Patents

Literature

45results about How to "Does not take up work space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

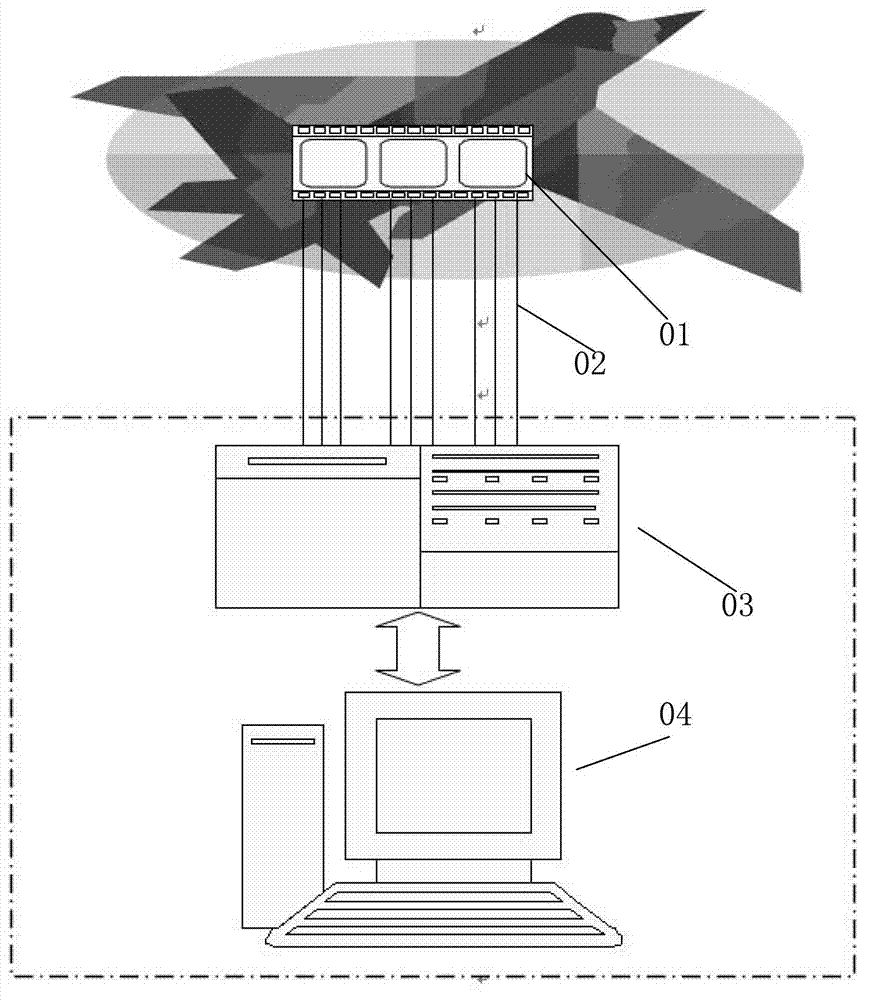

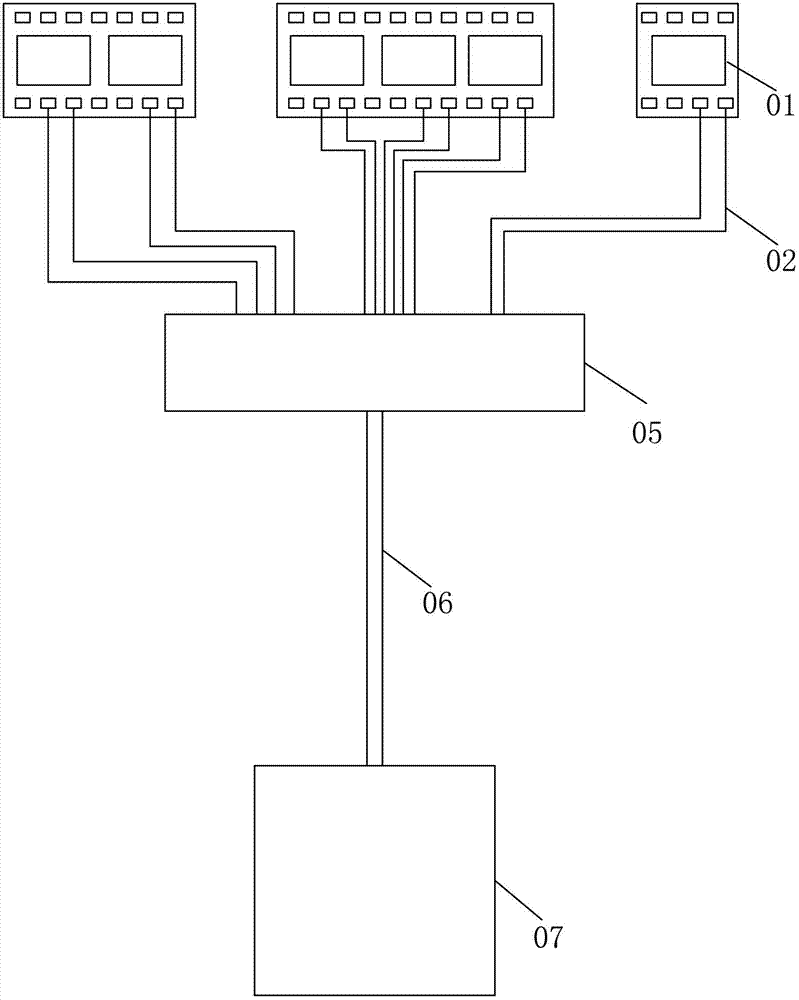

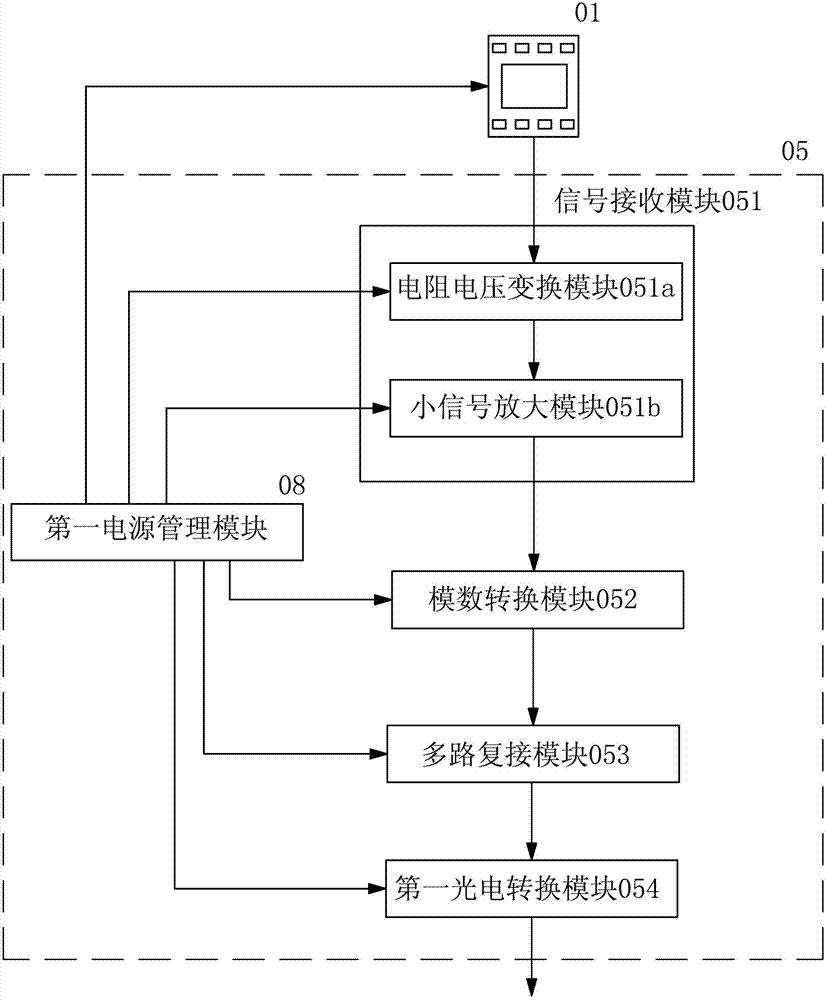

Airplane strength and strain detection method and airplane strength and strain detecting system adopting same

InactiveCN102878920AHigh bandwidthRealize transmissionNon-electrical signal transmission systemsElectrical/magnetic solid deformation measurementJet aeroplaneEngineering

An airplane strength and strain detection method includes the steps as follows: an onboard signal processing module is arranged on an airplane, a monitoring display module is arranged in a monitoring chamber, and a data transmission passage is built between the onboard signal processing module and the monitoring display module through optical cables; resistance strain gages distributed on nodes of airplane members are connected to the onboard signal processing module through conducting wires, and the onboard signal processing module is used for signal acquisition, analog-digital conversion, digital signal multiple connection, signal photovoltaic conversion and optical signal transmission for real-time voltage values of the resistance strain gages; the monitoring display module is used for photovoltaic conversion for received optical signals, obtaining the real-time voltage data of the resistance strain gages from a high-speed digital signal flow through multiple connection, processing the voltage data into strength and strain data corresponding to the voltage data, and storing the data; and strength and strain data at the nodes of the members can be displayed in real time through patterns. The method realizes the high-speed multiway data and signal transmission, greatly simplifies the complexity of wiring and reduces the signal error. The invention further discloses an airplane strength and strain detecting system.

Owner:8TH RES INST OF CETC

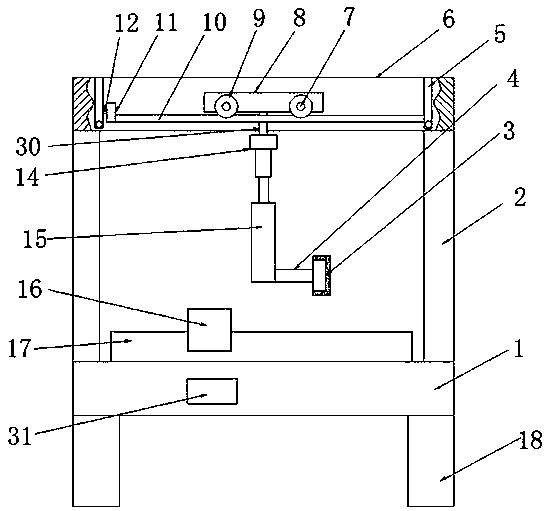

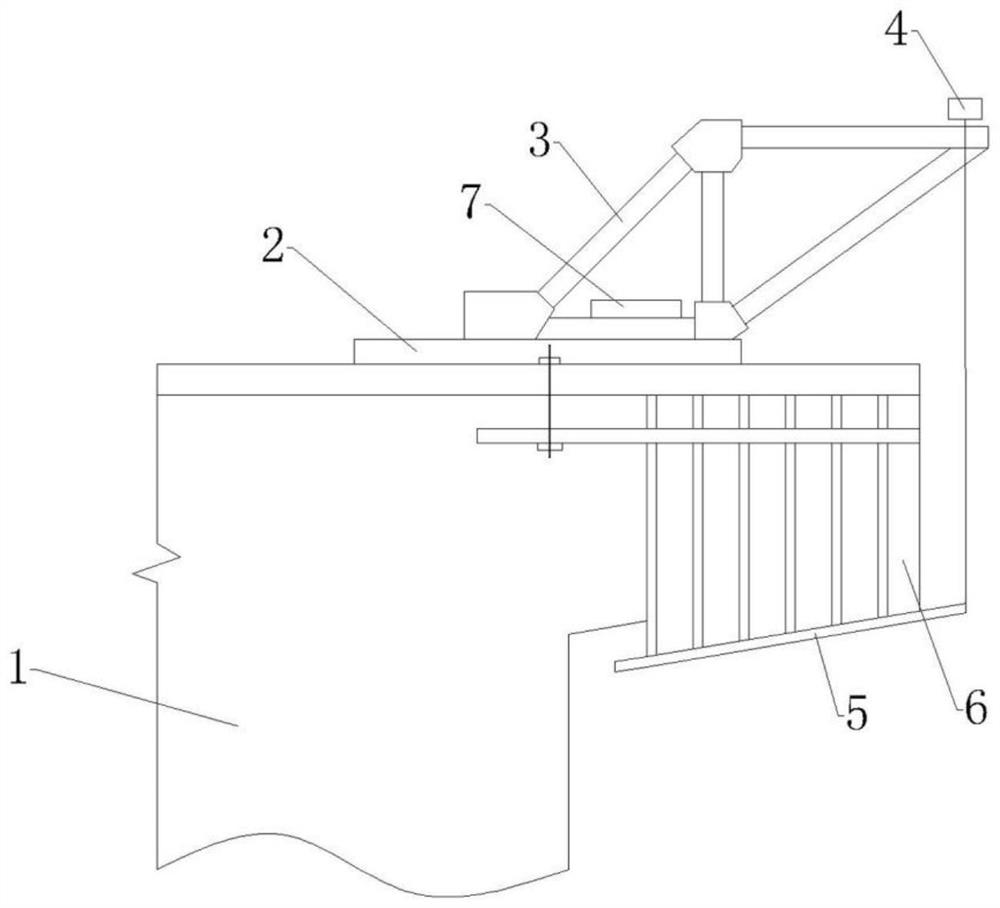

Cleaning device for numerical control machine

InactiveCN107931186AAchieve angle adjustmentRealize multi-angle cleaningCleaning using toolsNumerical controlEngineering

The invention discloses a cleaning device for a numerical control machine. The cleaning device comprises a base, wherein symmetrically distributed supporting plates are fixedly connected with the topof the base; the tops of the two supporting plates are fixedly connected with a suspension plate which is of a hollow structure jointly; a rectangular opening is formed in the bottom of the suspensionplate; symmetrically distributed first fixed links and symmetrically distributed second fixed links are fixedly connected with the inner wall of the top of the suspension plate; the two first fixed links and the two second fixed links are correspondingly and fixedly connected with a first track bar and a second track bar; a plurality of first rollers are connected to the wall of the first track bar in a rolling manner, and a plurality of second rollers are connected to the wall of the second track bar in a rolling manner; and a third track bar and a fourth track bar are correspondingly and rotationally connected between the multiple first rollers and the second rollers. The cleaning device for the numerical control machine can automatically clean the insides of sliding tracks and a worktable at multiple angles, and brings convenience for workers.

Owner:李超

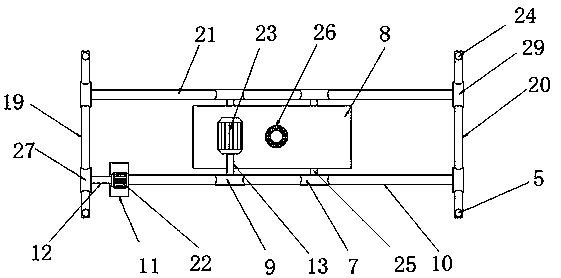

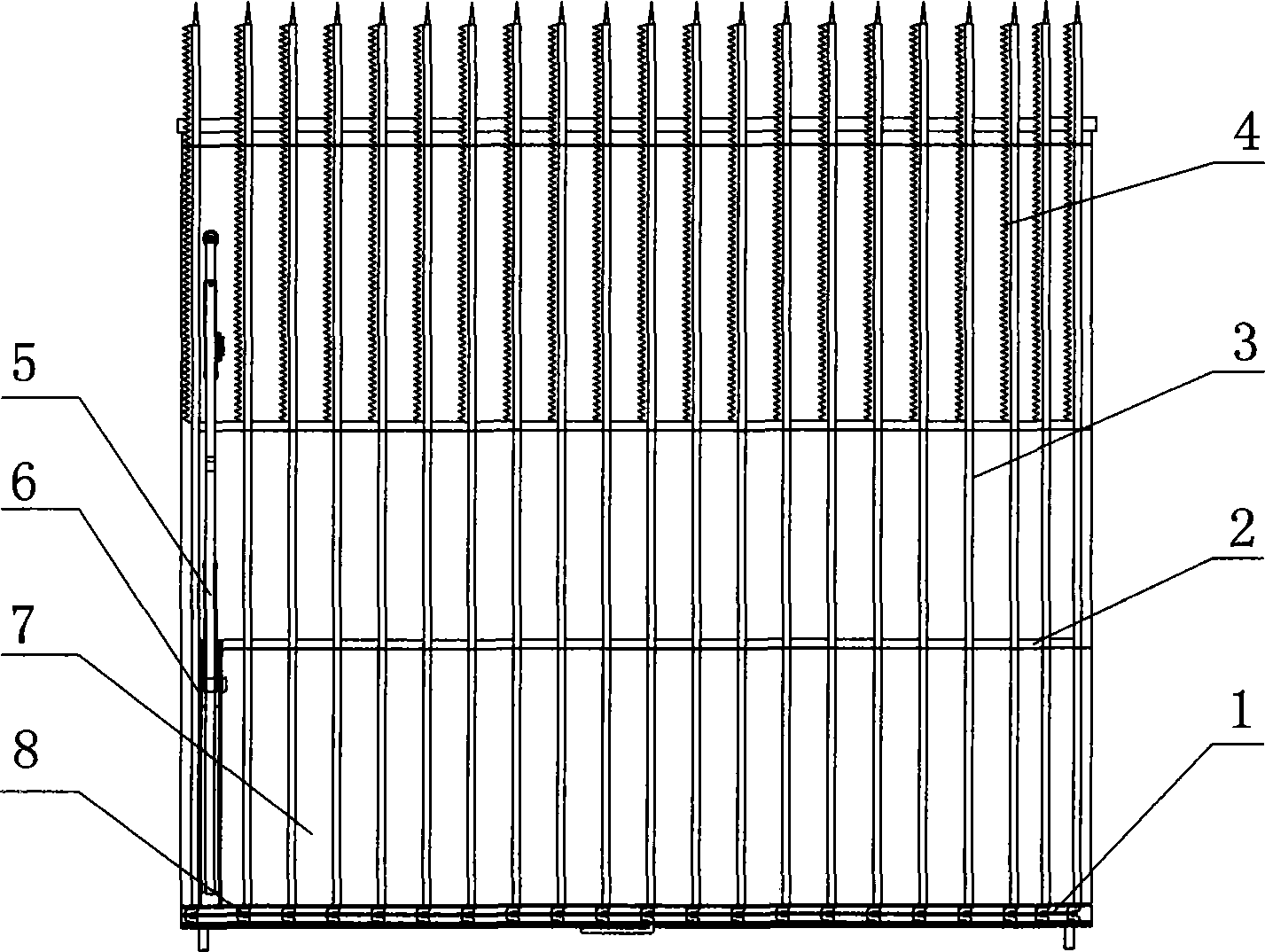

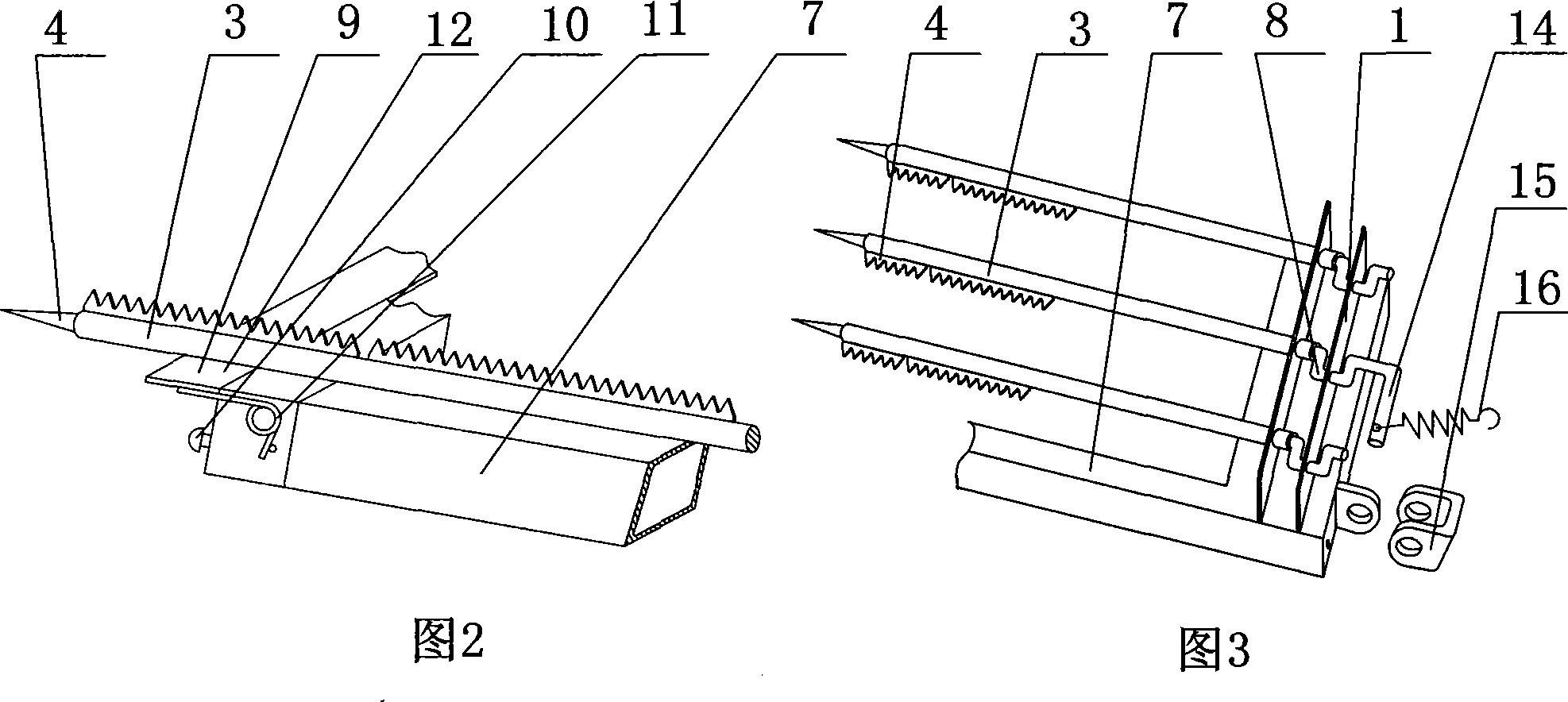

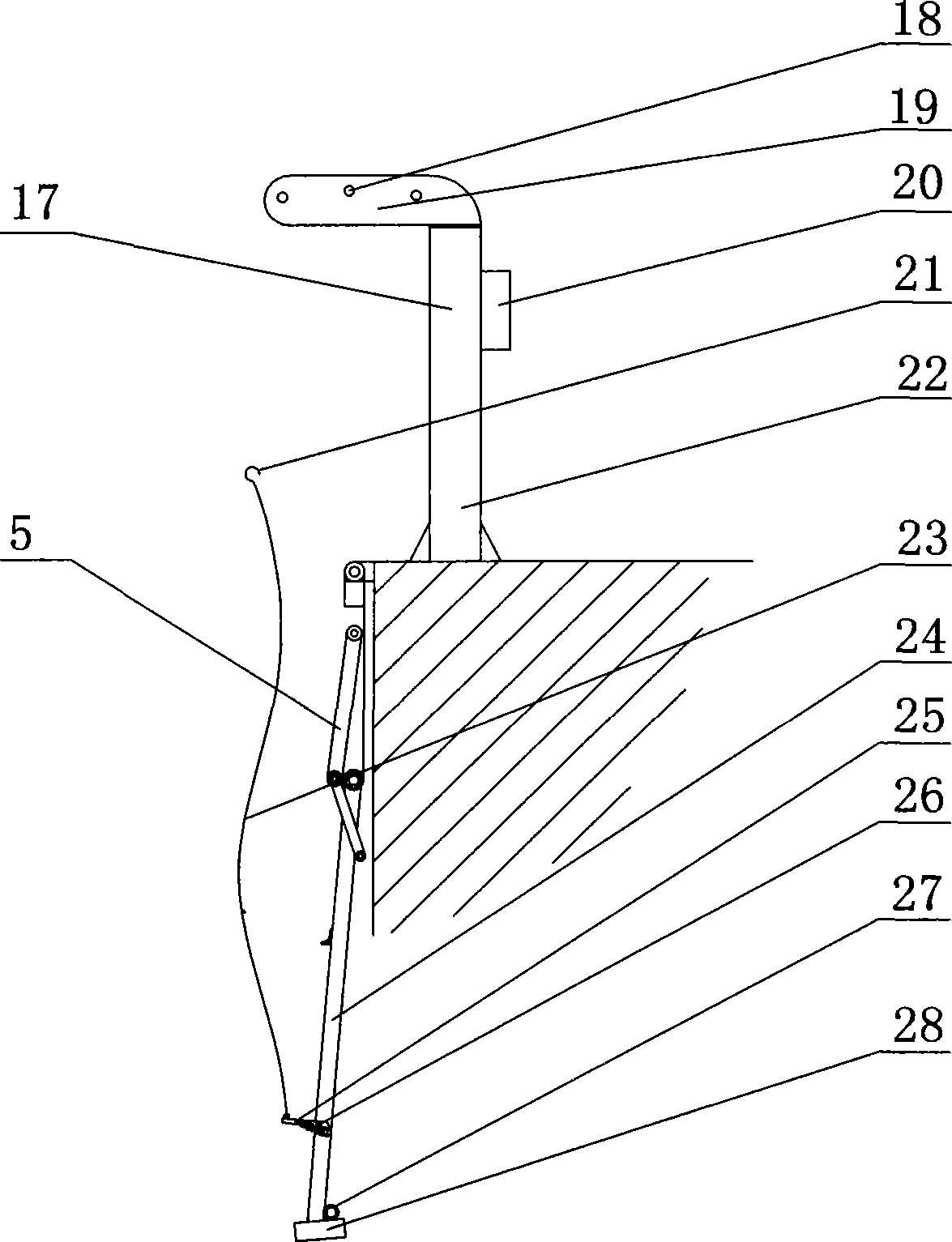

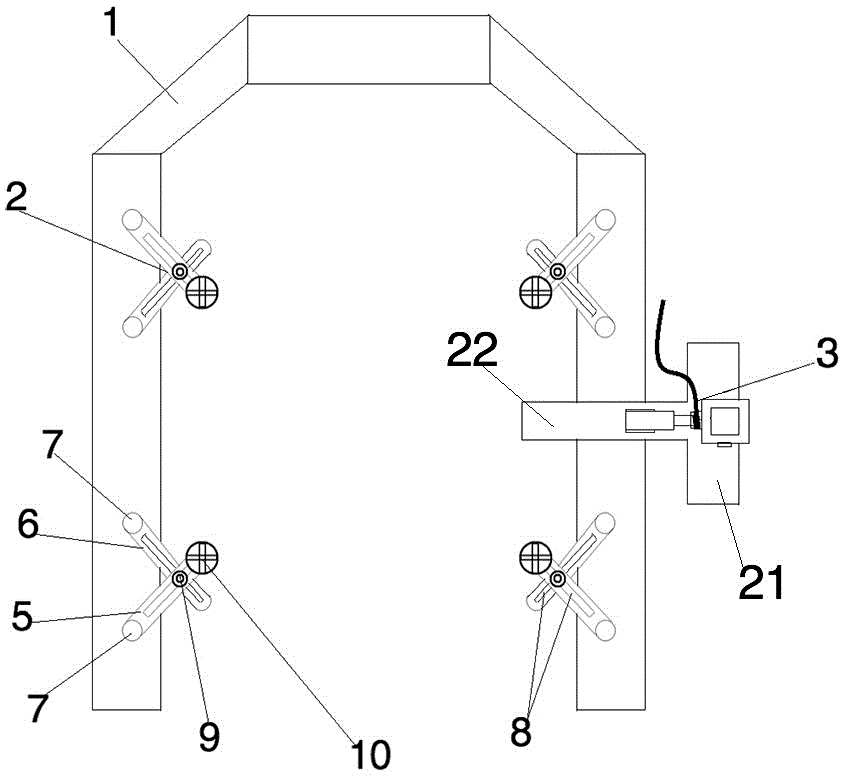

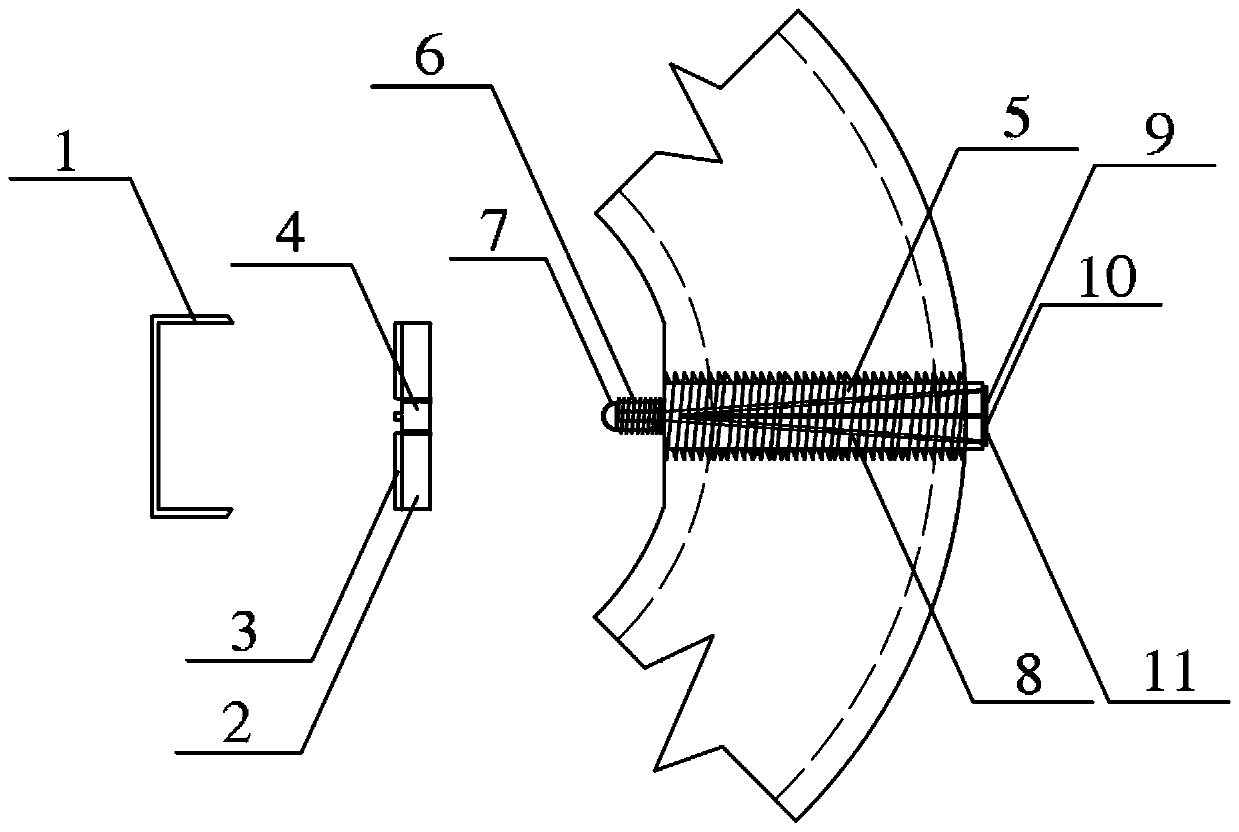

Folding anti-boarding device

The invention relates to a folding anti-boarding device, relating to an improved anti-boarding device. The invention provides the folding anti-boarding device, which is difficultly damaged by being shot by a gun, is convenience for use, and is capable of preventing a plurality of batches of pirates from boarding. The folding anti-boarding device disclosed by the invention comprises an anti-creeping fence, wherein the anti-creeping fence is composed of a transverse rod and a longitudinal rod; a control device is arranged at one side of the anti-creeping fence; a fixed device is arranged corresponding to the control device; sharp thorns are arranged on the front end and the side surface of the longitudinal rod; a crankshaft is arranged at the tail end of the longitudinal rod; the crankshaft is connected with a linkage plate; and the tail end of the anti-creeping fence is connected with a support base through a pin shaft.

