Patents

Literature

39results about How to "Adjust the temperature in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method, control system and refrigerator

InactiveCN104833171AControl speedAdjust the temperature in timeLighting and heating apparatusCooling fluid circulationControl systemStop time

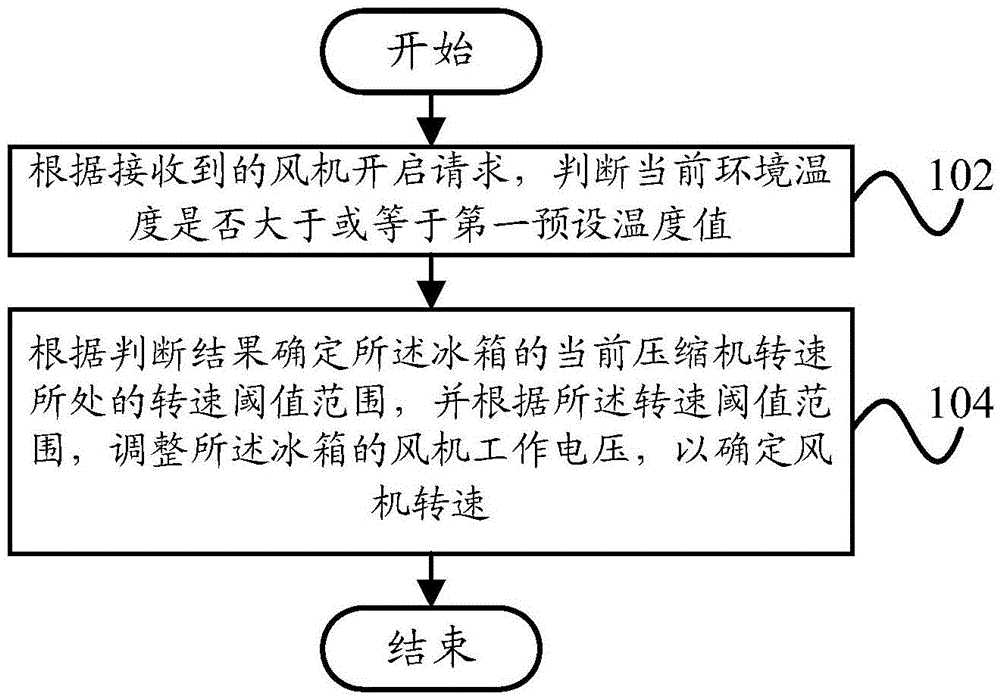

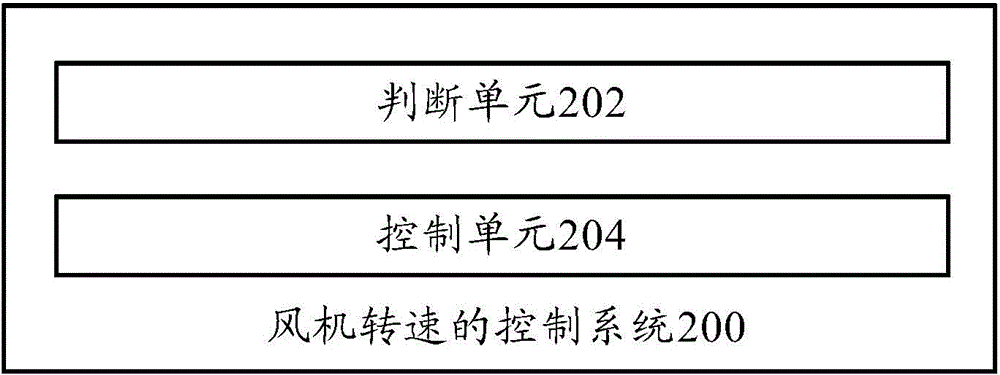

The invention provides a control method, a control system and a refrigerator. The control method is used for controlling the rotation speed of a draught fan of the refrigerator, and includes the steps that according to a received draught fan start request, whether current environment temperature is larger than or equal to a first preset temperature value is judged; a rotation speed threshold range of current compressor rotation speed of the refrigerator is determined according to a judgment result, and draught fan work voltage of the refrigerator is adjusted according to the rotation speed threshold range so as to determine the rotation speed of the draught fan. By means of the technical scheme, the rotation speed of the draught fan can be reasonably adjusted through cooperation of the environment temperature, the compressor rotation speed and refrigeration requirements of chambers in the refrigerator, so that start and stop time of a compressor is optimized and overall energy consumption of a refrigerator system is reduced while the cooling speed is guaranteed.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

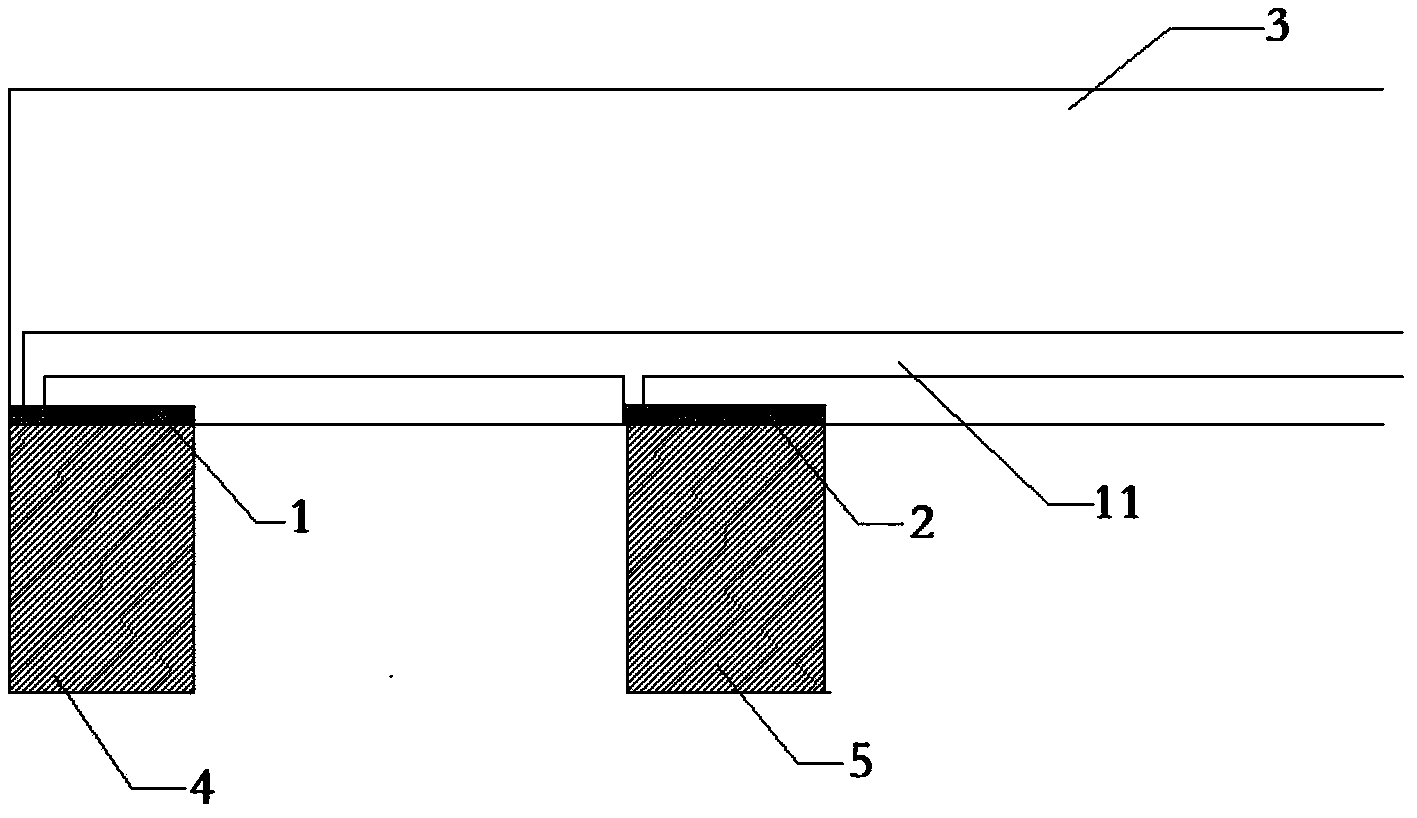

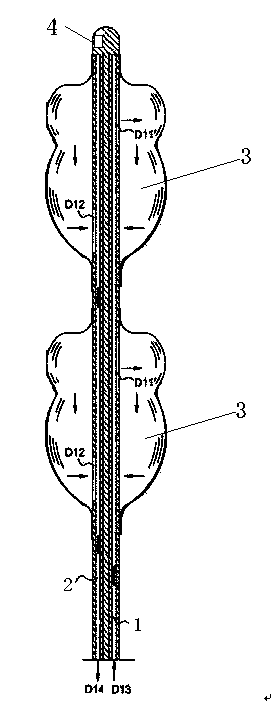

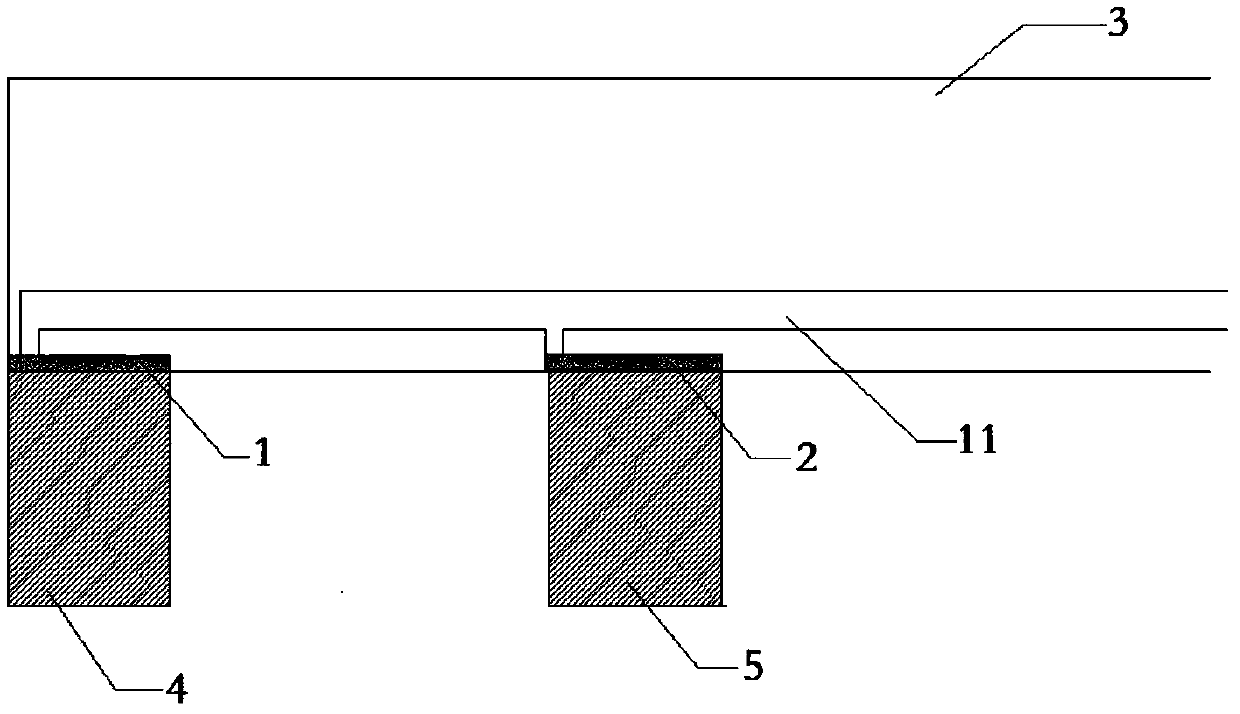

Renal sympathetic nerve removing radiofrequency ablation electrode and system

ActiveCN104287827ALess destructiveShorten operation timeSurgical instruments for heatingBurning outPostoperative recovery

The invention relates to a renal sympathetic nerve removing radiofrequency ablation electrode and system. The renal sympathetic nerve removing radiofrequency ablation electrode comprises a first electrode and a second electrode which are opposite in polarity. The two electrodes with the opposite polarities can effectively control the current flowing direction and range, and the radiofrequency ablation energy is concentrated, so that the renal sympathetic nerve on the outer wall of the renal artery blood vessel is burnt out accurately, unwanted injuries to organs and tissues outside the target treatment range are avoided, and the advantage of small destructiveness is achieved. Besides, as the radiofrequency ablation energy is concentrated, the renal sympathetic nerve on the outer wall of the renal artery blood vessel can be burnt out accurately and rapidly, the operating time is shortened greatly, and postoperative recovery of patients is facilitated.

