Automatic sprinkling type phosphatization treatment system for surface of steel barrel

A technology of automatic spraying and phosphating treatment, applied in the direction of metal material coating process, etc., can solve the problems of long process route, low production line efficiency, increased personnel inspection, etc., to optimize the working environment, improve production efficiency, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

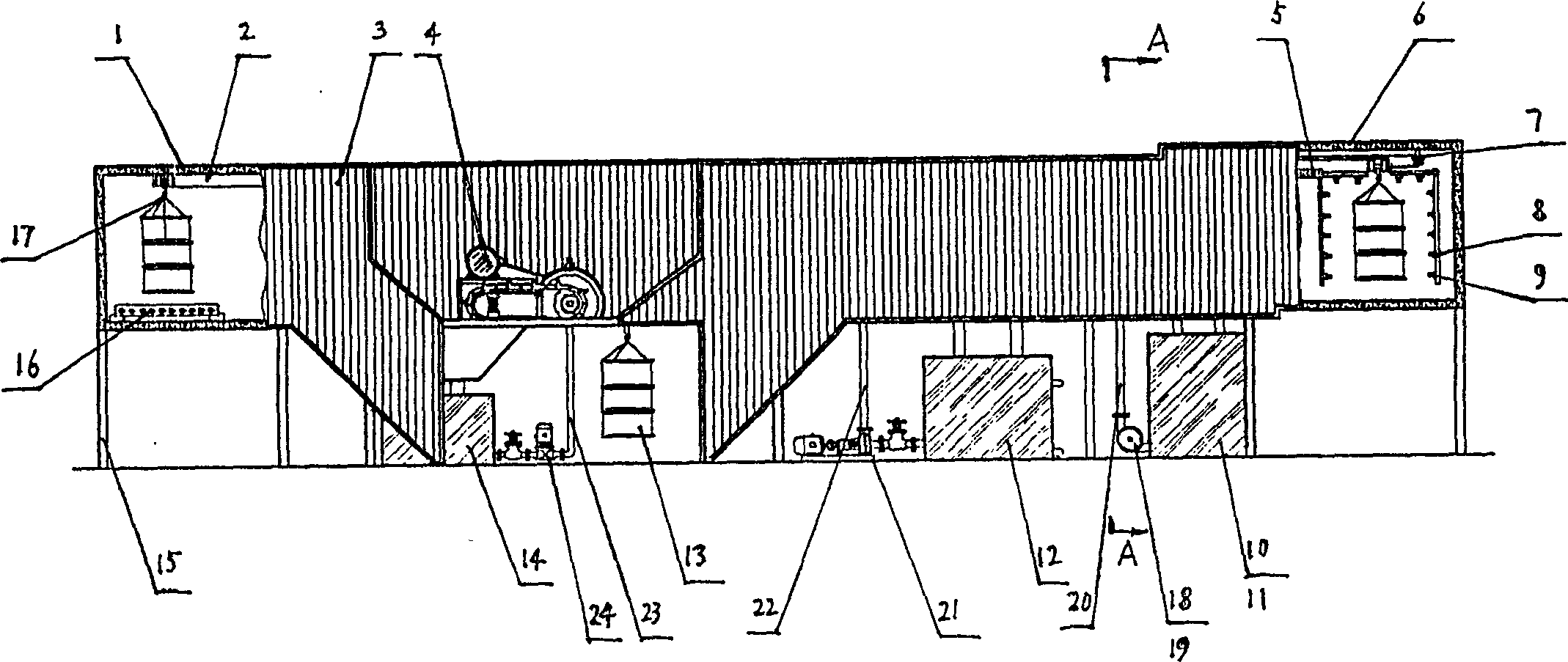

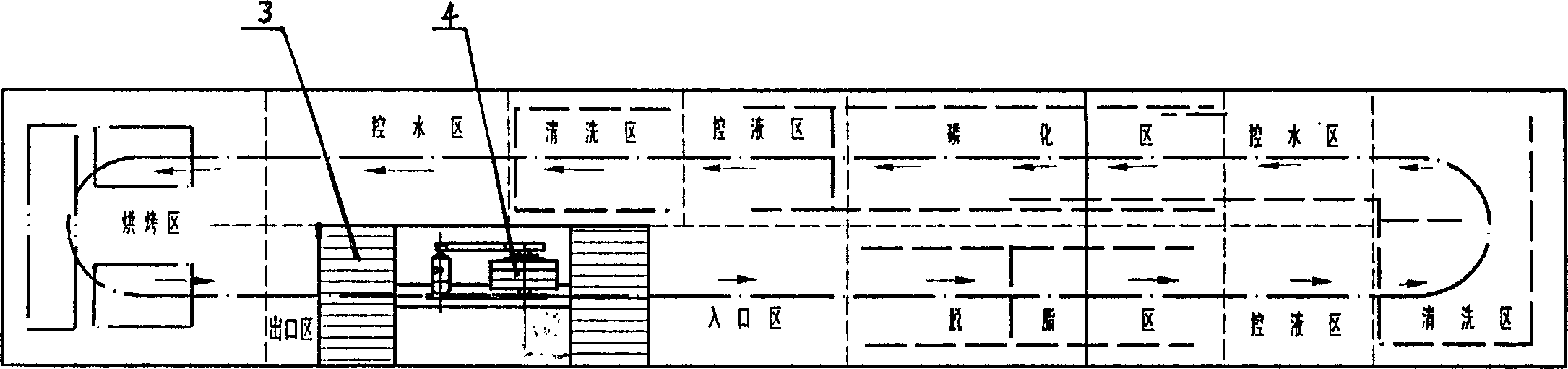

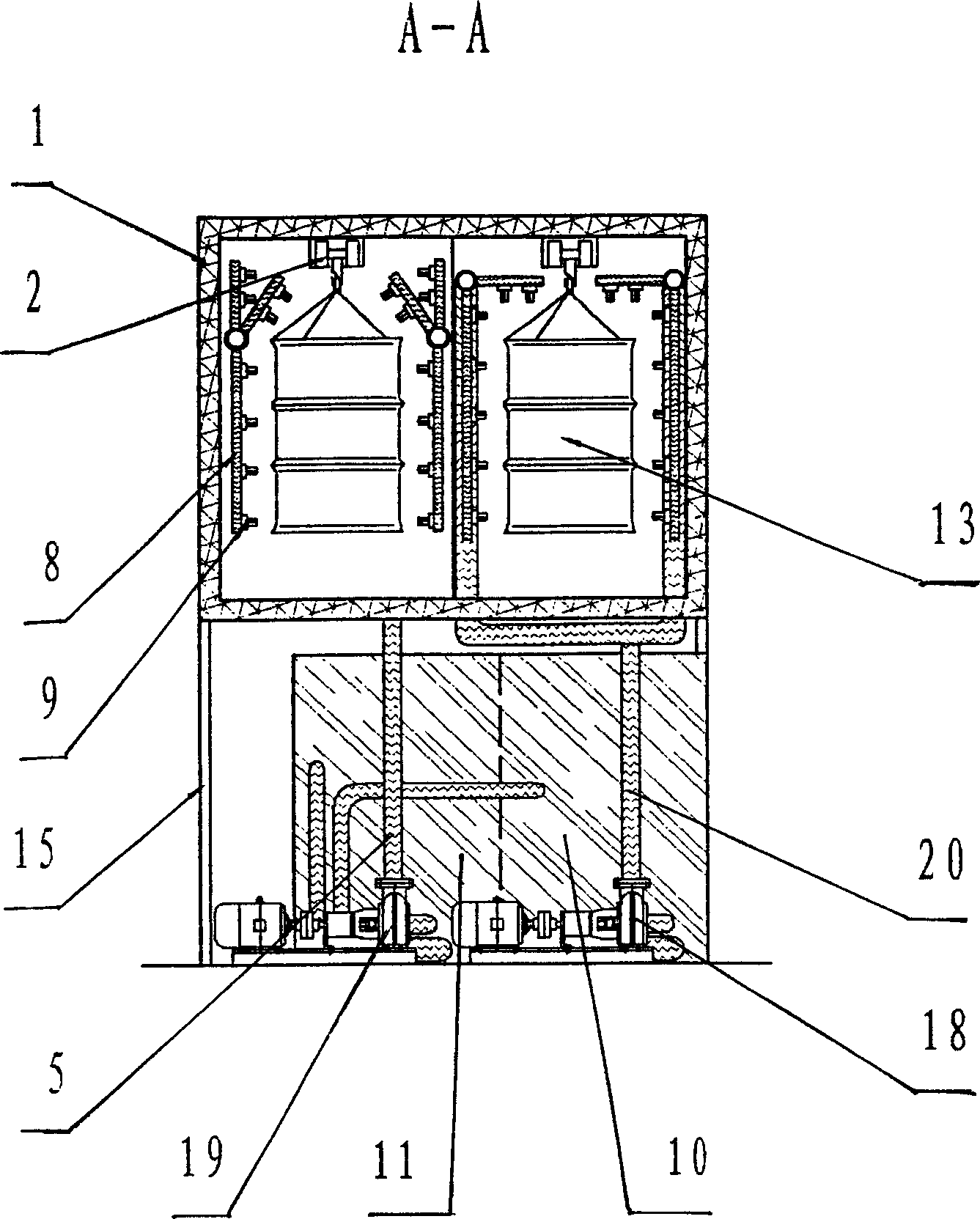

[0027] The structure of the present invention is as Figure 1-Figure 5 Shown: Including insulation cotton 1, transmission chain system 2, color steel tile 3, power mechanism 4, clear water main pipe 5, vent hole 6, tensioner 7, spray pipe 8, spray head 9, degreasing liquid tank 10 , cleaning water tank 11, phosphating solution tank 12, product 13 (steel drum), cleaning water tank 14, steel structure frame 15, electric heater 16, hanger 17, degreasing liquid pump 18, water pump 19, degreasing liquid main pipeline 20, Phosphating solution pump 21, inclined phosphating solution main pipeline 22, clean water main pipeline 23, water pump 24. The sprinkler pipes and sprinkler head structures and specifications of the pipeline systems in each district of the present invention are all the same, represented by 8 and 9 respectively;

[0028] Working principle of the present invention: the system works in a cyclic manner, and the workpiece 13 (steel drum) enters the entrance area, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com