Owner:SHENYANG LIANHENG MACHINERY

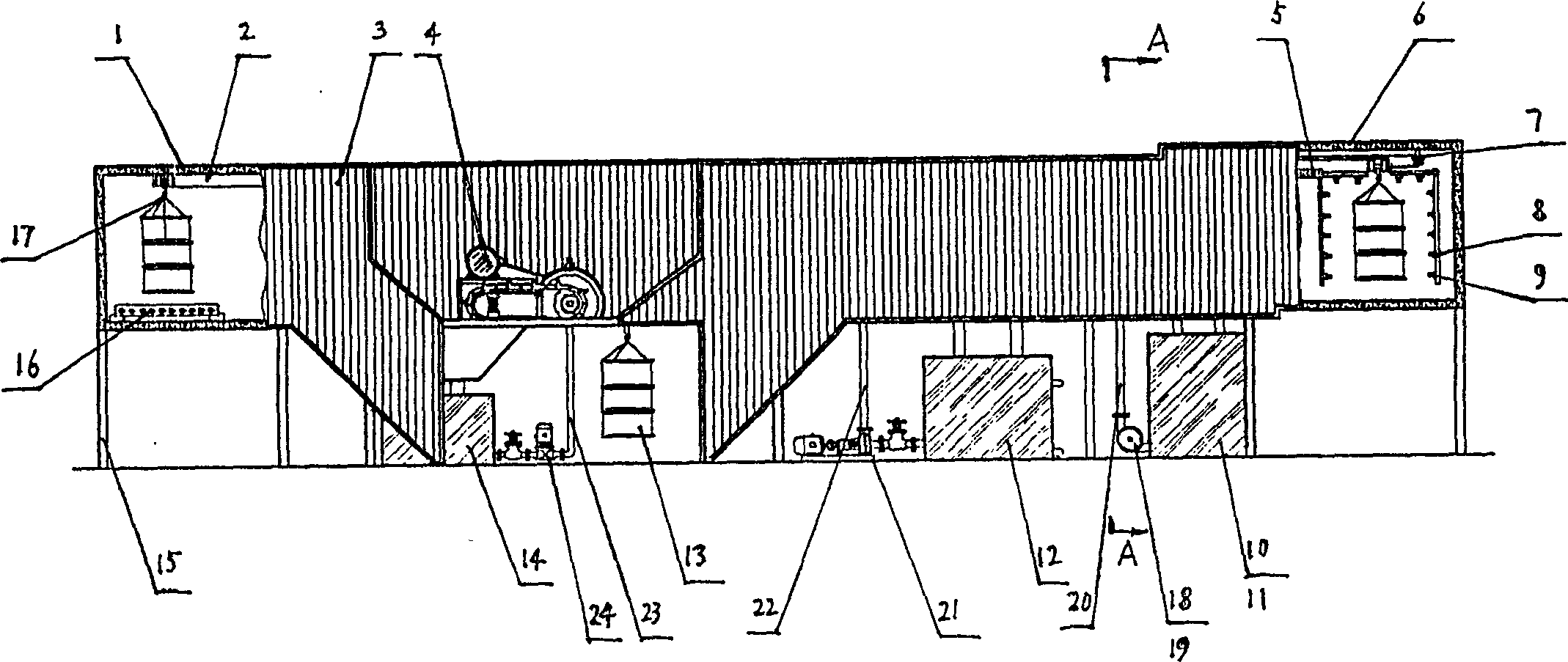

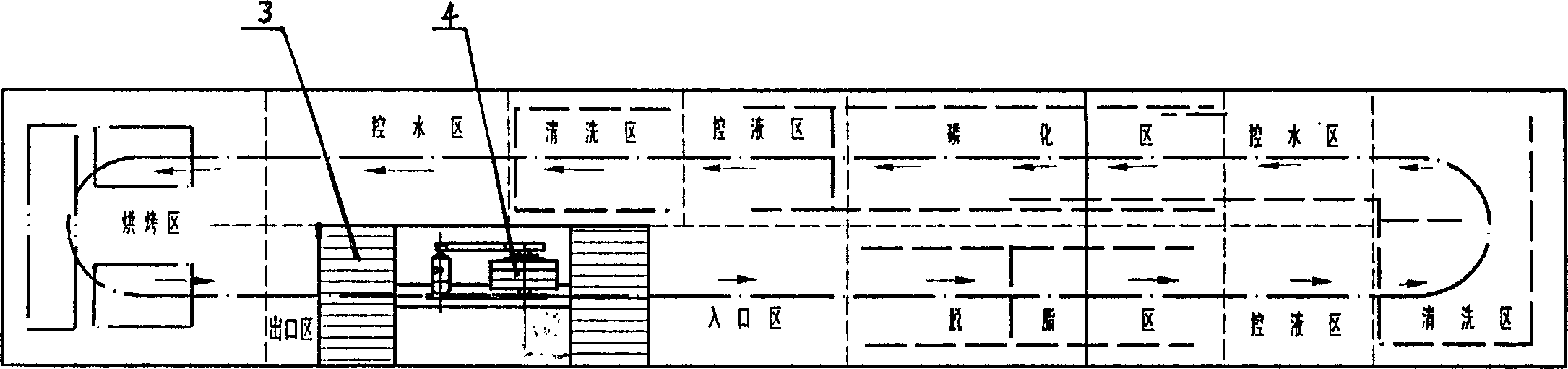

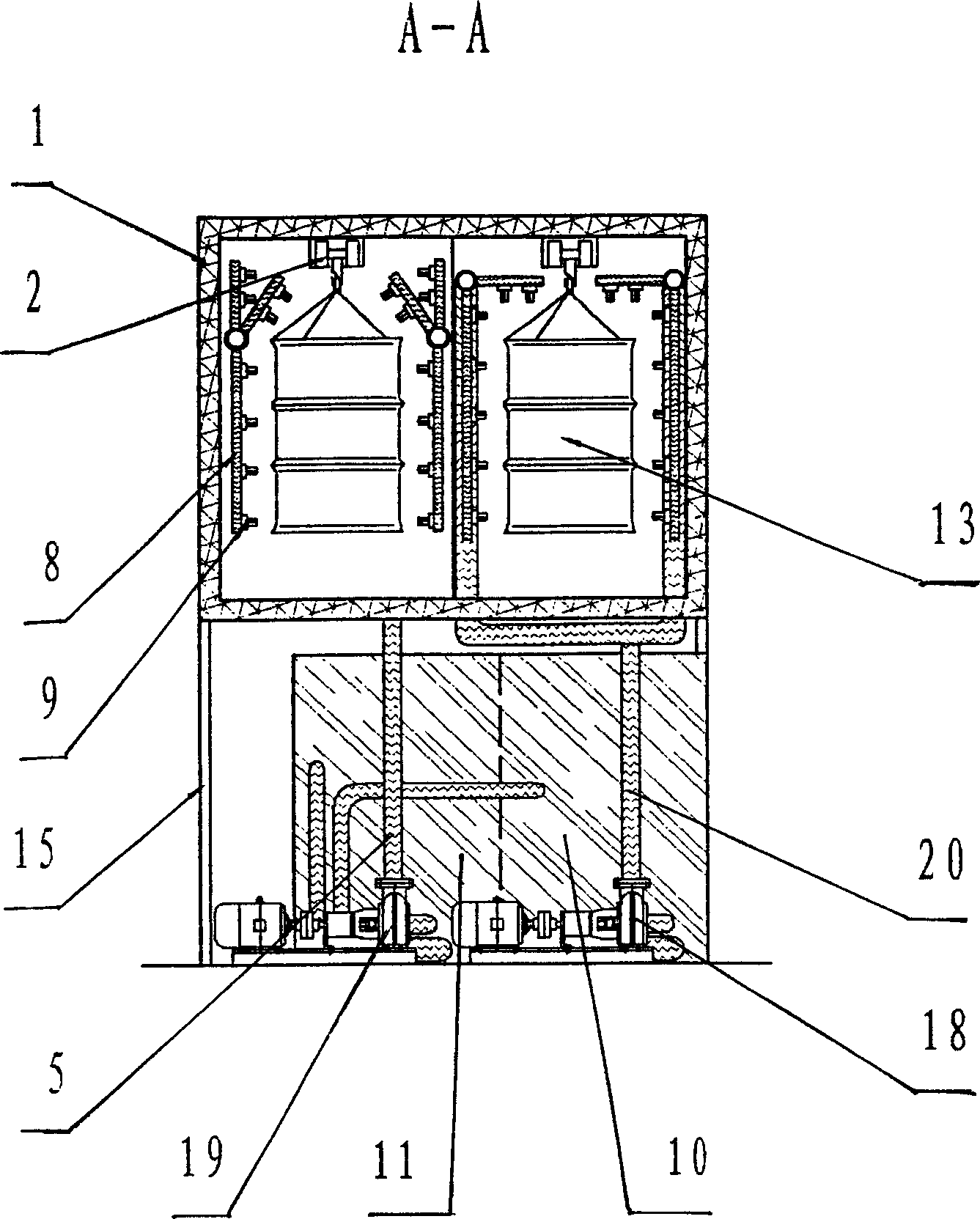

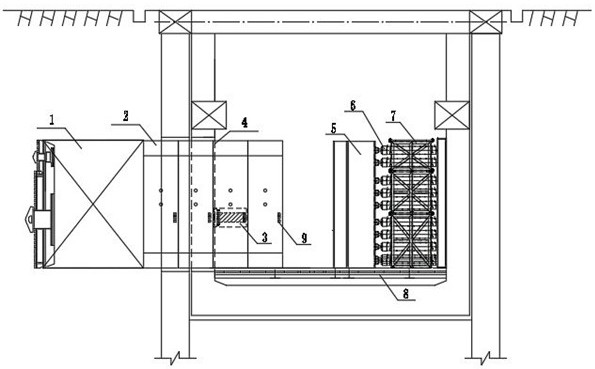

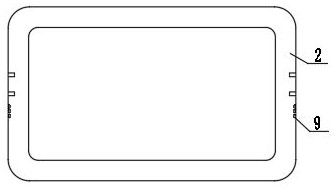

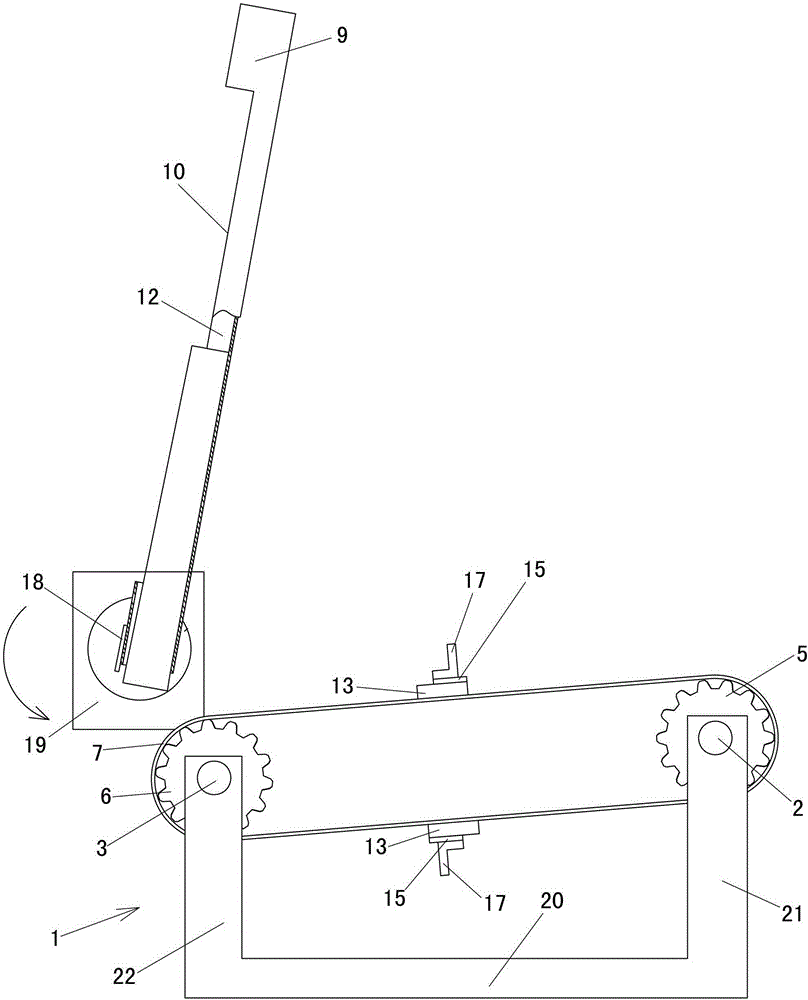

Automatic sprinkling type phosphatization treatment system for surface of steel barrel

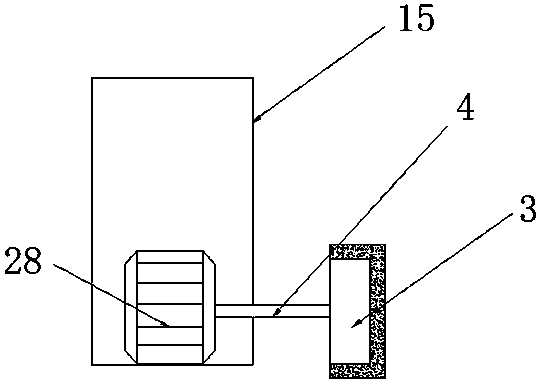

InactiveCN1840734ADoes not take up work spaceSmall footprintMetallic material coating processesEngineeringEnergy consumption

The disclosed auto-spray phosphating system on steel barrel surface comprises an overhead ring tunnel with ports and ring gear chain device inside. Wherein, the said chain device comprises for work piece in turn an entrance area, a degrease area, a liquid regulating area, a cleaning area, a water regulating area, a phosphating area, a liquid regulating area, a cleaning area, a water regulating area (hole-form), a roasting area, and an exit area. The advantages of this invention include: saving space and energy consumption, convenient to clean precipitate, and cutting length.

Owner:SANMENXIA CITY JINHUI PACKAGING

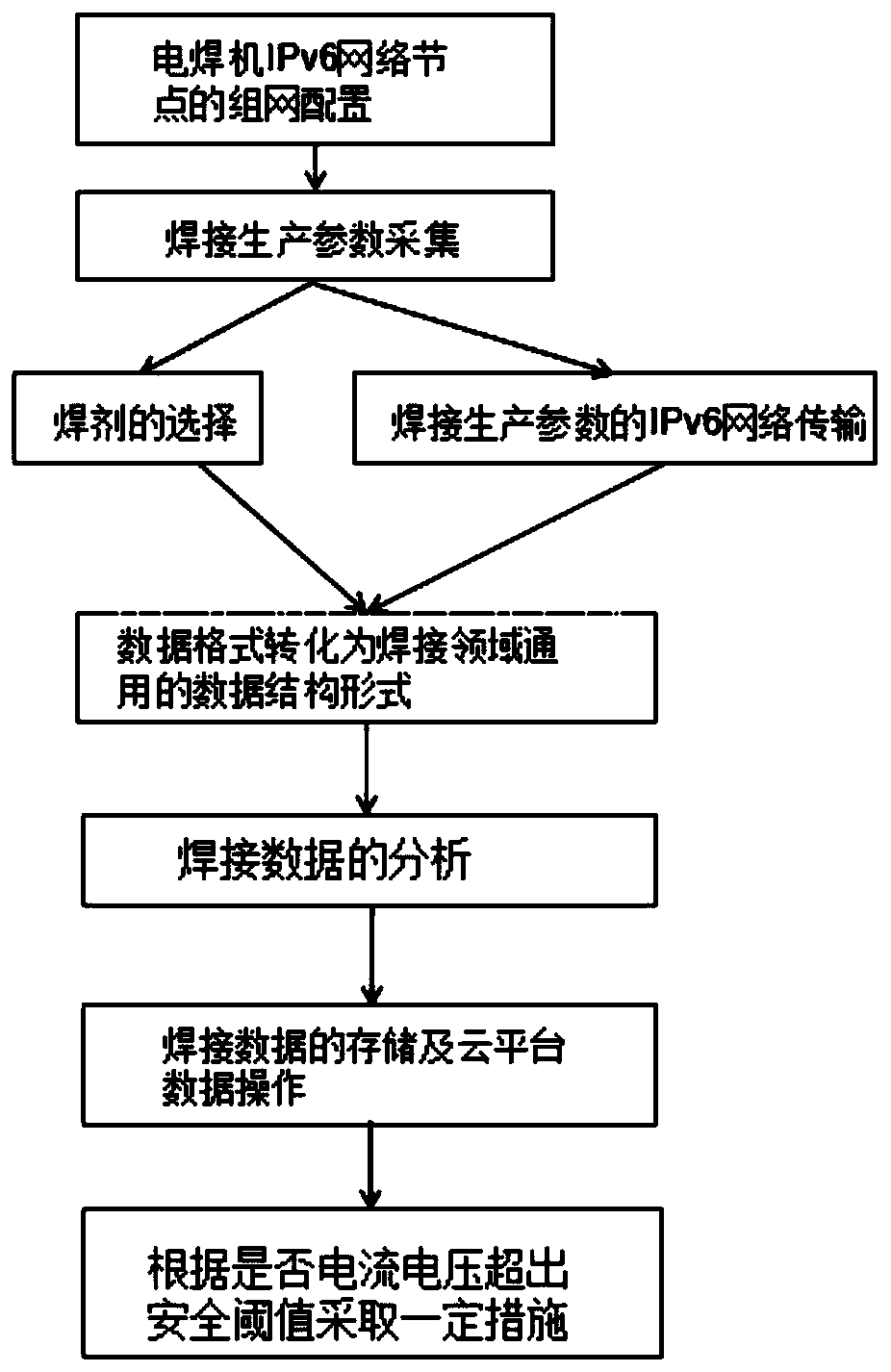

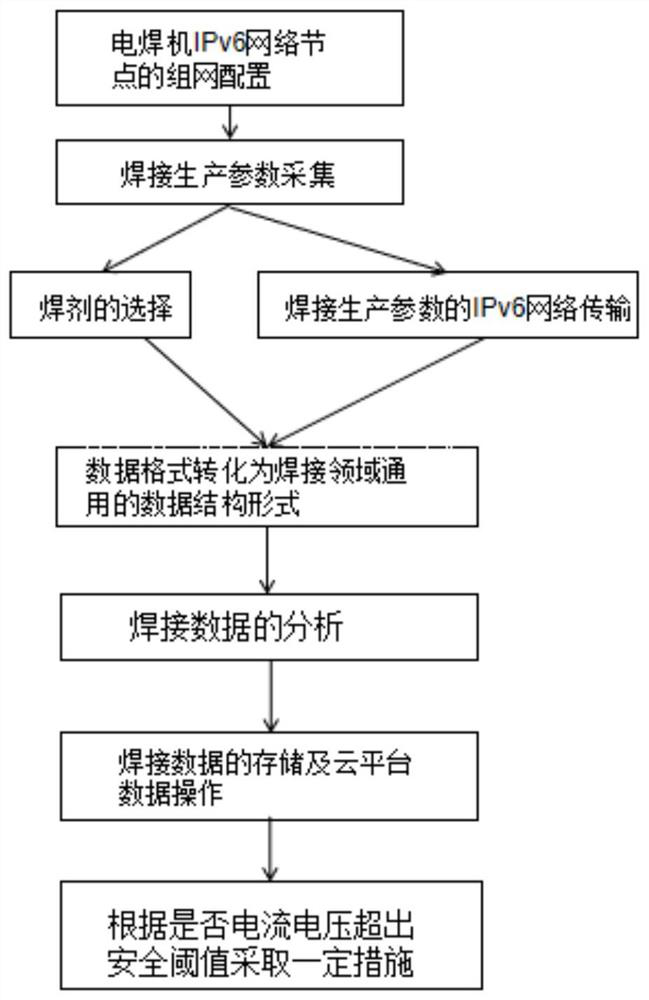

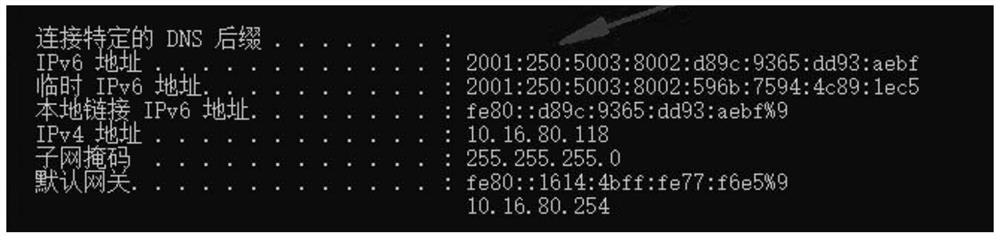

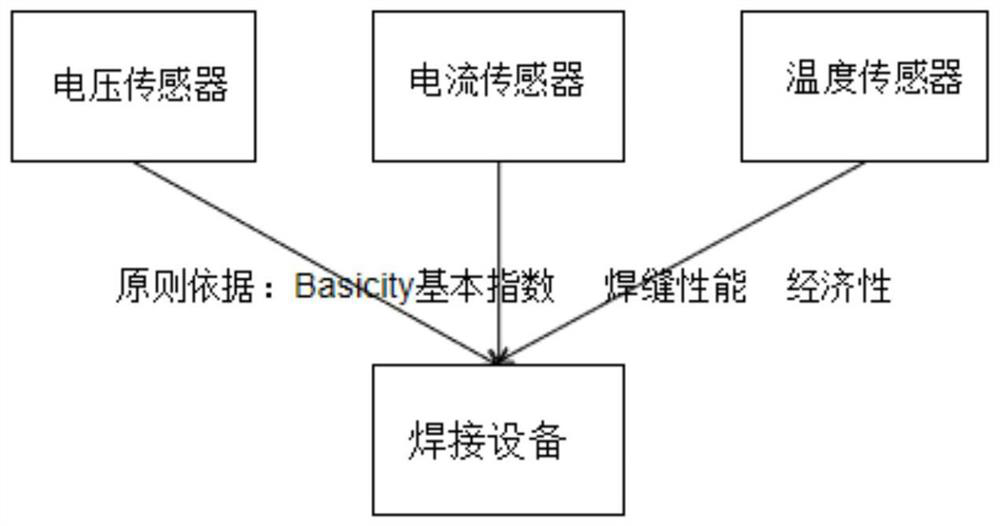

Electric welding machine cluster monitoring control method based on IPv6

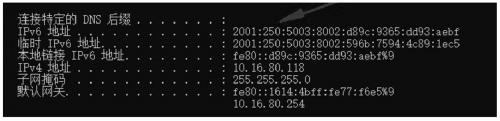

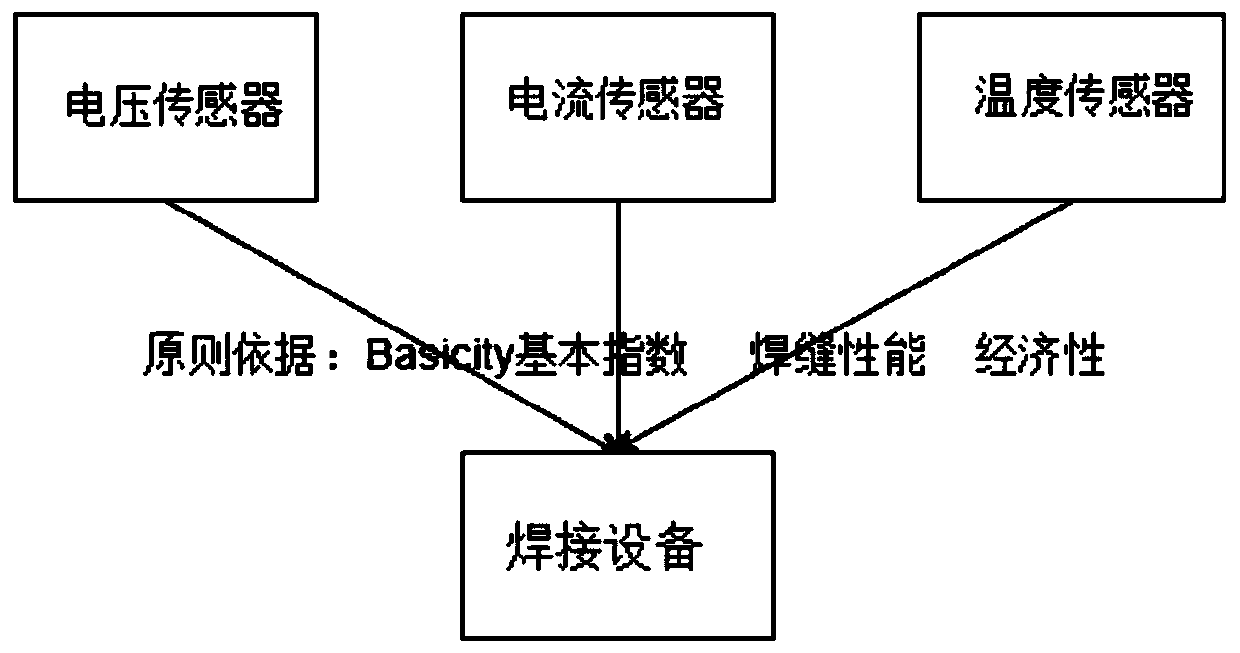

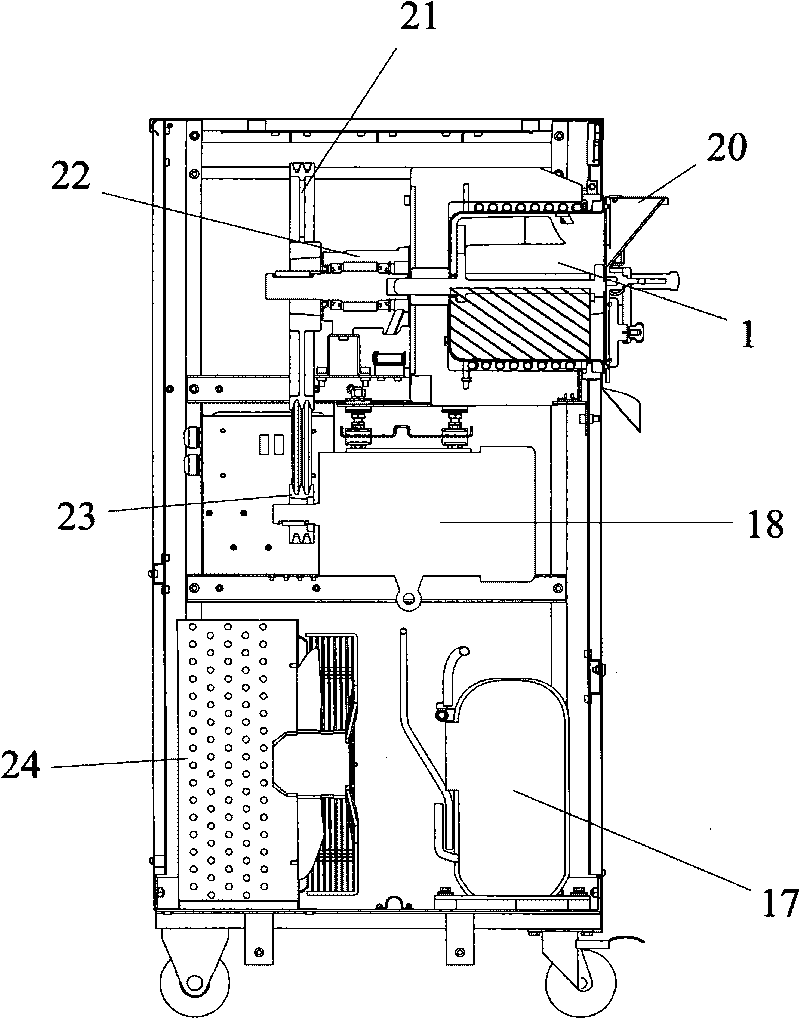

ActiveCN111168195AReduce volumeDoes not take up work spaceArc welding apparatusTransmissionWireless communication protocolData acquisition