Owner:CARDEA MEDSYST TIANJIN

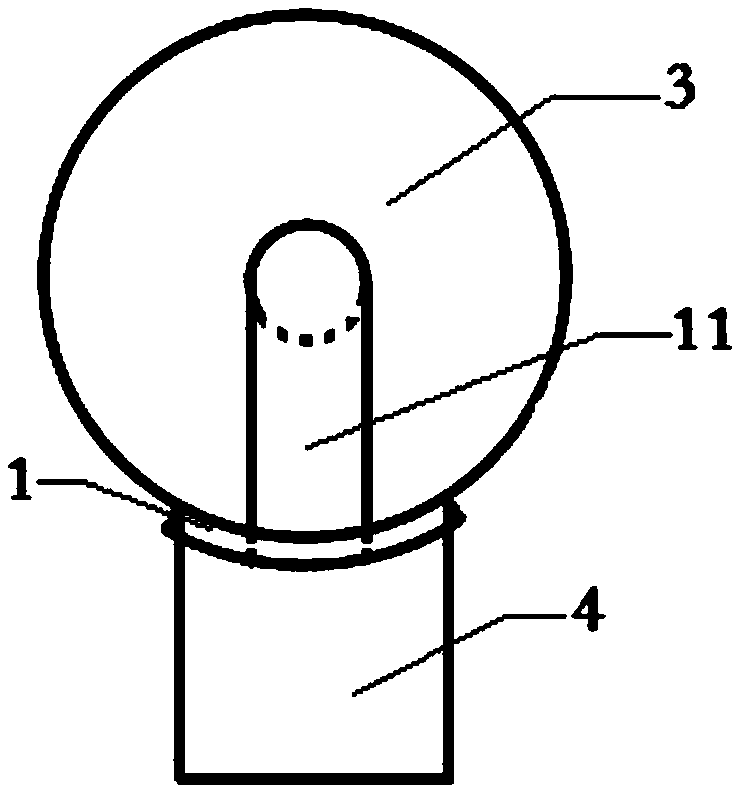

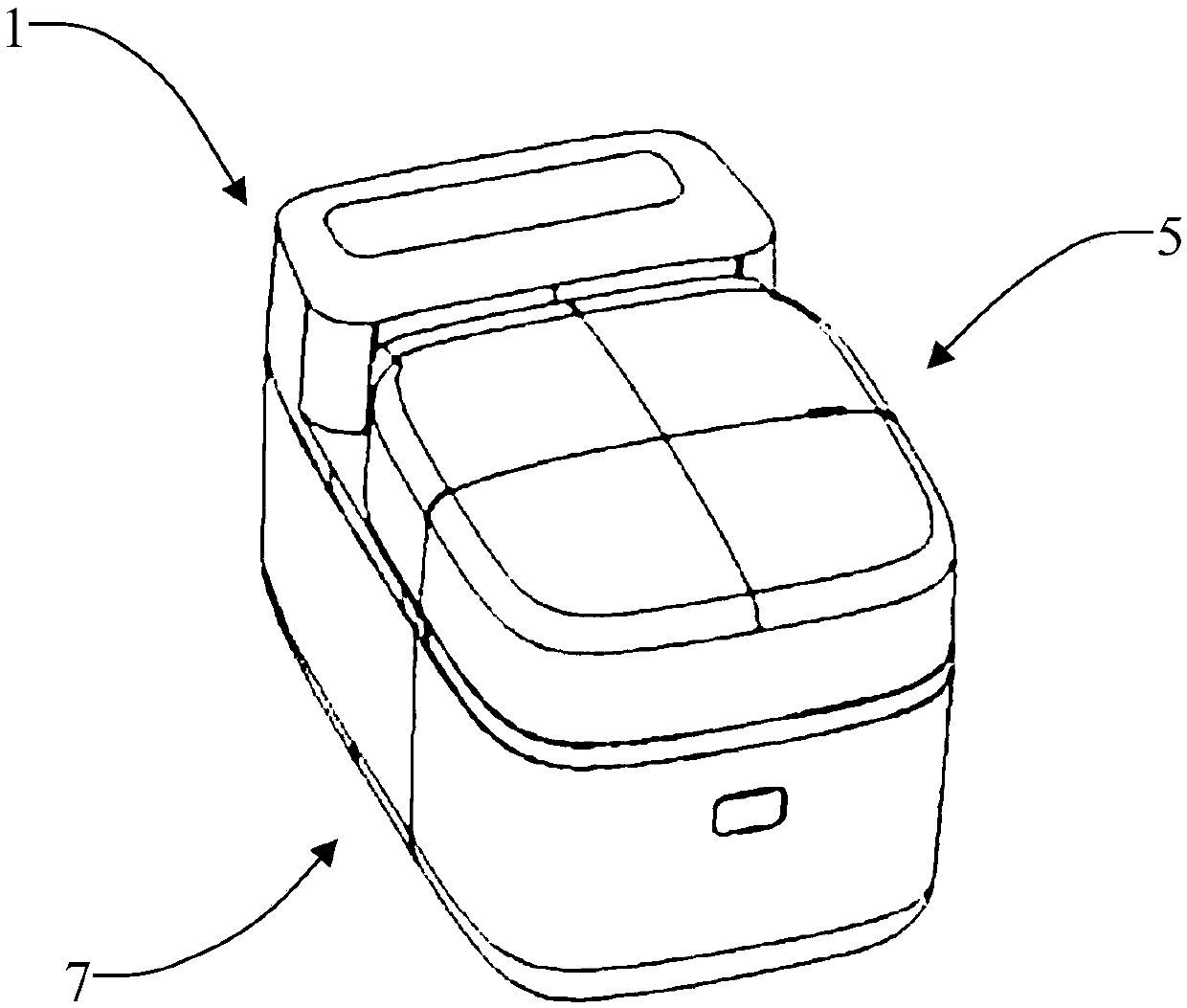

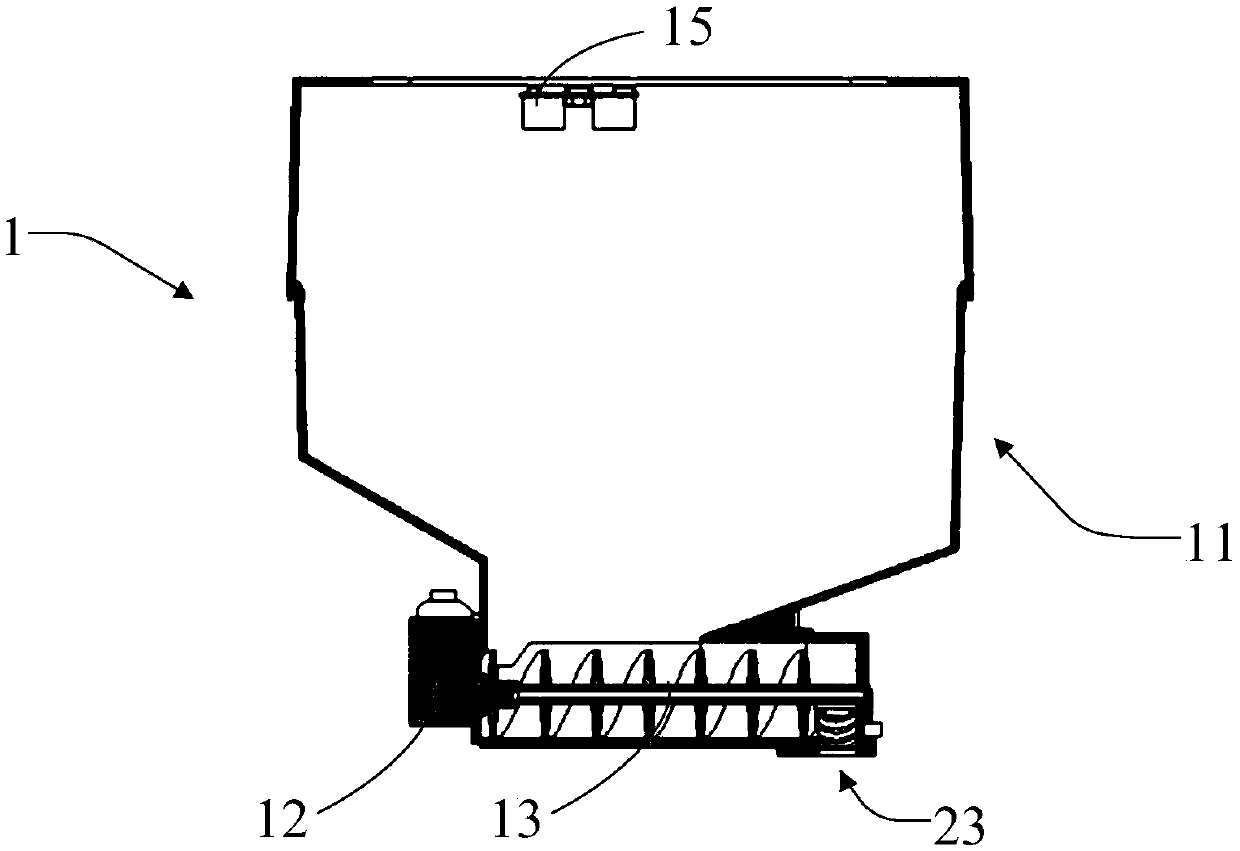

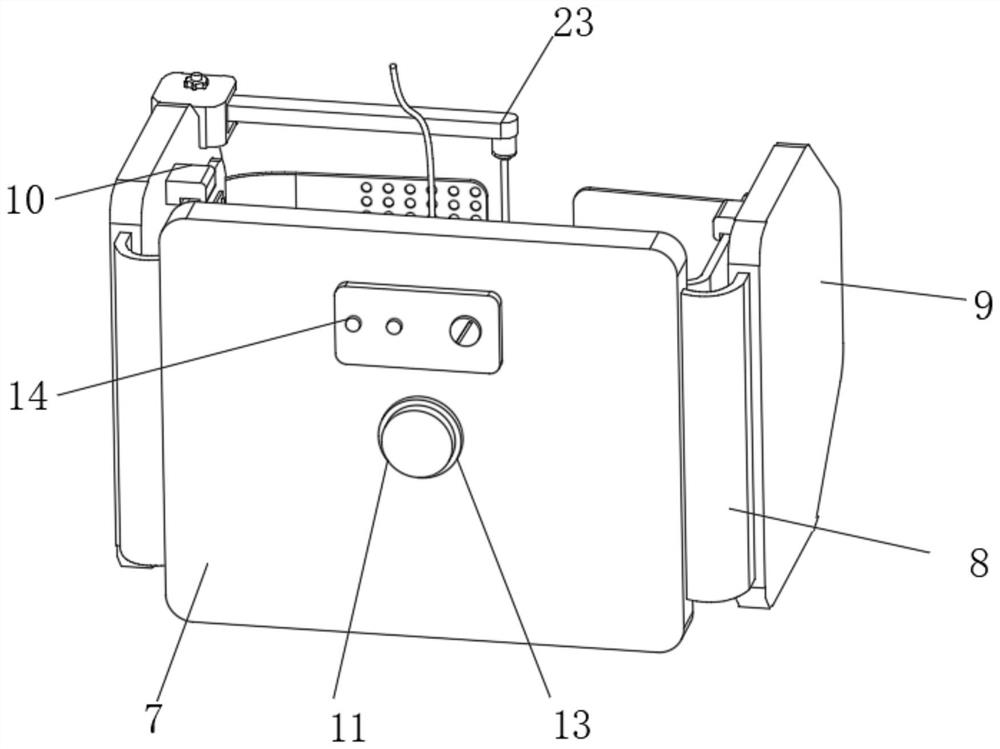

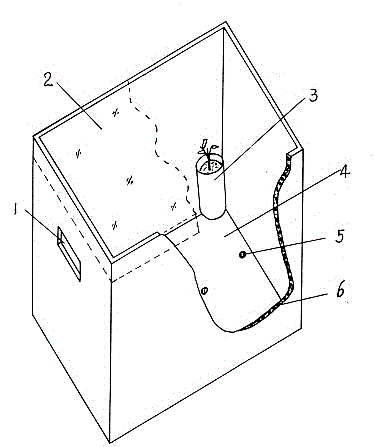

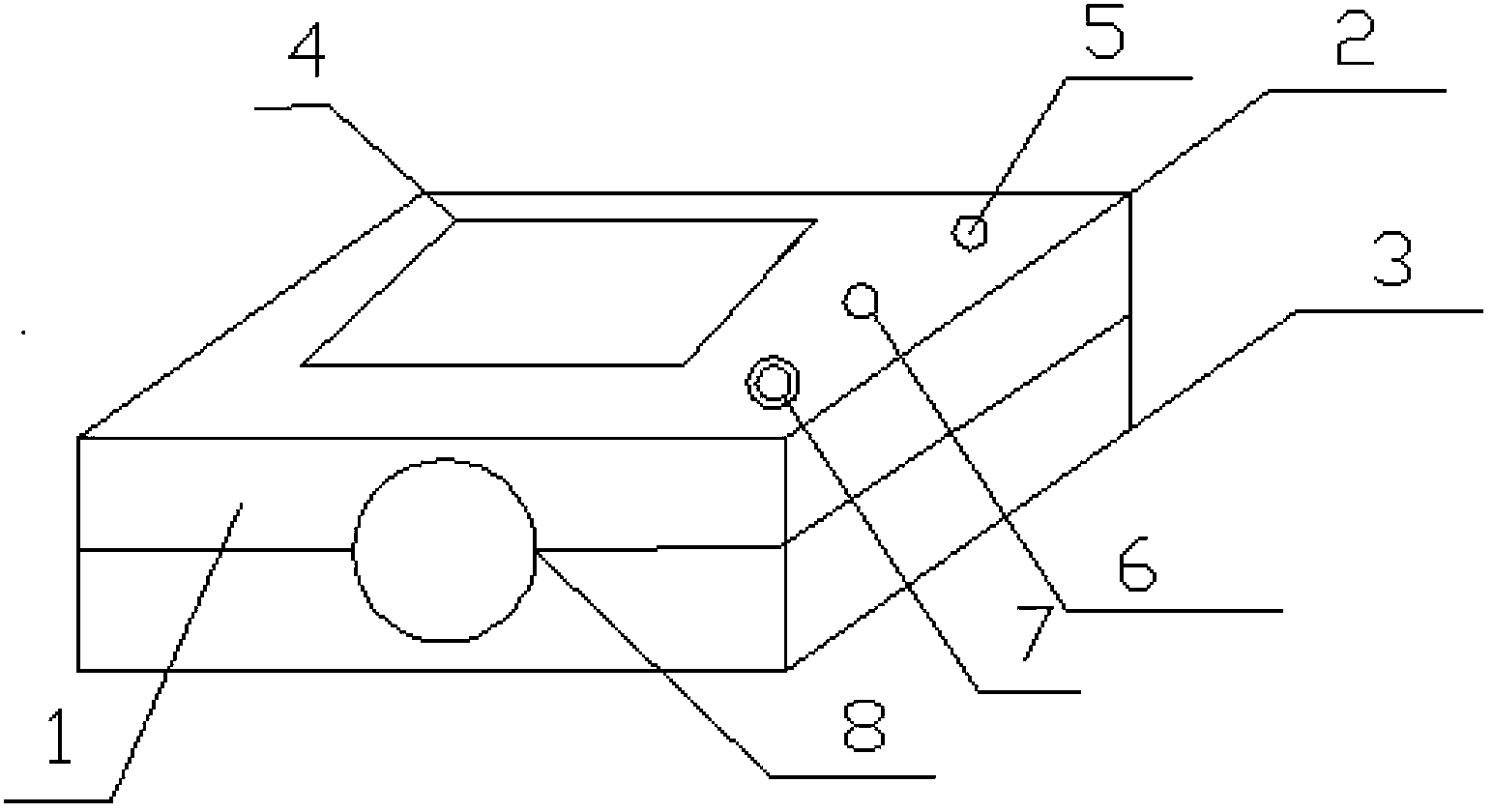

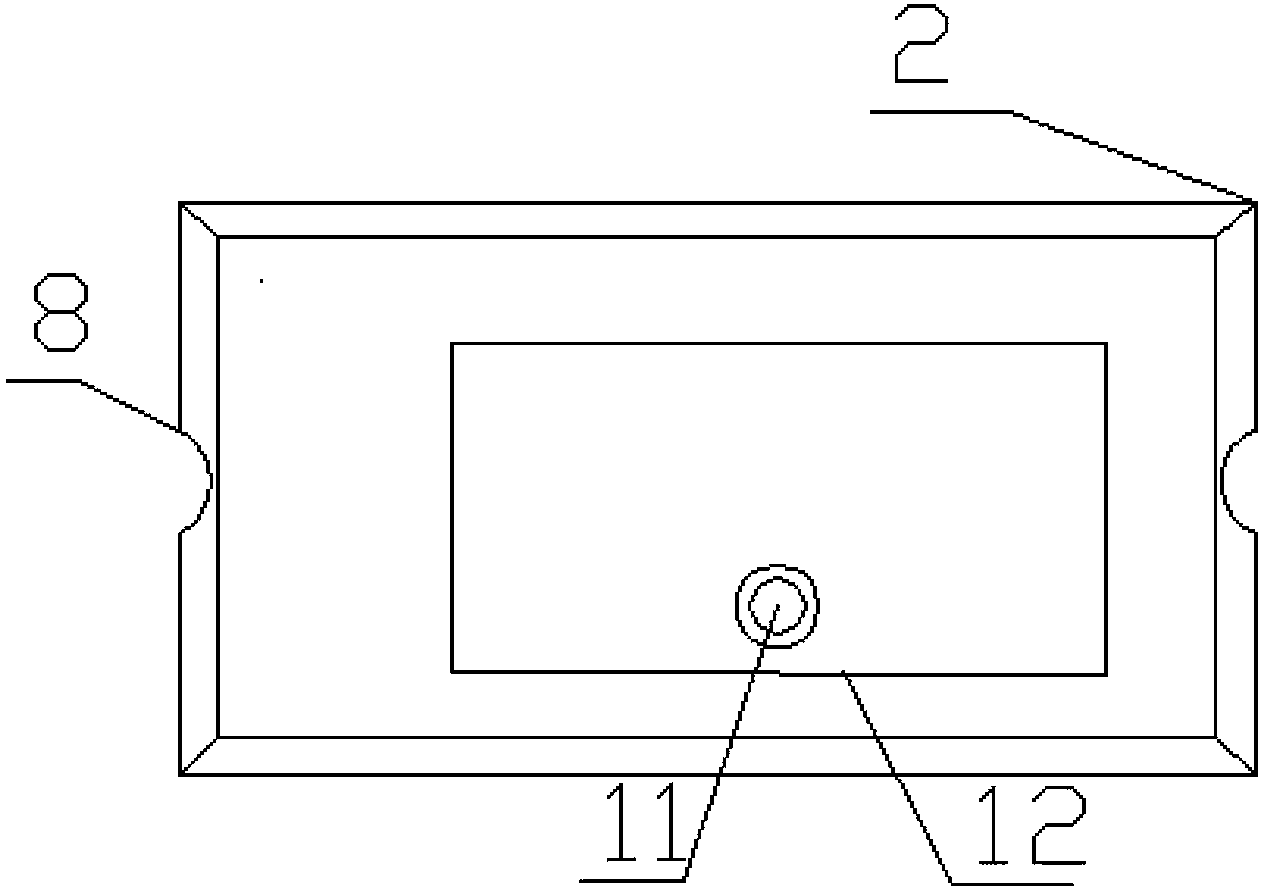

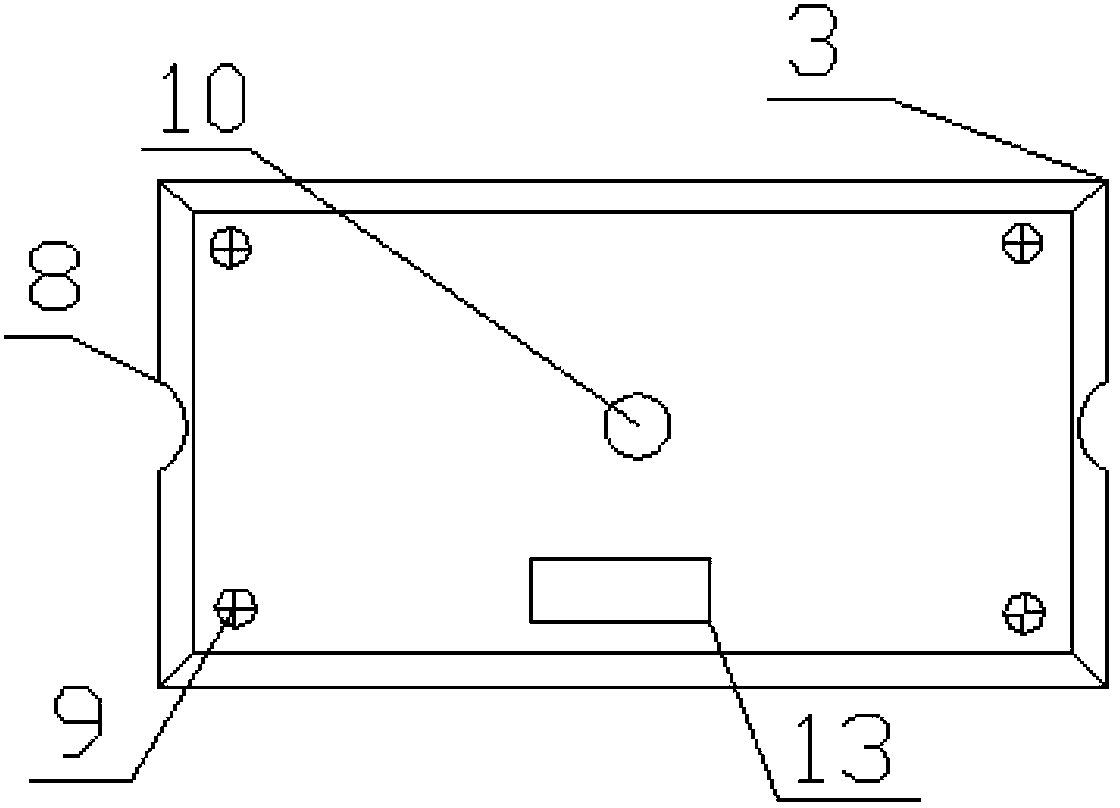

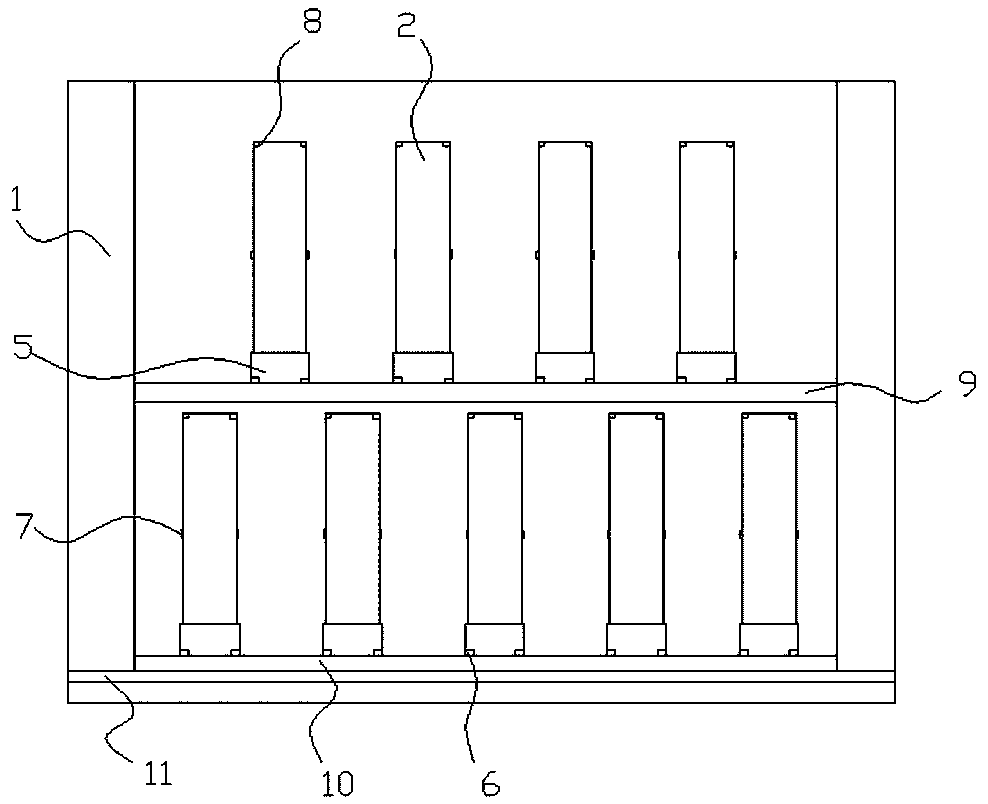

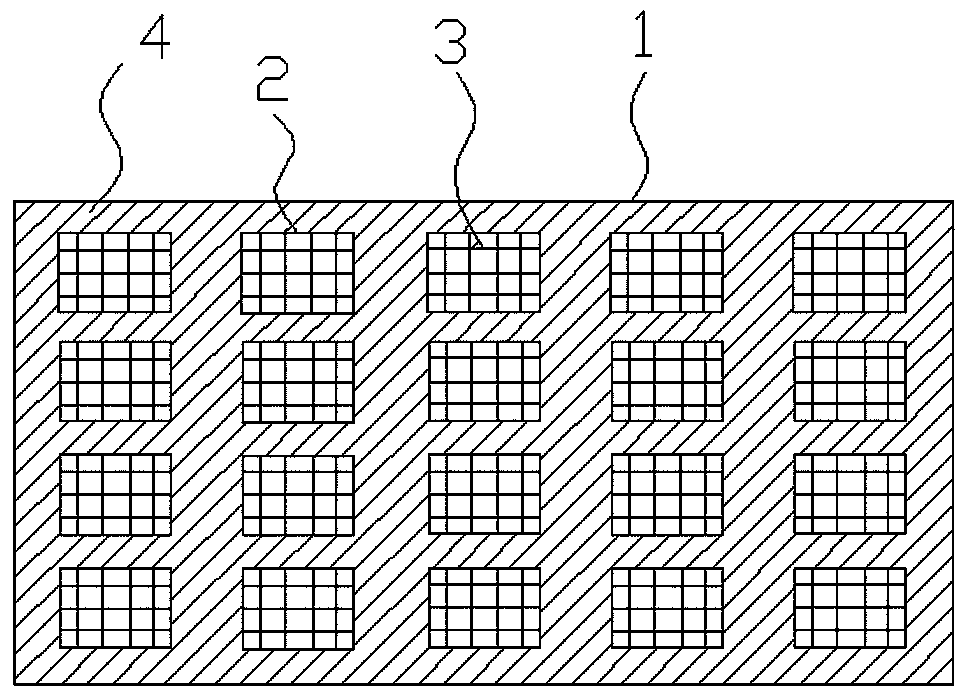

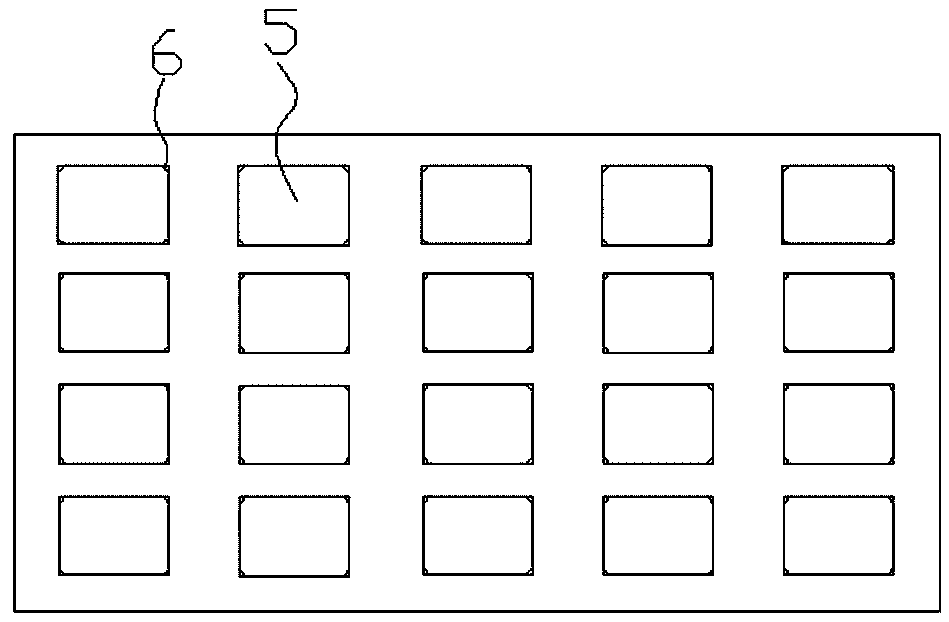

Stem cell heat insulation and moisturizing transport box

InactiveCN111017375ANot easy to damageAvoid shakingDomestic cooling apparatusLighting and heating apparatusTemperature controlCryopreservation

The invention discloses a stem cell heat insulation and moisturizing transport box. The transport box comprises a box body, a box cover arranged at the top of the box body and a handle arranged at thetop of the box cover, and further comprises a stem cell cryopreservation tube fixing device, a temperature control device, an ultrasonic humidifying device, a control panel, a wireless communicationmodule and a controller. A miniature camera device is arranged at the bottom of the box cover, and protective layers wrap the outer side of the box body and the outer side of the box cover; a first horizontal partition plate is arranged in the box body, the box body is divided into two chambers, a stem cell storage chamber is arranged above the first horizontal partition plate, a humidifying chamber is arranged below the first horizontal partition plate, the ultrasonic humidifying device is arranged in the humidifying chamber, and the stem cell cryopreservation tube fixing device and the temperature control device are arranged in the stem cell storage chamber; and the control panel, the wireless communication module and the controller are all arranged at the top of the box cover. The transport box is simple in structure and convenient to use, the heat insulation and moisturizing effects are excellent, transportation of stem cells is facilitated, it is ensured that the state of the cells in the transportation process is good, and users can monitor the state in the box in real time.

Owner:上海美致臻心生物医学科技有限公司

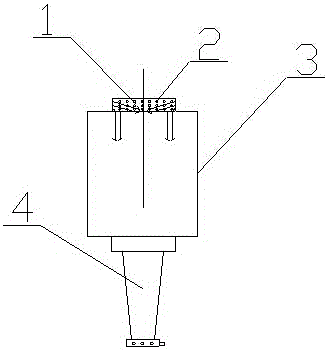

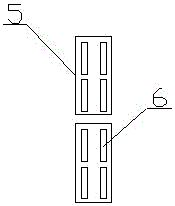

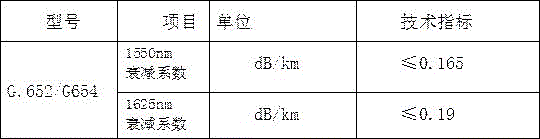

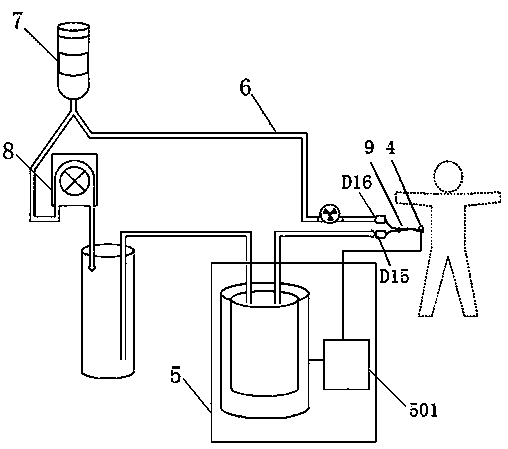

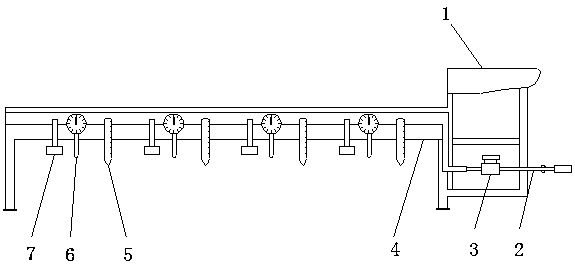

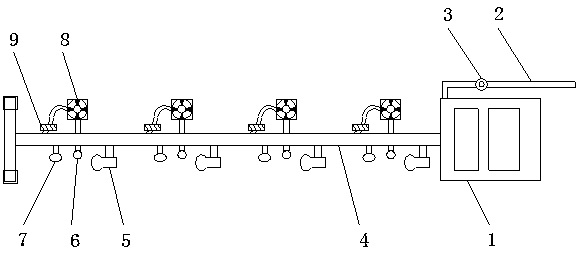

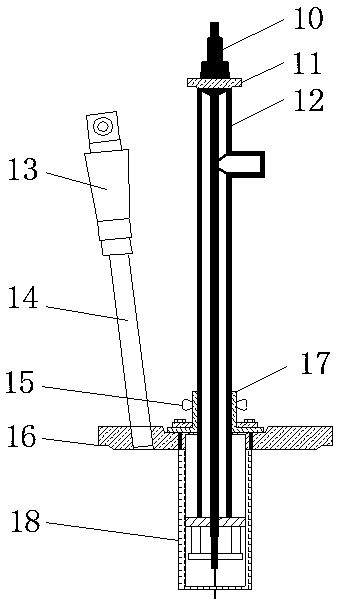

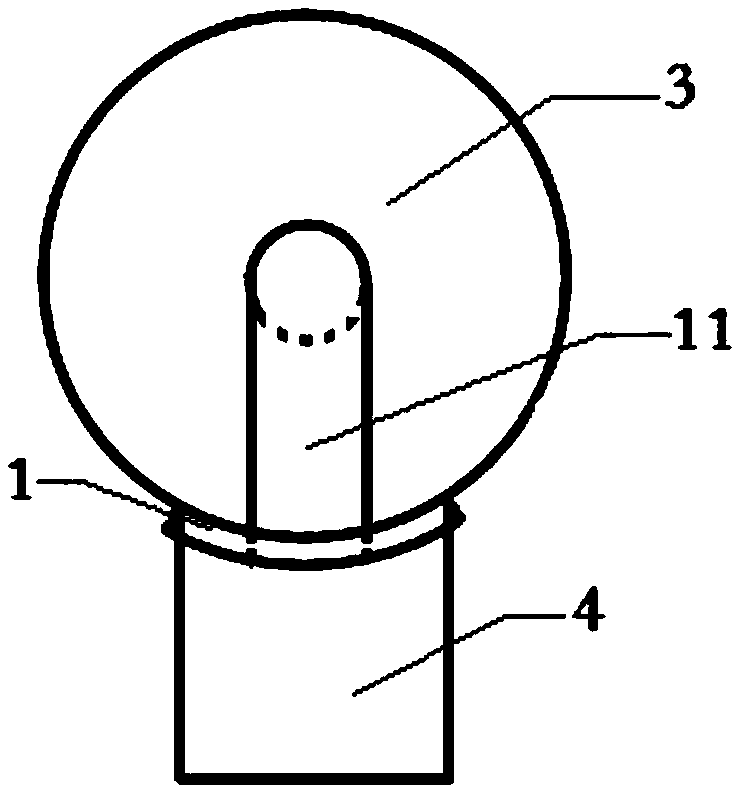

Ultralow loss optical fiber production system and technology used for production

InactiveCN106019465AAvoid contaminationRealize remote controlCladded optical fibreGlass fibre drawing apparatusRemote controlUltraviolet lights

