Rectangular pipe jacking automatic retaining device with pawls

A backstop device and rectangular pipe jacking technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low degree of automation, low work efficiency, and occupation of work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

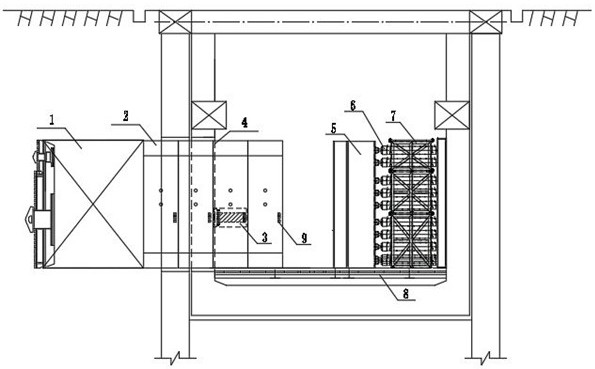

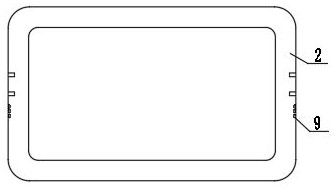

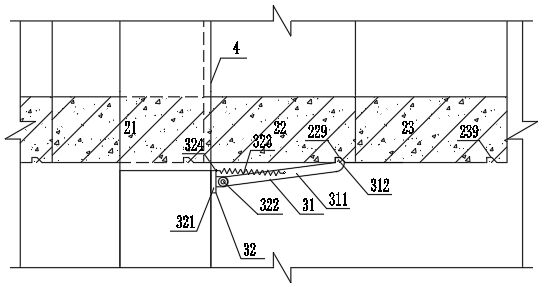

[0030] The present invention proposes a rectangular pipe jacking automatic stop device 3 with a pawl 312, including a pipe jacking machine 1, an oil cylinder frame 7, a jack cylinder 6, a top iron 5, a guide rail 8 and a multi-section pipe joint 2. The retreating device 3 includes a backstopping part 31 and a fixing part 32. The backstopping part 31 is horizontally and symmetrically arranged on both sides of the pipe section 2 along the length direction of the pipe section 2, and is used to fix the pipe section 2. In this embodiment, the The anti-retraction device 3 is arranged on the lower half of the pipe joint 2, and there is at least one set of the anti-retraction device 3; Under the cooperation of devices such as the retreating part 31 and the fixing part 32, the technology of stopping the retreat of the pipe jacking machine 1 and the pipe joint 2 is realized;

[0031] The anti-retraction component 31 includes an integrally formed working support 311 and a ratchet 312. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com