The invention discloses an electric welding machine cluster monitoring control method based on IPv6. The electric welding machine cluster monitoring control method comprises the steps that 1, electricwelding machine IPv6 network nodes are subjected to networking configuration, a wireless communication protocol of 6LoWPAN is configured on welding data collecting nodes, an IPv6 address is set, andcollecting node networking of a welding production site is carried out through the automatic configuration of PIv6 and the self-networking characteristics; 2, welding production parameters are collected, data is collected through a current-voltage data collecting sensor on an electric welding machine, current and voltage are collected, and the data is transmitted to a data processing center; 3, the data format is converted to a data structure form commonly used in the welding field; 4, the welding data is analyzed; 5, the welding data is stored, and cloud platform data operation is carried out; and 6, certain measures are taken according to whether the current and voltage exceed a safety threshold value. According to the electric welding machine cluster monitoring control method based on IPv6, IPv6 networking of welding monitoring equipment is achieved, the size of the welding monitoring equipment is reduced, the work space is not occupied, and the electric welding machine cluster monitoring control method is suitable for large-scale mass production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

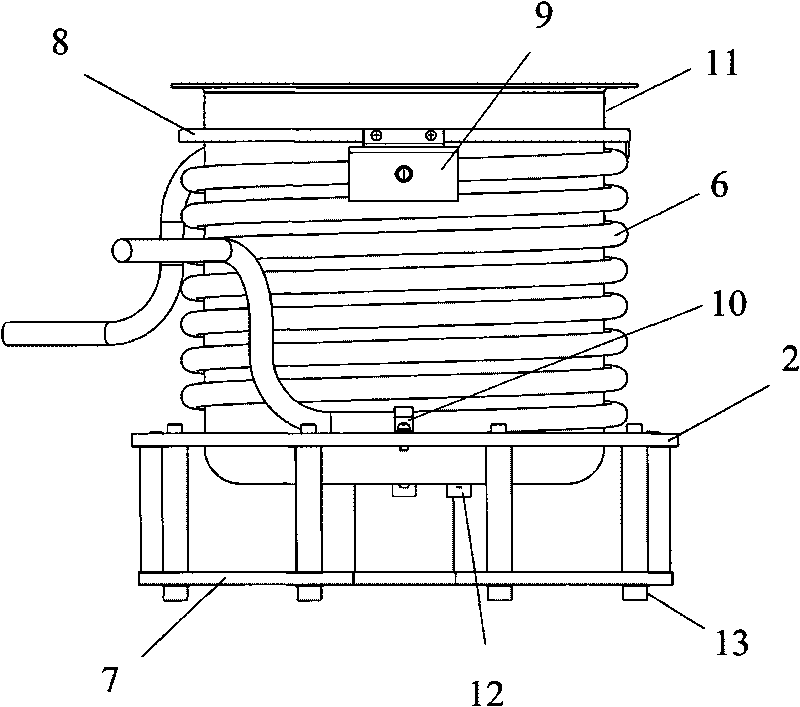

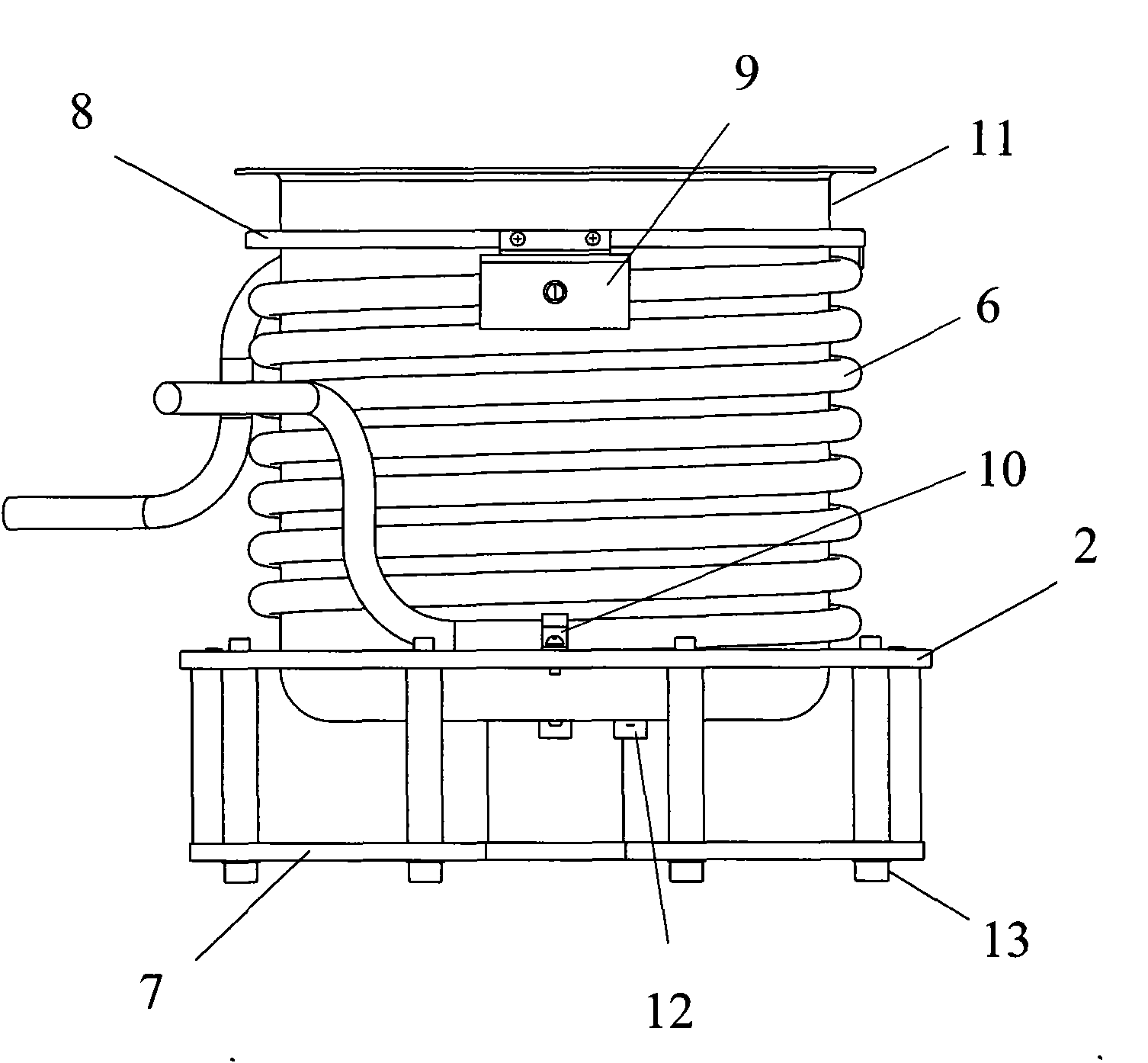

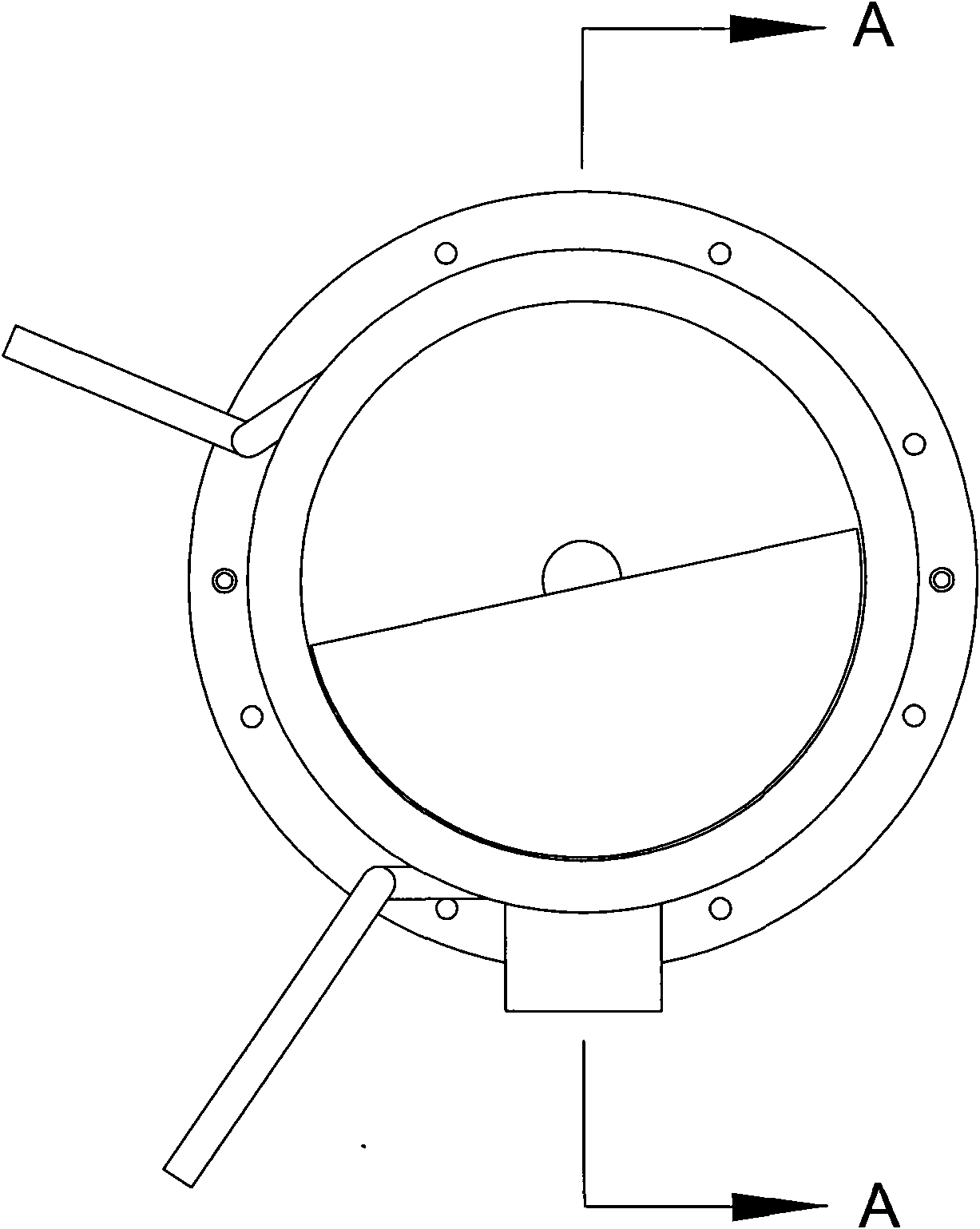

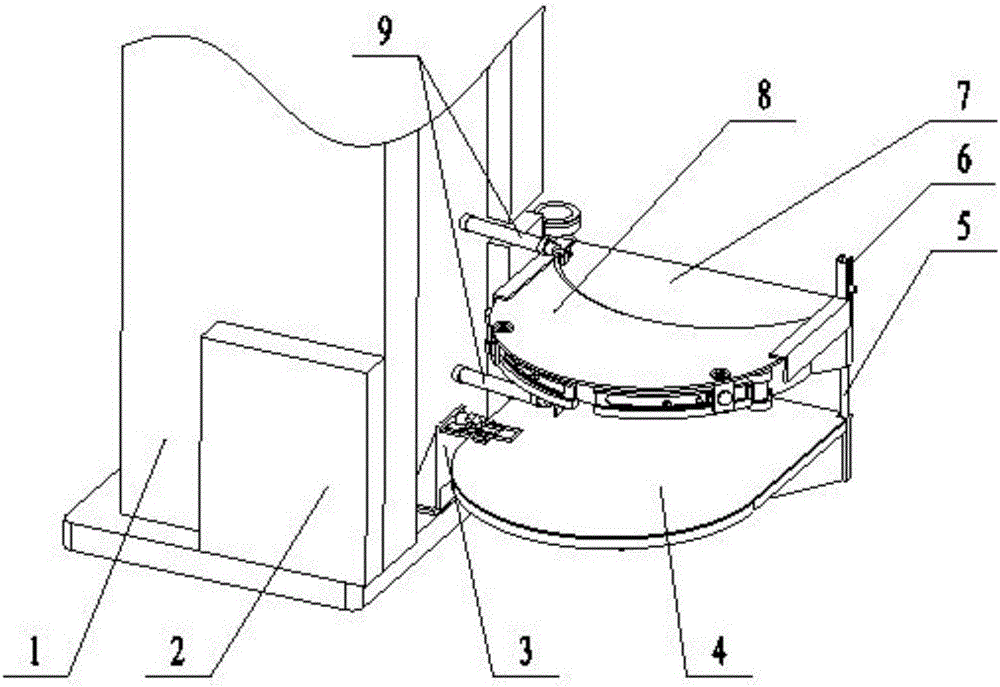

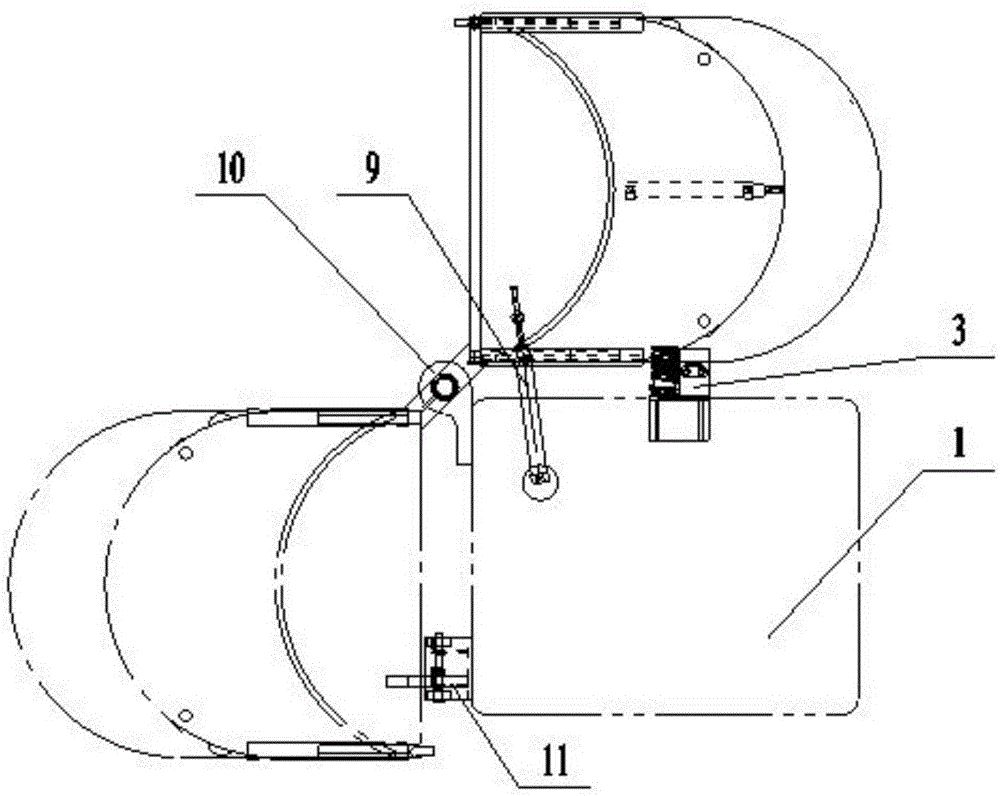

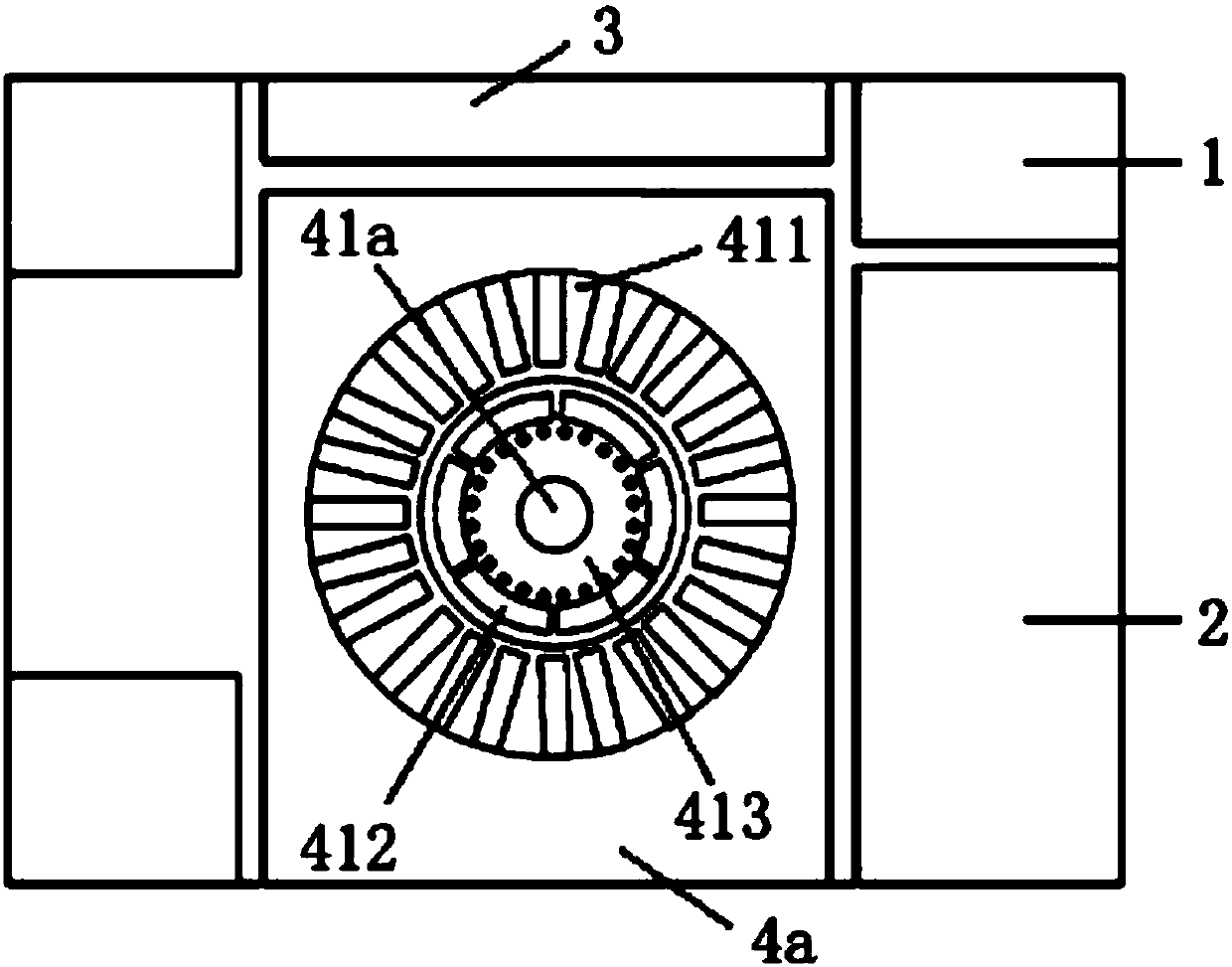

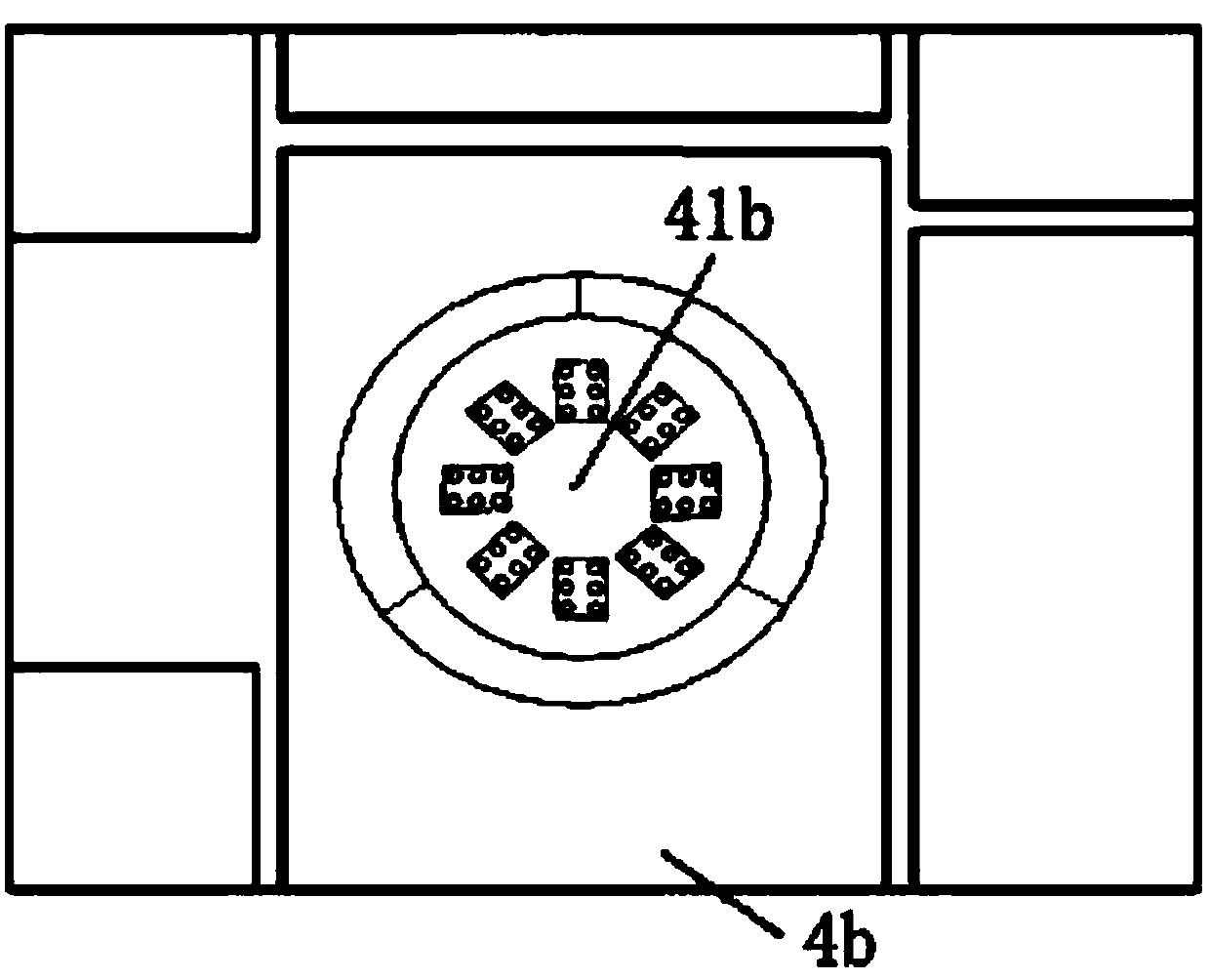

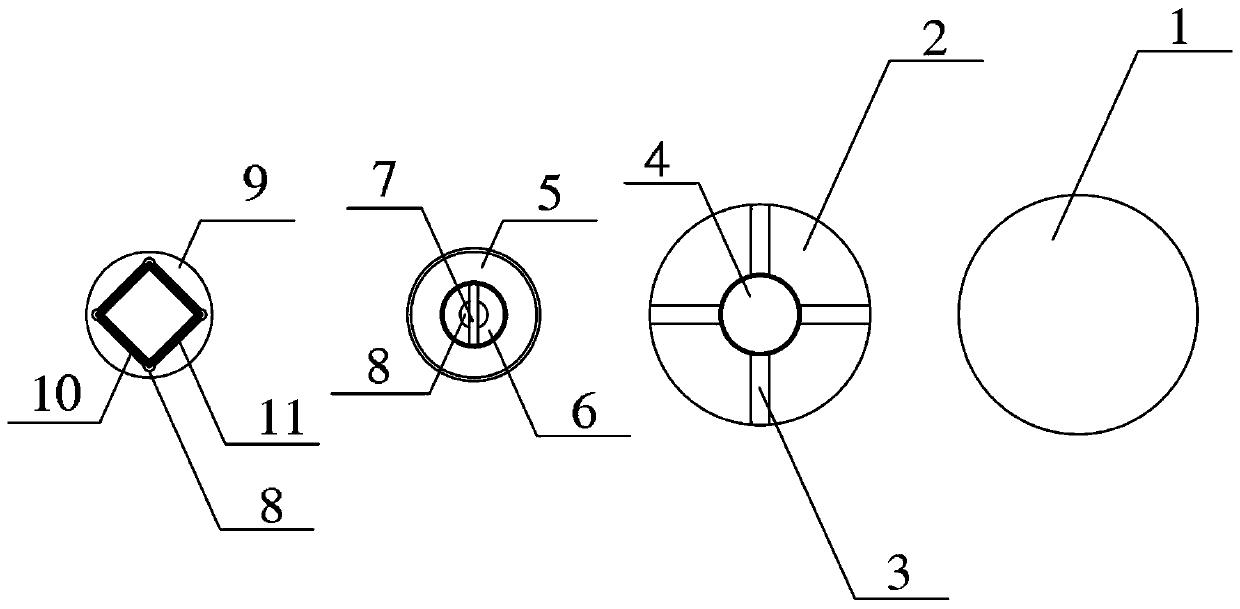

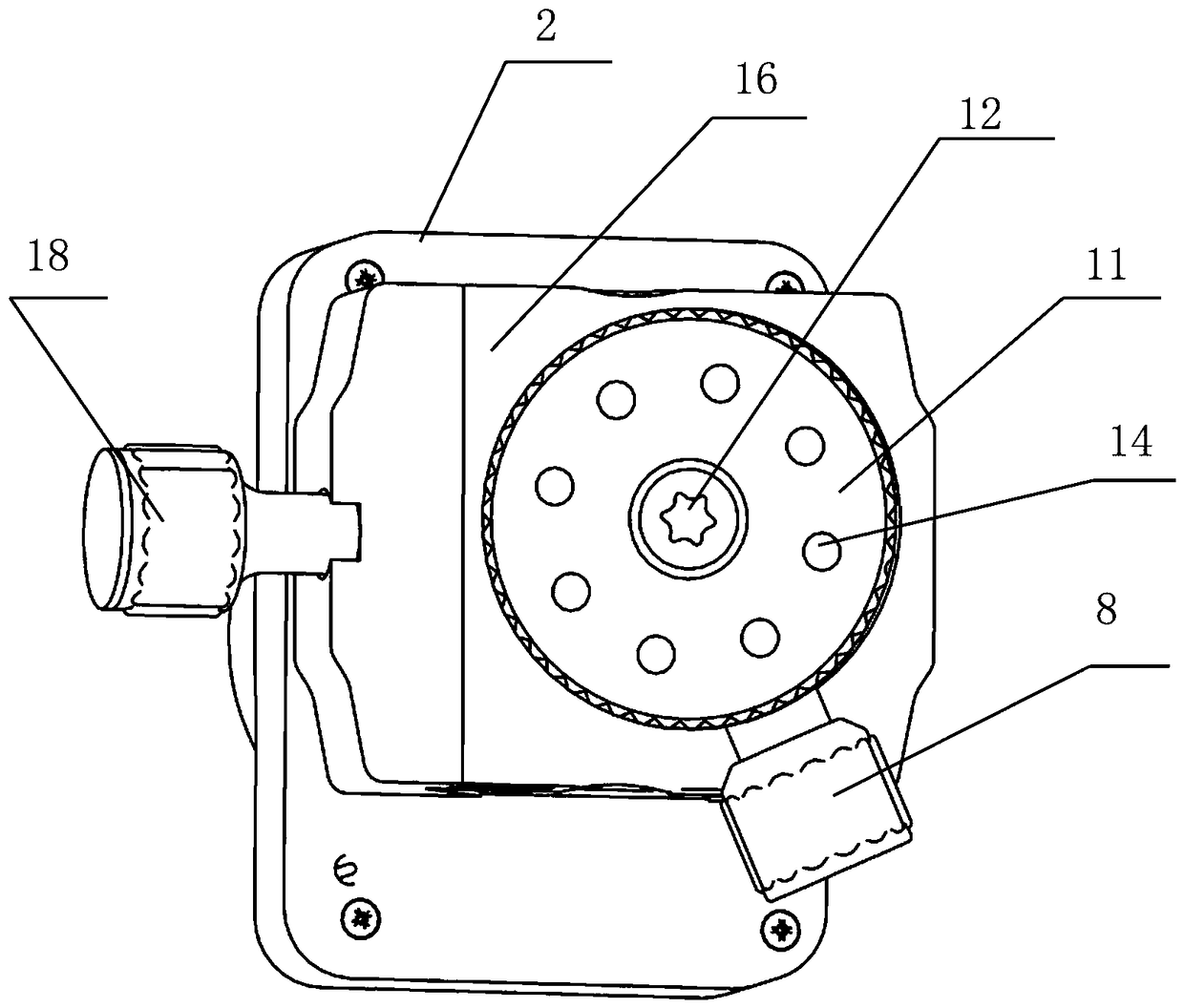

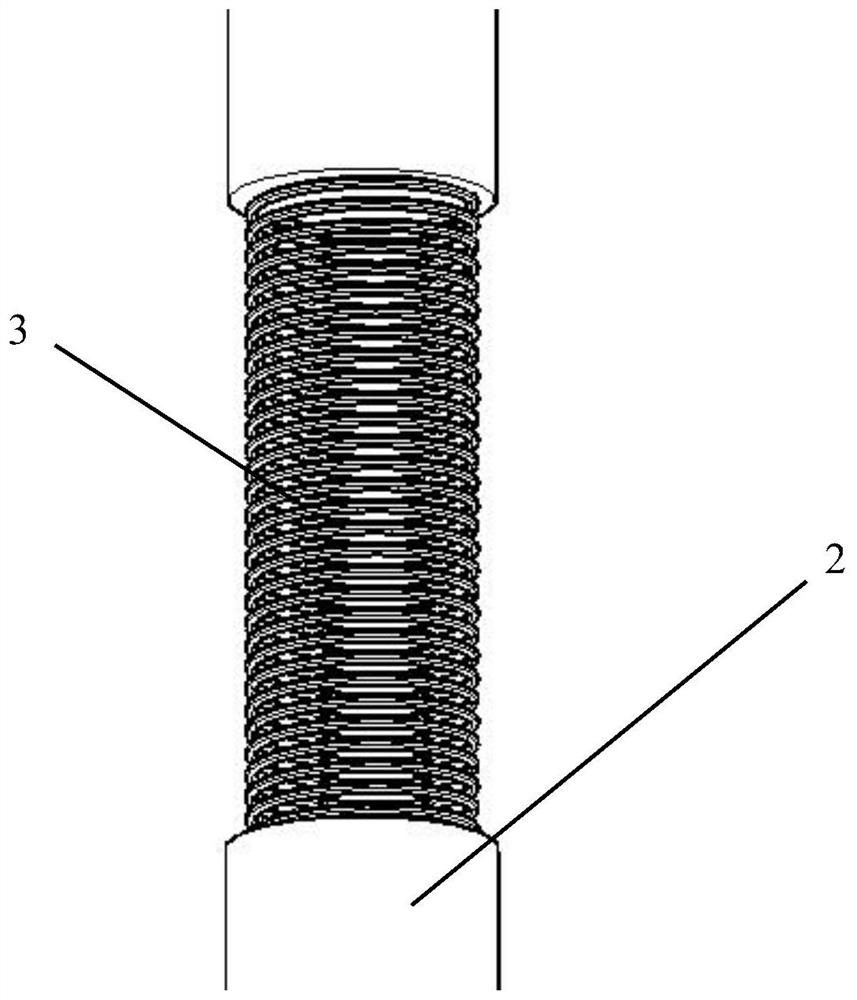

Hard ice cream machine evaporator, fixture and method for winding copper condensation tube

InactiveCN101749894ASimple structureImprove cooling effectEvaporators/condensersManufacturing technologyEngineering

The invention discloses a hard ice cream machine evaporator with copper condensation tubes and additionally discloses a fixture and a method for winding copper condensation tubes. A copper condensation tube is placed on the winding fixture, the winding fixture is sheathed on a cylinder, an adjusting bolt is turned, a sliding block moves in a guide block to enable the copper condensation tube to be closely attached onto the periphery of the cylinder, the winding fixture rotates around the cylinder and the copper condensation tube is wound on the periphery of the cylinder. The manufacturing technology of the hard ice cream machine evaporator is simple, the production efficiency is high, not lots of people but only one people is required to operate the relevant mechanisms and devices for manufacturing the hard ice cream machine evaporator, the cost is greatly saved, no harmful gas is produced and no environmental pollution is caused because no argon arc welding is conducted when in manufacturing the hard ice cream machine evaporator, no large worksite is occupied, the production efficiency of the evaporator is high and the intermediate link is omitted because the manufactured evaporator can be immediately installed on the hard ice cream machine.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

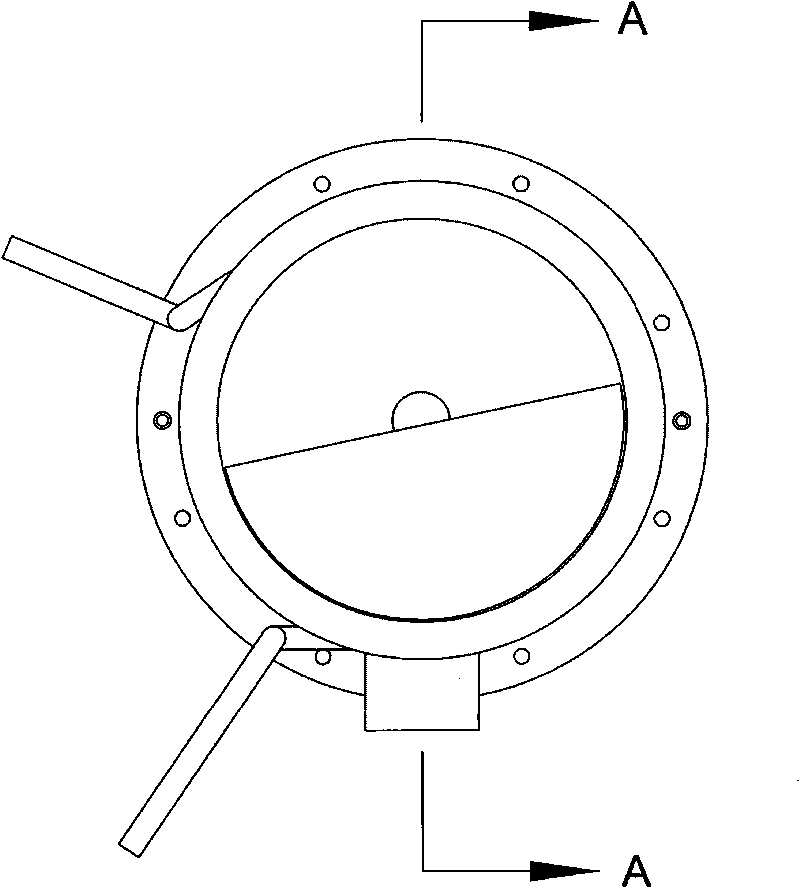

Mine air fan protection hood

ActiveCN107989829ASimple structureNo need to disassemblePump componentsPumpsFixed bearingEngineering

The invention provides a mine air fan protection hood and discloses a protection hood device which is installed on an air fan, is capable of opening and closing following the running state of the airfan and performs protection on the air fan. The mine air fan protection hood does not need to be disassembled, does not occupy the working space and is capable of opening and closing automatically according to the running state of the air fan, and the protection effect on the air fan is effectively improved. The mine air fan protection hood is characterized in that a fixed plate is arranged insideone end of a main body tube, the two ends of the fixed plate are connected with the inner wall of the main body tube correspondingly, a fixed ring is arranged on the center portion of the fixed plate, a connection plate is arranged inside the fixed ring through a fixed bearing, the connection plate is of an annular plate-shaped structure, one side of the connection plate is provided with a magnetpiece, a rotating sleeve is arranged inside the main body tube, one end of the rotating sleeve is connected with the middle of the other side of the connection plate, the inner wall of the rotating sleeve is provided with threads, one end of a twist rod is arranged inside the rotating sleeve and is connected with the connection plate through a spring, the other end of the twist rod is arranged inside the main body tube, the twist rod is in thread coordination with the rotating sleeve, and the twist rod is provided with a plurality of sliding grooves.

Owner:徐州新南湖科技有限公司

Hard ice maker evaporator, winding clamp for condensation copper pipe and winding method thereof