The invention relates to an ultralow loss optical fiber production system and a technology used for production. The ultralow loss optical fiber production system comprises a wire drawing device, an annealing device, a coating curing device, and a control unit A. The wire drawing device is a wire drawing furnace, which, from top to bottom, comprises a furnace top gas disc, a wire drawing furnace body, and a lower end annealing tube, which are in a coaxial arrangement. The annealing device is a heat preservation annealing furnace, and the coating curing device comprises a coating device and an ultraviolet light curing furnace, which are sequentially arranged. When the ultralow loss optical fiber is disposed in the production system, the optical fiber passes through the wire drawing device, the annealing device, the coating curing device, and the control unit A. The ultralow loss optical fiber production system and the technology used for the production are advantageous in that the wire drawing furnace top gas disc is provided with a plurality of gas inlets, and the original single heating element of the heat preservation annealing furnace is changed into an upper heating element and a lower heating element, which are independent from each other, and are controlled respectively by independent power supplies; the connection with the wire drawing furnace is realized by a data line, and then remote control is realized; the ultraviolet light curing furnace is used for on-line monitoring of a gas exhaust condition, and is used to adjust the gas exhaust condition automatically.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

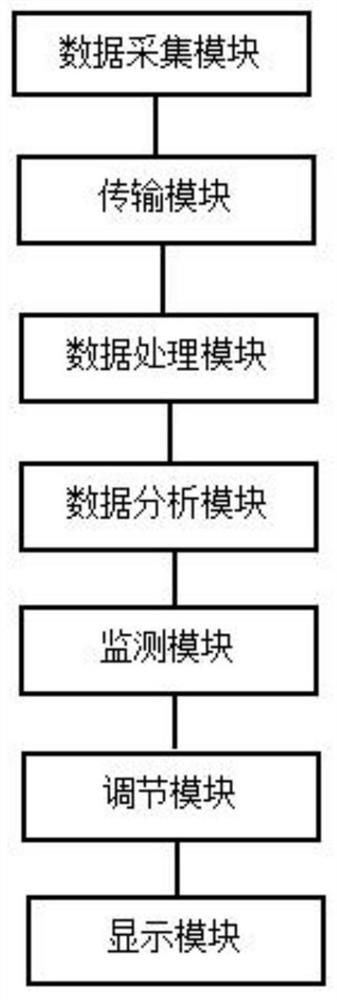

Cold chain storage environment monitoring system

InactiveCN112162539AImprove monitoring effectGood gas environmentTotal factory controlSimultaneous control of multiple variablesCold chainOxygen monitoring

The invention discloses a cold chain storage environment monitoring system. A data acquisition module is used to acquire data information of a cold chain storage environment, a data processing moduleis used to process the data information, and a data analysis module is used to analyze the data processing information. A monitoring module is used for receiving the data analysis information sent bythe data analysis module and monitoring the condition of the cold chain storage environment. An adjusting module is used for receiving a temperature monitoring set signal, a humidity monitoring set signal, an oxygen monitoring set signal and a carbon dioxide monitoring set signal, and adjusting a temperature and humidity, an oxygen concentration and a carbon dioxide concentration in the cold chainstorage environment. A display module is used for displaying the temperature and humidity, the oxygen concentration and the carbon dioxide concentration in the cold chain storage environment. A transmission module is used for transmitting data among all the modules. According to the invention, defects that the environmental condition in the cold chain storage cannot be monitored and displayed inreal time and the monitoring accuracy is poor can be solved.

Owner:合肥快乐通冷链物流配送有限公司

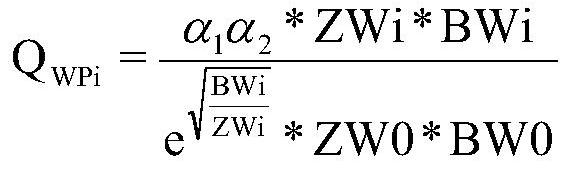

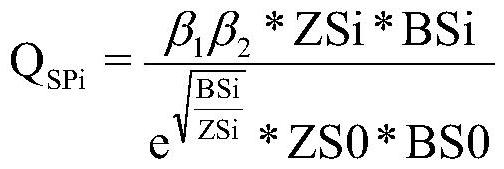

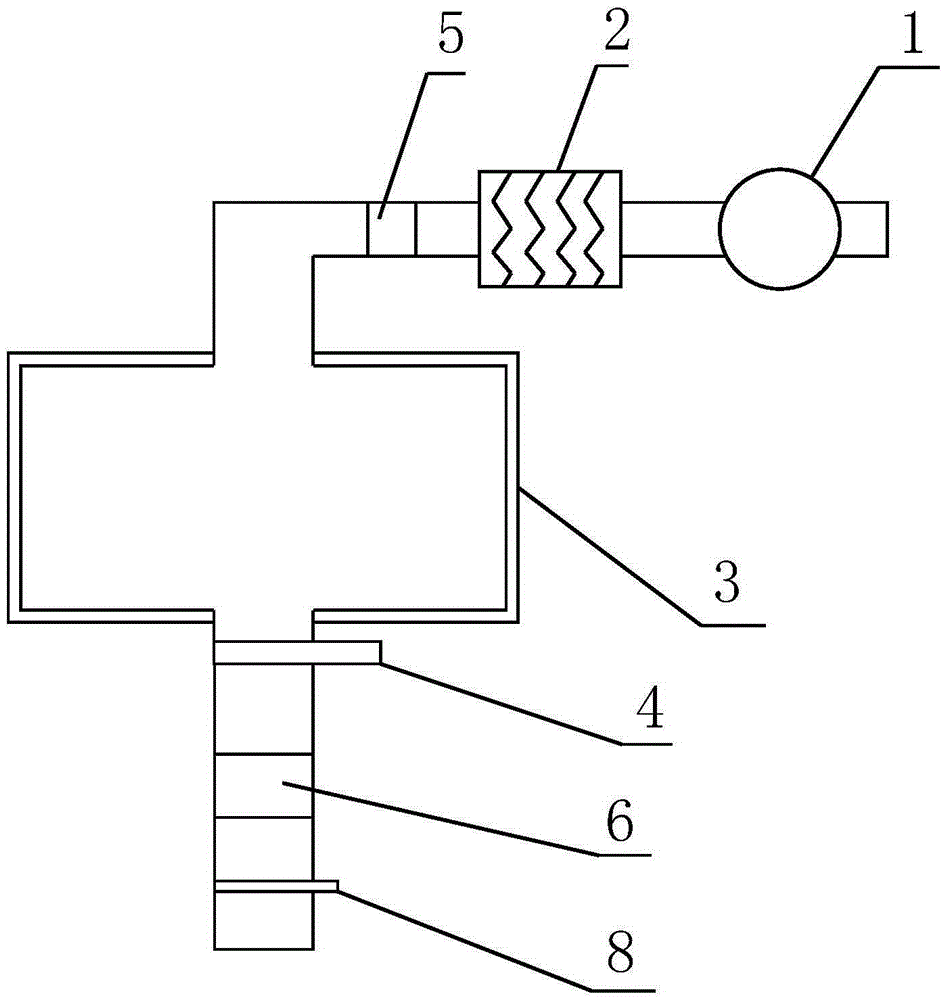

Device for reducing generation of biuret in urea ammonium nitrate solution industrial production process and application method thereof

