Automatic plugging device

A technology of automatic plugging and unplugging and mounting holes, which is applied to the connection/disconnection of connection devices, electrical components, circuits, etc., can solve a lot of labor problems, and achieve the effect of convenient movement, saving manpower, and small and exquisite devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

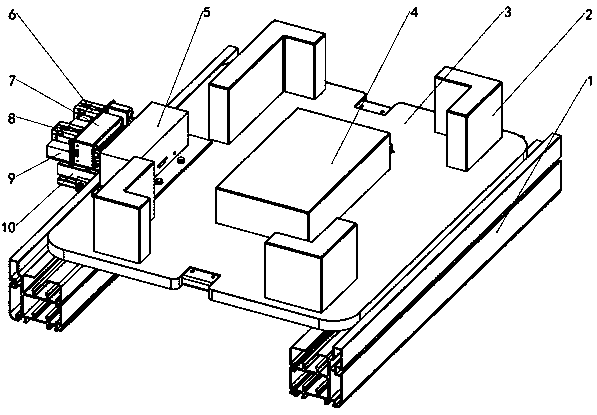

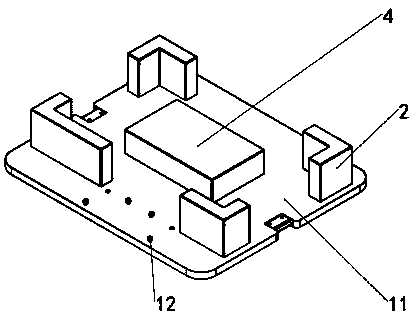

[0028] Embodiment 1: as Figure 1-13 As shown, an automatic plug-in device is characterized in that it includes a conveying line 1, a tray 3, a block 2, a support block 4, a signal receiving device 5, and a signal transmission device 6, and the block 2 is fixed around the tray 3. The support block 4 is fixed in the middle of the pallet 3, the pallet 3 is placed on the conveying line 1, the signal receiving device 5 is fixed on the edge of the pallet 3, the signal transmitting device 6 is placed on the side of the conveying line 1, and the signal transmitting device 6 is placed on the cylinder 7 It can move forward under the push of the button and contact with the receiving signal device 5 to complete the signal transmission.

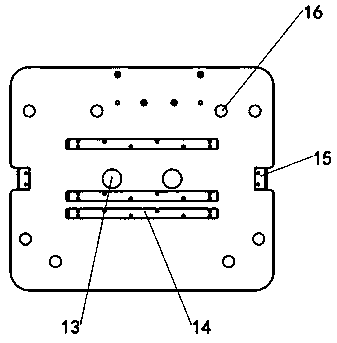

[0029] The tray 3 includes a bottom plate 11, four stoppers 2, a support block 4, a conductive strip sheet metal part 14 and an edge blocking cylinder sheet metal part 15, wherein there are mounting holes 12 for a signal receiving device and a support bl...

Embodiment example 2

[0034]Implementation case 2: The structure of this implementation device is the same as that of implementation case 1. The power line and the signal line are respectively inserted into two signal transmission devices 7, and the signal transmission device 7 connected to the power supply is relatively small, and the two signal transmission devices 7 are respectively They are fixed on cylinder 6 and cylinder 8. When in use, they can be plugged in together, separated and plugged in separately, and are suitable for various working occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com