Automobile body correcting system

A technology for calibrating system and car body, applied in the field of automobiles, can solve the problems of inconvenient installation and disassembly, multi-manpower, material resources and time, occupying too much working space, etc., to avoid installation and disassembly, the overall structure is simple, and the utilization rate is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

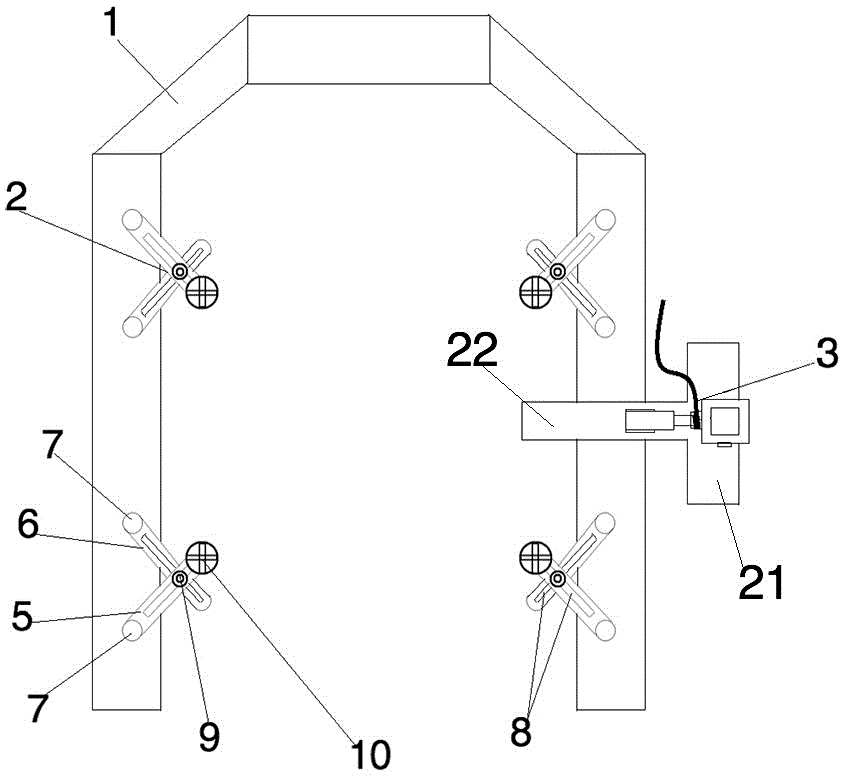

[0023] figure 1 It is a schematic diagram of the overall structure of the present invention;

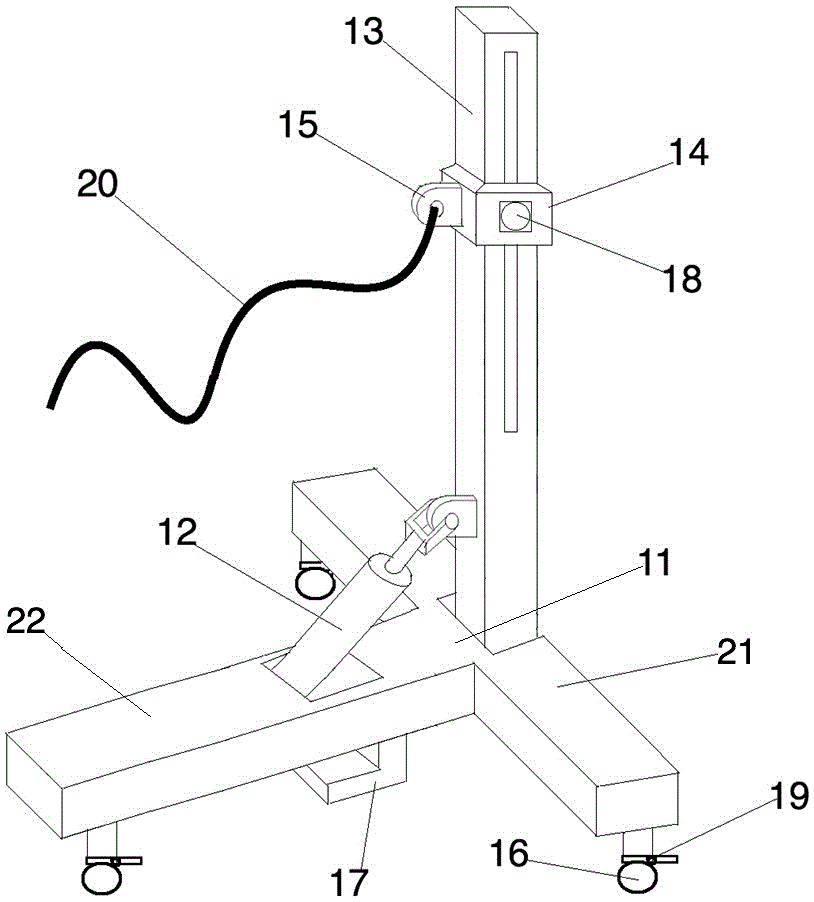

[0024] figure 2 It is a structural schematic diagram of the hydraulic stretching column of the present invention;

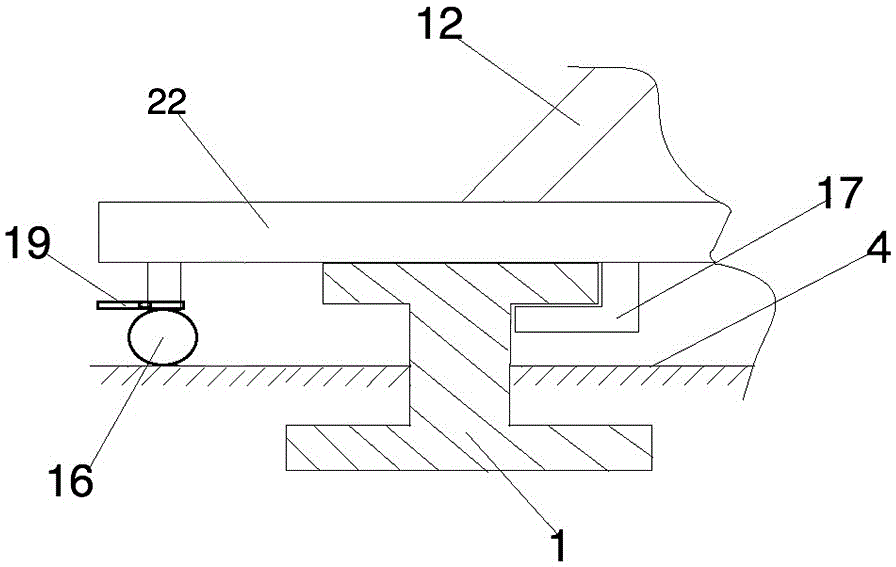

[0025] image 3 It is a schematic diagram of the connection between the hydraulic stretching column and the correction platform frame of the present invention;

[0026] Such as Figure 1-3 As shown: this embodiment is a vehicle body correction system, including a correction platform frame 1, a clamp 2, and a hydraulic stretching column 3, wherein the correction platform frame 1 is U-shaped, and its top is set above the ground 4, and the bottom Then it is buried below the ground 4, and the cross-sectional shape of the correction platform frame 1 is I-shaped, which has the advantages of good structural stability, high compression resistance, tensile streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com