InactiveCN104311163ANot prone to condensation reactionsReduce generationAmmonium nitrate fertilisersUrea compound fertilisersAmmonium nitrateChiller

The invention provides a device for reducing generation of biuret in a urea ammonium nitrate solution industrial production process, which comprises a urea solution tank, a urea solution pump, a urea ammonium nitrate preparation tank, a urea ammonium nitrate solution pump, a cooler and a delivery pipeline, wherein the bottom of the urea solution tank is connected with an inlet of the urea solution pump through a pipeline; the urea solution pump is connected with an inlet of the urea ammonium nitrate preparation tank through the delivery pipeline; a heat tracing pipeline is arranged outside the delivery pipeline; the bottom of the urea ammonium nitrate preparation tank is connected with an inlet of the urea ammonium nitrate solution pump through a pipeline; the urea ammonium nitrate solution pump is connected with an inlet of the cooler through a pipeline; the pipeline between the ammonium nitrate solution pump and cooler is connected with a urea ammonium nitrate solution product discharge pipeline; and the cooler is connected with a top inlet of the urea ammonium nitrate preparation tank through a pipeline. The device optimizes the production control, reduces the generation of biuret, and effectively improves the product quality. The invention also provides an application method of the device.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

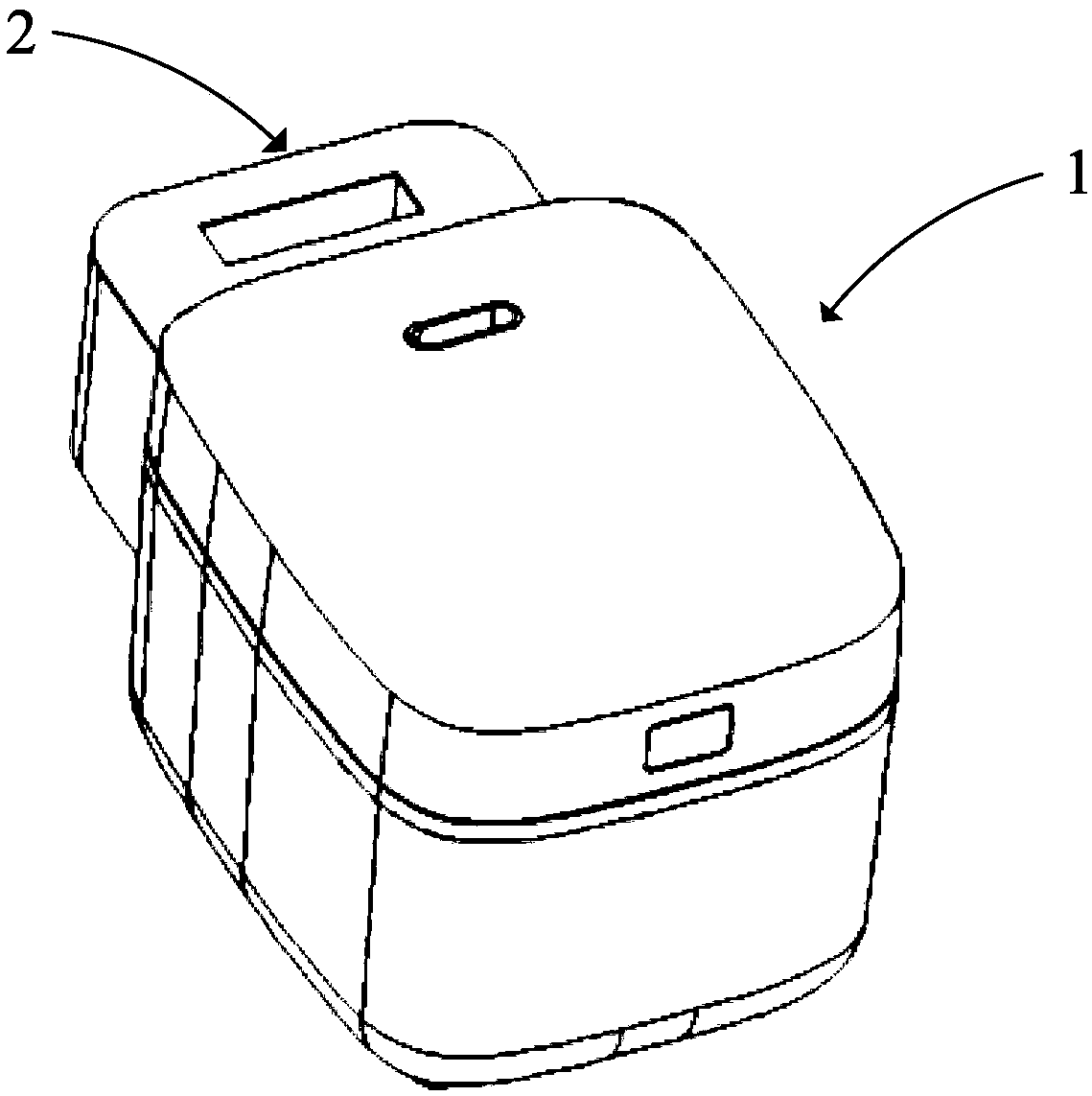

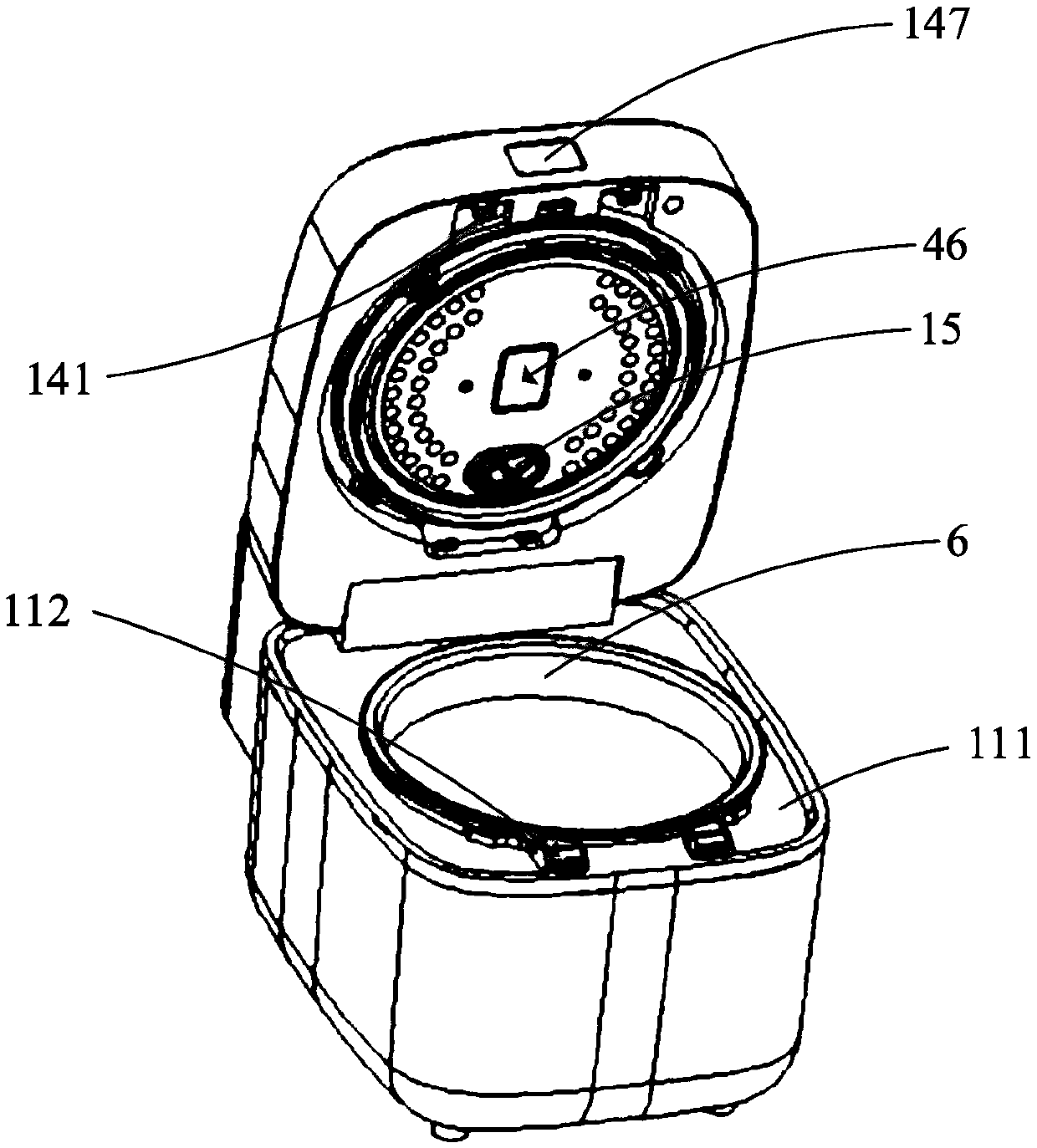

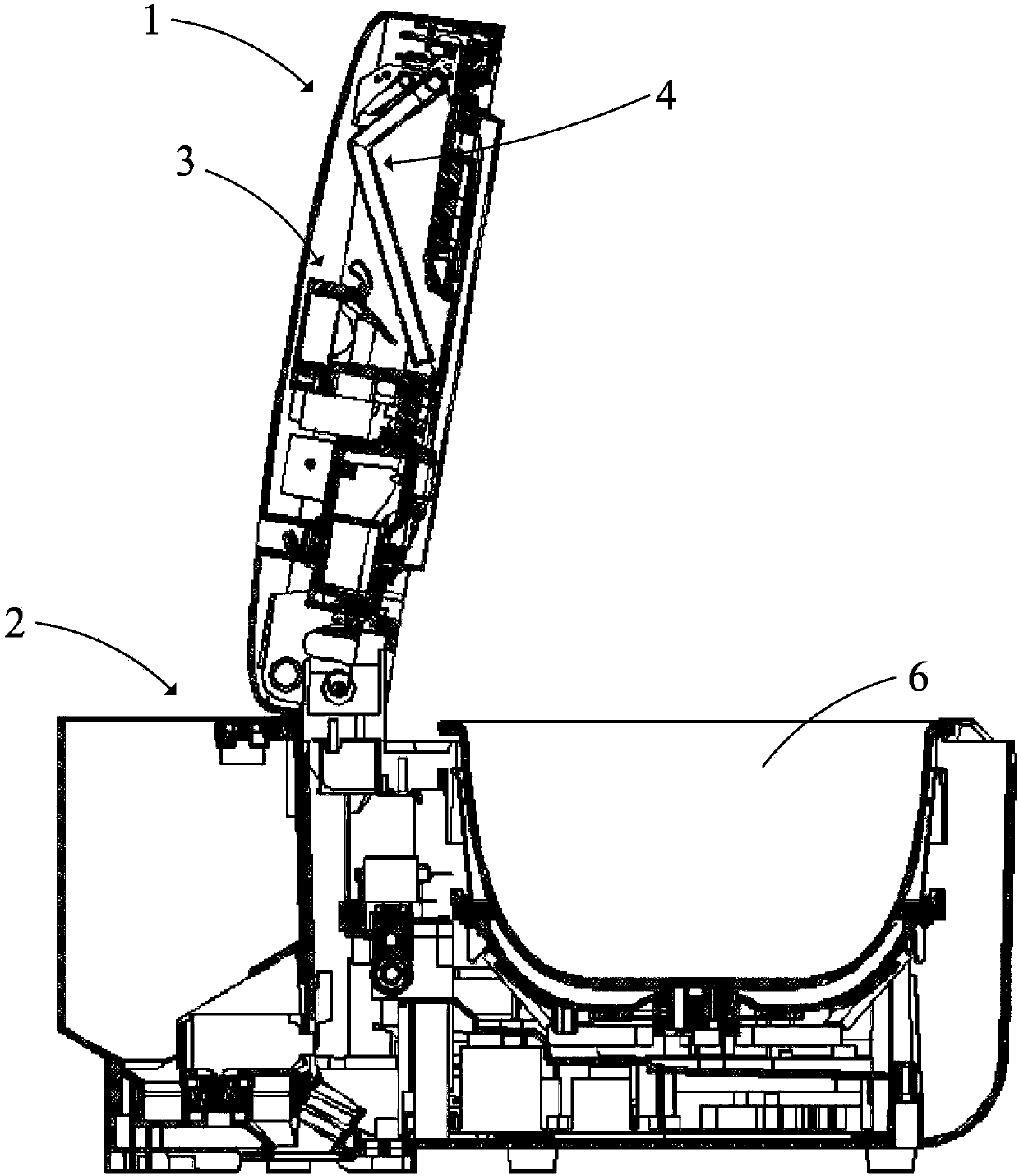

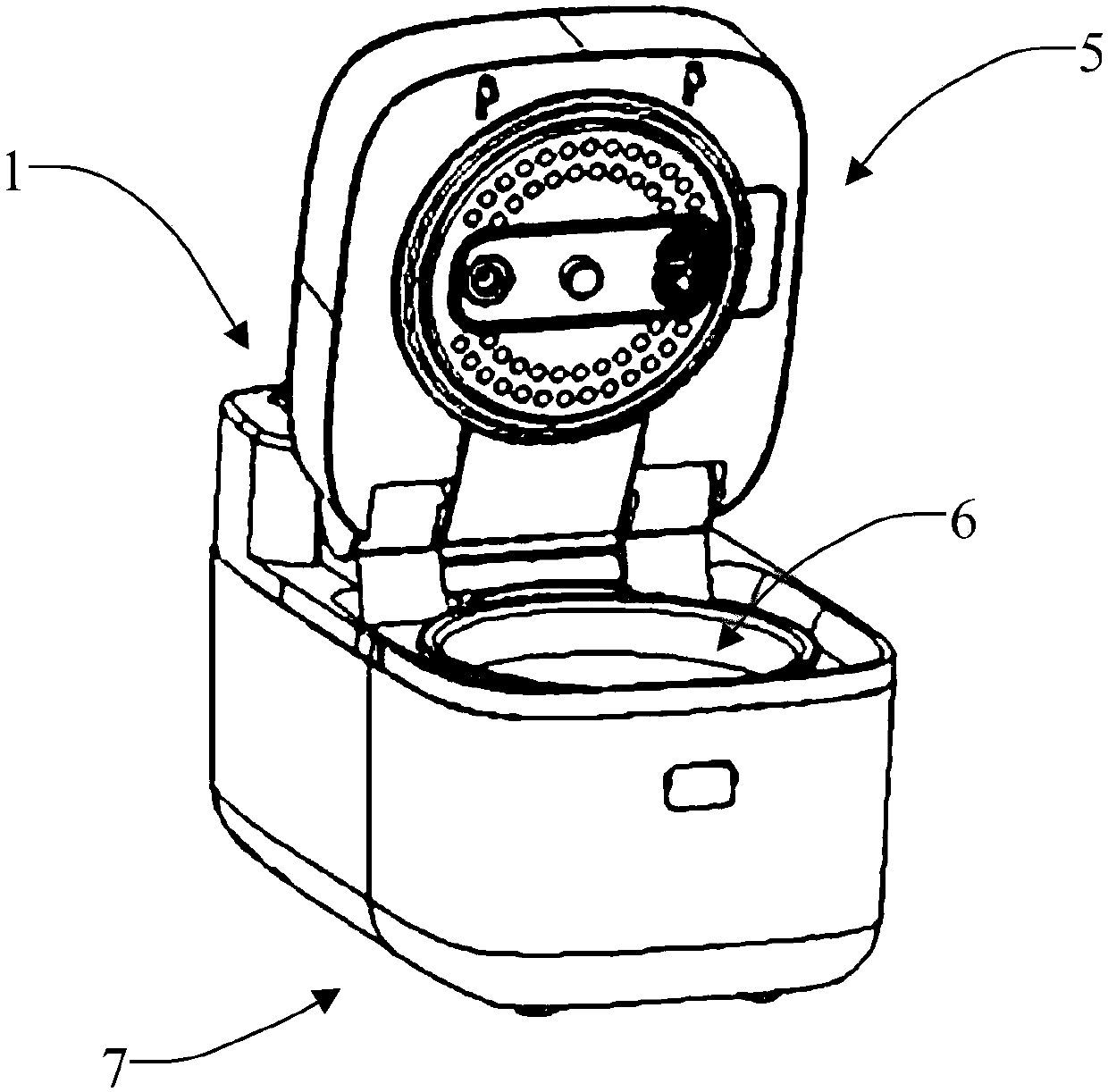

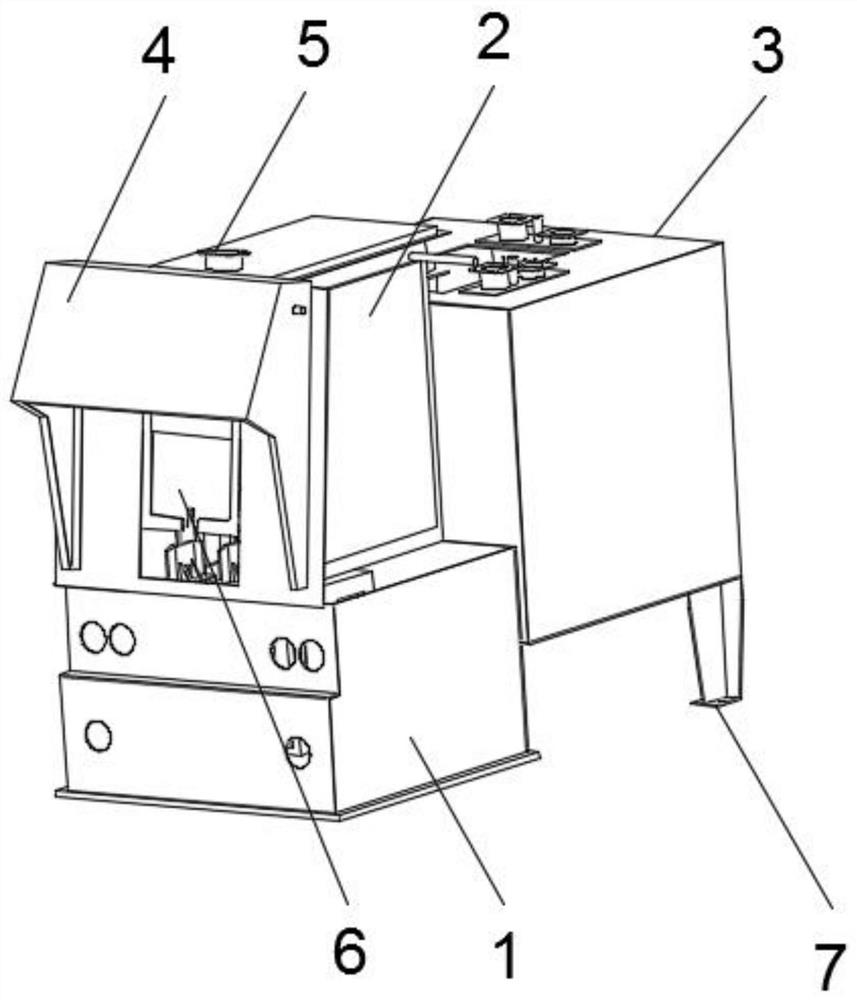

Smart cooking robot

ActiveCN107853983AGuaranteed heating effectReal-time temperature monitoringCooking-vessel lids/coversVessels with intergral heatingEngineeringLinkage concept

The invention discloses a smart cooking robot, which comprises a linkage cover body, a rice storage and weighing mechanism, a rice feeding device, a rice washing device, a water system, a pot body anda heating device; the a rice storage and weighing mechanism is connected with the rice feeding device, and the rice feeding device is used for conveying rice in the rice storage and weighing mechanism to the pot body; the rice washing device is connected with the water system, and the rice washing device is used for entering or leaving the pot body; when the rice washing device enters the pot body, the water system fills in the pot body through the rice washing device or discharges water in the pot body. Through the mutual cooperation of the linkage cover body, the rice storage and weighing mechanism, the rice feeding device, the rice washing device, the water system, the pot body and the heating device, the automatic rice feeding, washing and cooking are completed; the whole process is automatically carried out; time of the processing process is saved, the effort for cooking is reduced, and the living quality is better improved.

