplane glass substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com