A rotating and telescopic ladder climbing device

A technology of climbing ladders and telescopic plates, applied in the field of rotating and retractable ladder devices, can solve the problems of affecting the travel of beams, inconvenience, limited space, etc., and achieve the effects of saving floor space, reducing the loss of driving force, and increasing working length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

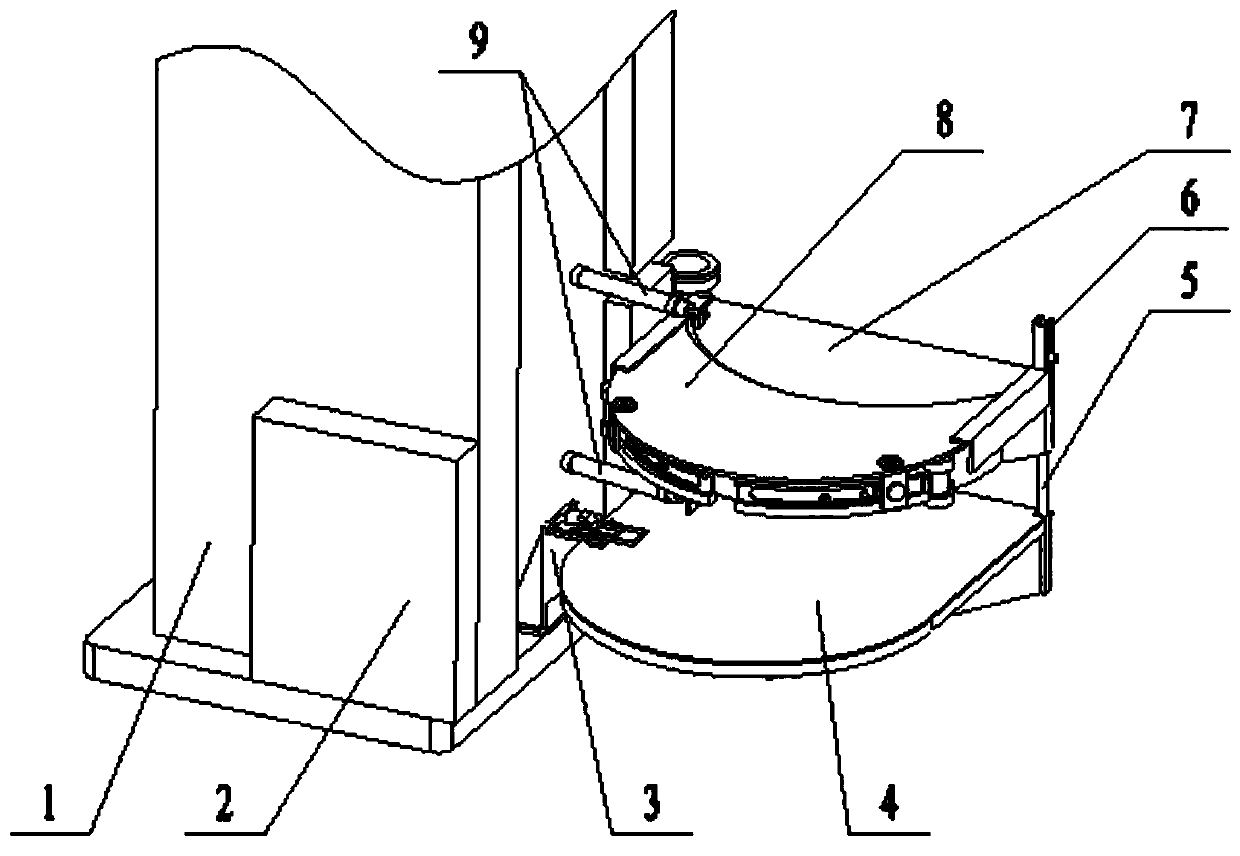

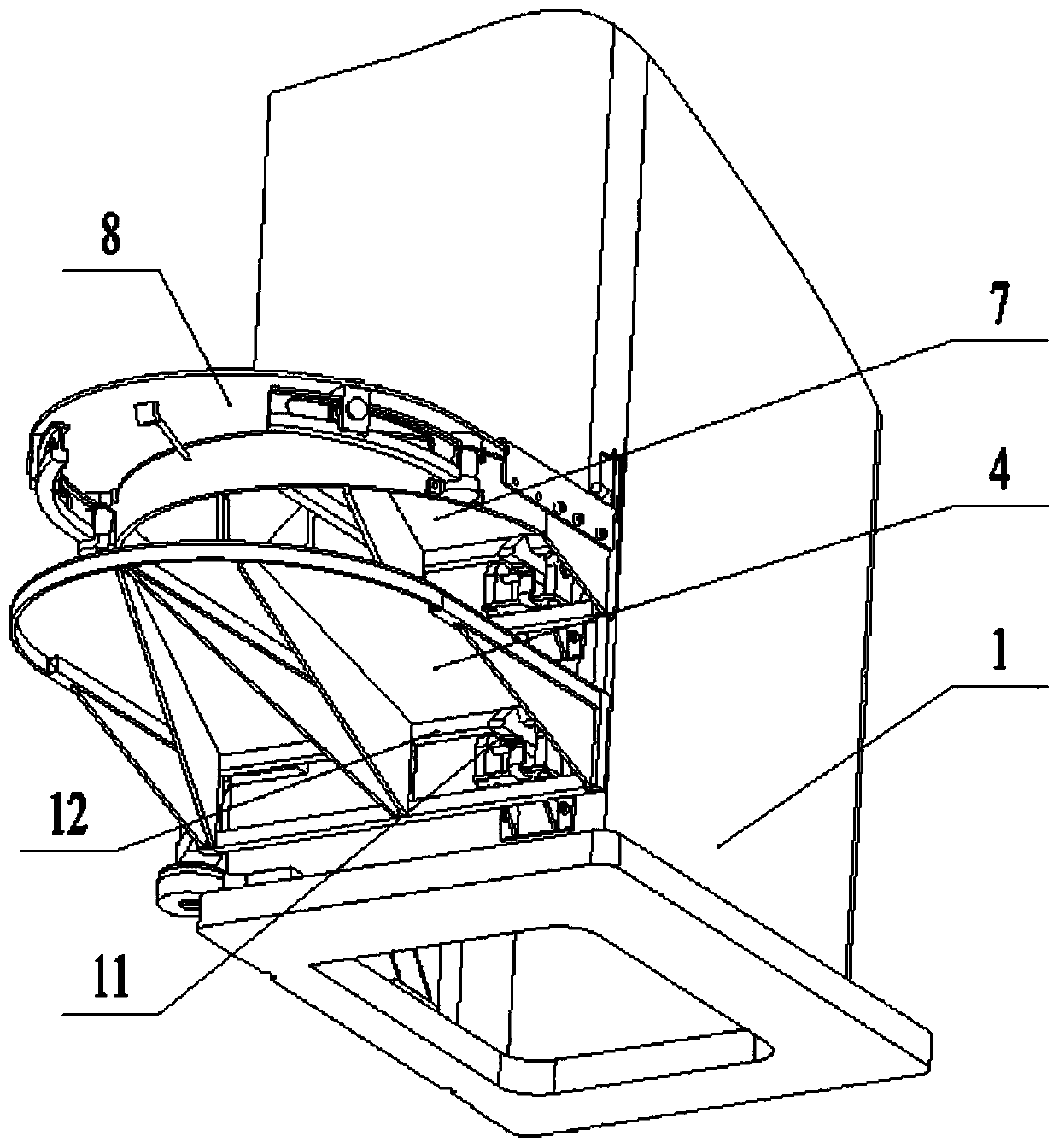

[0057] First, determine the number of floors of the platform according to the actual needs of the workpiece. Here, the platform is set to include the first floor 4 of the ladder and the second floor 7 of the ladder. The platform is locked by the self-locking device 11 at the initial position, and the operating height is assumed to be the second floor 7 of the ladder. high.

[0058] The controller 2 controls the work of the cylinder 9, the cylinder rod stretches out, the thrust of the cylinder 9 is greater than the elastic force at the hook 113 of the self-locking device 11, and pushes the first floor 4 of the ladder and the second floor 7 of the ladder to leave the self-locking device 11, the first floor of the ladder 4 and the ladder The second floor 7 rotates around the column 1 through the rotating part 10. After rotating 90 degrees relative to the initial position, the stroke of the cylinder 9 reaches the maximum. This signal is fed back to the controller 2, and the control...

