Airplane strength and strain detection method and airplane strength and strain detecting system adopting same

A technology for aircraft strength and detection systems, applied in signal transmission systems, non-electrical signal transmission systems, electric/magnetic solid deformation measurement, etc., can solve the problems of difficult elimination of sensor signal errors, complex detection circuit wiring, and low signal acquisition efficiency , to achieve the effect of omitting the resistance compensation circuit, improving layout efficiency and reducing wiring complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Aircraft strength strain detection method of the present invention mainly passes through the following steps:

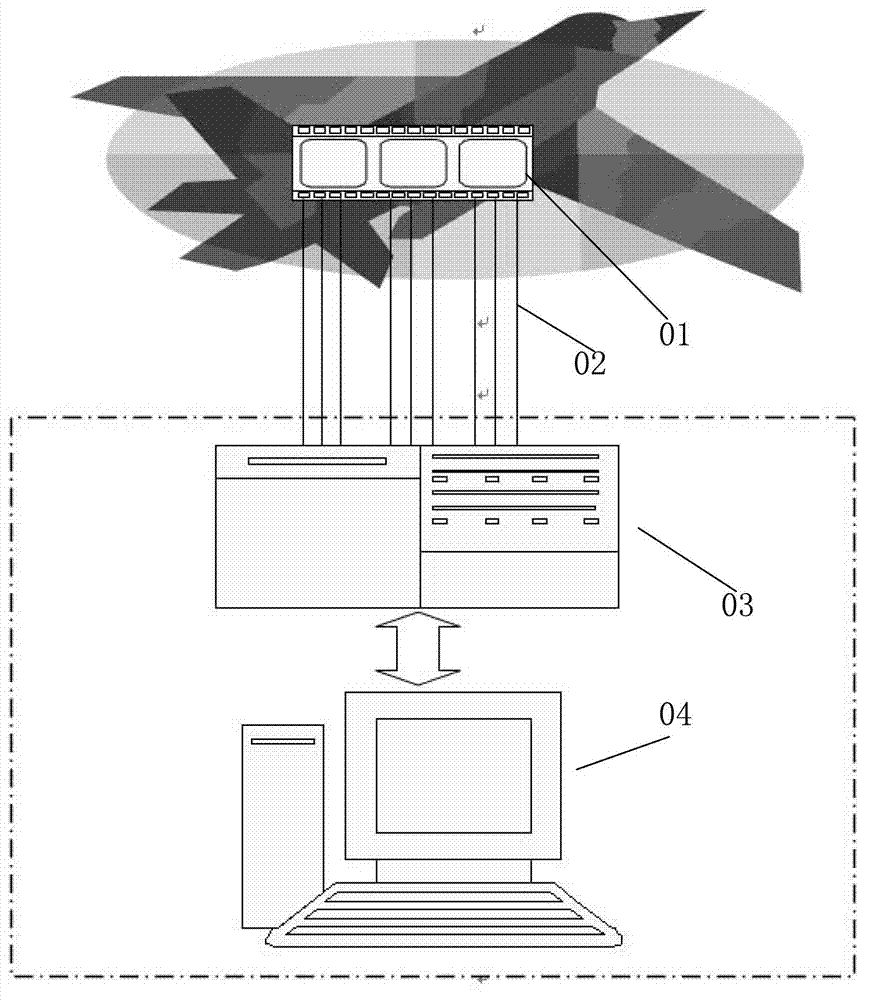

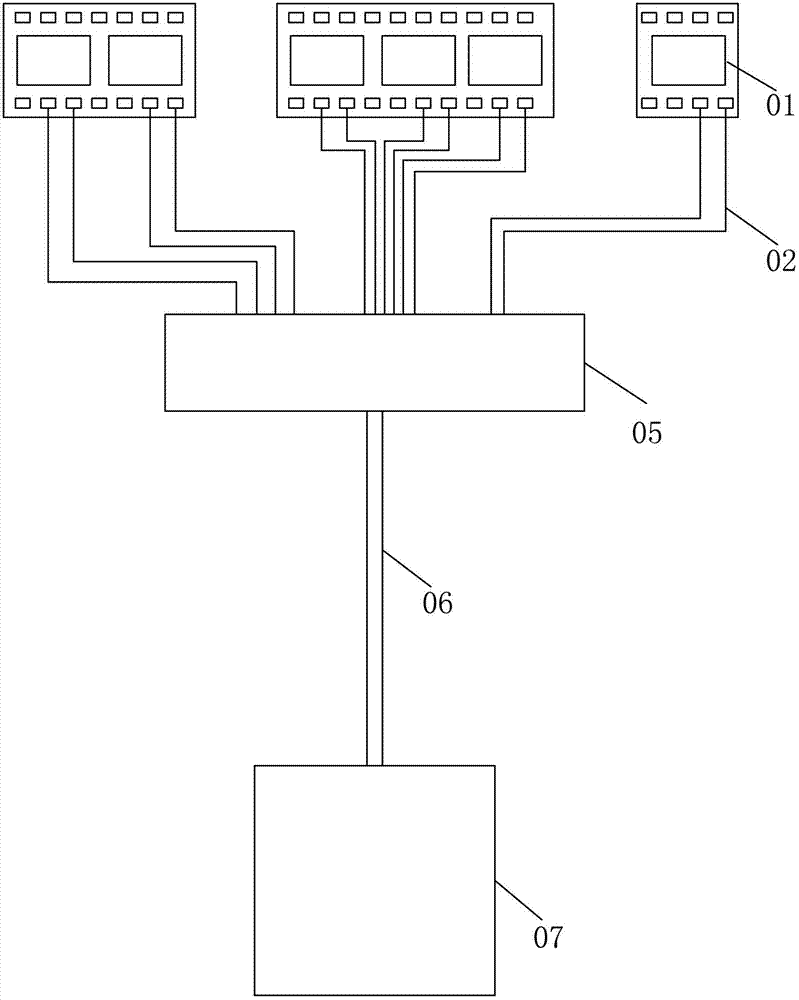