InactiveCN101849602ASimple structureImprove cooling effectFrozen sweetsEvaporators/condensersConductor CoilCopper tubing

The invention discloses a hard ice maker evaporator with a condensation copper pipe, and discloses a winding clamp special for the condensation copper pipe and a winding method thereof. The condensation copper pipe is placed on the winding clamp; and after the winding clamp is sleeved on a cylinder, an adjusting bolt is rotated, a slide block moves in a guide block so that the condensation copperpipe is tightly attached to the periphery of the cylinder, and the winding clamp rotates around the cylinder to wind the condensation copper pipe on the periphery of the cylinder. The method for manufacturing the hard ice maker evaporator has simple manufacturing process and high production efficiency, does not need many persons to operate related mechanism and equipment to manufacture the hard ice maker evaporator, and only needs one person to manufacture the hard ice maker evaporator so as to greatly save the cost; meanwhile, the method does not burn argon arc for welding during manufacturing, does not produce harmful gas, does not pollute the environment, and does not occupy much working site; and the method has higher production efficiency, and the manufactured evaporator can be arranged on a hard ice maker so as to save a middle link.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

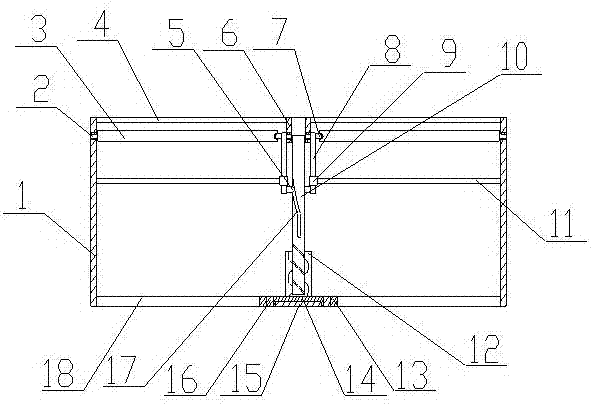

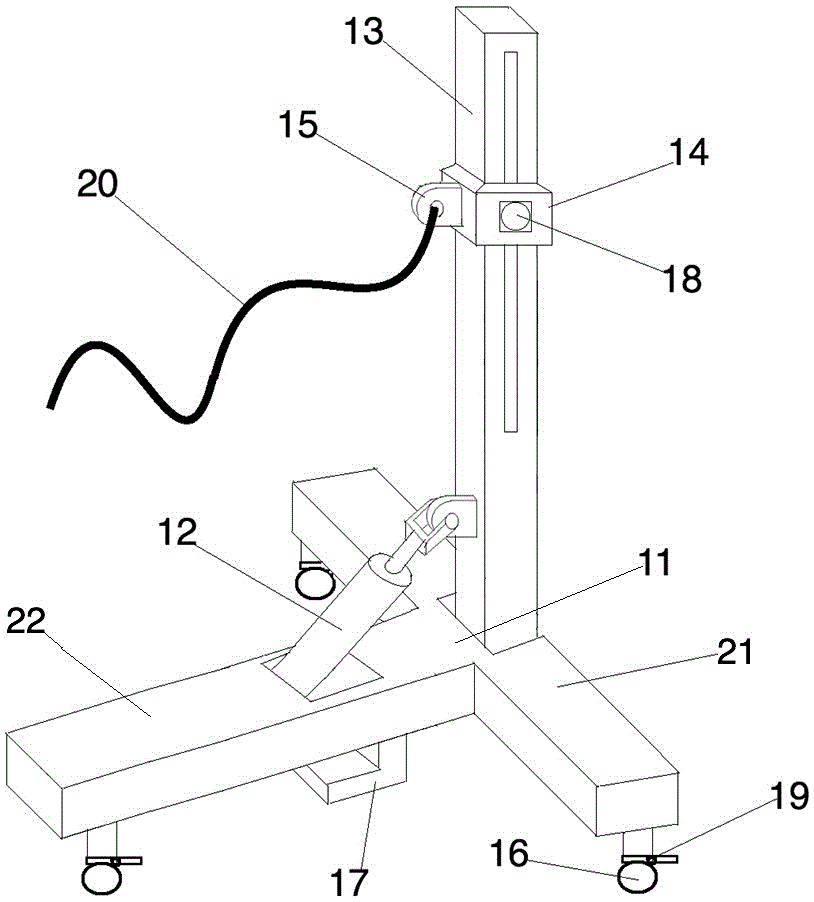

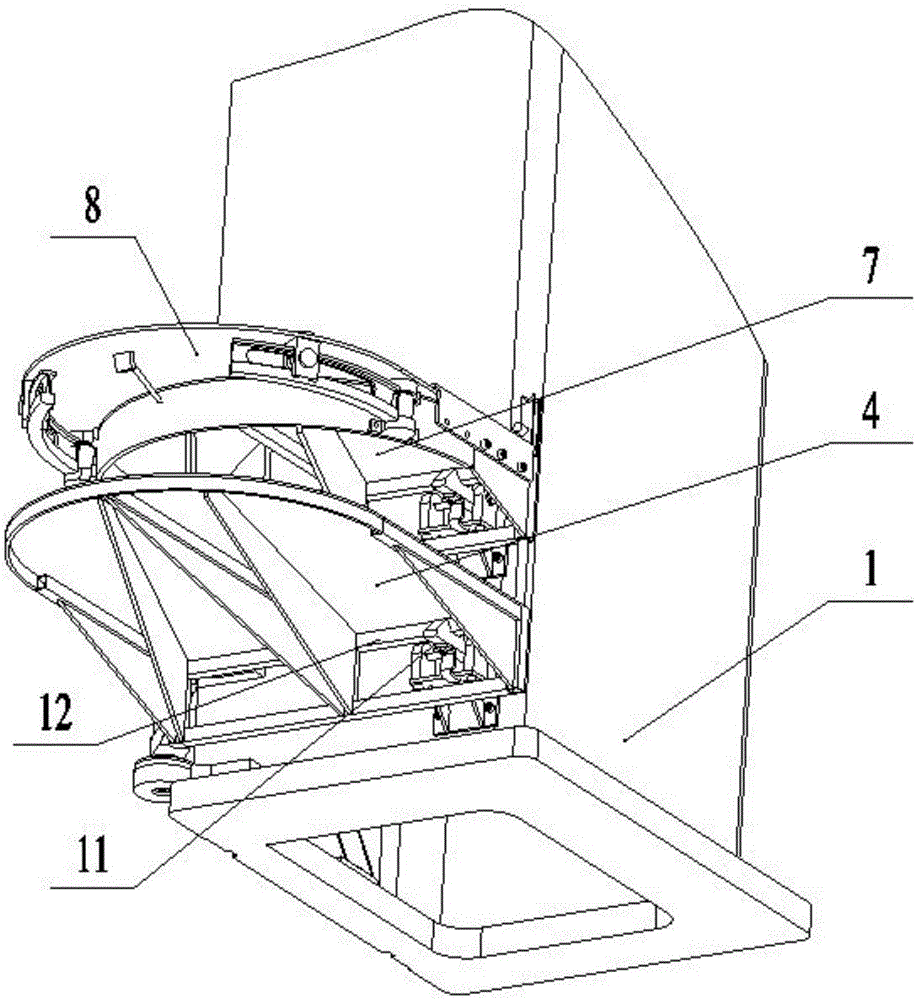

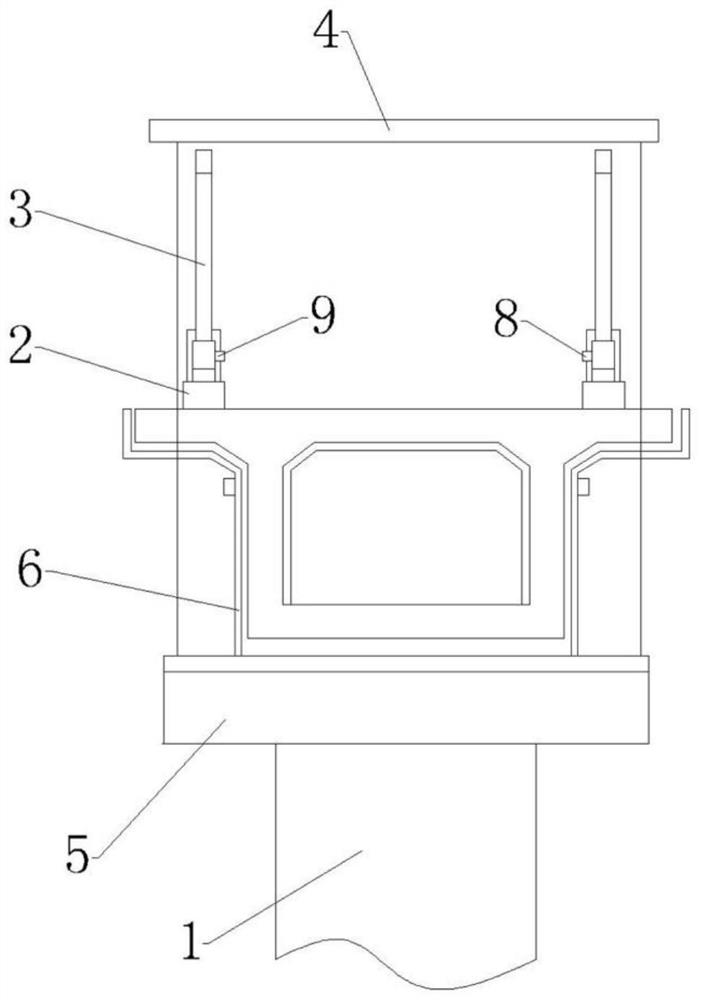

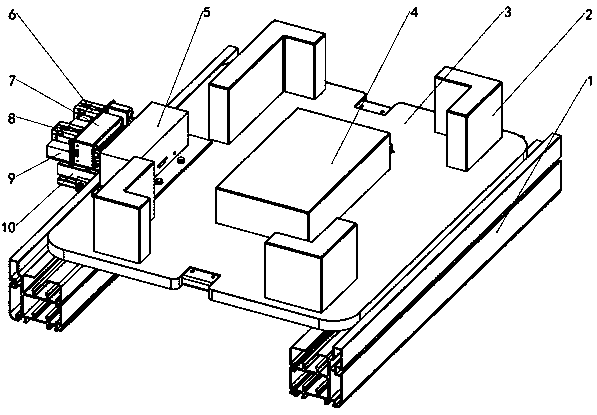

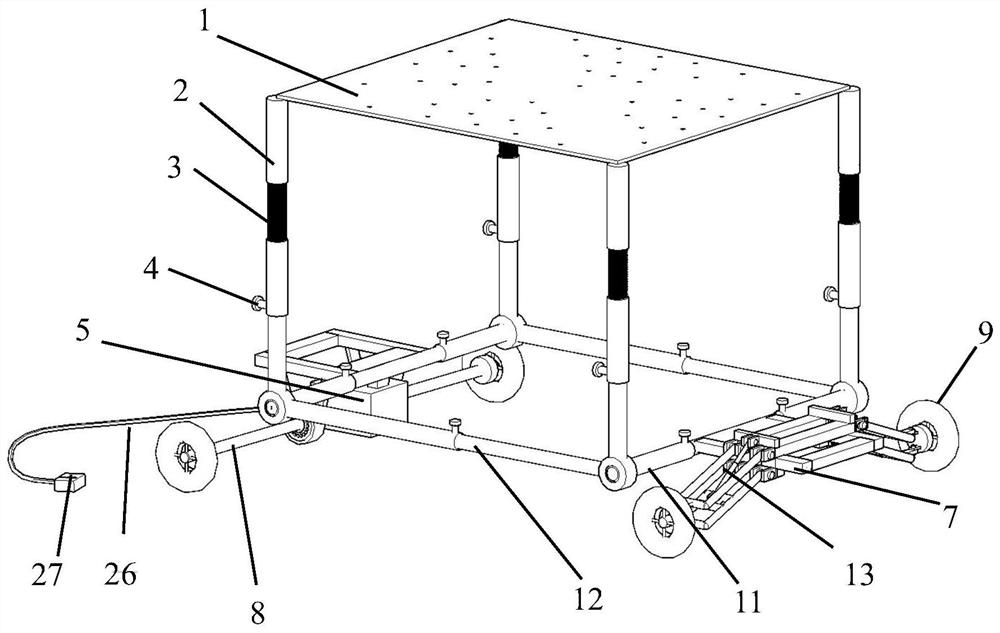

Automobile body correcting system

ActiveCN106378366AAvoid installationAvoid disassemblyMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention discloses an automobile body correcting system. The automobile body correcting system comprises a correcting platform framework, a clamp and a hydraulic stretching column, wherein the correcting platform framework is U-shaped, the clamp comprises a fixing rod and a locating rod which are arranged in a crossed manner, the hydraulic stretching column comprises a T-shaped base, a hydraulic oil cylinder, a stretching column and a stretching slider, the T-shaped base comprises a transverse arm and a longitudinal arm, the longitudinal arm is arranged on the correcting platform framework in a crossing manner and is connected with the correcting platform framework through a framework connector arranged at the bottom of the longitudinal arm, the stretching column is vertically arranged in the middle of the transverse arm of the T-shaped base, the hydraulic oil cylinder is arranged on the longitudinal arm of the T-shaped base, and the end part of a piston rod of the hydraulic oil cylinder is connected with the stretching column. The structure is simple. As the clamp is arranged on the correcting platform framework, the mounting and disassembly of the clamp in each automobile body correcting process are avoided, and time spent on correcting an automobile body and the labor intensity of operators are effectively reduced. As the hydraulic stretching column and the correcting platform framework are separately arranged, the working space is not occupied.

Owner:NANJING WOYU MECHANICAL & ELECTRICAL EQUIP CO LTD

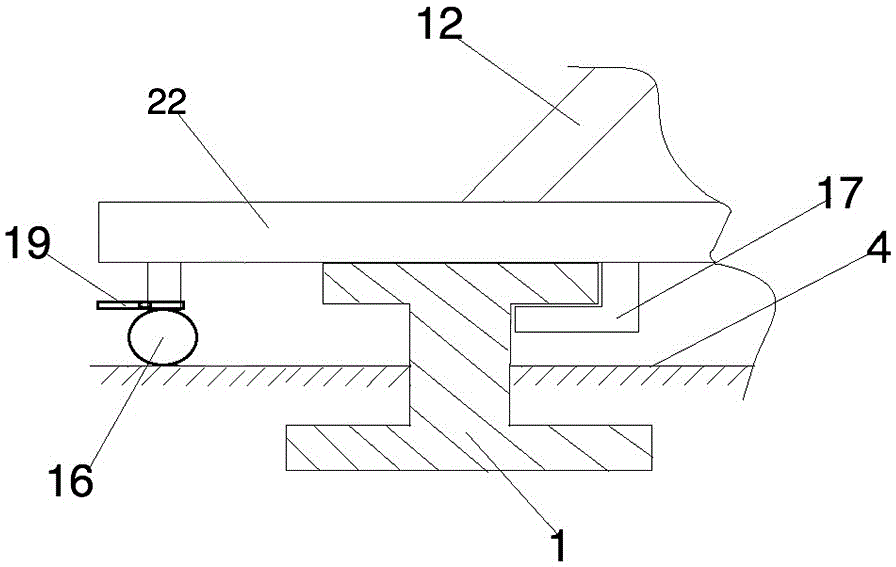

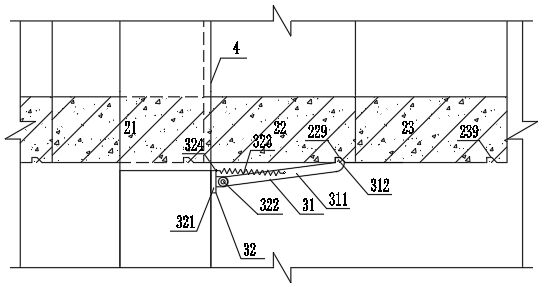

Rectangular pipe jacking automatic retaining device with pawls

PendingCN112901184AImprove construction efficiencySimple structureTunnelsRetainer (device)Structural engineering

The invention relates to the technical field of underground mechanical method underground excavation construction, and particularly relates to a rectangular pipe jacking automatic retaining device with pawls. The rectangular pipe jacking automatic retaining device comprises retaining components and fixing components; the retaining components are horizontally and symmetrically arranged on the two sides of a pipe joint in the length direction of the pipe joint and used for fixing the pipe joint; each retaining component comprises a working support and the corresponding pawl; a reserved groove matched with the corresponding pawl is formed in the surface of the pipe joint; the fixing components are used for fixing the retaining components and providing counter force for preventing a pipe jacking machine and the pipe joint from retreating; and each fixing component comprises a fixing support, a fixing bolt, a spring and a spring fixing device. According to the retaining device, in the continuous jacking process of the pipe jacking machine and the pipe joint, under the cooperation action of the retaining components, the fixing components and other devices, the technology of retaining of the pipe jacking machine and the pipe joint is achieved; and compared with traditional retaining measures, the device is simple in structure, high in automation degree and shorter in consumed time, pipe joint retaining can be effectively achieved, ground surface settlement is effectively controlled, jacking construction can be more continuous, and the pipe jacking construction efficiency is effectively improved.