Embodiment 2

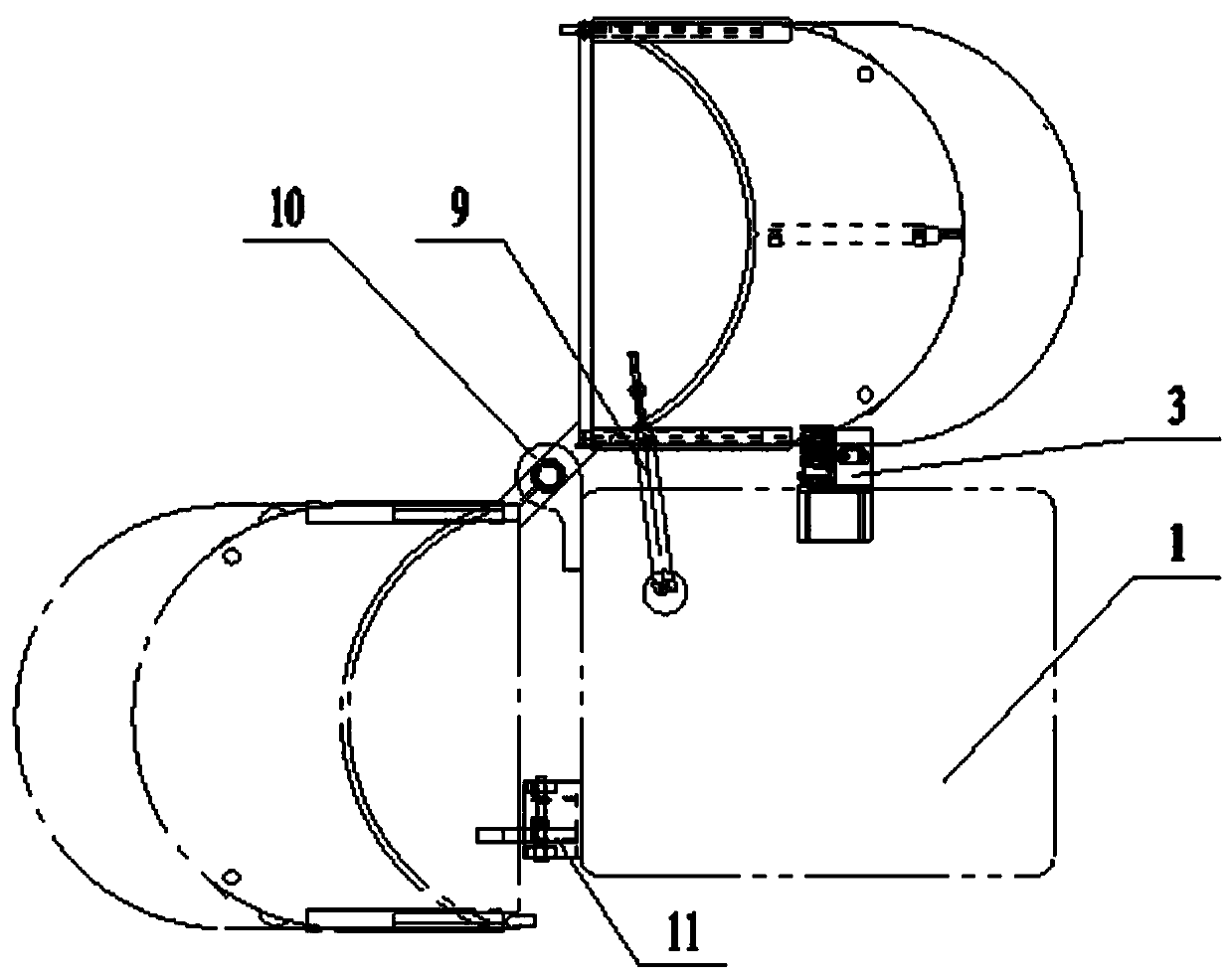

[0061] The same places as in Embodiment 1 will not be repeated. When the working height only needs to be the height of the first floor 4 of the ladder, the second floor 7 of the ladder that does not participate needs to be rotated back to the initial position. The controller 2 controls the cylinder rod of the telescopic drive 808 to shrink, and the cylinder The rod drives the telescopic plate 801 to retract, and the bracket 802 fixedly connected to the telescopic plate 801 closes the curved rail 807 through the pin shaft 803 .

[0062] Pull out the pin shaft 803 from the pin hole 6 of the second floor 7 of the ladder, the controller 2 controls the cylinder 9 of the second floor 7 of the ladder to extend, and the second floor 7 of the ladder rotates around the column 1 through the rotating part 10, and rotates 90 degrees relative to the working position. After a certain angle, the stroke of the cylinder 9 at the bottom of the second floor 7 of the ladder reaches the maximum, and...

Embodiment 3

[0065] The same places as those in Embodiments 1 and 2 will not be repeated. When the first floor 4 of the ladder returns to the initial position, the controller 2 first controls the contraction of the cylinder 9 of the first floor 4 of the ladder, and locks the hasp lock 304 on the first floor 4 of the ladder from the locked position. The hasp hook 305 of the device is taken off, and the controller 2 controls the cylinder 9 of the ladder one floor 4 to stretch out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com