Owner:FOSHAN IMIBAR TECH CO LTD

Intelligent cooking robot

ActiveCN107550248AGuaranteed heating effectReal-time temperature monitoringSievingScreeningEngineeringProcess engineering

The invention relates to an intelligent cooking robot which comprises a material supply device, a conveying mechanism, a cleaning tank, a water system, an uncovering mechanism and a heating mechanism.The material supply device and the cleaning tank are both connected with the conveying mechanism which is used for conveying materials supplied by the material supply device into the cleaning tank, the water system is connected with the cleaning tank and used for delivering water into the cleaning tank or discharging the water in the same, the uncovering mechanism is connected with the cleaning tank and used for driving the same to swing, and the cleaning tank is matched with the heating mechanism. Automatic input, automatic conveying, automatic cleaning and automatic processing of the materials are completed through cooperation of the material supply device, the conveying mechanism, the cleaning tank, the water system, the uncovering mechanism and the heating mechanism, and full-automatic treatment of the materials is realized in the whole process, so that time is saved in the process of treatment.

Owner:FOSHAN IMIBAR TECH CO LTD

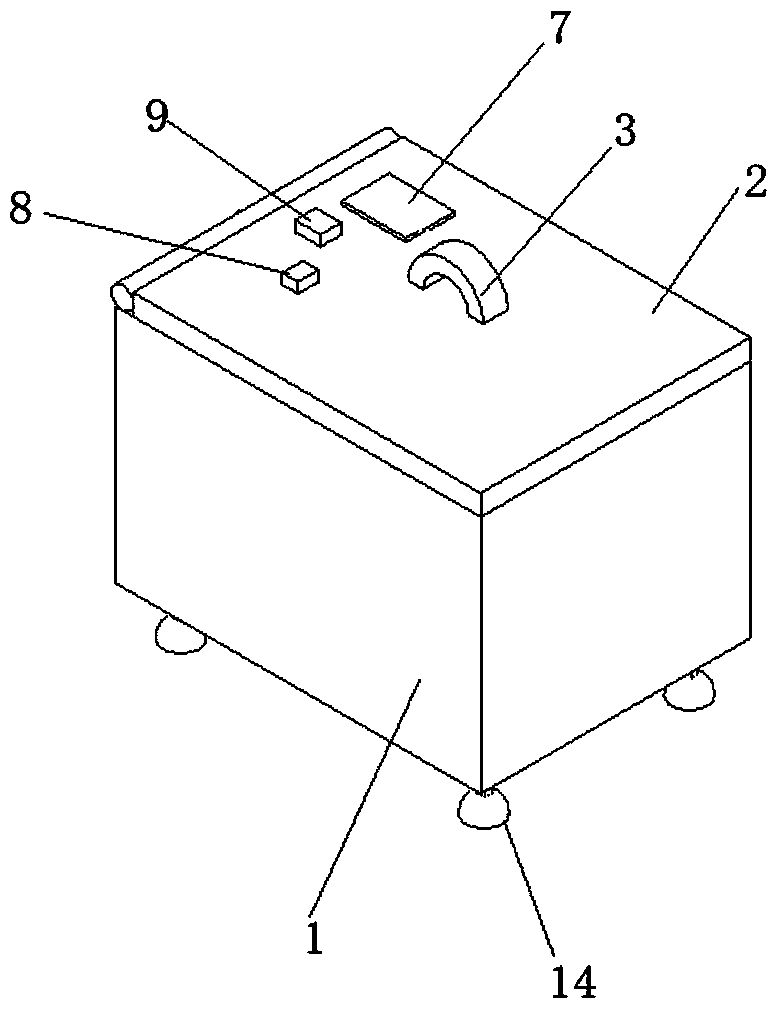

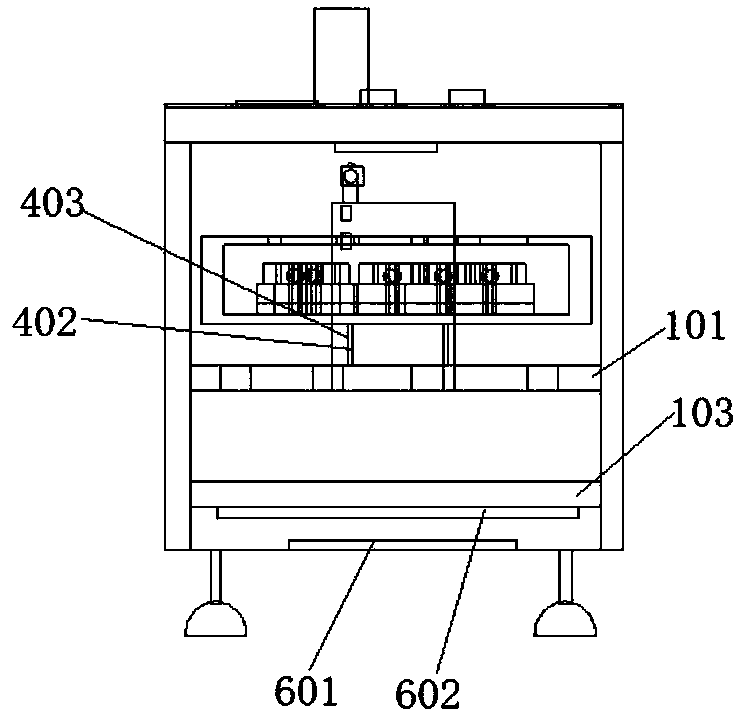

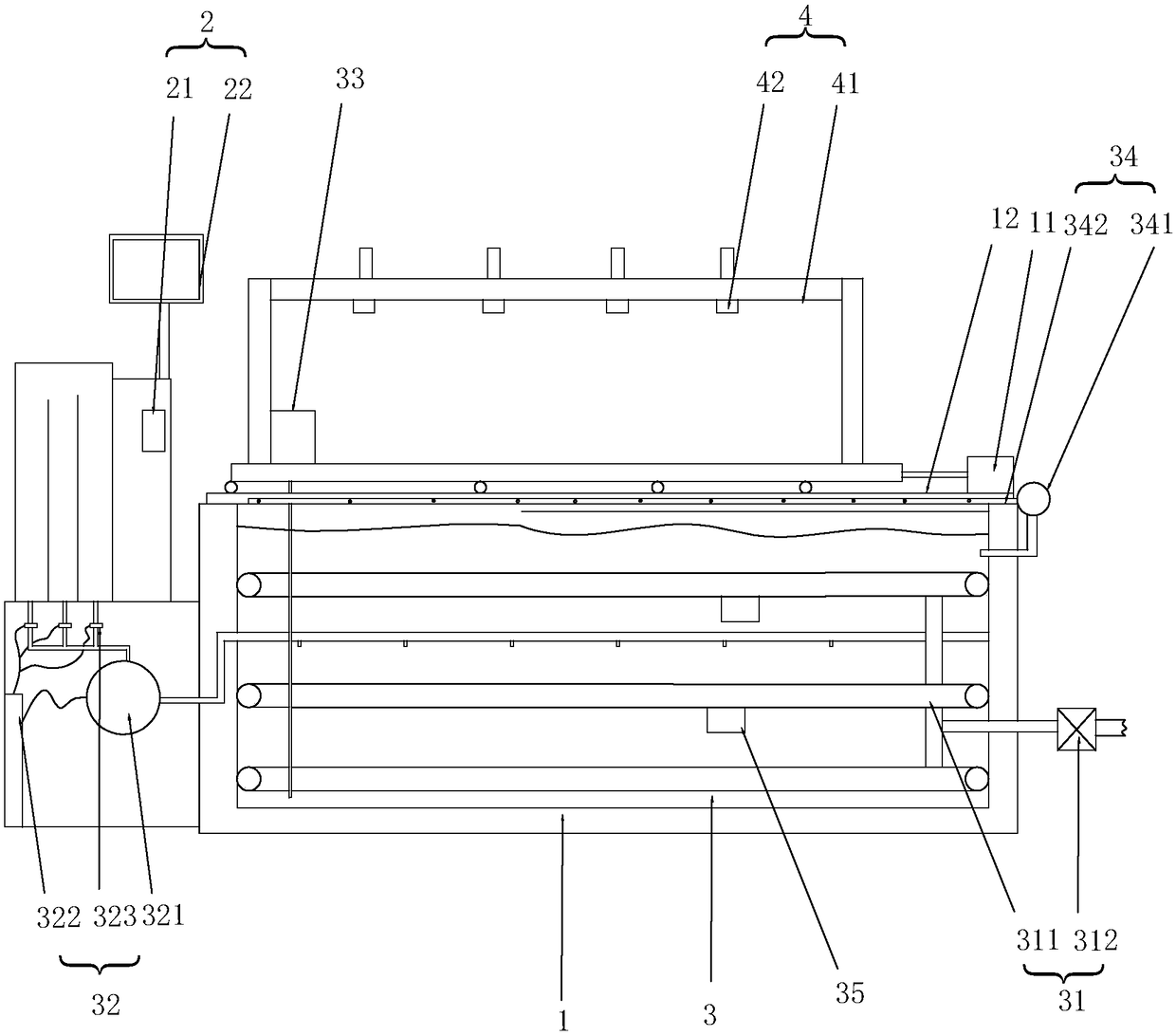

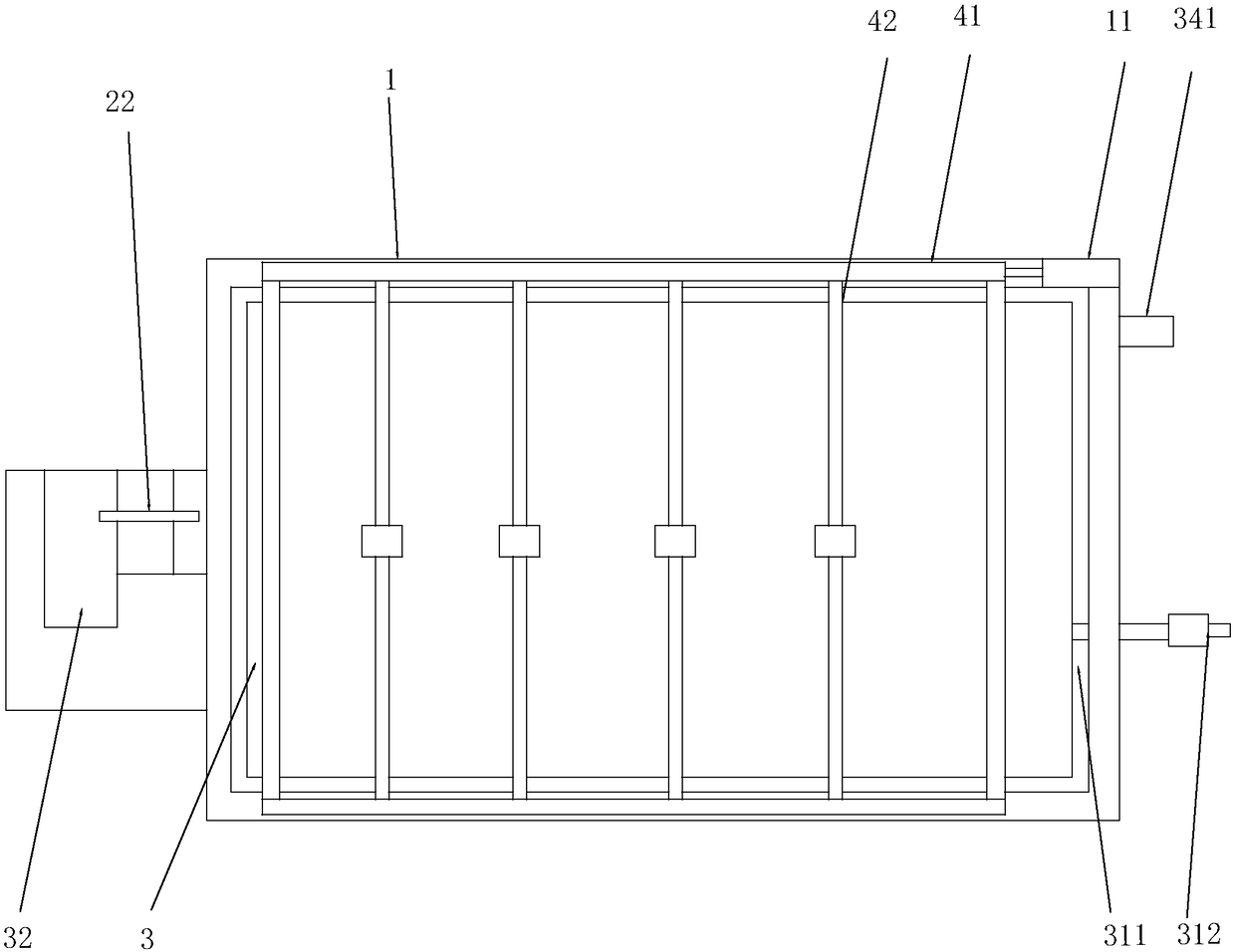

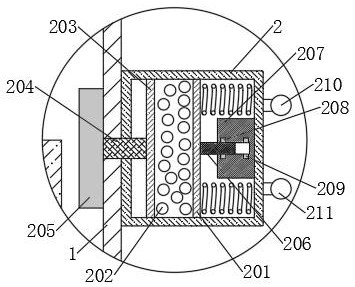

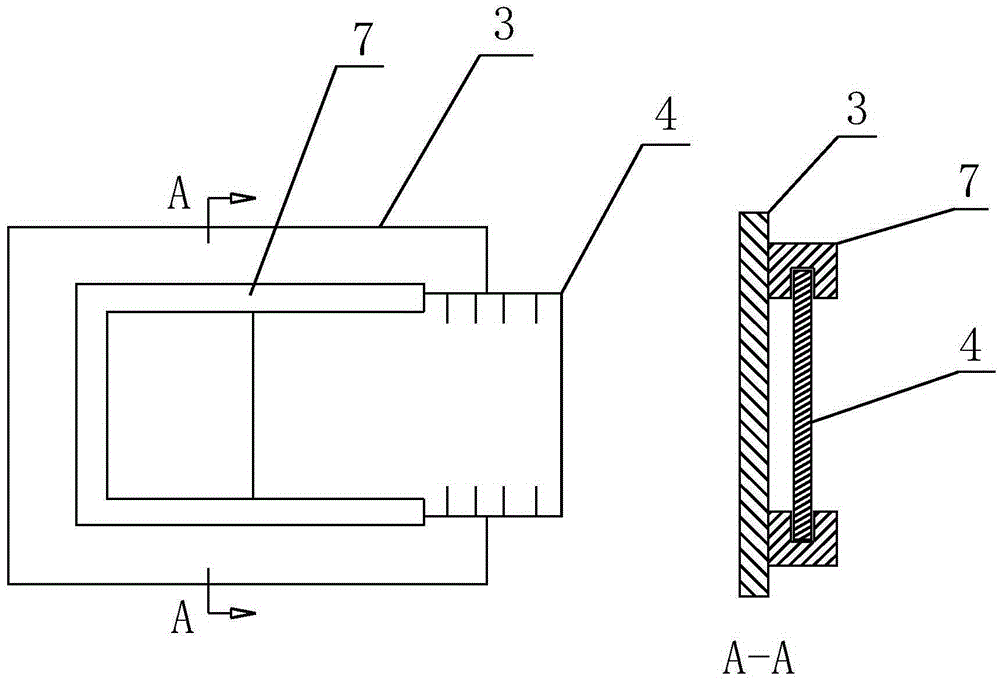

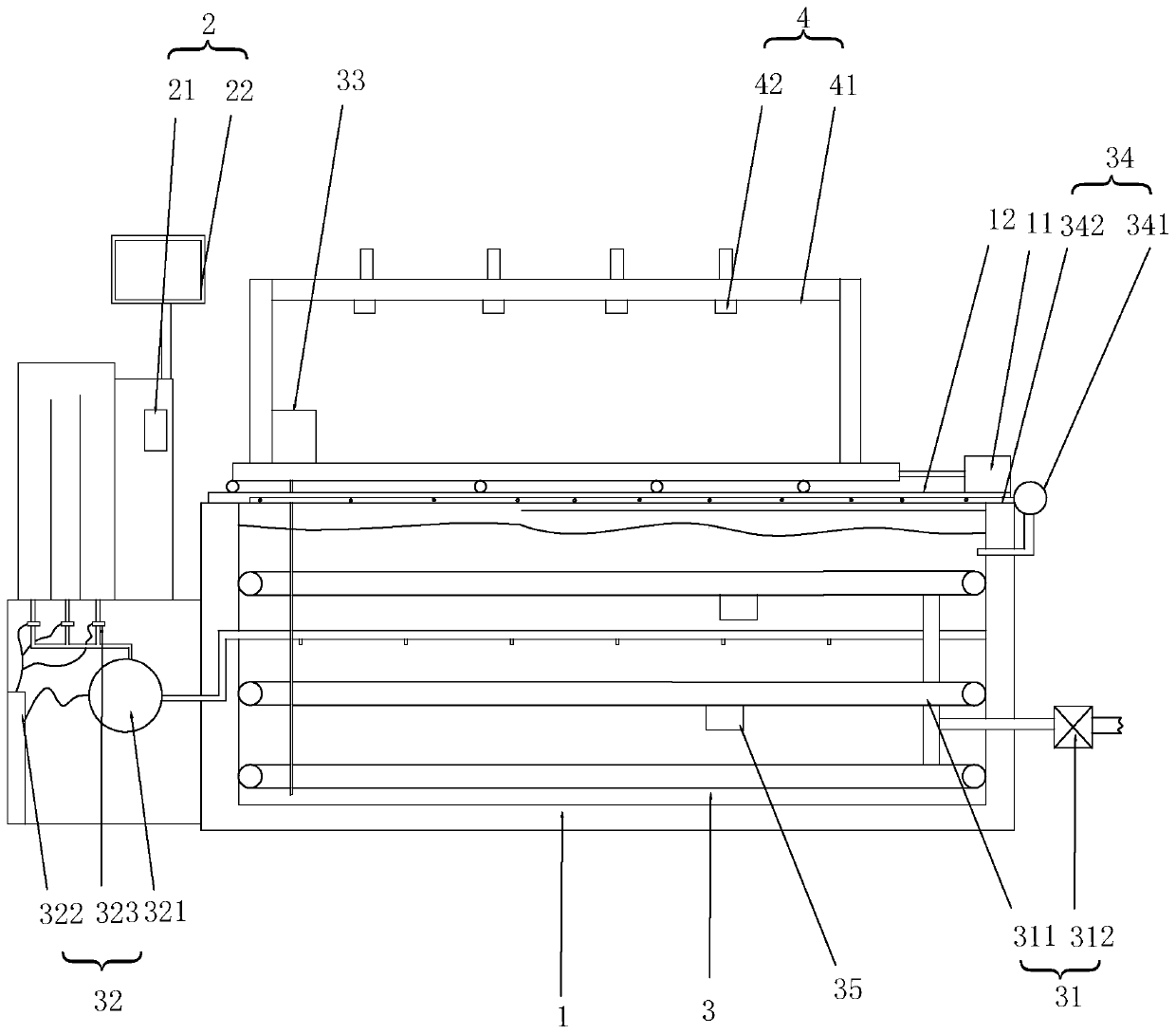

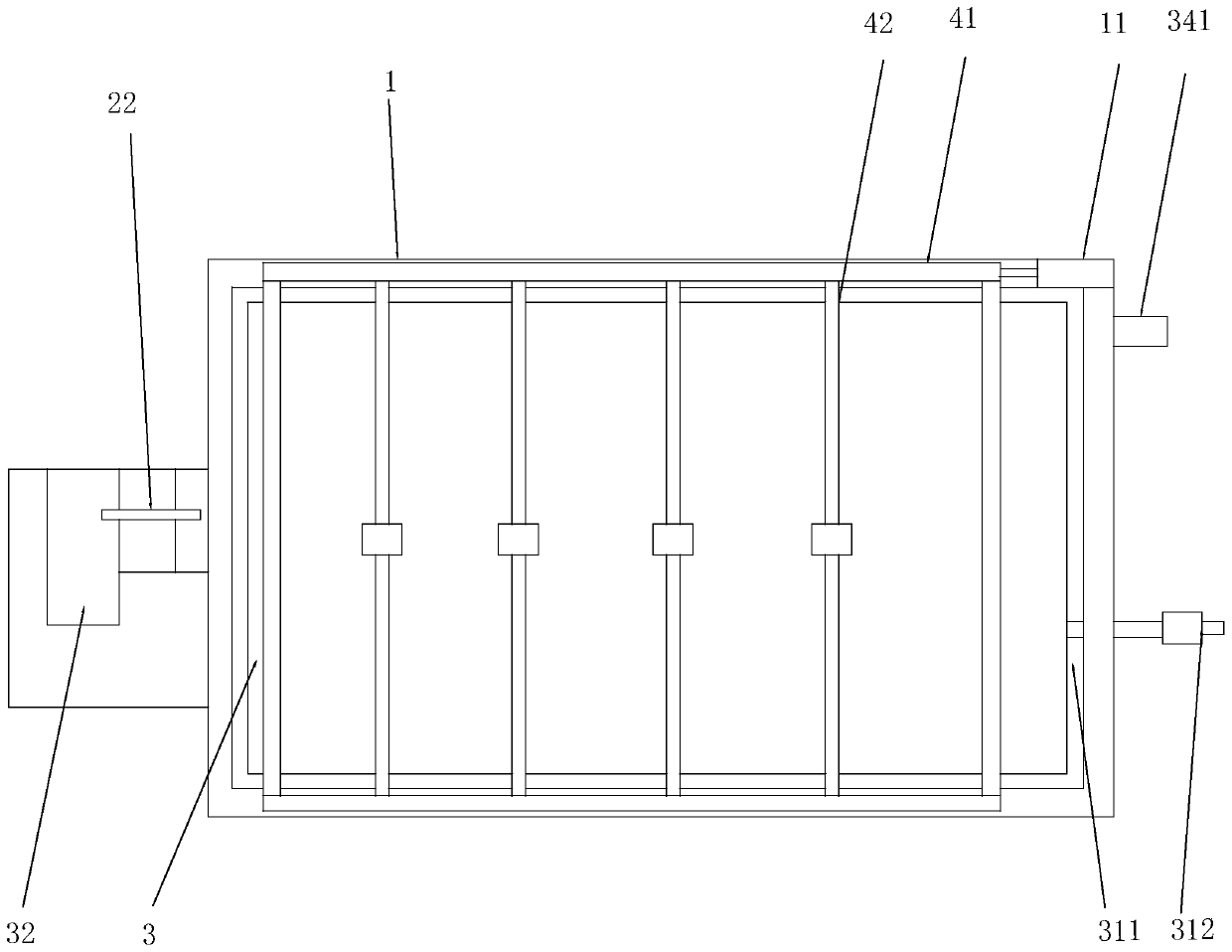

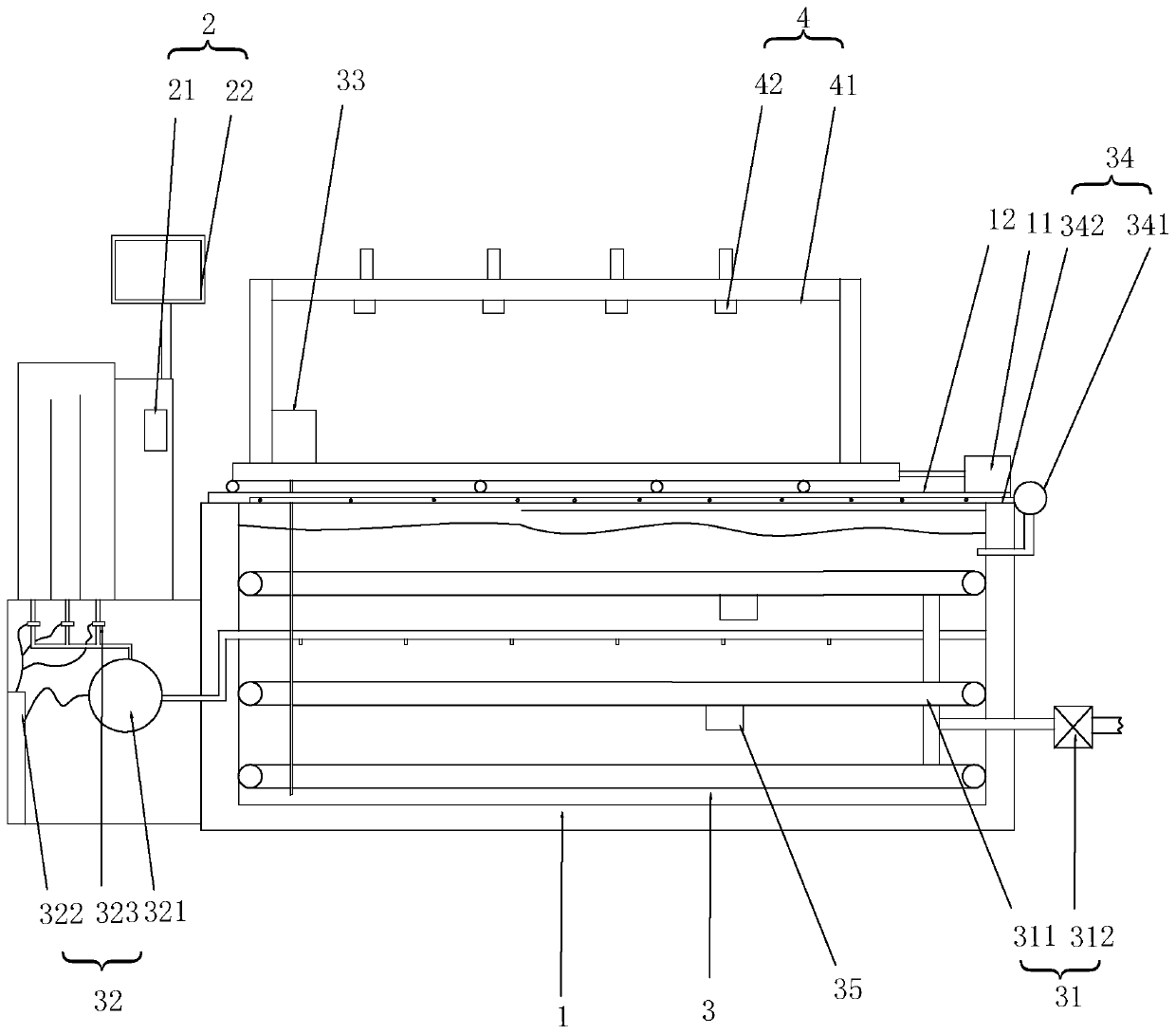

Nickel-gold depositing device

ActiveCN108149291ARealize automated productionQuality improvementCellsPrinted circuit manufactureElectricityTemperature control

The invention discloses a nickel-gold depositing device. The nickel-gold depositing device comprises a support, a control assembly, a nickel cylinder arranged on the support, and a material frame; thematerial frame is arranged on the upper portion of the nickel cylinder; the nickel cylinder is internally provided with a temperature control system, a charging assembly and an electroplating assembly; the temperature control system, the charging assembly and the electroplating assembly are all electrically connected with the control assembly; and a defoaming device is further arranged on the nickel cylinder. According to the nickel-gold depositing device, the temperature control system used for controlling the temperature of a solution in the nickel cylinder, the charging assembly used for adding nickel ions and the electroplating assembly used for increasing the electroplating speed are arranged in the nickel cylinder and all electrically connected with the control assembly, nickel depositing automatic production can be effectively achieved by controlling the temperature control system, the charging assembly and the electroplating assembly through the control assembly so that the solution temperature can be adjusted timely, the nickel ion solution can be added automatically and the magnitude of the electroplating current can be adjusted according to the solution temperature andthe nickel ion concentration in the nickel cylinder in the nickel depositing process of a circuit board, thus, the nickel-gold depositing device can adapt to electroplating work of the different circuit boards automatically, and the automation degree is high.