Owner:广州金土岩土工程技术有限公司 +1

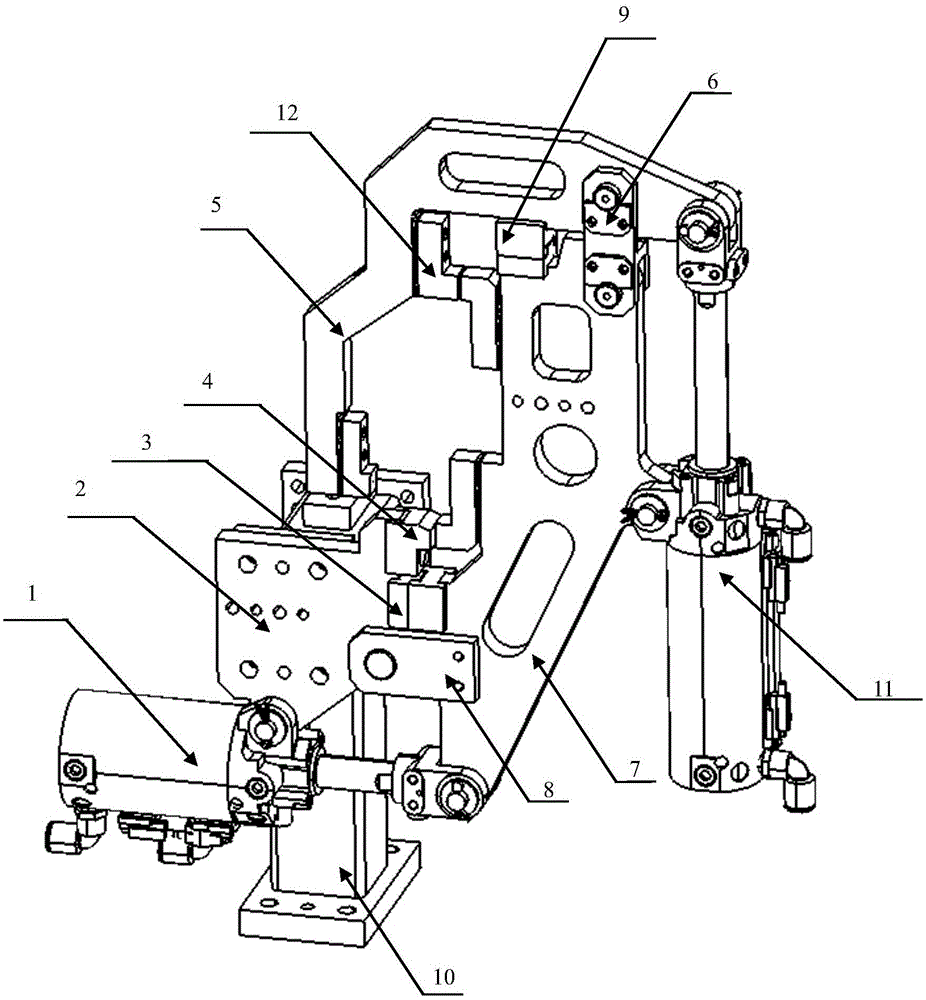

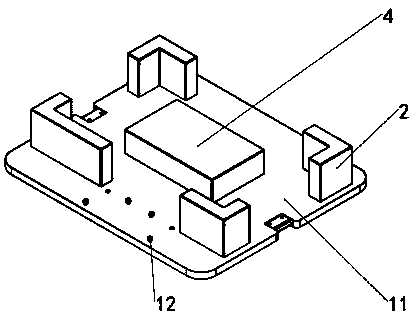

Clamp

InactiveCN106363329AAchieve clampingRealize the second clampingWelding/cutting auxillary devicesAuxillary welding devicesPivot jointEngineering

The invention discloses a clamp. The clamp comprises a base, a first power device, a first pressing arm, a second power device and a second pressing arm, wherein a first clamping block is fixedly arranged on the base; the first power device is in pivot joint with the base; the first pressing arm is in pivot joint with the base, one end of the first pressing arm is driven by the first power device, the first pressing arm is provided with a second clamping block and a third clamping block, and the second clamping block corresponds to the first clamping block; the second power device is in pivot joint with the first pressing arm; and the second pressing arm is in pivot joint with the other end of the first pressing arm, one end of the second pressing arm is driven by the second power device, and a fourth clamping block is arranged on the second pressing arm and corresponding to the third clamping block. The clamp can clamp at least two portions of a workpiece and does not occupy two much space.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

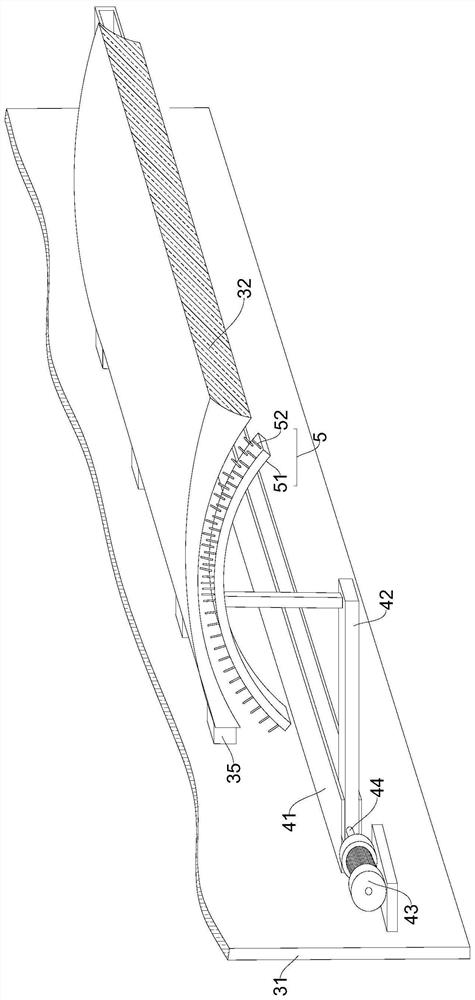

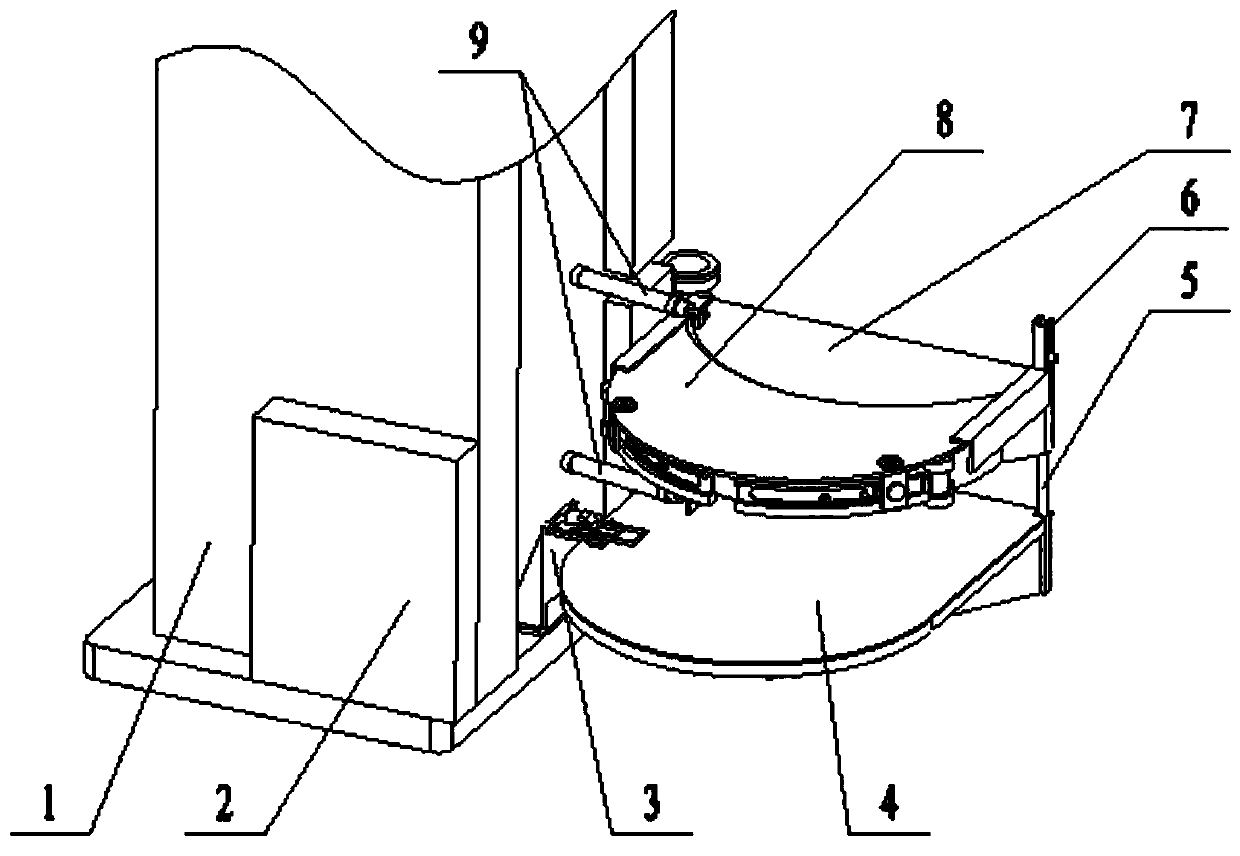

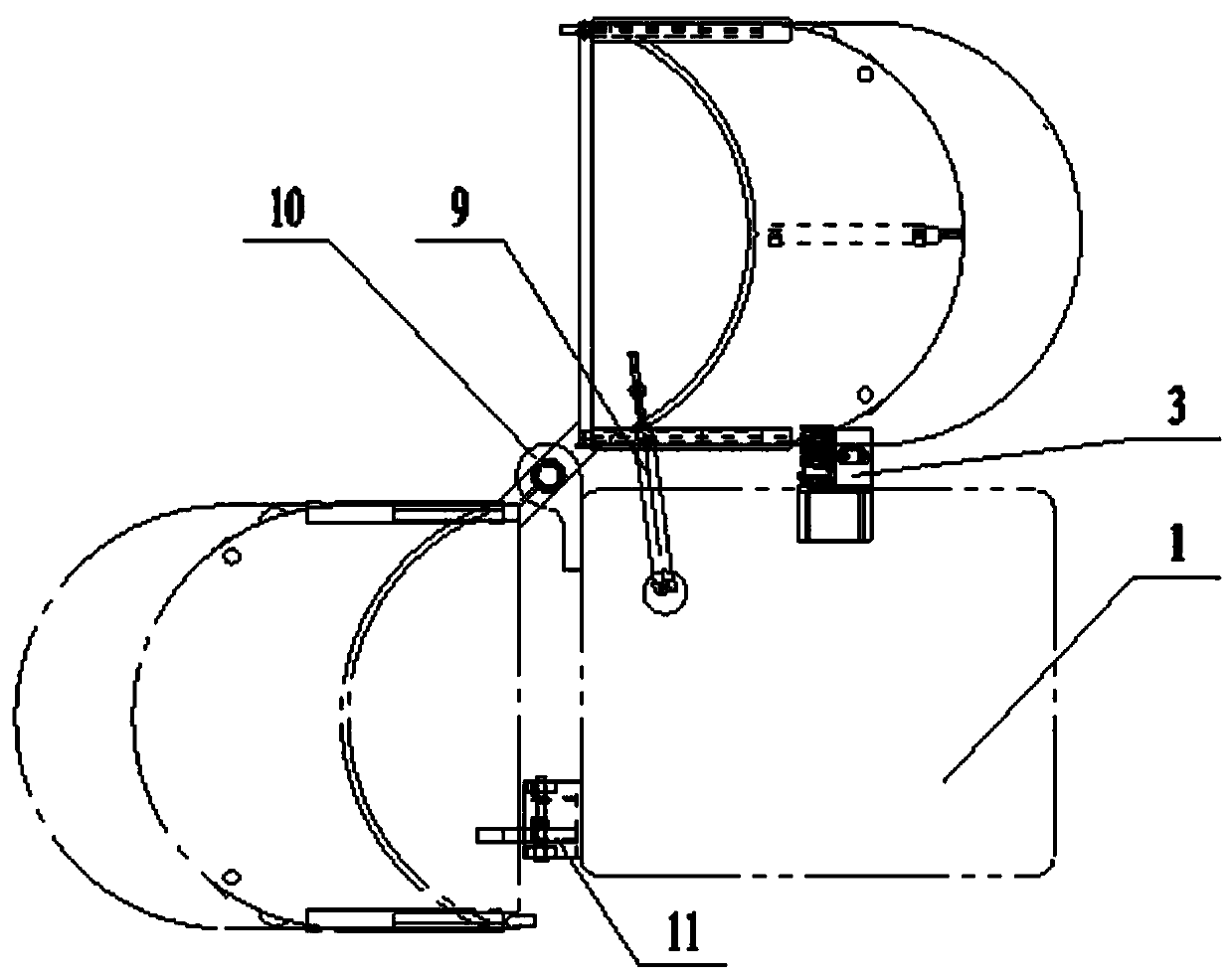

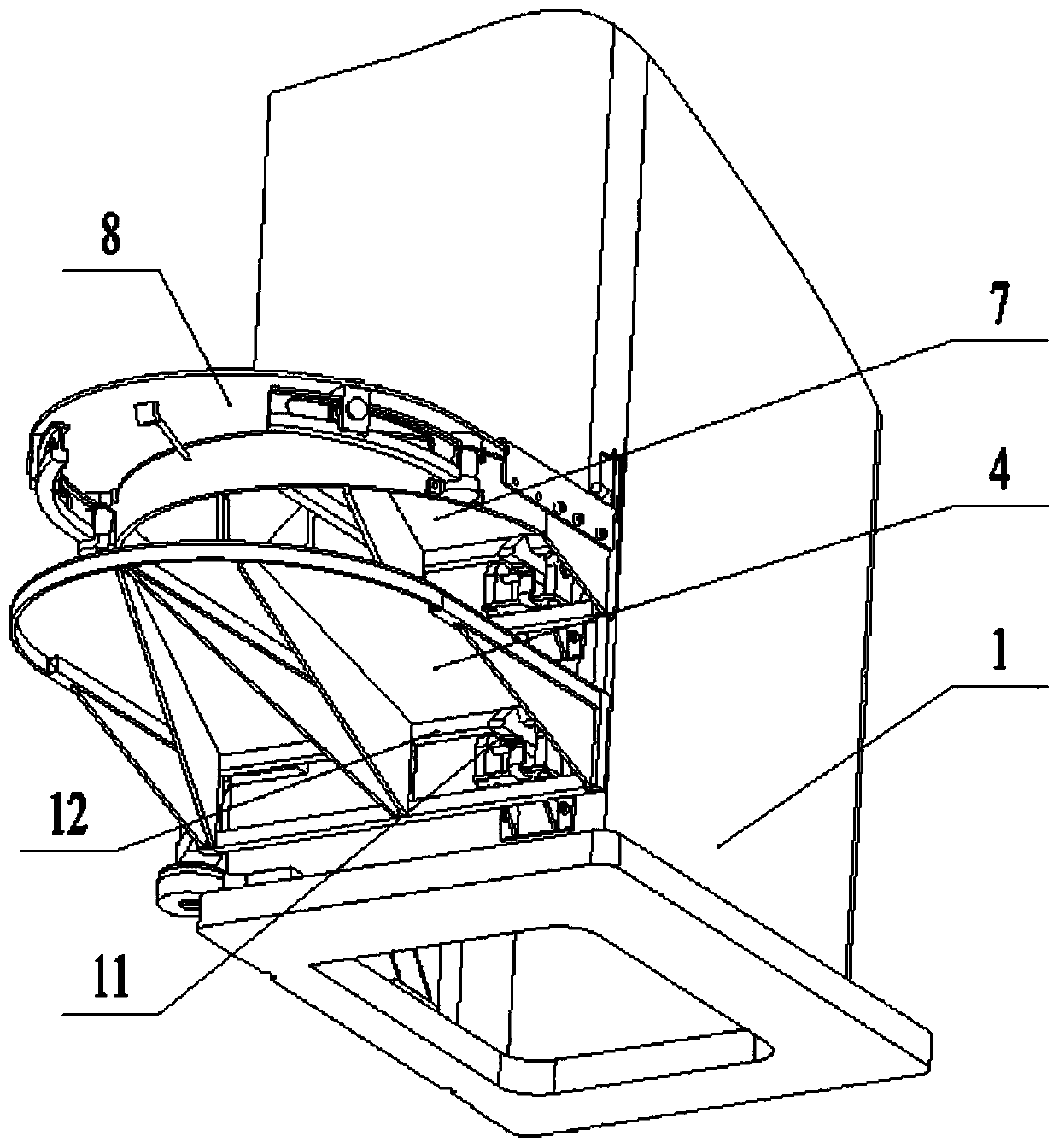

Rotary extension-type ladder device

ActiveCN106272315ADoes not take up work spaceFlexible adjustment of layersOther workshop equipmentEngineeringSelf locking

The invention discloses a rotary extension-type ladder device and belongs to the field of operation platforms. The rotary extension-type ladder device comprises a column, wherein at least one layer of platform is arranged on the column, the number of layers can be adjusted flexibly according to different working heights, actuators are arranged on the column and drive the platforms to rotate around the column, a self-locking device and a locking device are arranged on the column, an extension part is arranged on each platform, the working space of the platform can be increased, when the height of a workpiece is lower, the rotary extension-type ladder device which doesn't participate in working rotates to the other side of equipment completely, up-and-down motion can be realized by the aid of the ladder, the problem that the working platforms are inconvenient to carry is solved, and the utilization of the processing spaces is further improved by rotation and extension of the platforms.

Owner:HIMILE MECHANICAL MFG

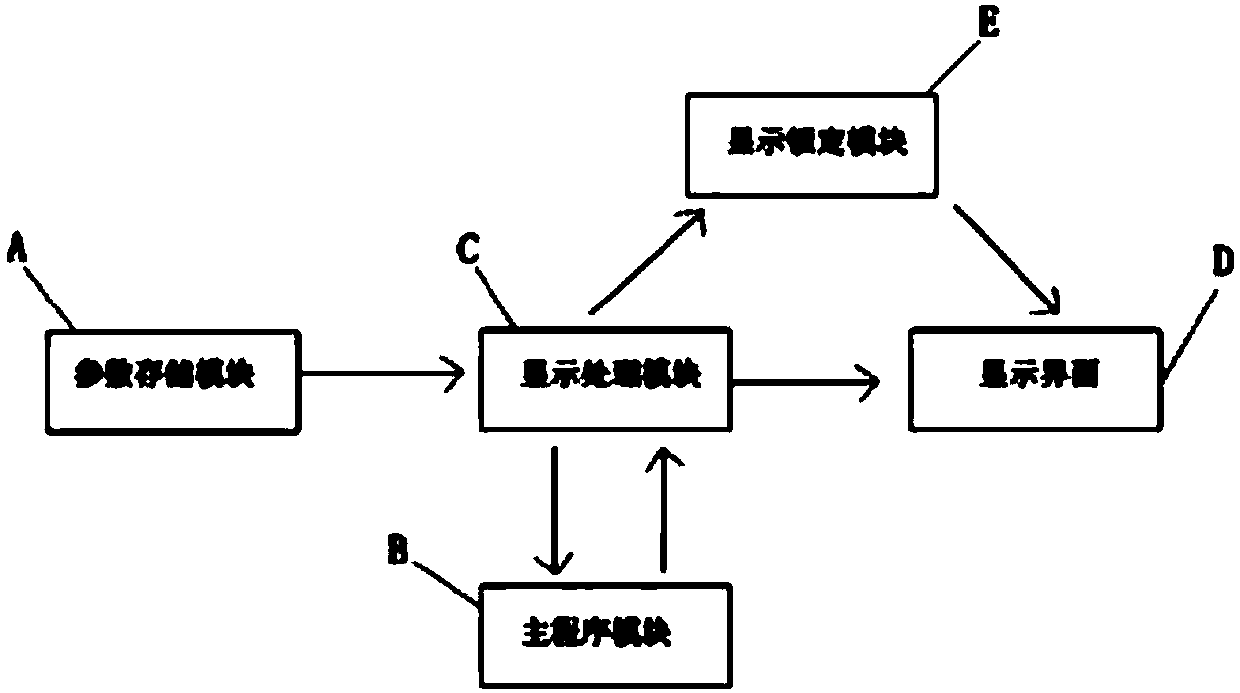

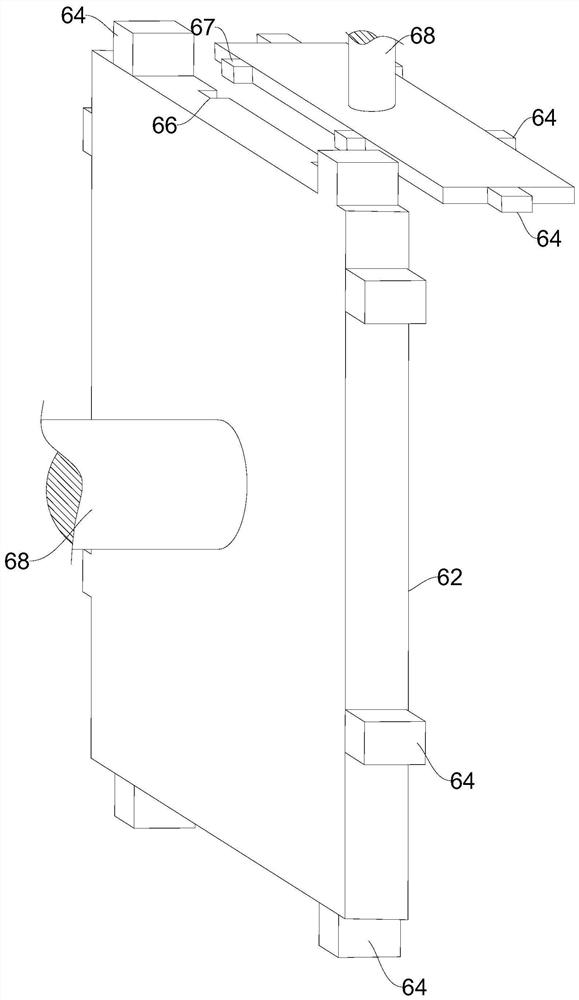

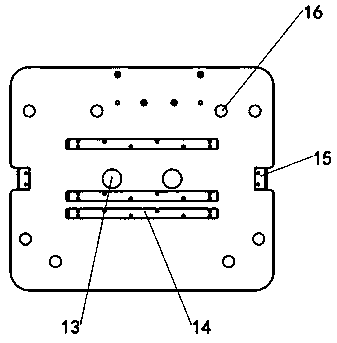

Parameter setting device for liquid-based thin layer cell film maker

InactiveCN109781479AImprove setup efficiencyImprove conveniencePreparing sample for investigationShortest distanceThin layer

The invention discloses a parameter setting device for liquid-based thin layer film maker. The device comprises a parameter storage module, a main program module, an interface processing module, a display interface and an interface locking module, wherein the display interface is provided with a parameter selection unit, an instruction selection unit, a first feedback signal display unit and a second feedback signal display unit; the parameter selection unit is used for selecting a sample quantity; the instruction selection unit is used for confirming a consumable item placing operation and controlling equipment to be started / stopped; the first feedback signal display unit is used for displaying an operation state and an operation prompt of the equipment; and the second feedback signal display unit is used for displaying groups of consumable items. According to the device, the display interface is reasonably distributed, so that the original fussy parameter setting operation becomes simple, easy and efficient, thereby furthermore improving the using convenience and safety of users, well keeping the stability and accuracy of the equipment when facilitating the parameter input operation, bringing benefit to carry out short-distance monitoring and operation on the equipment in time by the users, saving the cost of the equipment and not occupying redundant working space.

Owner:GUANGZHOU SUNRAY MEDICAL APP

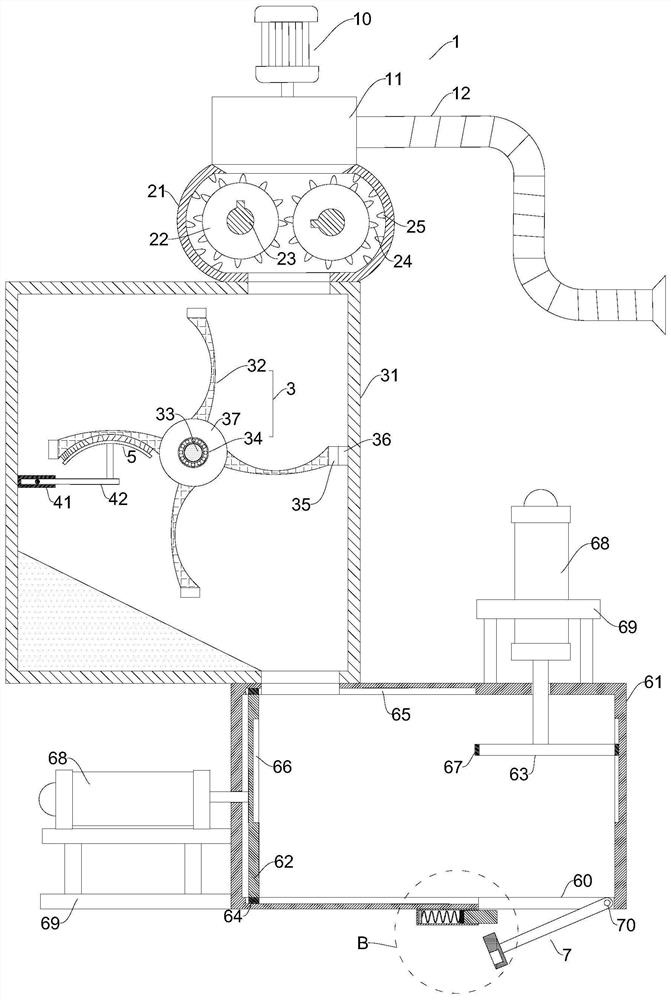

Cast film offcut recycling equipment

InactiveCN112847951AImprove recycling efficiencyEasy to collect and organizePlastic recyclingMechanical material recoveryStructural engineeringCast films

The invention provides cast film offcut recycling equipment which comprises a crushing mechanism, a quantitative separation mechanism and a pressing block mechanism, the crushing mechanism comprises a material suction machine used for collecting offcut and a cutting mechanism, and the cutting assembly is used for crushing the collected offcut; the cutting assembly comprises a cutting bin, a plurality of pairs of roller shafts rotationally connected into the cutting bin, a plurality of cutters constructed in the circumferential direction of the roller shafts and a plurality of groups of smashing cutters constructed along the inner wall of the cutting bin; the quantitative separation mechanism comprises a separation bin communicating with the cutting bin, a bearing hopper rotationally connected to the separation bin and a control unit for controlling the bearing hopper to overturn and discharge; and the pressing block mechanism comprises a forming bin communicating with the separating bin, a pressing plate and a pushing plate, the pressing plate and the pushing plate are connected into the forming bin in a sliding mode, and the pressing plate is perpendicular to the pushing plate. The cast film offcut recycling equipment solves the problems that according to an existing offcut recycling device, chippings are inconvenient to collect and store, and the working intensity of workers is increased, the purposes that people can conveniently collect materials and quantitatively package the chippings are achieved, the offcut recycling efficiency is improved, and the production cost of enterprises is saved.

