Pneumatic cutting assembly with one-way valve stop function

A technology of pneumatic cutting and one-way valve, which is applied to the parts of grinding machine tools, grinding drive devices, grinding machines, etc., can solve problems such as industrial accidents, and achieve the effects of convenient braking, compact structure, and improved use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

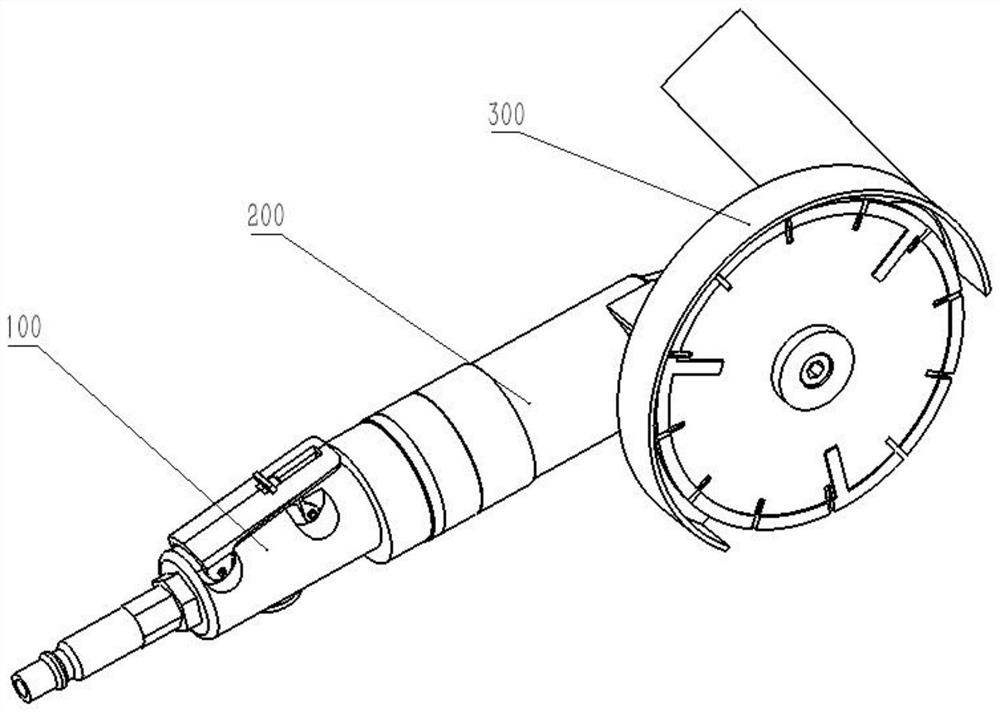

[0035] The present invention provides a one-way valve-stopped pneumatic cutting assembly, specifically a one-way valve-based air-loss braking pneumatic cutting machine, such as figure 1 As shown, it includes a control unit 100 , a braking and power unit 200 and an execution unit 300 .

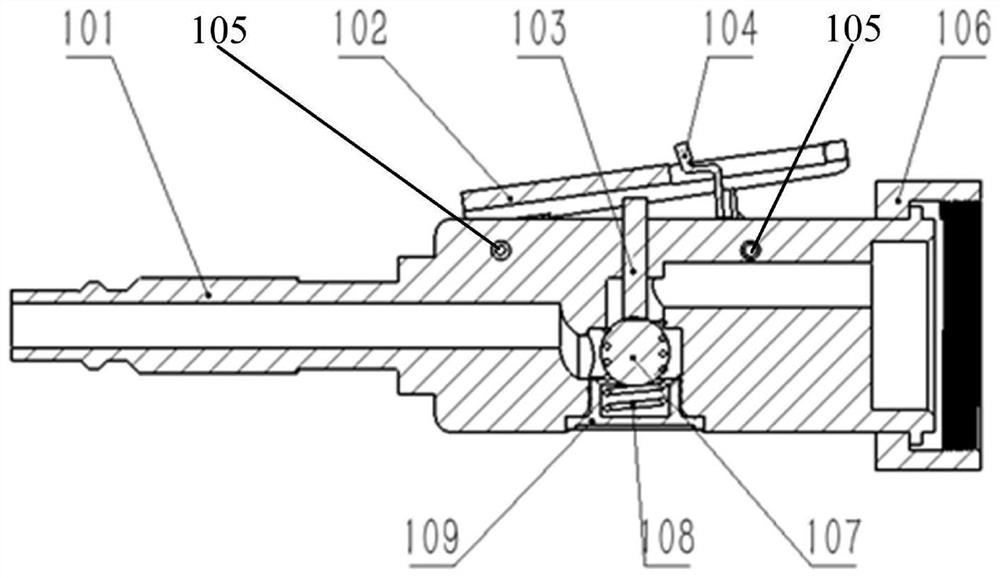

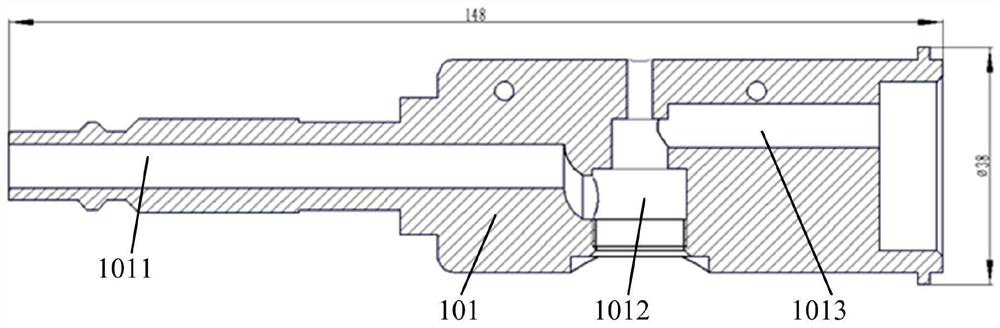

[0036] Such as figure 2As shown, the control unit 100 is connected to the brake and power unit 200 through the first threaded connection 106, and the control unit 100 includes a handle 101, a switch 102, a thimble 103, a buckle 104, a first threaded connection 106, and a sealing ball 107 , the compression spring 108 and the sealing nut 109, the handle 101 is provided with a plurality of air passages, the switch 102 and the buckle 104 are connected to the outside of the handle 101 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com