Parameter setting device for liquid-based thin layer cell film maker

A thin-layer cell and parameter setting technology, applied in the field of medical equipment, can solve problems affecting equipment stability and accuracy, adverse equipment monitoring and operation, data transmission delay, etc., to facilitate parameter input operation and maintain stability. and accuracy, improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

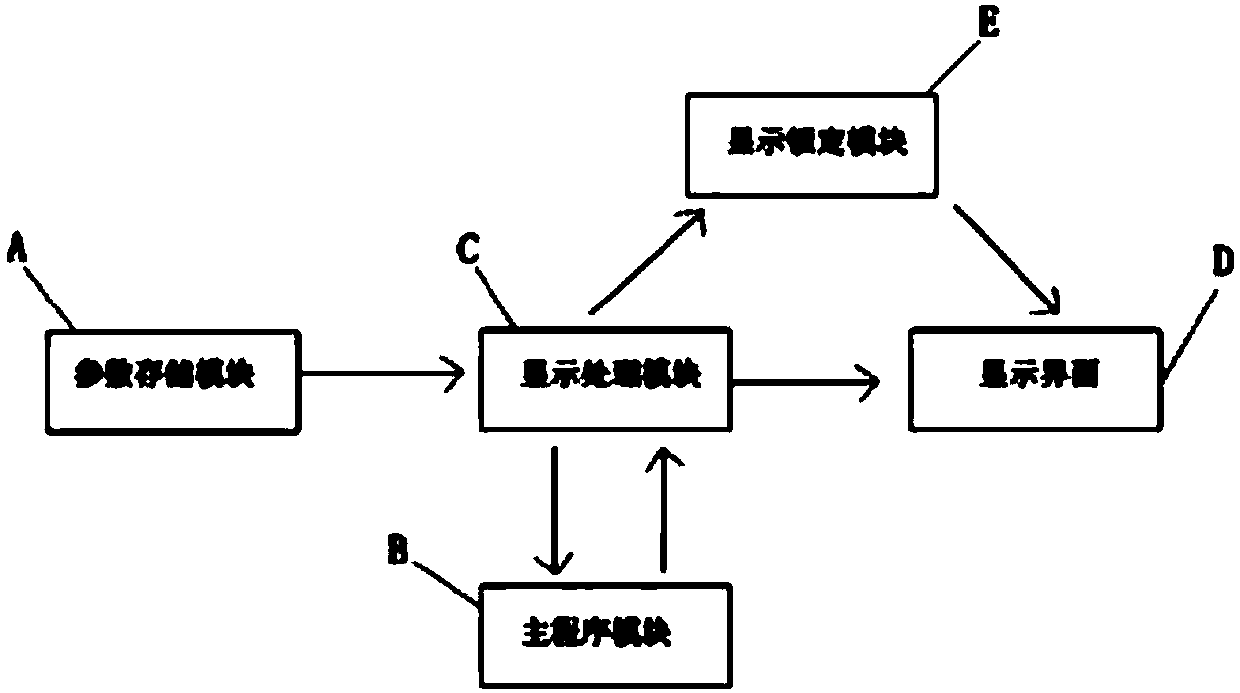

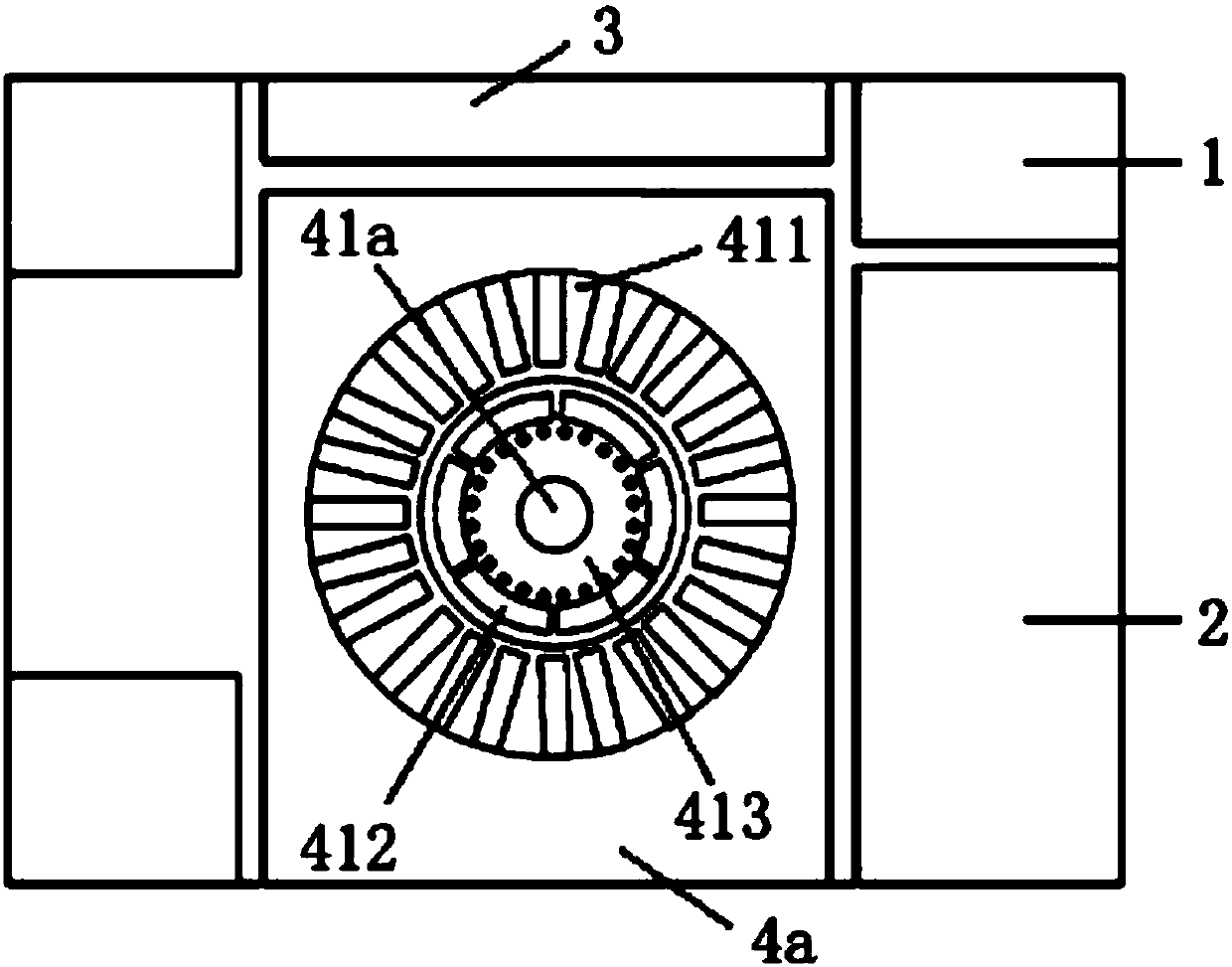

[0035] refer to figure 1 with figure 2 As shown, the present embodiment is a parameter setting device of a liquid-based thin-layer cell slicer, including:

[0036] The parameter storage module A is used to store preset parameter types and range values corresponding to the parameters;

[0037] The main program module B is used to read the selected parameter type and the range value corresponding to the parameter, and output the feedback signal;

[0038] The display processing module C is used to select the parameter type and the range value corresponding to the parameter, and receive the feedback signal output by the main program module;

[0039] The display interface D is used to display the available parameter types and the range values corresponding to the parameters, and to display the feedback signal received by the interface processing module in real time;

[0040] The interface locking module E is used to keep the display interface in a locked state before inputt...