Owner:珠海市鸿天万达电子科技有限公司

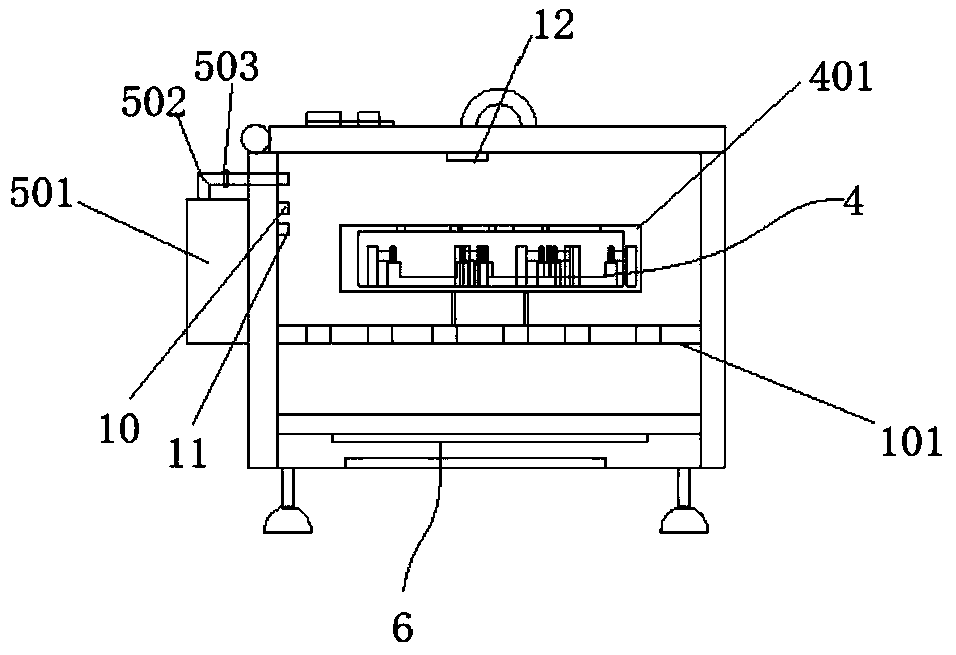

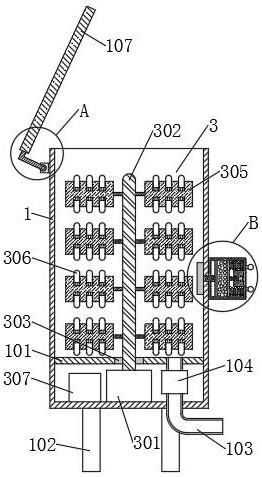

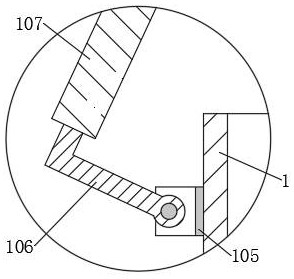

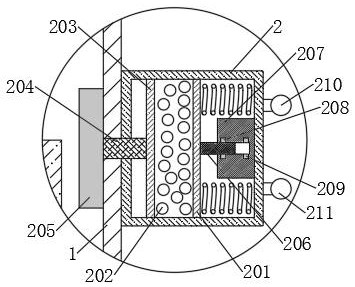

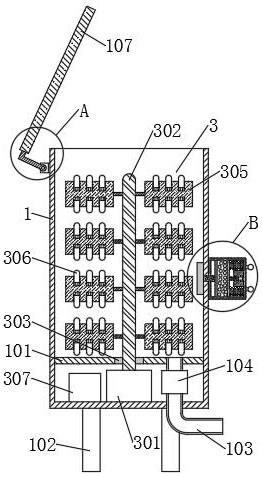

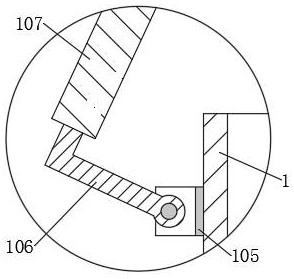

Temperature alarm device for production equipment

InactiveCN114134039AAdjust the temperature in timeDoes not affect fermentation qualityThermometer detailsBioreactor/fermenter combinationsFixed frameControl engineering

The invention discloses a temperature alarm device for production equipment. The temperature alarm device comprises a fermentation cylinder, a fixed frame, an alarm triggering device and a rotary temperature adjusting mechanism, a partition plate is arranged in the fermentation cylinder, and a discharge pipe is mounted on the partition plate; the fixed frame is installed on the outer wall of the fermentation vat, a sliding partition plate is arranged in the fixed frame, a plurality of memory alloy balls are arranged on one side of the sliding partition plate, and an alarm triggering device is arranged on the side, away from the memory alloy balls, of the sliding partition plate; the rotary temperature adjusting mechanism is arranged in the fermentation cylinder, and the rotary temperature adjusting mechanism is used for stirring the product in the fermentation cylinder and can heat the product, so that the temperature of the product in the fermentation cylinder is conveniently adjusted. By arranging corresponding mechanisms in the fermentation cylinder, an alarm can be given out in time when the temperature in the fermentation cylinder is relatively high or relatively low, and a worker can conveniently adjust the temperature in the fermentation cylinder in time, so that the fermentation quality of a product is not influenced, and the taste of the product is not reduced.

Owner:SICHUAN PROVINCE PIXIAN COUNTY BEAN PASTE

High-sensitivity alarm device

InactiveCN114317257AAdjust the temperature in timeDoes not affect fermentation qualityBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyEngineering

The invention discloses a high-sensitivity alarm device which comprises a fermentation vat, a fixing frame, an alarm triggering device and a rotary temperature adjusting mechanism. A partition plate is arranged in the fermentation cylinder, and a discharge pipe is mounted on the partition plate; the fixed frame is installed on the outer wall of the fermentation vat, a sliding partition plate is arranged in the fixed frame, a plurality of memory alloy balls are arranged on one side of the sliding partition plate, and an alarm triggering device is arranged on the side, away from the memory alloy balls, of the sliding partition plate; the rotary temperature adjusting mechanism is arranged in the fermentation cylinder, and the rotary temperature adjusting mechanism is used for stirring the product in the fermentation cylinder and can heat the product, so that the temperature of the product in the fermentation cylinder is conveniently adjusted. By arranging corresponding mechanisms in the fermentation cylinder, an alarm can be given out in time when the temperature in the fermentation cylinder is relatively high or relatively low, and a worker can conveniently adjust the temperature in the fermentation cylinder in time, so that the fermentation quality of the thick broad-bean sauce cannot be influenced, and the taste of the thick broad-bean sauce cannot be reduced.