Owner:CHONGQING HETAI PLASTIC

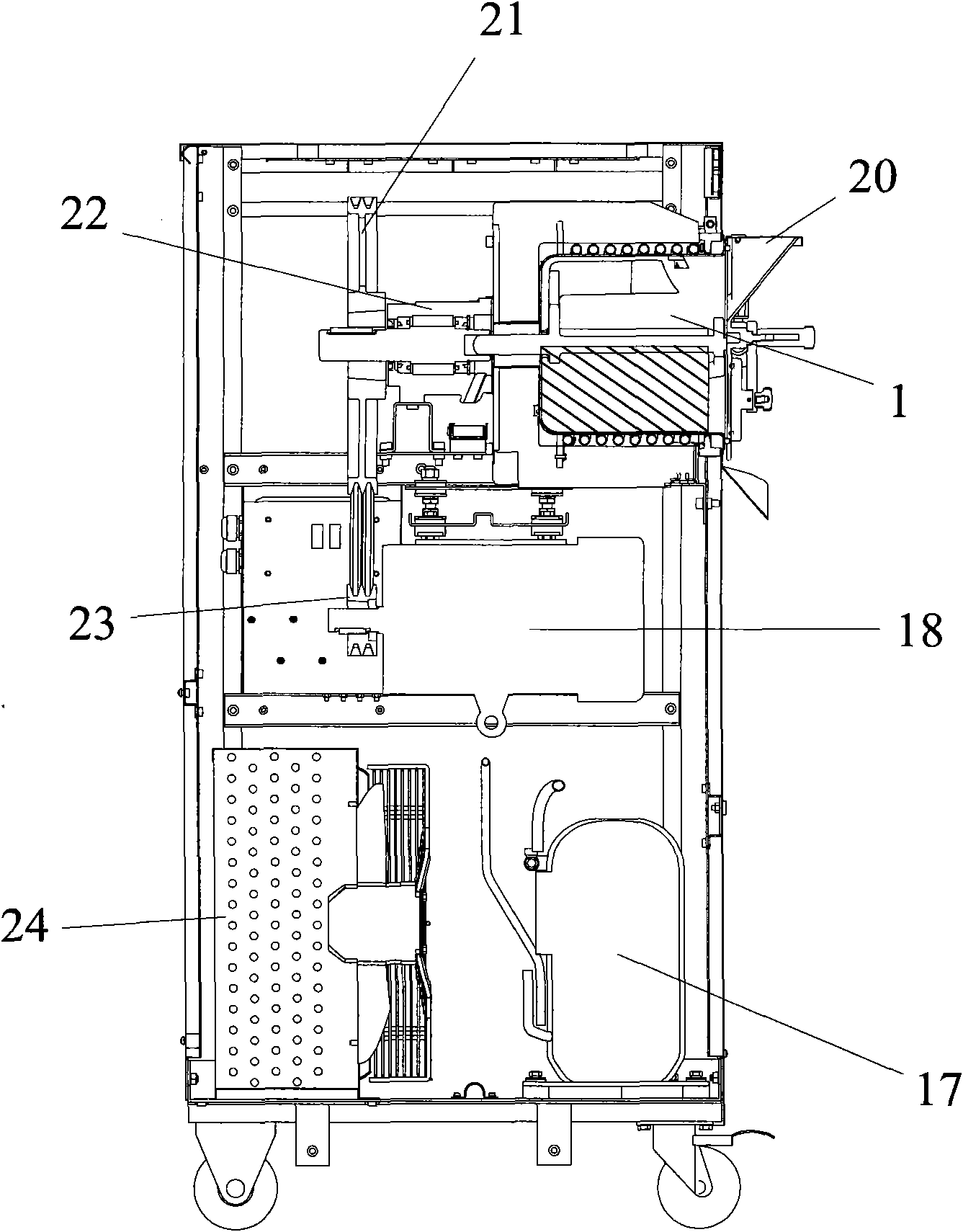

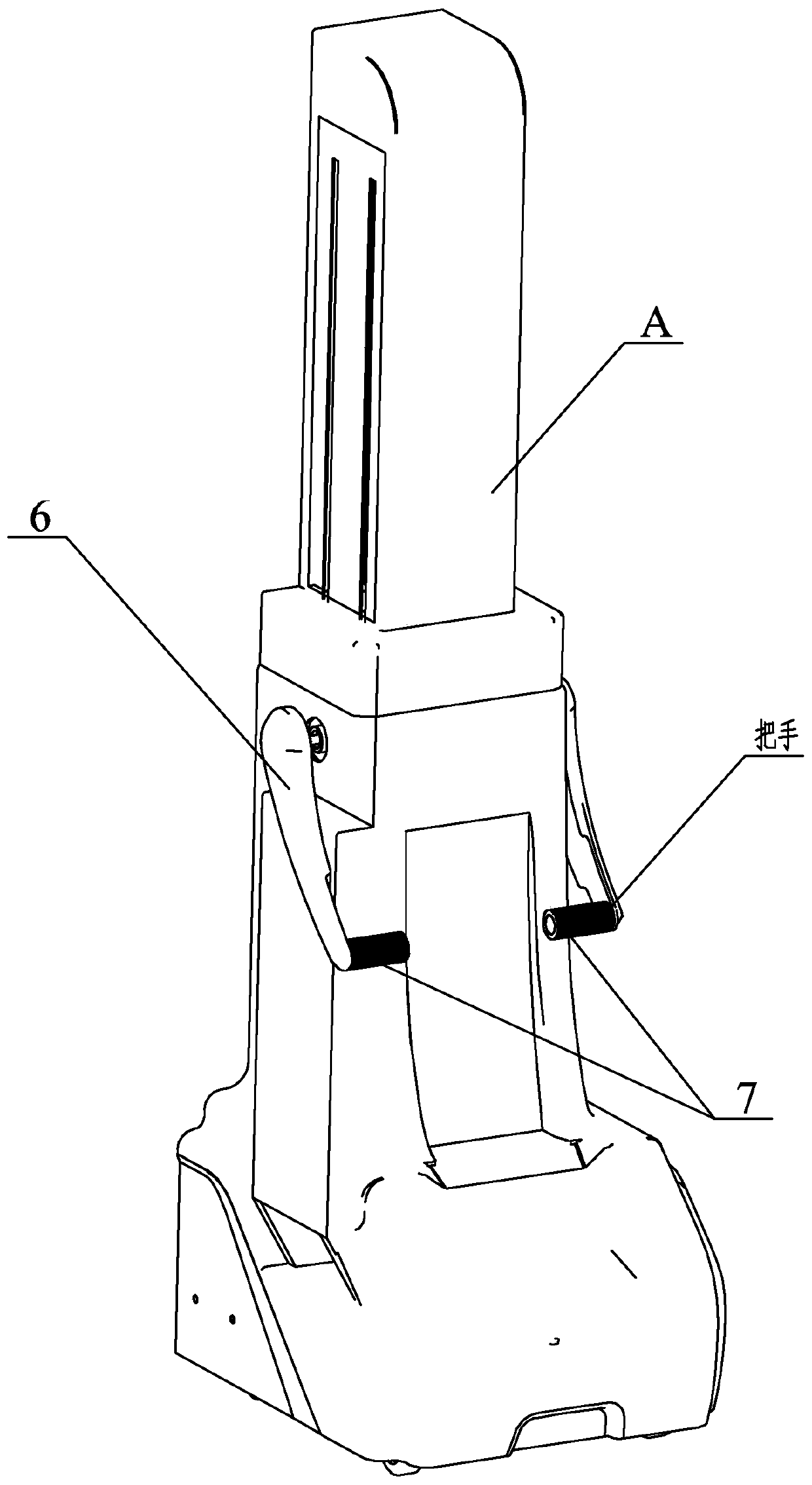

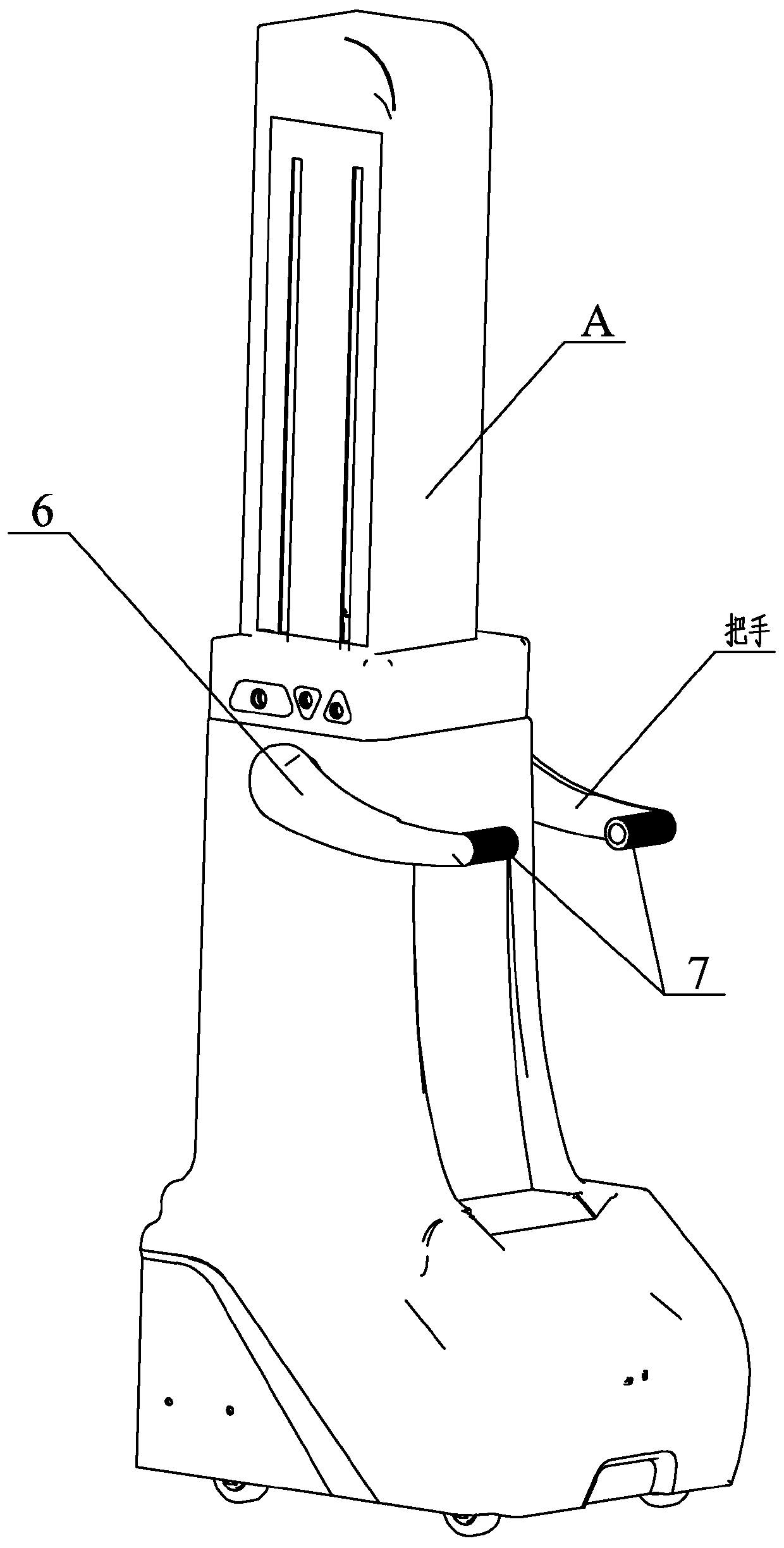

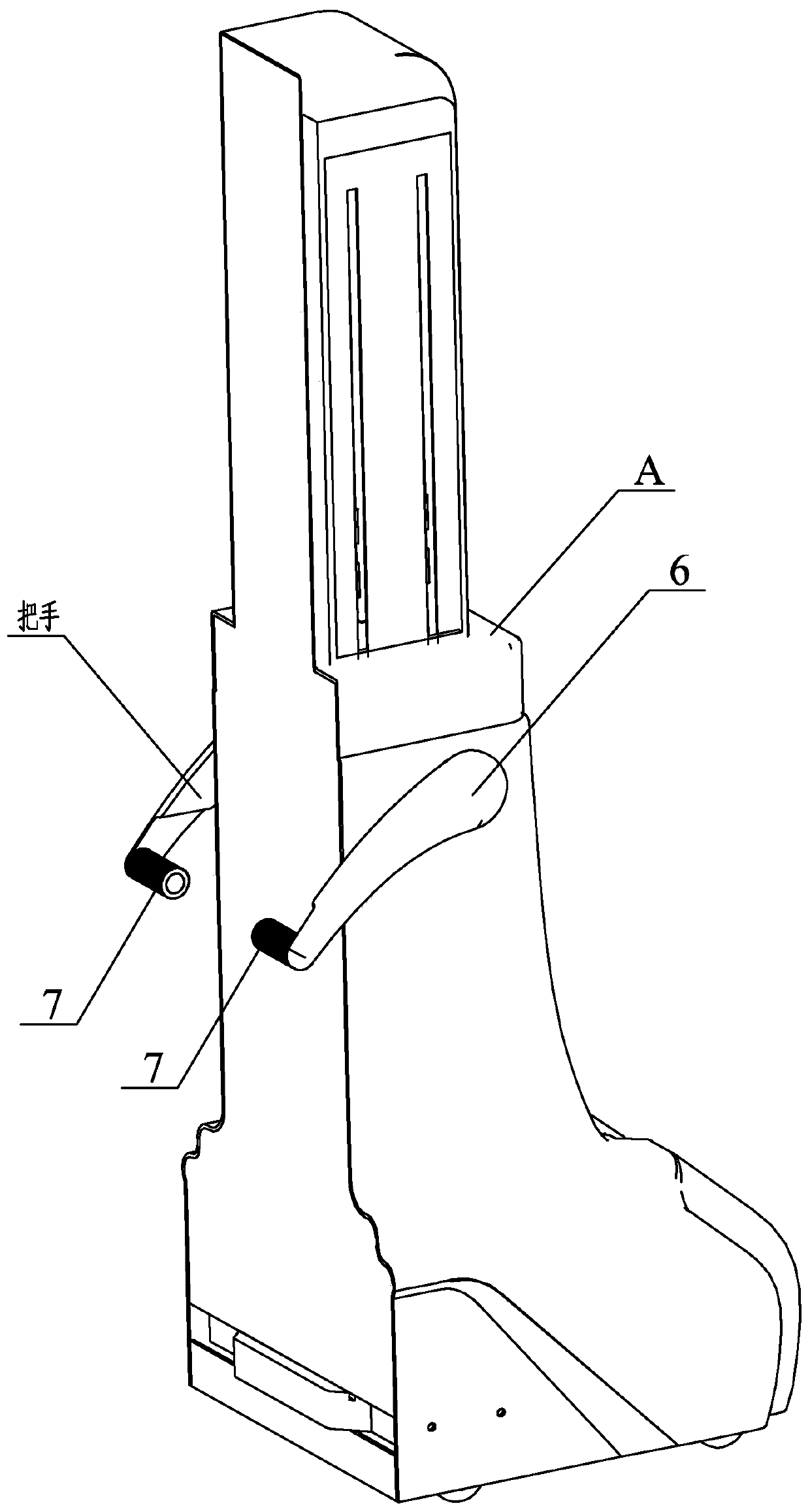

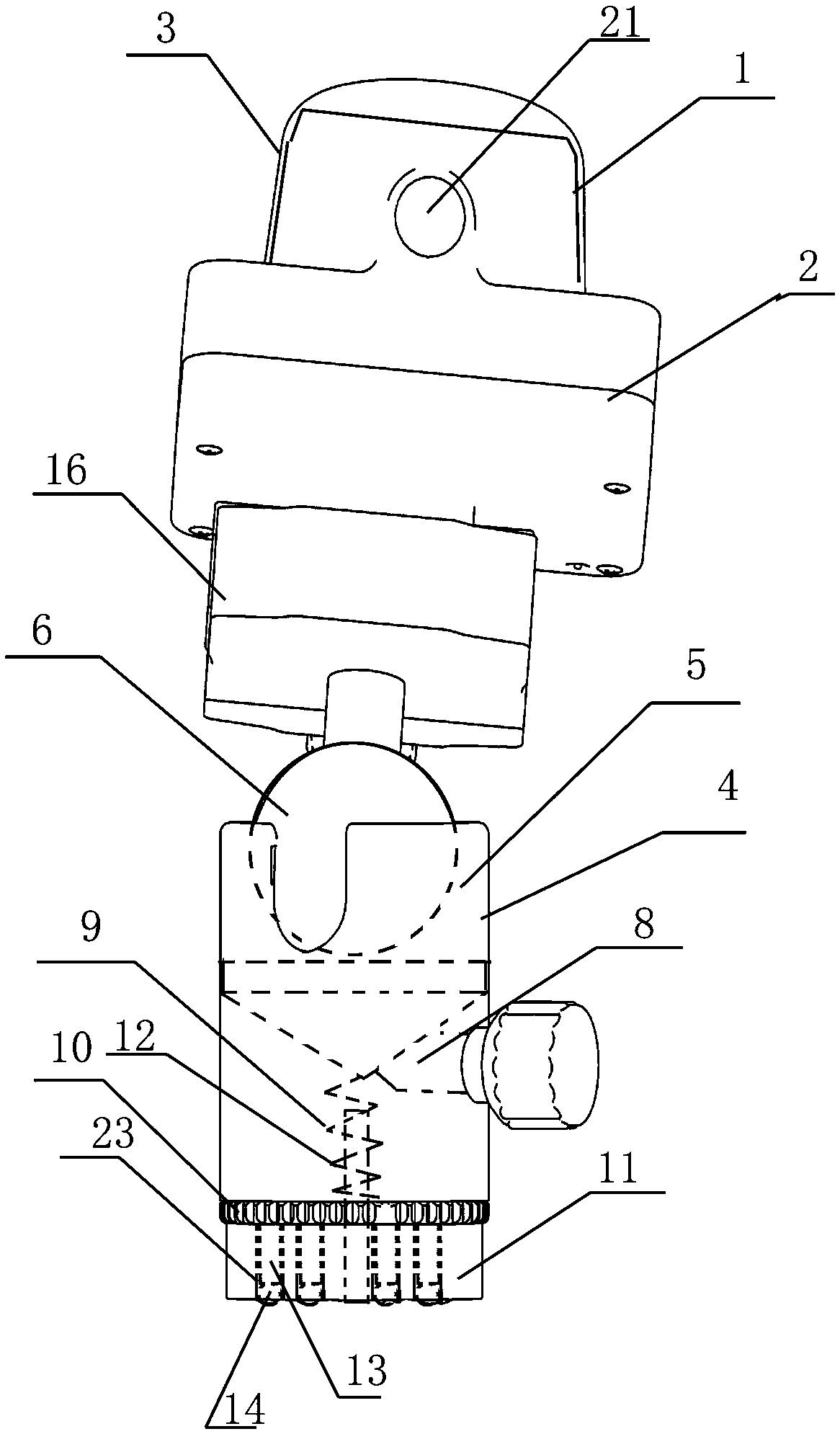

Handle for moving trolley of surgical robot

ActiveCN110772336AEasy to move forwardGood backSurgical furniturePhysical medicine and rehabilitationEngineering

The invention discloses a handle for a moving trolley of a surgical robot, and relates to the field of handles. The invention aims to solve the problems that handles of a moving trolley of an existingoperation robot are very inconvenient when reverse pushing is carried out, and when the moving trolley moves to an appointed position, handle assemblies are not adjustable and occupy the working space, so that inconvenience is brought to the work of operation-related workers. A handle fixed part (1) is embedded and mounted on the moving trolley (A) of the surgical robot, a limiting assembly is mounted on a handle shaft (2), the handle fixed part (1) achieves three states of standby state, forward stretching pushing and backward stretching pushing through inserting and pulling at different positions on the handle shaft (2), one end of each of handles (6) is connected with the handle fixed part (1), and the other ends of the handles (6) are connected with handles (7). The handle is used onthe moving trolleys of surgical robots.

Owner:杭州唯精医疗机器人有限公司

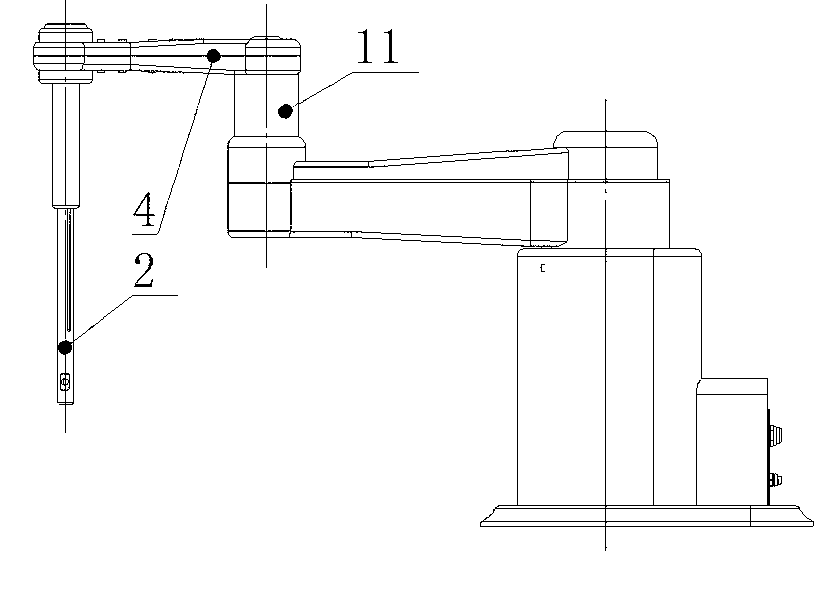

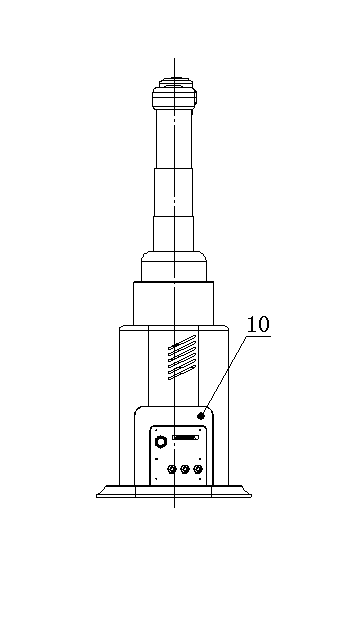

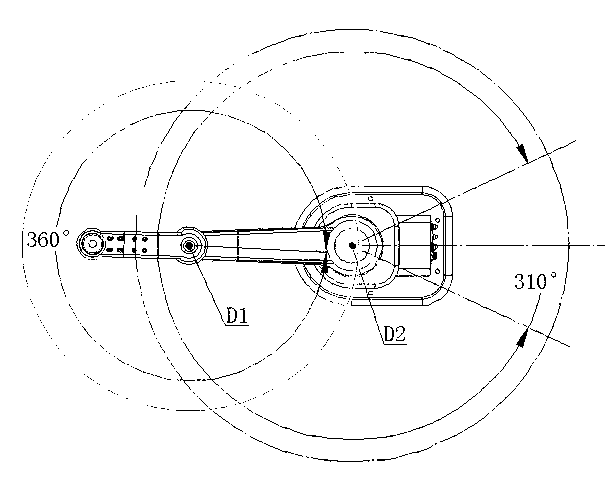

Precise robot

InactiveCN102922518AFlexible rotationImprove return accuracyProgramme-controlled manipulatorHuman bodyWork performance

The invention relates to a precise robot, belongs to the field of machinery design and manufacture and is suitable for industrially operated robots. The precise robot is characterized in that four four-axis motors can perform five motions and do high-precision work in an extremely small working space region. Due to the fact that an upper shrinking barrel and a middle shrinking barrel can perform lifting operation on a first arm, a front end telescopic rod is telescopic, and the first arm can rotate for 360 degrees and can perform complex station work. A structural idea of human body arm is introduced, the front end structure is small and exquisite, four servo motors are installed on a backseat, the gravity center position of a machine body is designed on a (D2) shaft, a (D1) shaft rotates briskly, and a working point of the front end telescopic rod returns precisely. An electrical control line is all installed at the bottom of a fixed seat, is safe and reliable and does not occupy a working space. Ultra-novel design of the precise robot is adopted, and the precise robot is reasonable in design, simple in structure, stable in working performance, large in output load energy, free of negative effect and wide in application range.