Embodiment 2

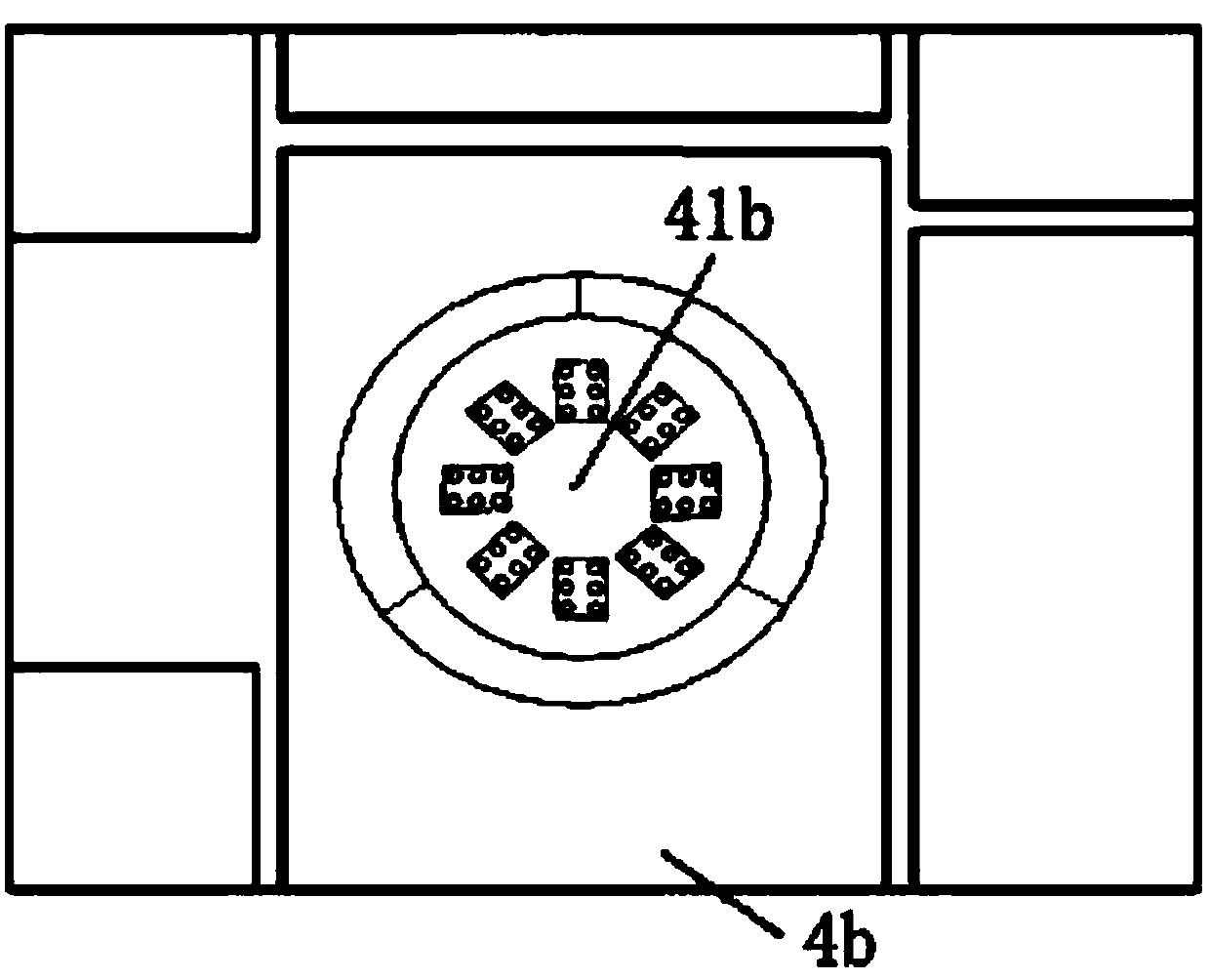

[0069] refer to image 3 As shown, in this embodiment, the second feedback signal display unit 4a in the solution of the first embodiment is deformed to obtain the second feedback signal display unit 4b.

[0070] The second feedback signal display unit 4b is designed as a ring, and the ring 41b has two layers.

[0071] The outer layer of the ring 41b is provided with three intervals, and the three intervals divide the outer layer of the ring into three blocks, which are respectively the slide display area, the test tube display area and the nozzle placement display area.

[0072] The three display areas are distinguished by displaying different colors after the user confirms the placement operation, such as: the display area for slide placement is white, the display area for test tube placement is black, and the display area for nozzle placement is indeed gray; before the user confirms the placement operation, The three display areas do not display any color.

[0073] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com