Cast film offcut recycling equipment

A technology of scrap recycling and cast film, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of increasing the working intensity of staff, inconvenient collection and storage of debris, etc., to improve the discharge efficiency and ensure effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

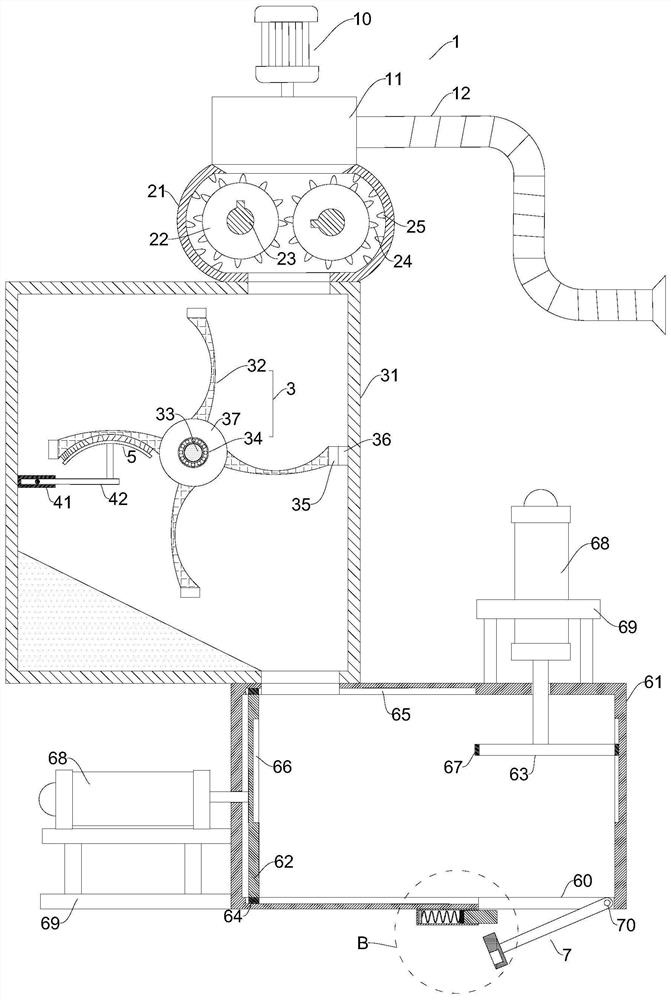

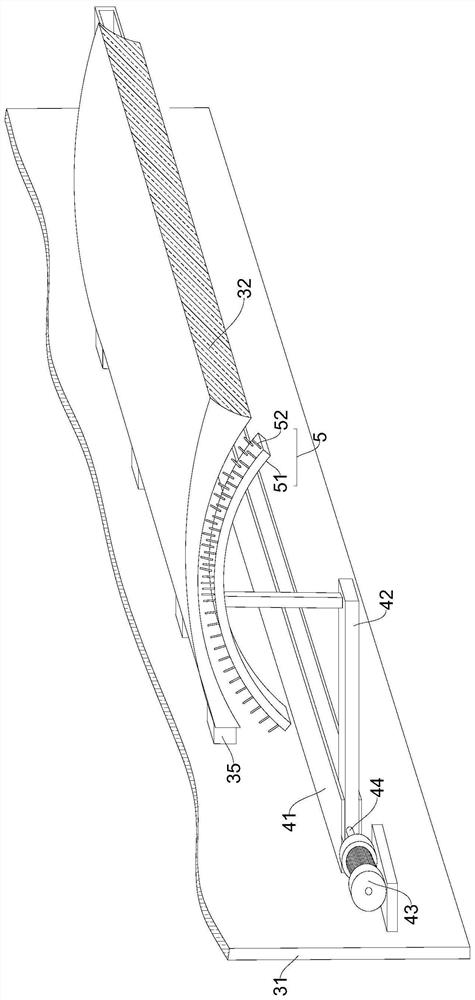

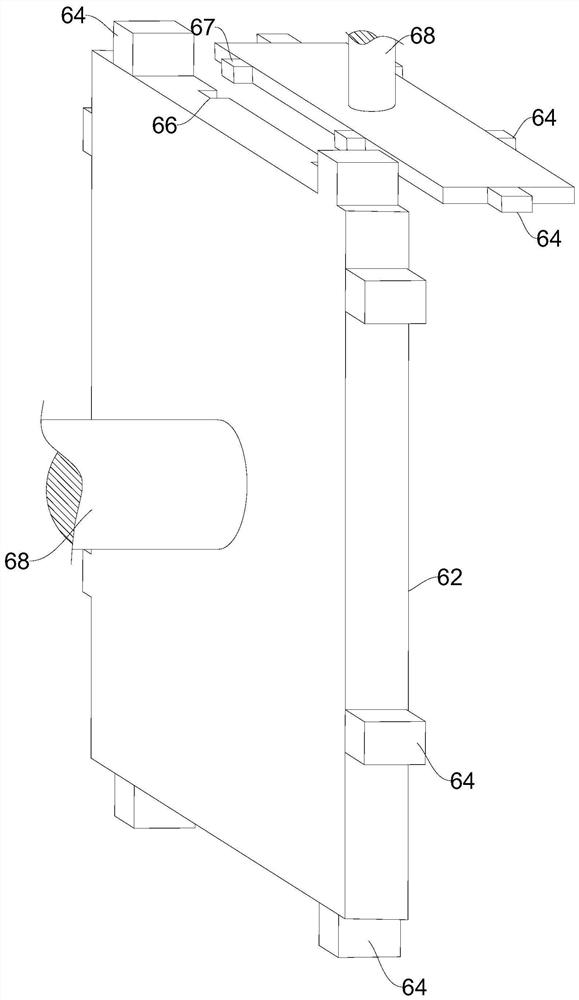

[0032] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] refer to figure 1 As shown, a cast film scrap recycling device proposed according to an embodiment of the present invention includes a crushing mechanism, a quantitative separation mechanism and a briquetting mechanism. The crushing mechanism includes a suction machine 1 for collecting side material and a cutting assembly for crushing the collected side material, and the suction machine 1 includes a wind bin 11, an exhaust motor 10 installed in the wind bin 11 and a connection The suction pipe 12 at the entrance of the exhaust motor 10, the suction pipe 12 adopts an organ design to allow the work to be picked up and bent. When in use, the staff aligns the air inlet of the suction pipe 12 with the scraps that need to be collected on the production line , let the side material be sucked into the air bin 11 through the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com