Owner:钱印

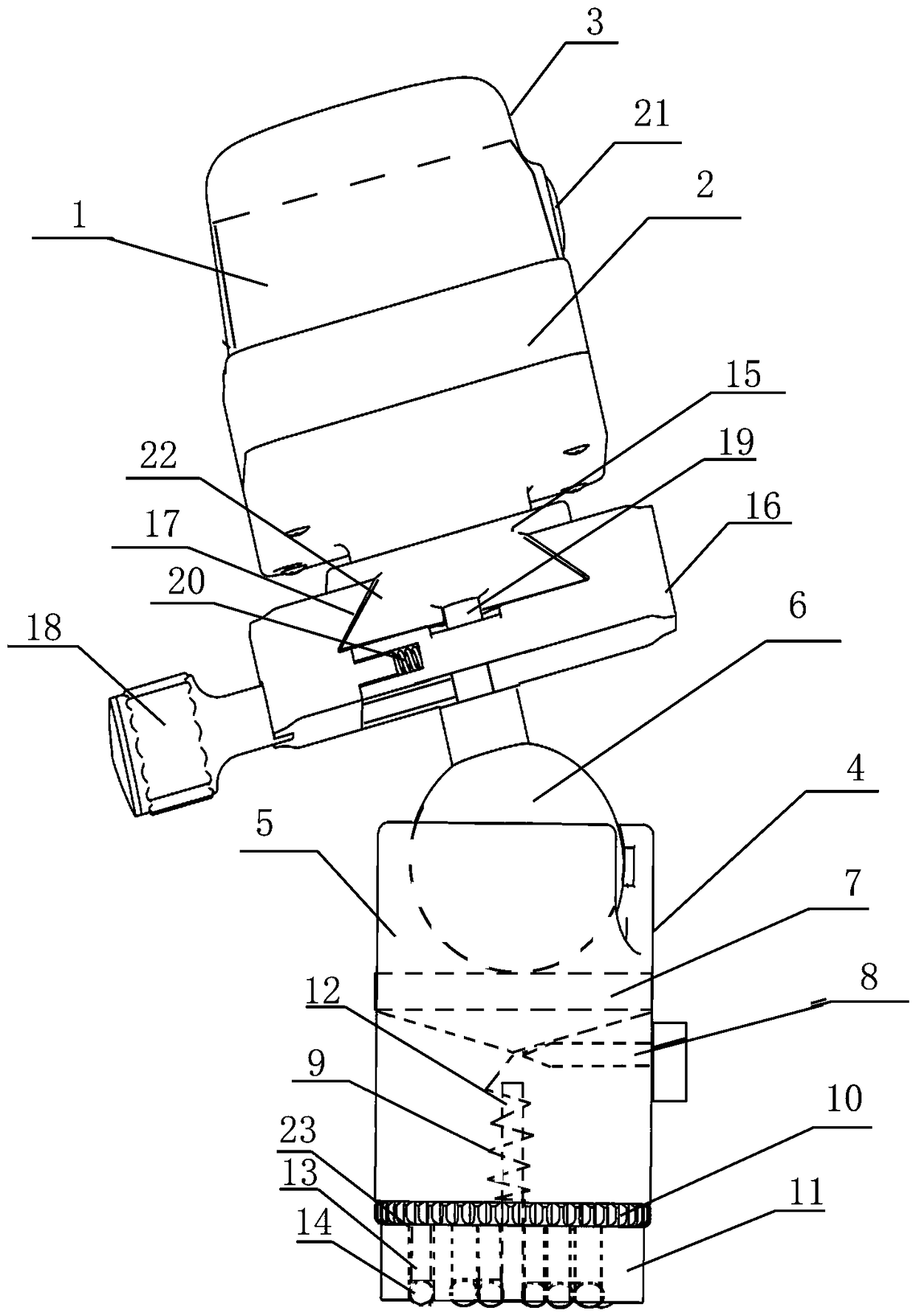

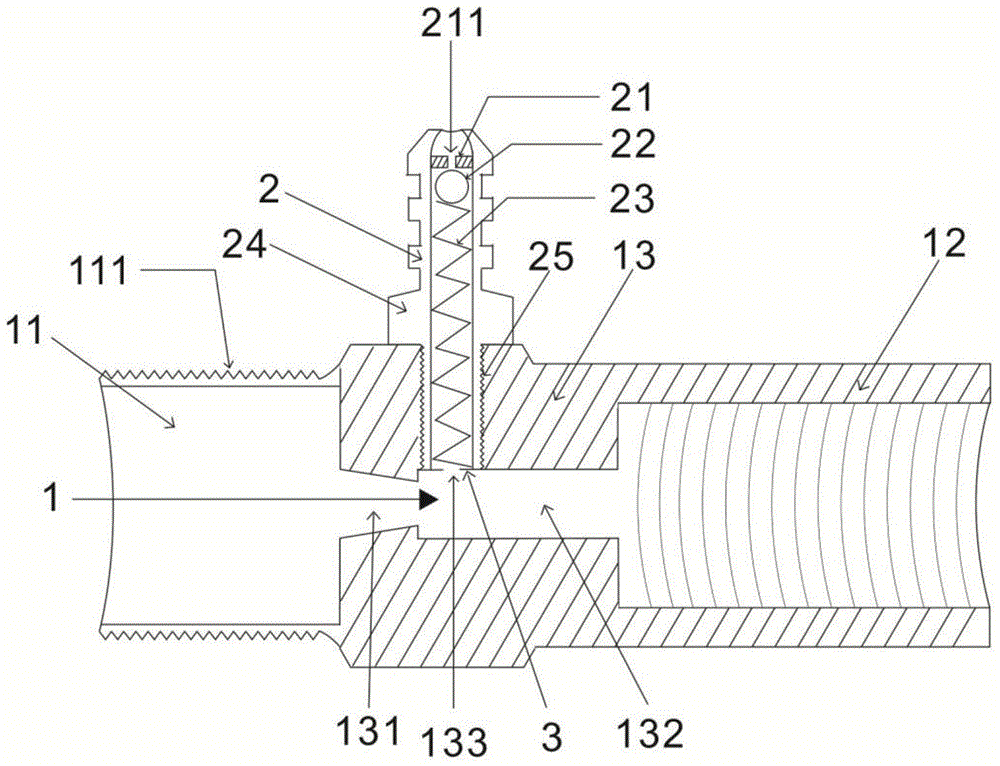

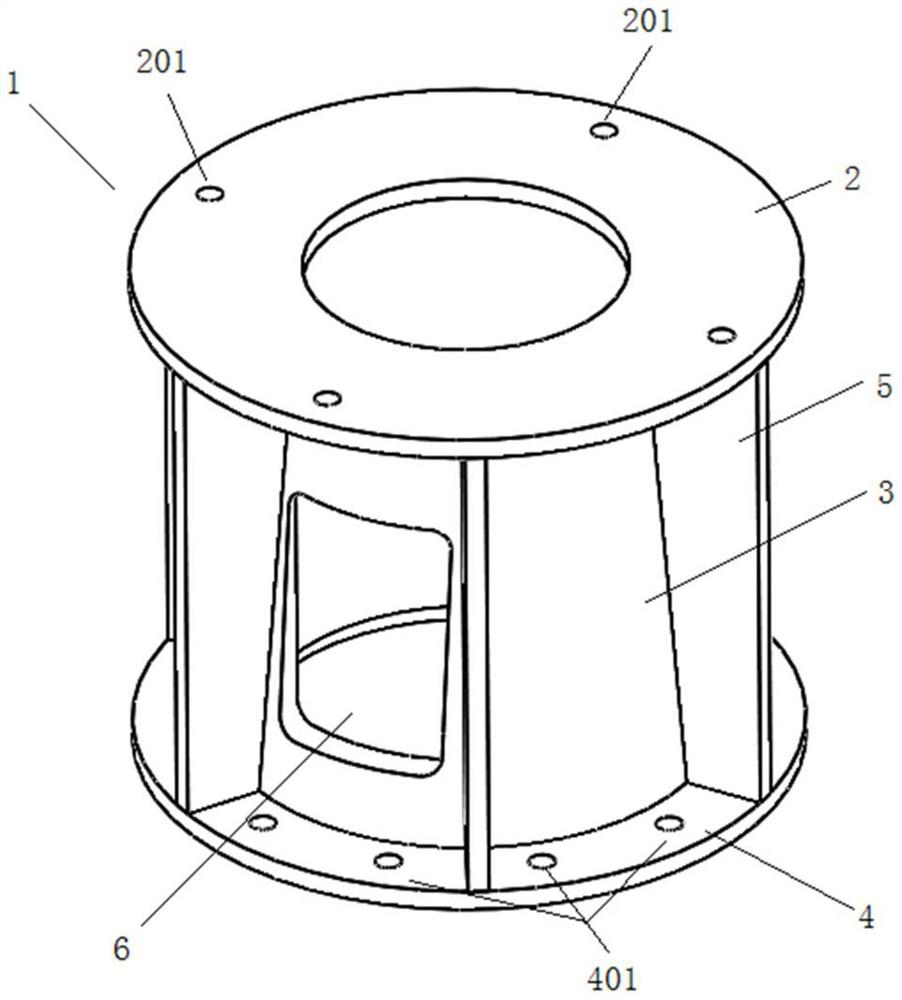

Fiber grating sensor and method for measuring pressure of shield segment

PendingCN110470418AReduce volumeEasy to assemble and disassembleUnderground chambersForce measurement by measuring optical property variationFiberGrating

The invention discloses a fiber grating sensor for measuring pressure of a shield segment. The fiber grating sensor includes a grouting hole shaft tube device, an inner ring protection device and an outer ring measurement device; and the grouting hole shaft tube device includes a grouting hole shaft tube (5), the grouting hole shaft tube (5) includes a grouting hole shaft tube segment (6) and a grouting hole shaft tube end section (7), a plurality of reserved holes (9) are disposed inside the grouting hole shaft tube (5), the inner ring protection device includes a steel protection cover (2),a threaded hole (4) is disposed in the center of the steel protection cover (2), and the outer ring measurement device includes a fiber grating (12). The invention also discloses a method for measuring the pressure of the segment. The fiber grating sensor of the invention can accurately measure the water and soil pressure outside the segment, can monitor the water and soil pressure outside the segment during an entire period, an entire interval, and an entire process, provides more comprehensive information outside a tunnel for tunnel construction and operation stages, and can be repaired andreplaced in time once the sensor is damaged,.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

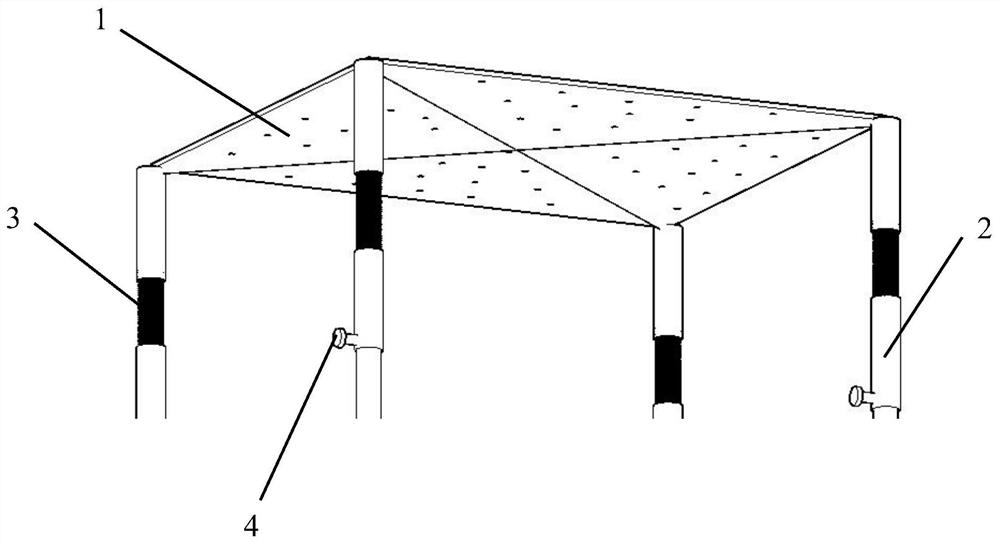

Novel synchronous forward-moving hanging basket and using method thereof

InactiveCN113565020AMove quicklyImprove reliabilityBridge erection/assemblyHydraulic cylinderHanging basket

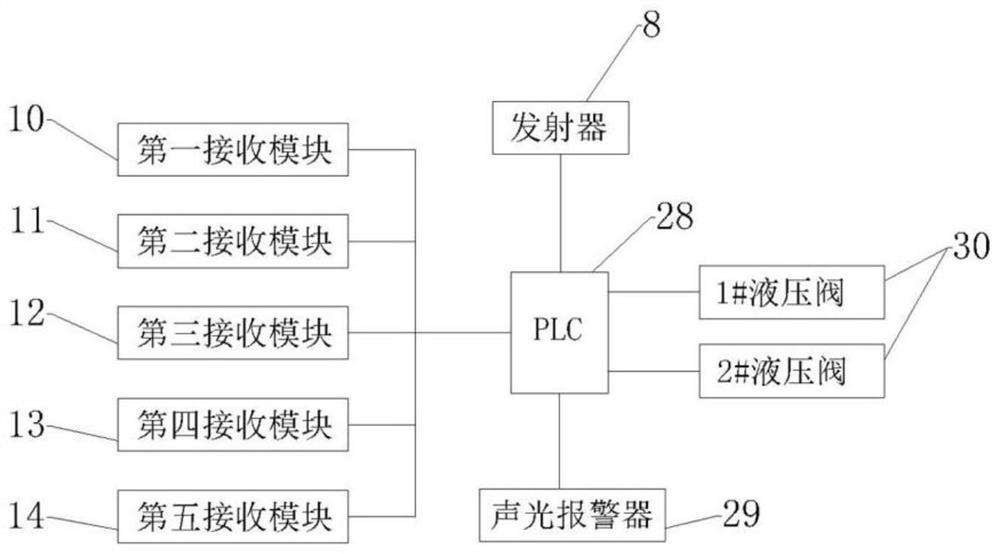

The invention discloses a novel synchronous forward-moving hanging basket and a using method thereof. The novel synchronous forward-moving hanging basket comprises a track, a main truss, a cross beam, a bottom die and a side die. A hydraulic walking mechanism is arranged on the main truss and comprises a hydraulic cylinder and a hydraulic valve used for controlling the hydraulic cylinder to stretch out and draw back. The hanging basket further comprises an emitter, an infrared receiving device and a PLC. The infrared receiving device comprises a shell, a second receiving module, a third receiving module and a fourth receiving module; the emitter is arranged on one main truss of the hanging basket, the infrared receiving device is arranged on the other main truss of the hanging basket, and infrared light emitted by the emitter is projected on a connecting line of the second receiving module and the fourth receiving module; and the emitter, the second receiving module, the third receiving module and the fourth receiving module are all electrically connected with the PLC, and the PLC is connected with a hydraulic valve of the hydraulic walking mechanism. Automatic intelligent control over movement of the hanging basket can be achieved, the construction efficiency can be improved, and the project period can be shortened.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Embedded automatic inclinometry robot and using method thereof

PendingCN111024039AWith waterproof functionImprove waterproof performanceIncline measurementSimulationElectric machinery

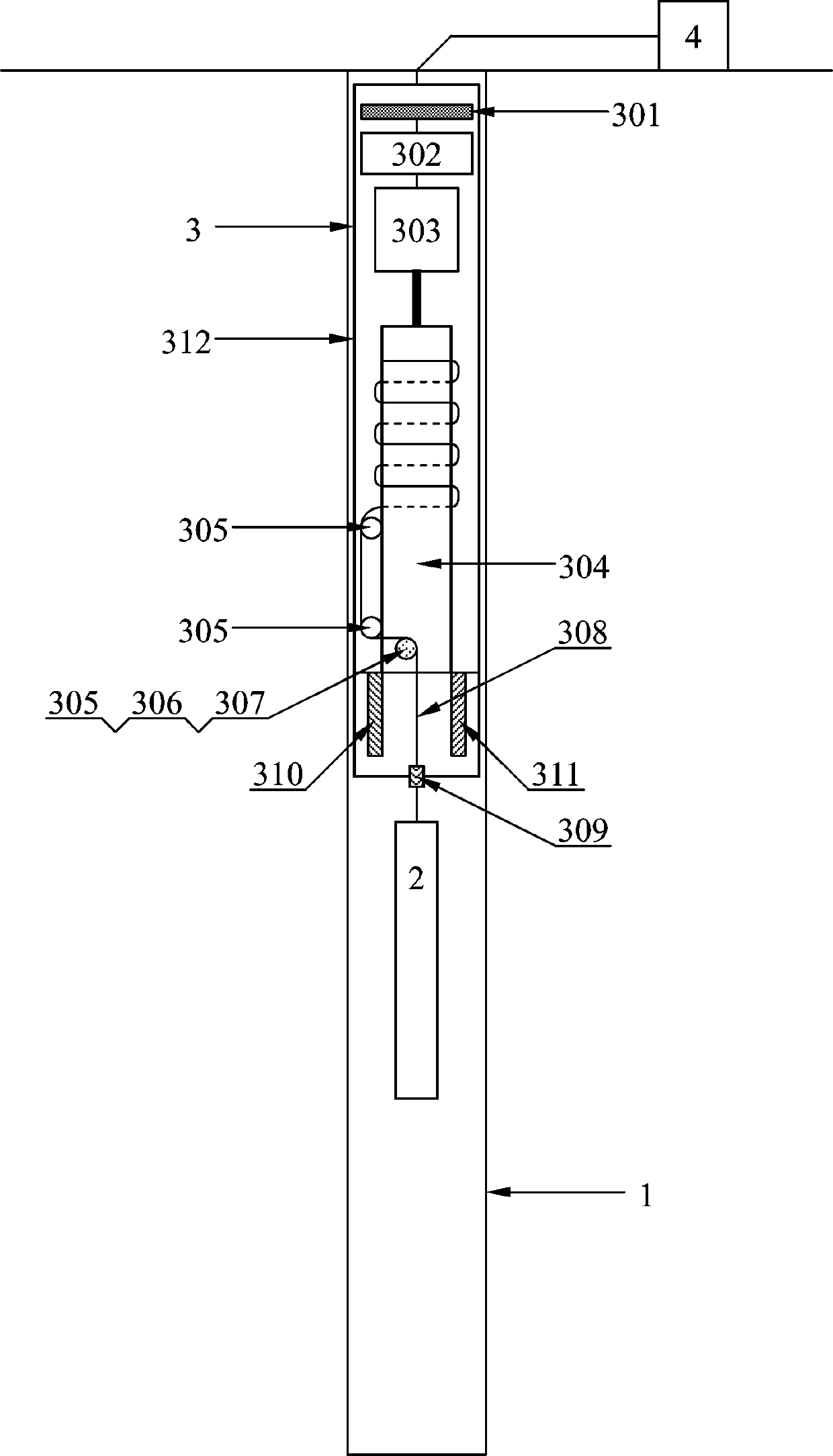

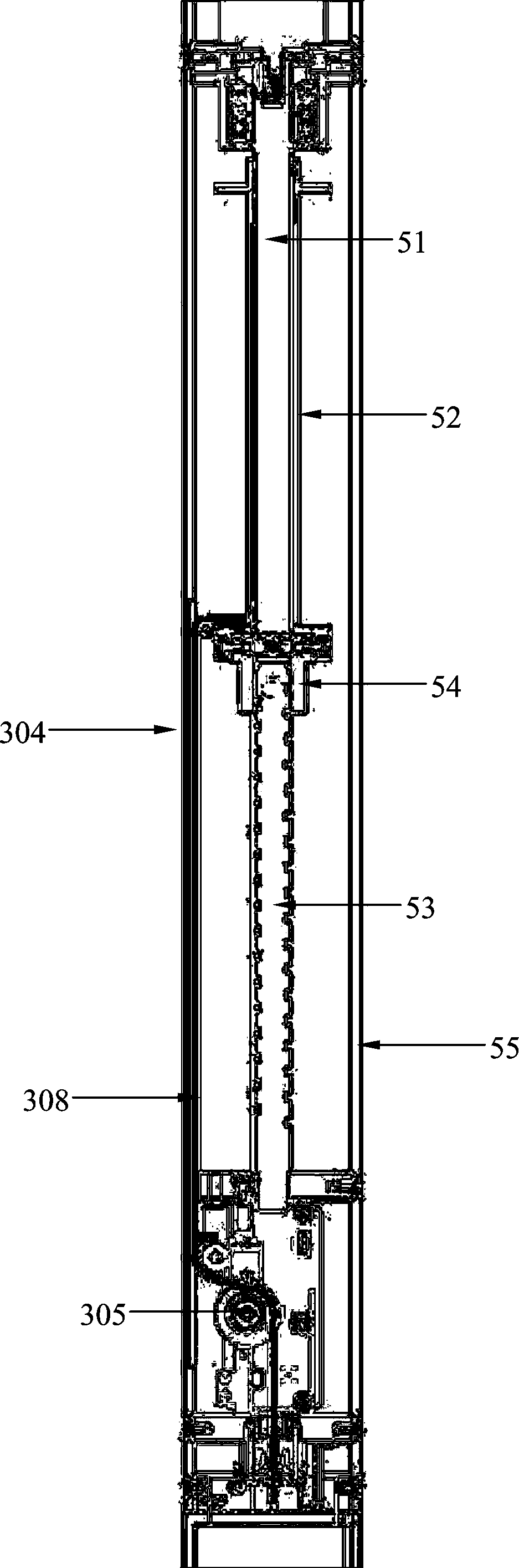

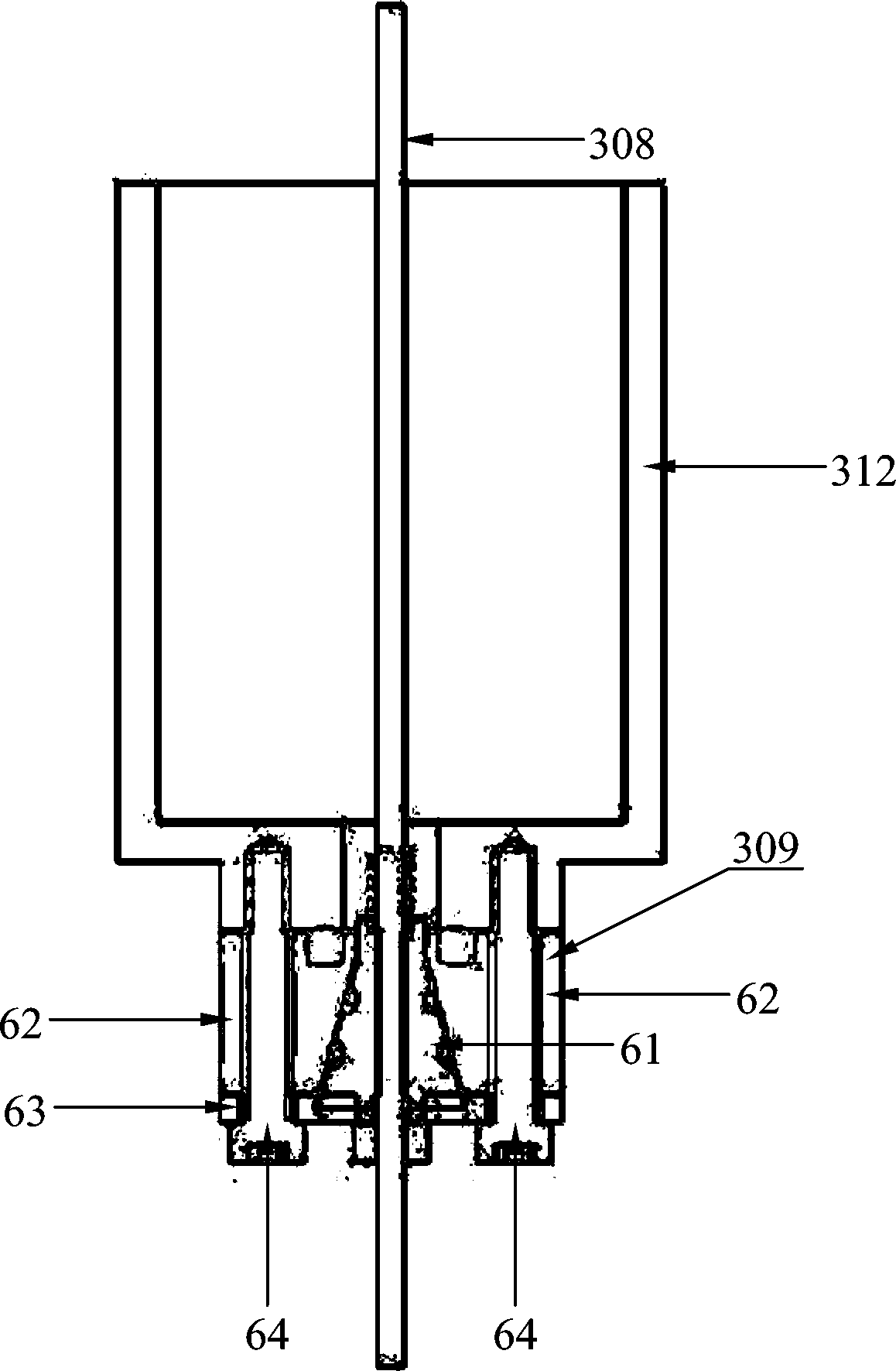

The invention relates to the field of inclination measurement, in particular to an embedded automatic inclinometry robot and a using method thereof. The embedded automatic inclinometry robot comprisesa wireless probe (2), and is characterized in that the robot further comprises a lifting device (3) and a power supply box (4), the lifting device (3) is fixed to the top of an inclinometer pipe (1),the lifting device (3) comprises a remote communication antenna (301), a main control circuit (302), a stepping motor (303), a lifting module (304), a Bluetooth communication module (310), a wirelesscharging module (311) and a sealed shell (312), and the power supply box (4) is connected with the lifting device (3) through a cable. The using method of the embedded automatic inclinometry robot ischaracterized by being implemented according to the following steps in sequence: (1) mounting; (2) supplying power; (3) setting; (4) communication; (5) measuring; and (6) sending. The robot is compact in structure and high in environmental adaptability.

Owner:浙江同禾传感技术有限公司

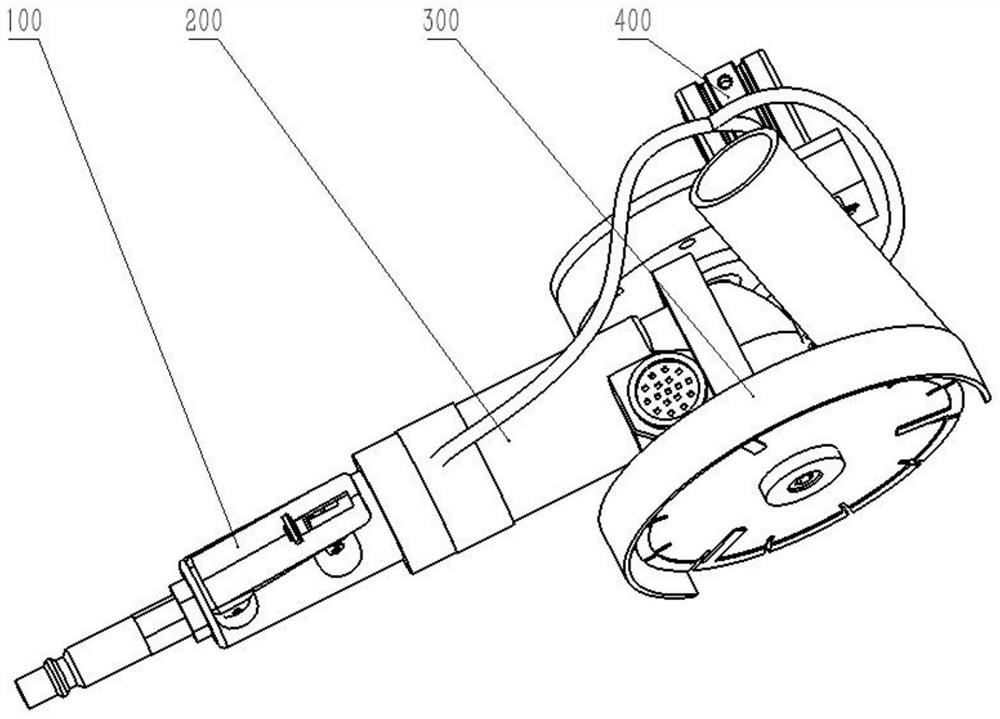

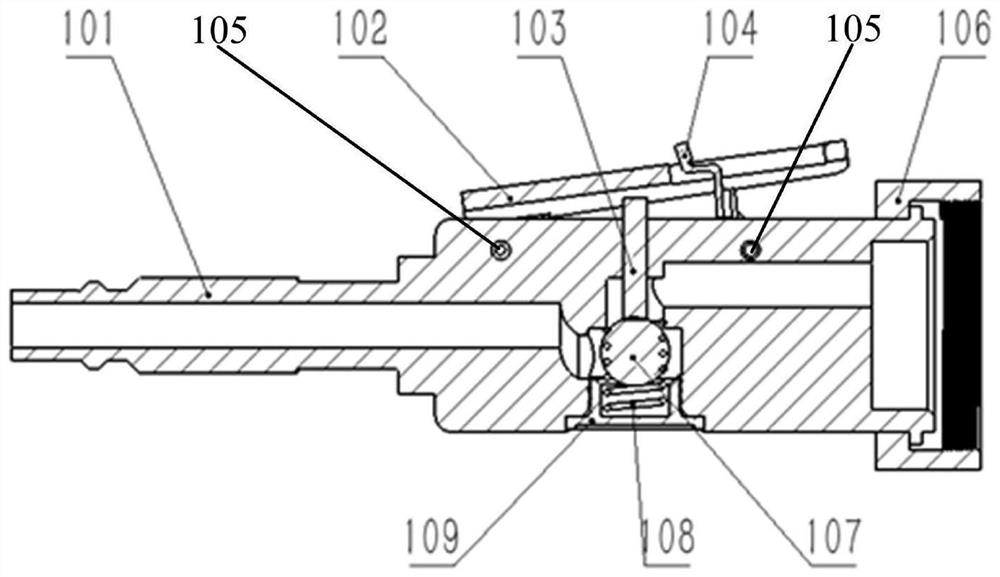

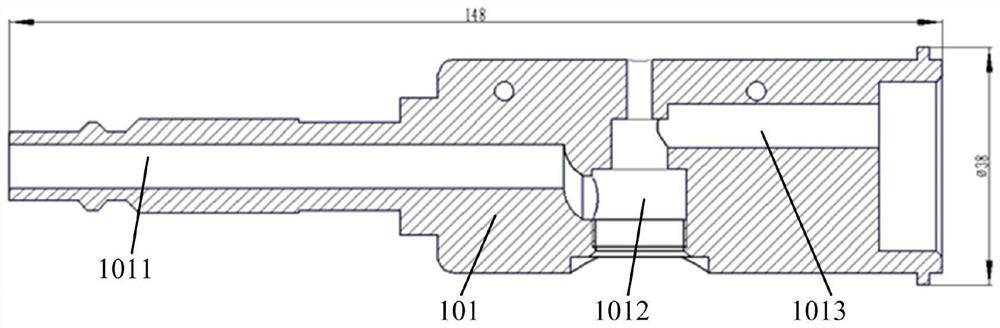

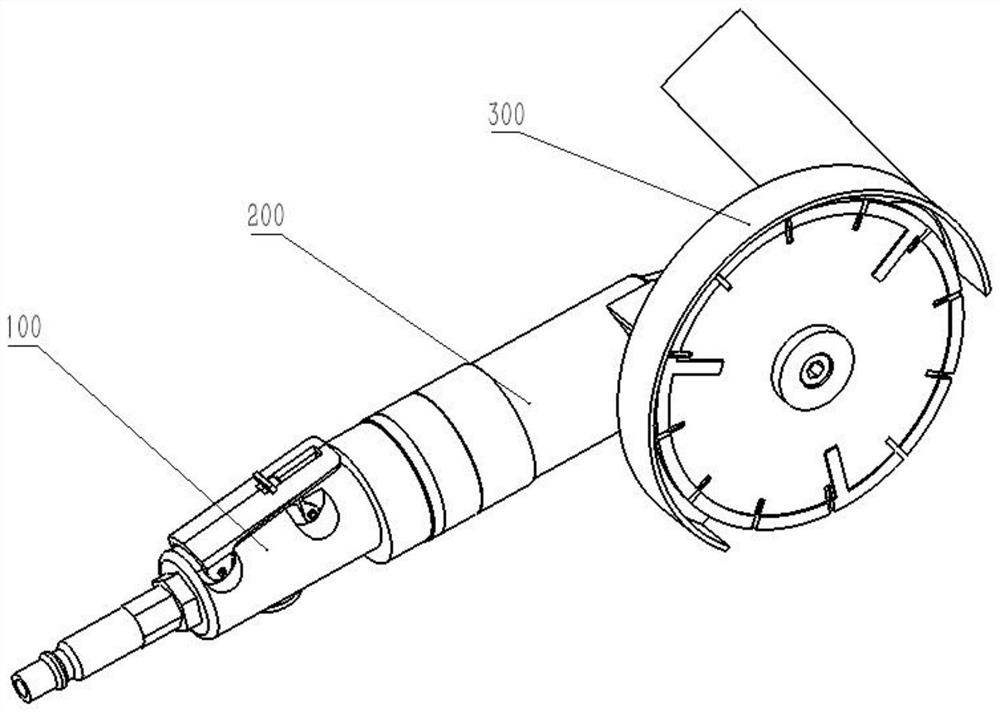

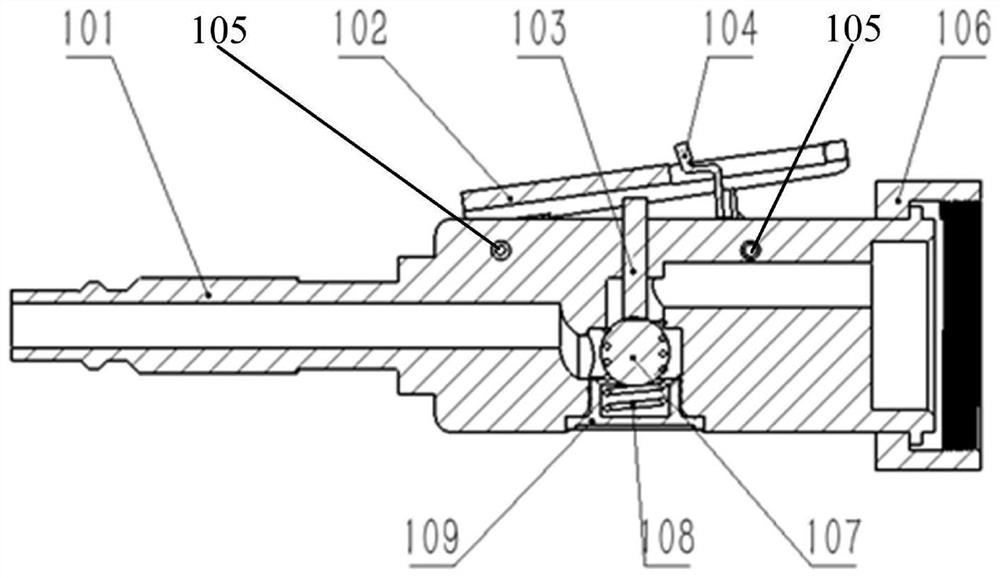

Disc brake braking type cutting mechanism

ActiveCN113333856ARealize opening and closingRealize Deqi StartMetal sawing devicesBrake liningPiston rod

The invention relates to a disc brake braking type cutting mechanism. The brake braking type cutting mechanism comprises a control mechanism, a power mechanism, an executing mechanism and a braking mechanism, wherein the control mechanism is connected with the power mechanism through a first threaded connecting piece, and the executing mechanism and the braking mechanism are both fixedly arranged on the two sides of a shell; in the braking mechanism, a rear cover covers a front cover a rear cover and forms a brake working chamber together with the front cover, a brake pad and a friction plate are both arranged in the brake working chamber, and a first single-acting cylinder and a second single-acting cylinder are symmetrically arranged on the outer sides of the front cover and the rear cover; piston rods of the first single-acting cylinder and the second single-acting cylinder are respectively connected with the outer side surface of the brake pad, and a second air hole and the first single-acting cylinder as well as the second air hole and the second single-acting cylinder are connected through air pipes. Based on the disc brake principle, the brake pad is extruded or separated from the friction disc through the air cylinder to make contact with the friction disc, air-loss brake of a pneumatic cutting machine can be achieved, and the disc brake braking type cutting mechanism has the advantages of being compact in structure, easy to operate, reliable in effect and the like.