Owner:SICHUAN PROVINCE PIXIAN COUNTY BEAN PASTE

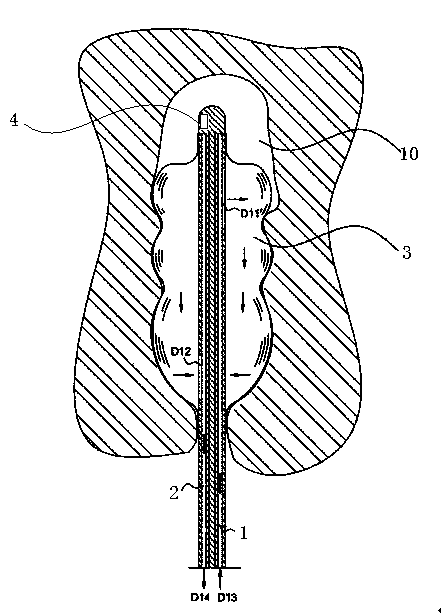

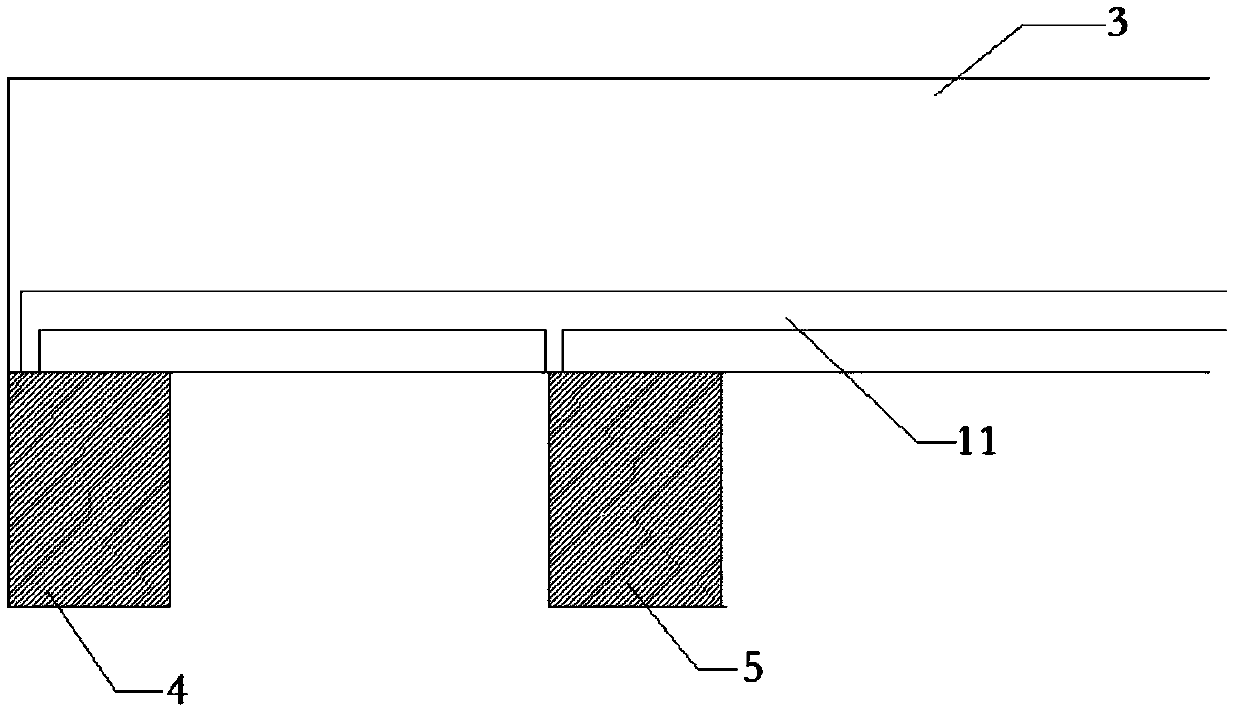

Temperature control catheter with temperature sensor

InactiveCN104042392ATemperature controlAvoid damageTherapeutic coolingTherapeutic heatingVeinTemperature control

The invention relates to the field of a medical appliance, in particular to a temperature control catheter with a temperature sensor. The temperature control catheter with the temperature sensor comprises a water inlet orifice, a water return orifice and a saccule, wherein the water inlet orifice comprises a far end water inlet, the water return orifice comprises a far end water return opening, the saccule is positioned at the far end of the catheter, openings of the far end water inlet and the far end water return opening are positioned in the saccule, the water inlet orifice also comprises a near end water filling opening, the water return orifice also comprises a near end water outlet, and the front end of the catheter is provided with the temperature sensor. The temperature control catheter has the advantages that the saccule is utilized for continuously carrying out heat exchange with the blood in the postcava of a patient, and the goal of controlling the human body temperature is achieved; the blood temperature of the patient can be detected in real time through the temperature sensor, and the temperature of heat exchange fluid filled into the saccule can be regulated in time; when the temperature control catheter is provided with a plurality of saccules, the heat exchange contact area can be further increased, and the temperature in the body can be fast changed.

Owner:CHENGDU JIAYI TECH

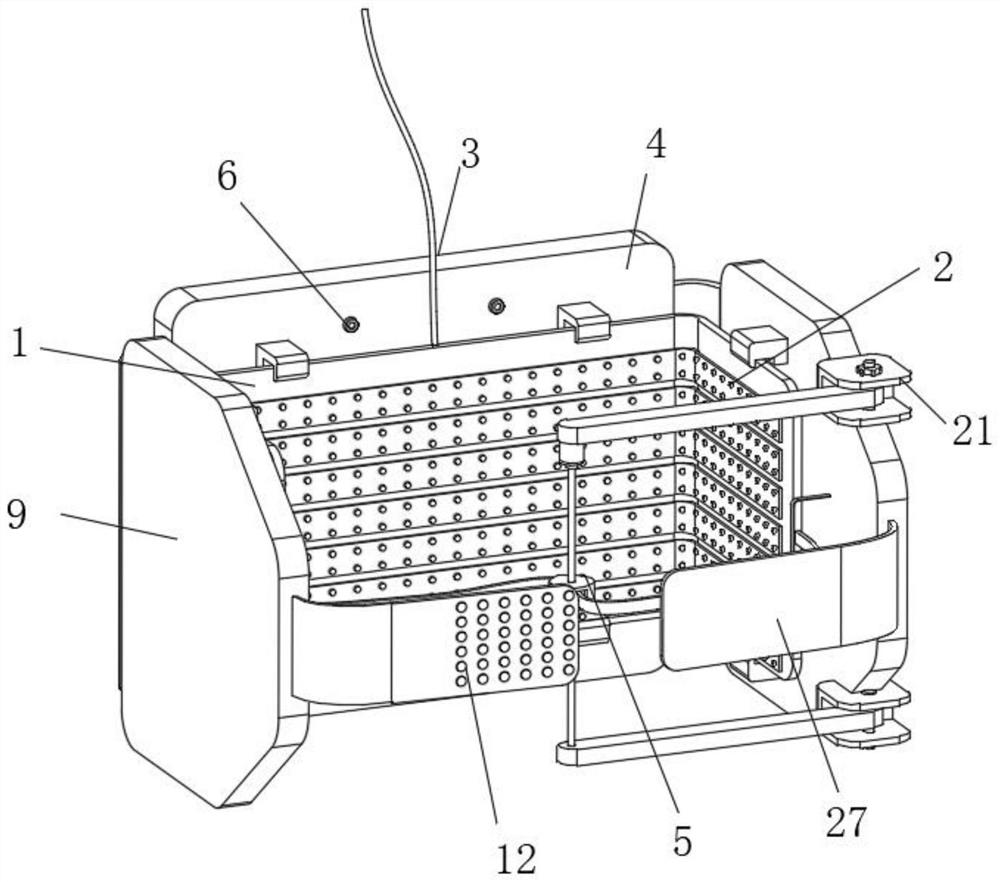

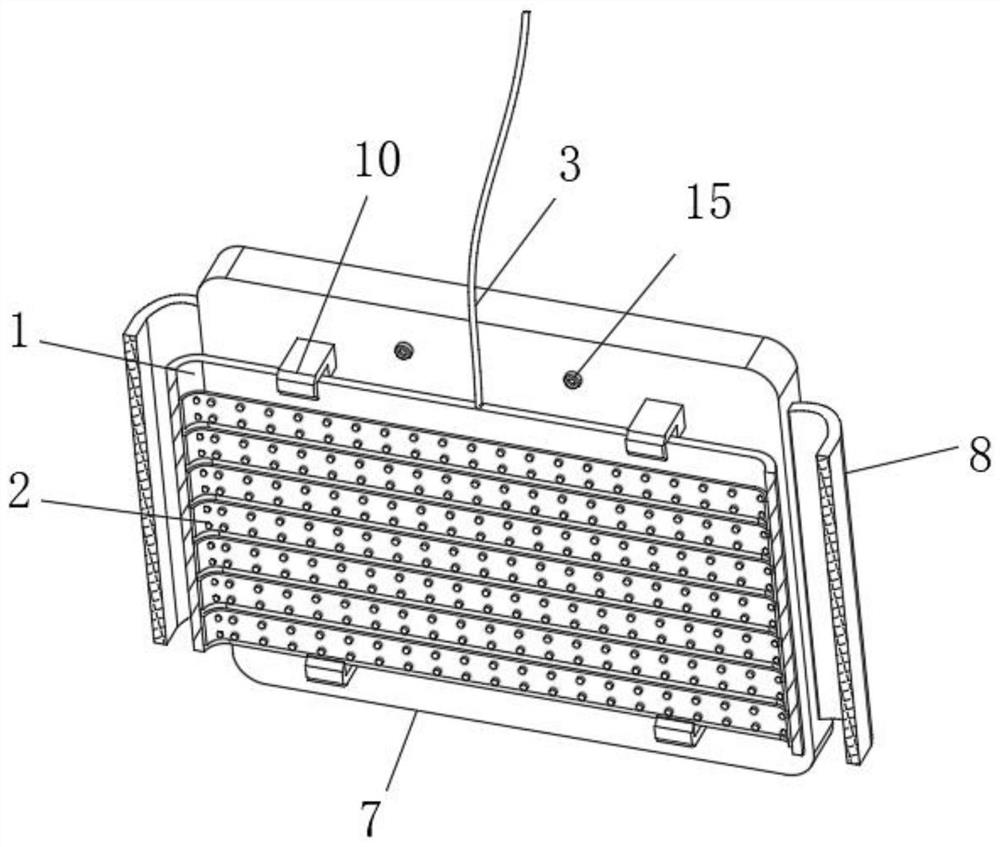

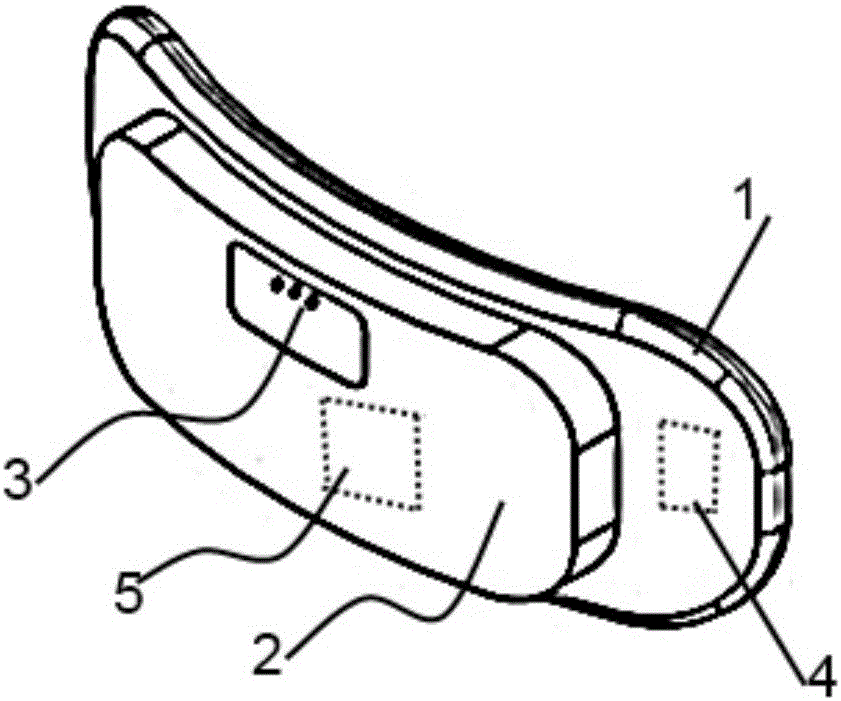

Wearable LED phototherapy device

PendingCN111701149AAdjust the temperature in timeAvoid the risk of burningLight therapyEngineeringLED lamp

The invention discloses a wearable LED phototherapy device. The wearable LED phototherapy device comprises a mounting tape, wherein a plurality of LED lamp strips are connected to the mounting tape inan equal spacing manner, a wire is connected to the top of the mounting tape, the outer side of the mounting tape is wrapped with a shape fixing element for maintaining the use shape of the mountingtape, temperature control elements for controlling light sources of the LED lamp strips are connected to one end of the shape fixing element, and a distance adjusting element for adjusting tightening-up distance of the mounting tape is connected to the other end of the shape fixing element. According to the wearable LED phototherapy device disclosed by the invention, the limb of a user is put at the position of the mounting tape, and the mounting tape can be maintained in a needed shape for phototherapy through the arranged shape fixing element; the arranged temperature control elements are used for detecting the temperature of lamp sources during phototherapy, so that the temperature of the LED lamp strips can be convenient to adjust timely; and besides, the arranged distance adjusting element is adjusted according to the length of the phototherapy time in a phototherapy process, so that the distance between the illuminants of the LED lamp strips and the limb for phototherapy is adjustable, the possibility that the illuminants of the LED lamp strips are in direct contact with skin can be reduced, and the risk that staff are burnt and scalded when the wearable LED phototherapy device is used is avoided.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Drying unit of printing machine

InactiveCN105346228AAdjustable temperatureAdjust the temperature in timePrinting press partsAir volumeDesiccant

The invention relates to the technical field of printing machines, in particular to a drying unit of a printing machine. The drying unit comprises a draught fan, a heat and an oven which are sequentially connected; the drying unit further comprises a baffle used for changing the area of an outlet of the oven, and the baffle is located at the outlet of the oven; and a drying agent is arranged at an outlet of the heater, and an adsorbent is further arranged at the outlet of the oven. The drying agent is arranged behind the heater, hot air can be dried, and the drying efficiency of the oven is improved. The adsorbent is arranged at the outlet of the oven, so that pollution of discharged gas to the environment is avoided. In addition, through the design of the baffle, the exhaust amount of the oven can be adjusted, and the using rate can be improved.

Owner:SICHUAN HANGDA ELECTROMECHANICAL TECH DEV SERVICE CENT

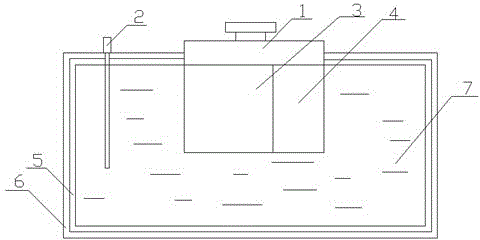

Novel disinfectant sterilized cotton ball heating and heat preserving device

InactiveCN104548325ASimple and reasonable structural designLess discomfortMedical applicatorsBiomedical engineeringCotton balls

The invention discloses a novel disinfectant sterilized cotton ball heating and heat preserving device which comprises a cover, a thermometer, a disinfectant box, a cotton ball box, a constant temperature heating device and an incubator, wherein the constant temperature heating device is mounted in the incubator; clean water is placed in the constant temperature heating box; the thermometer is arranged at the upper left part of the constant temperature heating box; the disinfectant box is arranged in the middle of the constant temperature heating box; the cotton ball is arranged on the right side of the disinfectant box; the cover is arranged above the disinfectant box and the cotton ball box. The novel disinfectant sterilized cotton ball heating and heat preserving device is simple and reasonable in structural design and can be used for carrying out heating and heat preservation on the disinfectant and the cotton ball; when the heated disinfectant and cotton ball are used for scrubbing patients, the discomfort of the patients can be decreased and the fear of the patients can be decreased; the novel disinfectant sterilized cotton ball heating and heat preserving device is particularly suitable for the disinfection of infant patients; a corking with the thermometer is arranged, so that the placement and taking are convenient, medical workers can grasp the water temperature in time and adjust the temperature in time, and the working efficiency of the medical workers is improved.

Owner:HARBIN GUANGKAI TECH DEV

Method for improving internal crystallization of aluminum products

The invention relates to a method for improving internal crystallization of products in nonferrous industries, in particular to a method for improving internal crystallization of aluminum products. The method includes that virgin aluminum serves as a raw material, an rear earth (RE) element is added into a holding furnace, after the holding furnace is full, nitrogen is fed into a prepared powder refining agent tank, the prepared powder refining agent is infiltrated into molten aluminum through nitrogen pressure to be stirred constantly, after fining, aluminum water is stirred evenly, molten aluminum scum is removed, the temperature of the holding furnace is adjusted timely to be kept in a range between 700 DEG C and 760 DEG C, and the molten aluminum is stood for 20 to 40 minutes. According to the method, the technique is unique, improvements of industrial pure aluminum strength and plasticity processed by the RE are larger than those processed by conventional fusing agents, the rate of finished products is improved, the RE value is saved, and the rare earth aluminum ingot loss value is saved.

Owner:QINGTONGXIA ALUMINUM GRP

Tea-oil tree grafted seedling rapid healing cultivation method and incubator

The invention provides a tea-oil tree grafted seedling rapid healing cultivation method and an incubator. The incubator is a box body made of foam plastic; a water discharging hole is formed in the bottom of the box and a vent hole is formed in a box wall; a box cover is a transparent plastic thin film; the box is internally connected with an electric heating element and a temperature and humidity sensor of an external air conditioner. The cultivation method comprises the following steps: paving a seedling bed with the thickness of 10-15cm by using clean river sand; scattering seeds used as stock seedlings on the sand bed and covering the clean river sand with the thickness of 5-10cm to carry out moisture and temperature management so as to promote the seeds to germinate; after the stock seedlings grow to be 3-5cm high in the sand and form sprout seedlings in the sand, grafting scions; putting grafted tea-oil tree seedlings into the incubator to keep moisture and temperature so that wounds are rapidly healed; and after 30-40 days, transplanting the grafted seedlings into a large field after the wounds are firmly healed. By the aid of the tea-oil tree grafted seedling rapid healing cultivation method, the survival rate of the tea-oil tree grafted seedling can be more than 95%, and dead stock seedlings are eliminated in time; the wastes of time and raw materials are avoided, and the sprouting of the grafted seedlings is brought forwards for more than one month; the cost is reduced by 30% and the seedlings can be bred all the year round.

