Monitoring and control method of electric welding machine cluster based on ipv6

A control method and electric welding machine technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult monitoring and management, and achieve the effects of cost reduction, improvement of utilization rate, reduction of scrap rate and product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

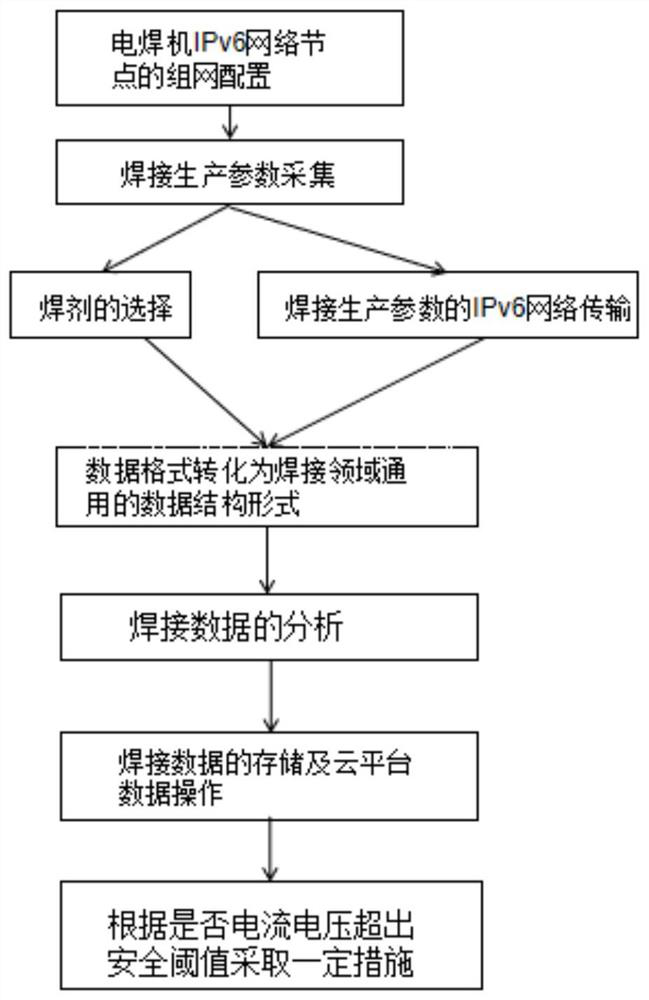

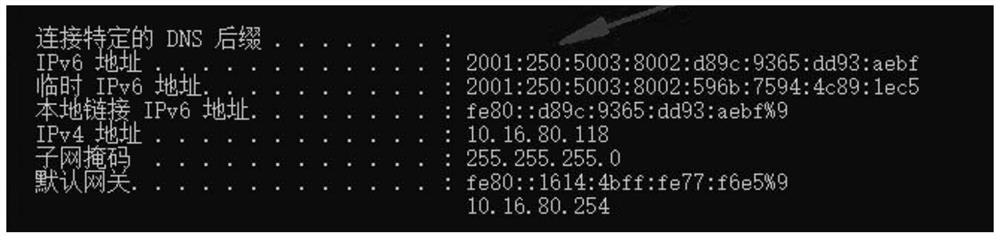

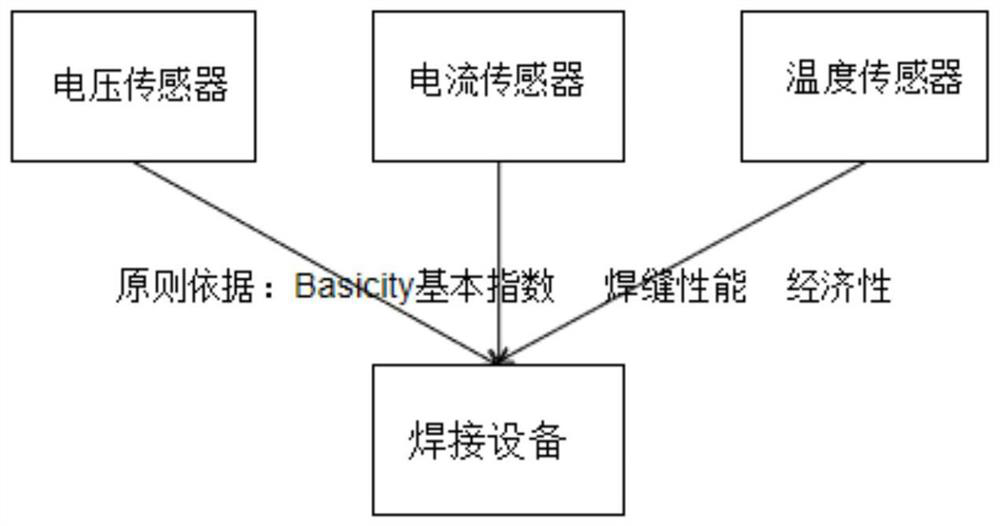

[0048] In view of some problems in the production management of the traditional welding industry, major equipment manufacturers, institutions and colleges at home and abroad have invested in the research work of the welding monitoring system, and achieved many research results. The welding monitoring systems obtained in these studies basically adopt a three-layer architecture, the perception layer, the network layer and the application layer. According to the different communication methods used in the network layer, it can be roughly divided into the following two types, welding systems based on wired communication technology and wireless communication technology. The use of welding monitoring equipment can reduce the scrap rate and product cost, improve the utilization rate of machine tools, and reduce the risk of defective parts caused by workers' misuse. A series of benefits brought by it are also very obvious.

[0049] After completing the construction and design of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com