Owner:YANSHAN UNIV

A portable all-angle safety lighting device

InactiveCN104033738BNot easy to damageWith explosion-proof functionLighting applicationsLighting support devicesEffect lightEngineering

The invention provides a portable full-angle safety lighting device, which is provided with a lamp and a rotating spherical table sequentially from top to bottom, and a connecting device is provided between the lamp and the rotating spherical table. The upper part of the lamp is an LED lamp head ( 1), the lower part of the lamp is provided with a lamp holder (2), the LED lamp holder (1) is fixed on the lamp holder (2), and a connection device is provided at the bottom of the lamp holder (2), and a rotating spherical shape is provided at the bottom of the connection device stage, the connecting device is connected with the rotating spherical stage for 360° rotation.

Owner:STATE GRID CORP OF CHINA +3

Self-priming adapter of vehicle washing solution

InactiveCN104832733AReduce electricity consumptionDon't waste waterMachines/enginesBranching pipesElectricityMechanical equipment

The invention discloses a self-priming adapter of a vehicle washing solution. The self-priming adapter of the vehicle washing solution comprises a hollow adapter body, wherein the body integrally consists of a water inlet section communicated with a water inlet pipe by one end, a liquid outlet section communicated with a liquid spraying pipe by the other end, and a line cavity section in the middle; the apertures of the water inlet section and the liquid outlet section are larger than the aperture of the line cavity section; a runner of the line cavity section consists of a truncated cone hole and a round hole; the starting end of the truncated cone hole is communicated with the water inlet section; the aperture of the starting end of the truncated cone hole is larger than the aperture of the tail end of the truncated cone hole; the aperture of the tail end of the truncated cone hole is smaller than the aperture of the round hole; a liquid inlet communicated with the washing solution is formed in the side surface of the line cavity section corresponding to the position of the round hole; a ball valve is sealed and mounted in the liquid inlet; and the washing solution is communicated with the liquid inlet through the ball valve. The self-priming adapter of the vehicle washing solution saves electricity and water, and is environment-friendly and low in cost; and one adapter is only needed to replace matched mechanical equipment required in the traditional vehicle washing solution spraying link, so that the operation use cost is largely reduced.

Owner:JINHUA OPS TECH CO LTD

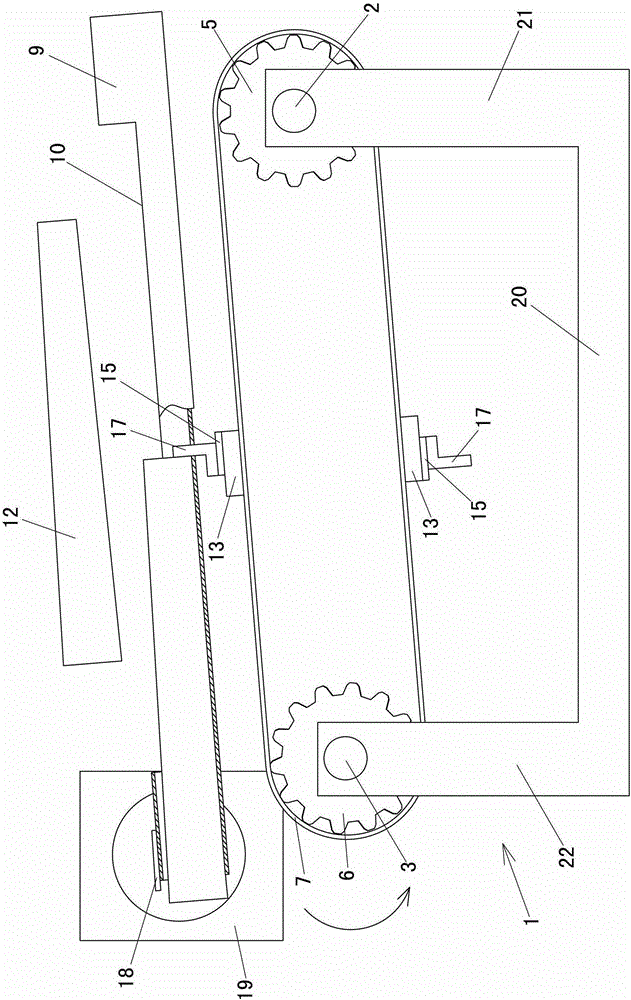

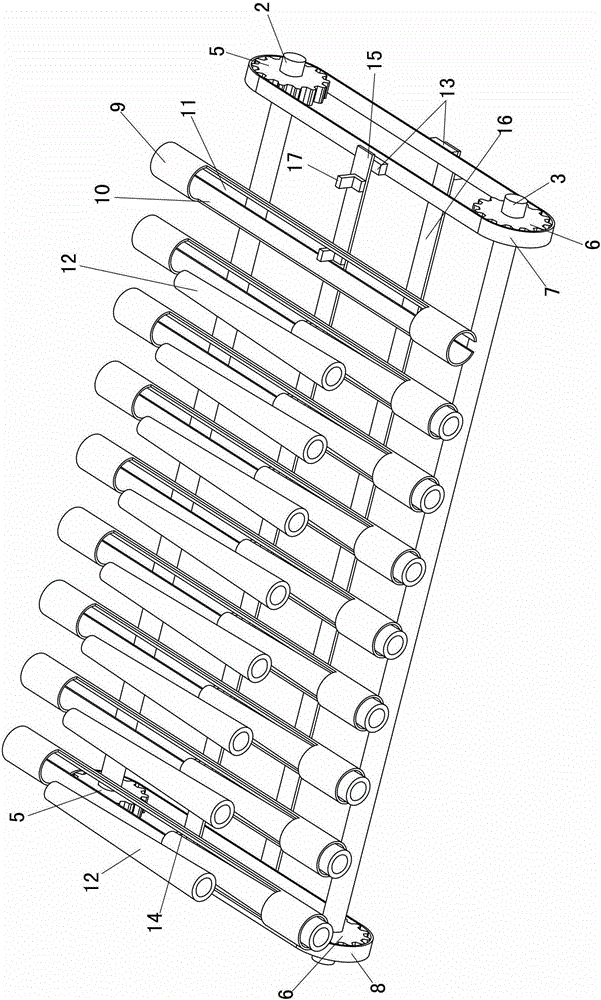

Empty bobbin delivery device

The invention provides a hollow bobbin delivery device and belongs to spinning frame doff equipment. The hollow bobbin delivery device comprises a base, wherein a first shaft and a second shaft are installed on the base, the first shaft is higher than the second shaft, two first synchronous pulleys are arranged at two ends of the first shaft, two second synchronous pulleys are arranged at two ends of the second shaft, a first synchronous belt is arranged on the first synchronous pulley arranged at the front end the first shaft and on the second synchronous pulley arranged at the front end of the second shaft, a second synchronous belt is arranged on the first synchronous pulley arranged at the back end the first shaft and on the second synchronous pulley arranged at the back end of the second shaft, a plurality of groove tubes are arranged above the first shaft and the second shaft, a long hole is formed in the upper surface of each groove tube, an open groove is formed in the lower surface of each groove tube, the upper surfaces of the first synchronous belt and the second synchronous belt are respectively perpendicularly connected with a first connecting plate, the first connecting plate is connected with a plurality of L-shaped push plates which are evenly distributed, the outer end of each push plate perpendicularly penetrates through the open groove of each groove tube, and the left end of each groove tube is fixed on a rotating cylinder. When the hollow bobbin delivery device works, the first synchronous belt and the second synchronous belt rotate in the anti-clockwise direction. The hollow bobbin delivery device can deliver simultaneously a plurality of hollow bobbins to spinning frame spindle blades, follow-up work can operate the plurality of hollow bobbins and therefore working efficiency is greatly improved.

Owner:TONGLING SOBONE INTELLIGENT EQUIP

Automatic plugging device

InactiveCN111162430ADoes not take up work spaceEasy to moveCoupling device engaging/disengagingEngineeringTransfer line

The invention discloses an automatic plugging device. The automatic plugging device is characterized by comprising a conveying line, a tray, stop blocks, a supporting block, a signal receiving deviceand a signal transmission device, wherein the stop blocks are fixed at the periphery of the tray, the supporting block is fixed in the middle of the tray, and the tray is placed on the conveying lineand moves along the conveying line; the signal receiving device is fixed at the edge of the tray, the signal transmission device is placed on the side surface of the conveying line, can be pushed by an air cylinder to move forwards, is contacted with the signal receiving device to transmit the signals. The automatic plugging device is simple in structure, a power supply and a signal line can be plugged in and out at the same time or separately, the signal transmission device is contacted with the signal receiving device through the cylinder to complete the signal transmission. The automatic plugging device has the characteristics of being simple and convenient to operate, being time and labor saving, convenient, safe and efficient, etc.

Owner:KUNMING UNIV OF SCI & TECH

A rotating and telescopic ladder climbing device

ActiveCN106272315BDoes not take up work spaceFlexible adjustment of layersOther workshop equipmentSelf lockingActuator

The invention discloses a rotary extension-type ladder device and belongs to the field of operation platforms. The rotary extension-type ladder device comprises a column, wherein at least one layer of platform is arranged on the column, the number of layers can be adjusted flexibly according to different working heights, actuators are arranged on the column and drive the platforms to rotate around the column, a self-locking device and a locking device are arranged on the column, an extension part is arranged on each platform, the working space of the platform can be increased, when the height of a workpiece is lower, the rotary extension-type ladder device which doesn't participate in working rotates to the other side of equipment completely, up-and-down motion can be realized by the aid of the ladder, the problem that the working platforms are inconvenient to carry is solved, and the utilization of the processing spaces is further improved by rotation and extension of the platforms.

Owner:HIMILE MECHANICAL MFG

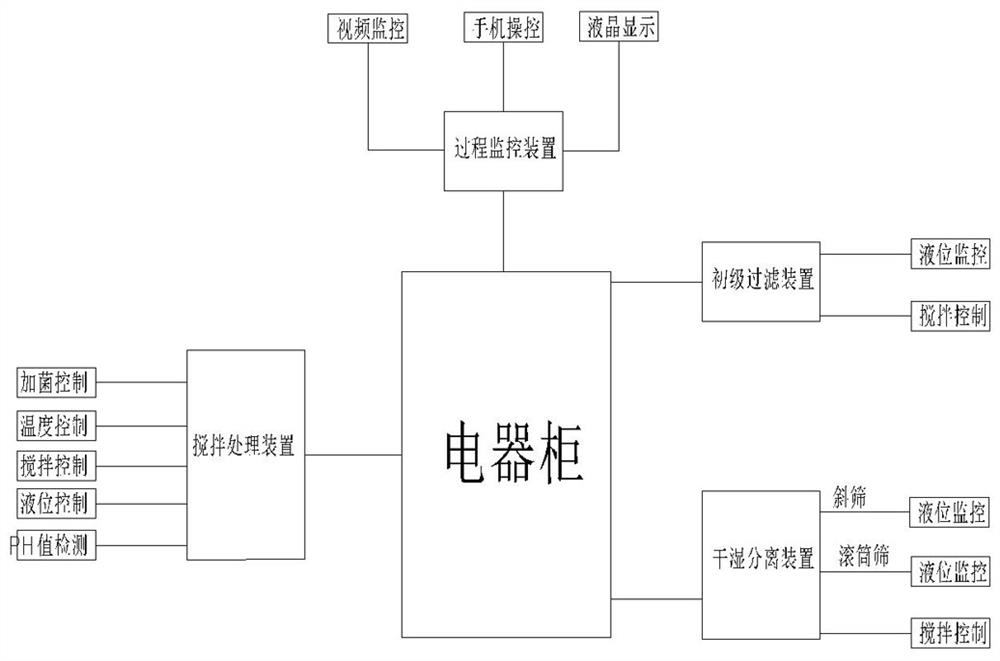

Intelligent manure centralized treatment method and system

PendingCN114213171AImprove processing efficiencyImprove processing powerBio-organic fraction processingClimate change adaptationSystems engineeringTreatment system

The invention relates to an intelligent manure centralized treatment method and system.The treatment method includes the steps that a full-automatic closed-loop treatment system based on mobile distribution is constructed and comprises a main module, sub-modules, a control unit and a communication module, and each sub-module corresponds to a treatment mechanism for manure treatment; an excrement centralized treatment work electronic instruction book is constructed in the main module, and a work electronic instruction book of the mechanism is constructed in the sub-module; the main module issues a command to the corresponding sub-module, the sub-module controls equipment in the mechanism to work, excrement is processed in the mechanism, the control unit collects corresponding excrement data and feeds back the data to the sub-module, the sub-module regulates and controls the equipment according to the data and feeds back the data and the working condition of the equipment to the main module, and the main module dynamically displays the data; and remotely checking the display data of the main module and remotely controlling the main module through the remote module serving as a sub-module.

Owner:北京天鼎熹科技有限公司

Monitoring and control method of electric welding machine cluster based on ipv6

InactiveCN111168195BReduce volumeDoes not take up work spaceArc welding apparatusTransmissionWireless communication protocolData acquisition

The invention discloses an IPv6-based monitoring and control method for electric welding machine clusters. 1. The networking configuration of the electric welding machine IPv6 network node, the wireless communication protocol of 6LoWPAN is configured on the welding data collection node, and the IPv6 address is set; through the automatic configuration of IPv6, and ad hoc network characteristics to carry out the networking of the collection nodes at the welding production site; 2: welding production parameter collection, collect data through the current and voltage data collection sensor on the welding machine, collect current and voltage and transmit the data to the data processing center; 3 data The format is transformed into a general data structure form in the welding field; 4: analysis of welding data; 5: storage of welding data and data operation on the cloud platform; 6: taking certain measures according to whether the current and voltage exceed the safety threshold; IPv6 networking reduces the size of the welding monitoring equipment, does not occupy the work space, and is suitable for mass production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

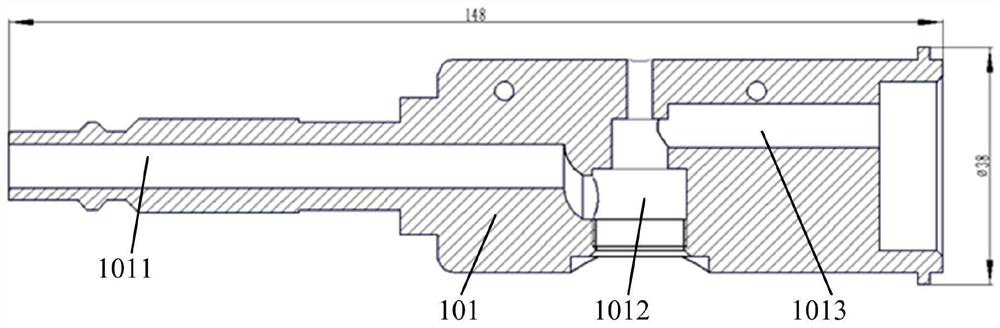

Pneumatic cutting assembly with one-way valve stop function

ActiveCN113442040AImprove the safety of useCompact structureGrinding drivesGrinding machinesPhysicsMotor shaft

The invention relates to a pneumatic cutting assembly with a one-way valve stop function. The pneumatic cutting assembly comprises a control unit, a braking and power unit and an execution unit, the control unit is connected with the braking and power unit through a first threaded connecting piece, a working chamber in the braking and power unit is connected with a shell, a blade type pneumatic motor is arranged in the shell, the two ends of a motor shaft are supported in the shell through motor bearings, a first end of the motor shaft is provided with a large bevel gear, the large bevel gear is in meshing transmission with a small bevel gear in the execution unit, a spring seat and a friction disc are arranged at a second end of the motor shaft, the friction disc is in sliding connection with the motor shaft through a friction disc positioning key, and a spring is arranged between the spring seat and the friction disc. A one-way valve principle is utilized, the friction disc and a second threaded connecting piece are separated or attached, and thus air-loss braking of a pneumatic cutting machine can be achieved, the use safety of the pneumatic cutting machine is improved, and the pneumatic cutting assembly has the advantages of being compact in structure, easy to operate, reliable in effect and the like.

Owner:YANSHAN UNIV

An underground automatic adjustable safety protection vehicle and its use method

ActiveCN113202547BEasy to carryReduce workloadMining devicesUnderground transportConvertersVehicle frame

The invention provides an automatic adjustable safety protection vehicle for underground mines and its use method. U-shaped steel frame, direction converter, adjustable length cross bar, U-shaped steel frame fixed rod, hydraulic frame, threaded knob, wire, controller and power unit fixed body. The invention adopts a node-connected structure, does not occupy a large amount of work space, greatly saves the safety protection cost of the mine, and combines a high-power motor and a gear transmission structure to endow the whole device with power that can move freely. At the same time, the safety protection vehicle Equipped with an all-terrain hydraulic frame, the size of the protective vehicle can be adjusted by adjusting the threaded knob on the rod. At the same time, the hydraulic support rod can freely expand and contract, ensuring that the protective device can better adapt to complex road conditions in the mine. working environment.

Owner:CENT SOUTH UNIV

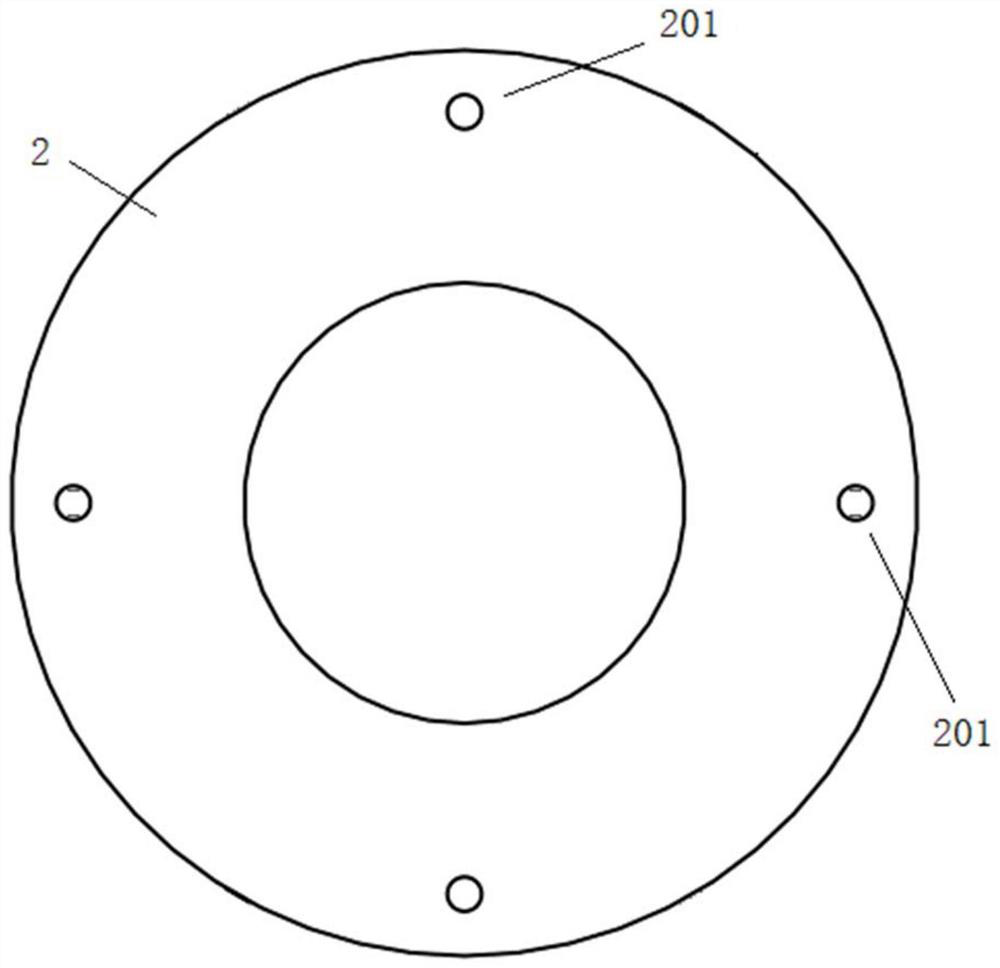

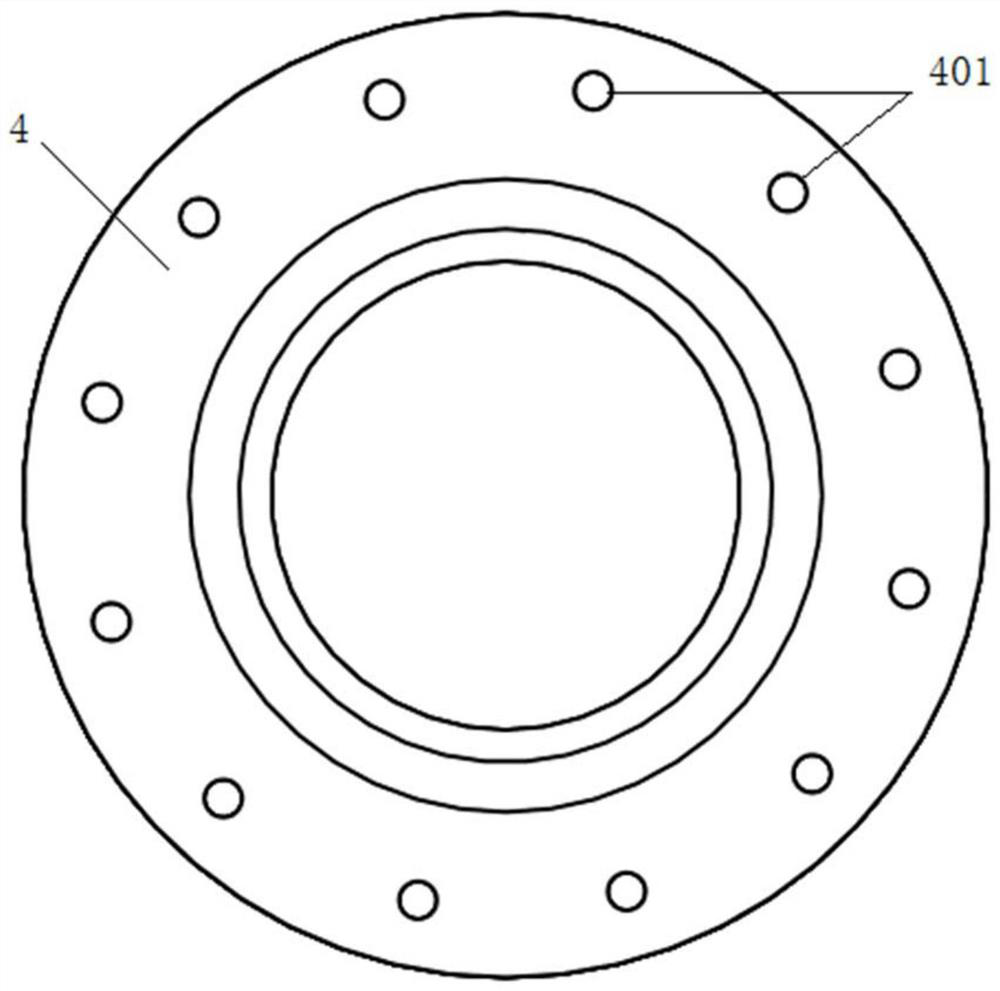

Special bracket for overhauling station water pump motor of nuclear power station

InactiveCN112583213AStable center of gravityImprove stabilityManufacturing dynamo-electric machinesNuclear powerCoupling

The invention relates to a special bracket for overhauling a station water pump motor of a nuclear power station, and the bracket is used for providing a stable support for motor maintenance. The bracket comprises a support body (1) and a nylon gasket; the support body (1) is fastened on the flat ground through foundation bolts, and the nylon gasket is fastened on the upper surface of the supportbody (1) through screws; the motor flange is locked with the upper surface of the support body (1) through a fastening bolt, the support body (1) is of a hollow structure, and the support body (1) isprovided with an equipment channel hole (6) used for transporting out a motor coupler detached from a motor during maintenance. Compared with the prior art, the motor coupler dismounting device has the advantages that the motor maintenance stability is improved, the dismounted motor coupler can be safely and conveniently transported out, and the space is saved.

Owner:CLP CHINA NUCLEAR POWER ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com