[0041] Step 1: Install an on-board signal processing module on the aircraft, install a monitoring display module in the monitoring room, and use an optical cable to establish a data transmission channel between the two;

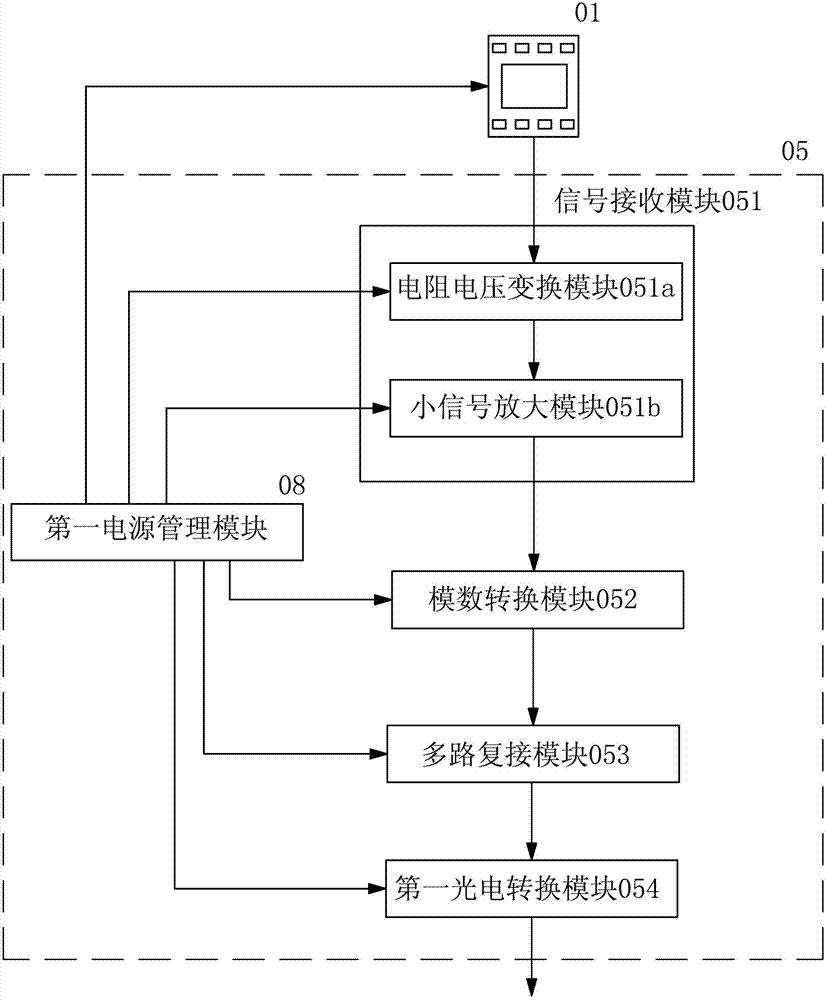

[0042] Step 2: Connect the resistance strain gauges arranged on the aircraft component nodes to the on-board signal processing module with wires, and the on-board signal processing module completes the signal acquisition of the real-time voltage value of each resistance strain gauge, signal analog-to-digital conversion, digital signal multiplexing, and digital signal processing. Photoelectric conversion and optical signal transmission;

[0043] Step 3: The monitoring and display module performs photoelectric conversion on the received optical signal, demultiplexes the real-time voltage data of each resistance strain gauge from the high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com