Owner:建水县浩野农林产业有限公司

Temperature detecting device based on natural gas heating system

InactiveCN104236753AAvoid wastingSimple structureThermometer applicationsLED displayTemperature difference

The invention provides a temperature detecting device based on a natural gas heating system. The temperature detecting device comprises a device body. The device body comprises a device cover and a base. Through holes are formed in the centers of the two sides of the device body. An LED display screen, a power indicator light, an alarm light and a horn are arranged on the outer surface of the device cover, a PCB is arranged on the inner side of the device cover and fixedly connected with the device cover, the PCB is provided with a temperature sensor, and the temperature sensor is fixedly connected with the PCB. Buckles are arranged inside the device cover, the device cover is fixedly connected with the base through the buckles, a wiring hole is formed in the center of the base, and a vent hole is formed in the base. The temperature detecting device has the advantages of being simple in structure, easy to install, movable and capable of displaying the temperature and the temperature difference in real time, an alarm can be given when the temperature difference exceeds the set range, the temperature is adjusted in time, and the energy waste is prevented.

Owner:TIANJIN NUOCHENG NATURAL GAS

Vacuum induction melting furnace equipment for casting alloy melting and its working method

ActiveCN111854432BAdjust the pressure in timeAdjust the pressure value in timeCharge manipulationCrucible furnacesCasting moldMetal

Owner:宁国市华成金研科技有限公司

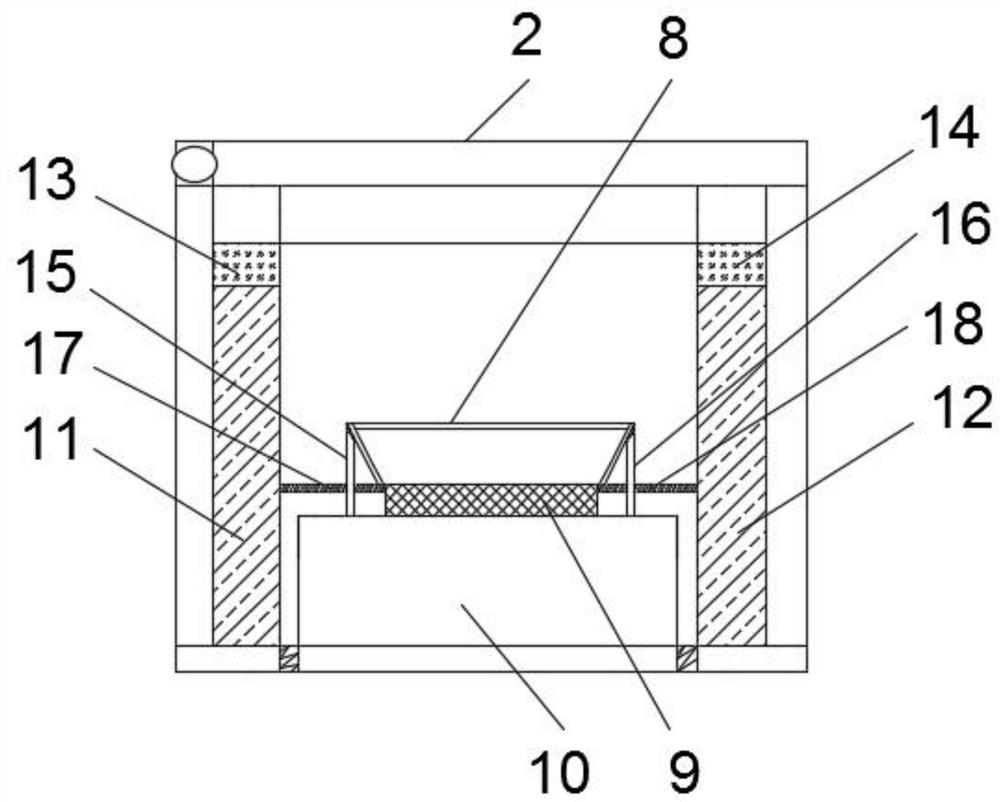

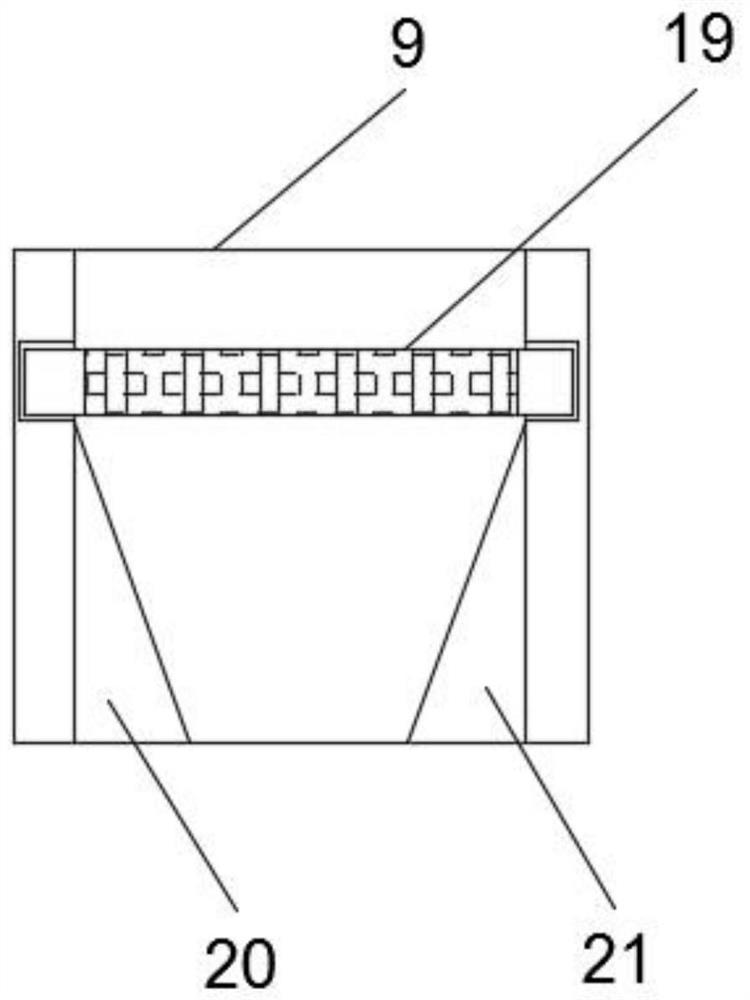

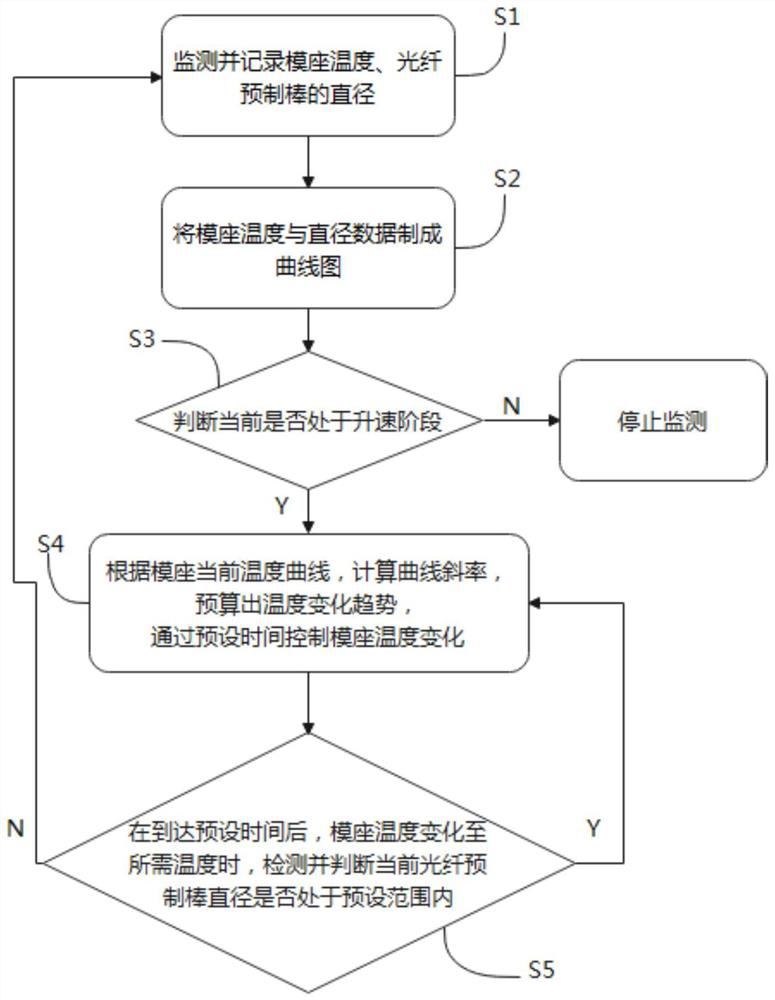

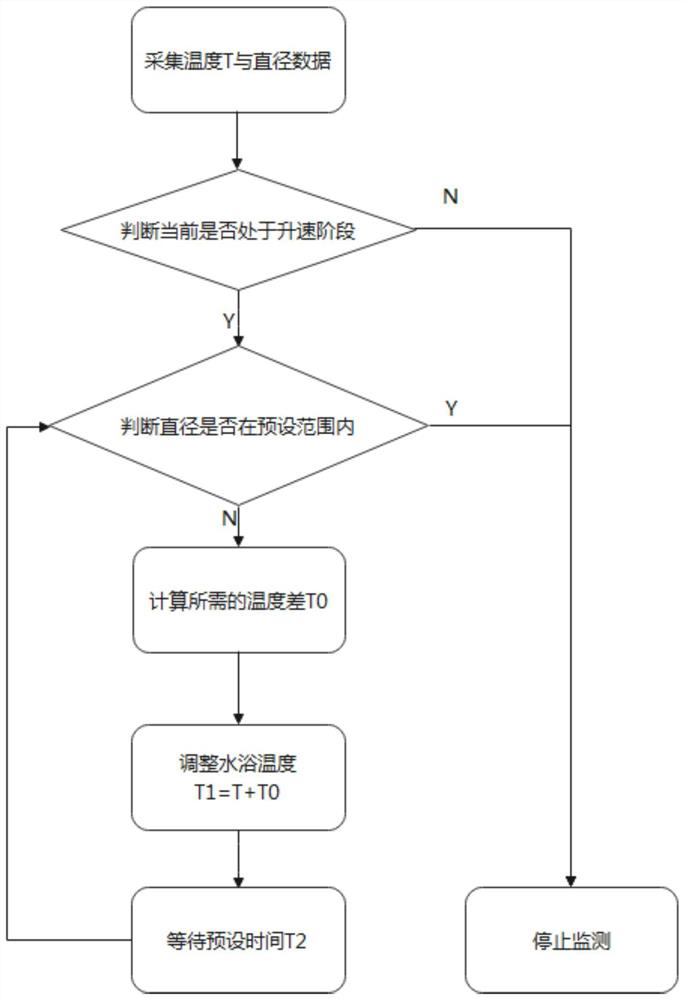

Temperature control method for optical fiber preform acceleration mold base, computer medium and computer

ActiveCN114326859AShort response timeImprove compliance rateGlass making apparatusTemperatue controlPhysicsEngineering

The invention relates to a temperature control method for an optical fiber preform acceleration mold holder, a computer medium and a computer, and the temperature control method for the optical fiber preform acceleration mold holder comprises the following steps: S1, monitoring and recording the temperature of the mold holder and the diameter of an optical fiber preform; s2, making a curve graph according to the temperature and diameter data of the die holder; s3, judging whether the current state is in a speed increasing stage or not; s4, according to the current temperature curve of the die holder, the curve slope is calculated, the temperature change trend is estimated, and the temperature change of the die holder is controlled through preset time; and S5, detecting and judging whether the diameter of the current optical fiber preform is in a preset range or not when the temperature of the die holder is changed to the required temperature after the preset time is up. According to the method for controlling the temperature of the speed-increasing die holder of the optical fiber preform, the temperature change trend is estimated according to the curve slope calculated according to the current curve graph, the temperature change of the die holder is controlled, the response time is shortened, and the temperature of the die holder is adjusted in time, so that the standard-reaching rate of the coating diameter of the optical fiber preform is increased.

Owner:江苏南方光纤科技有限公司

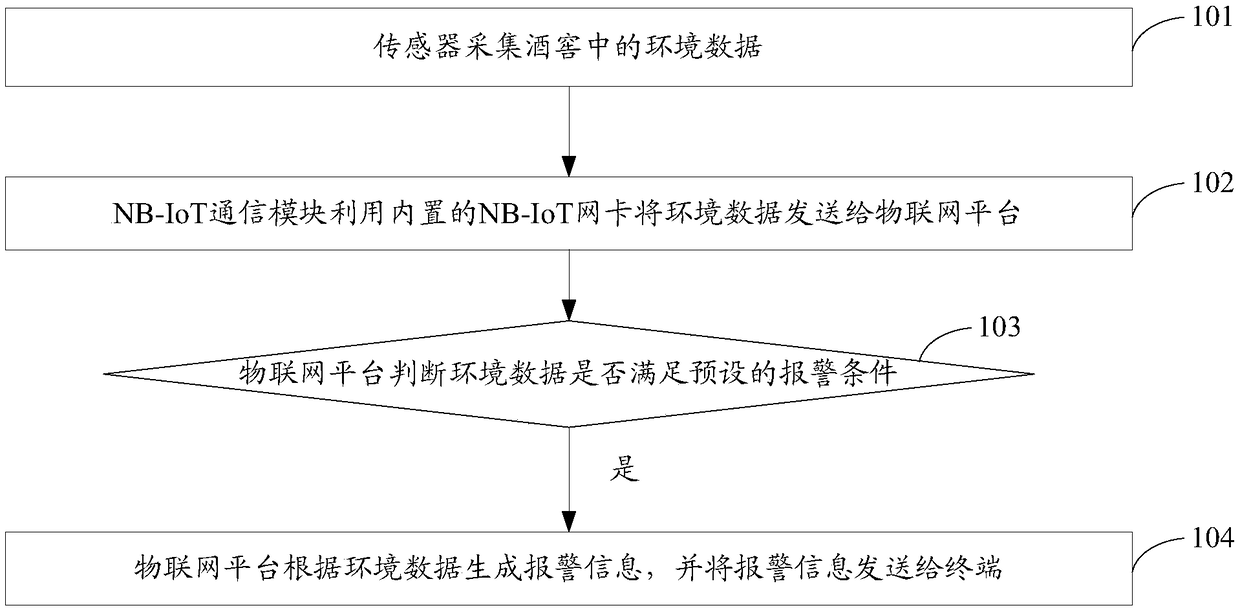

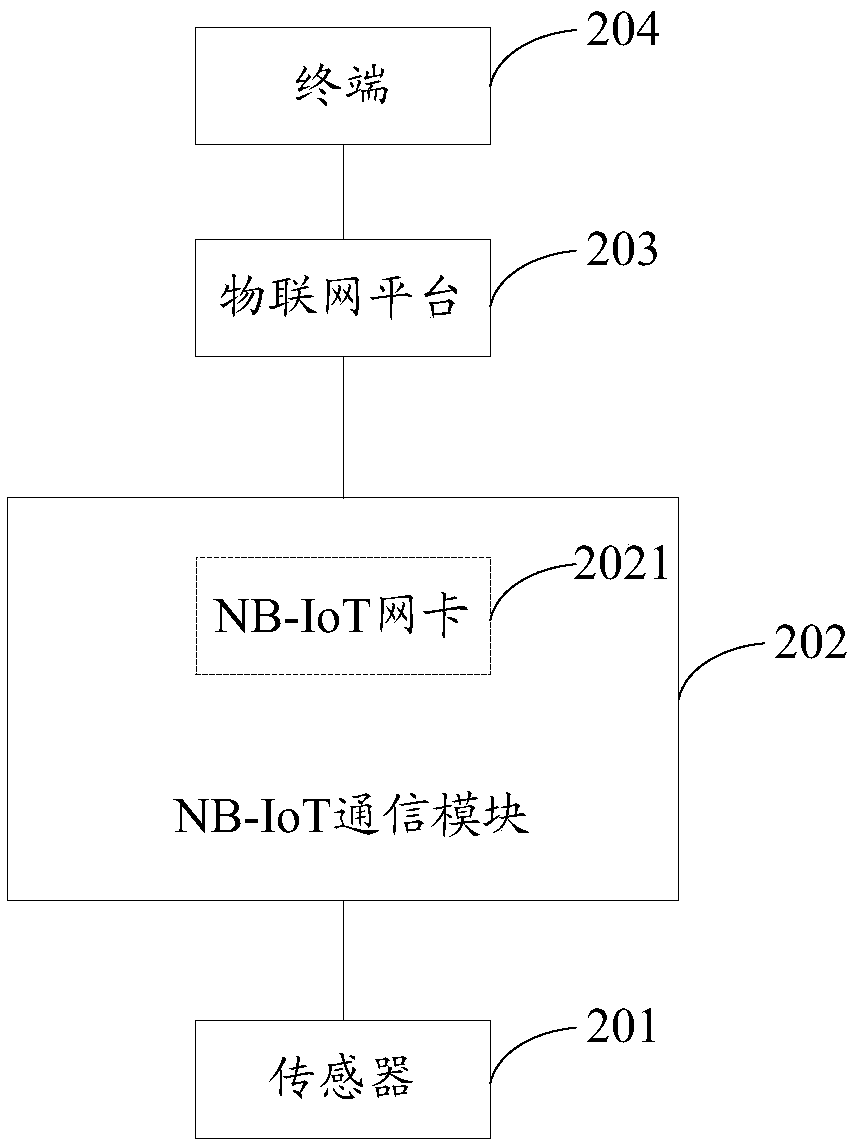

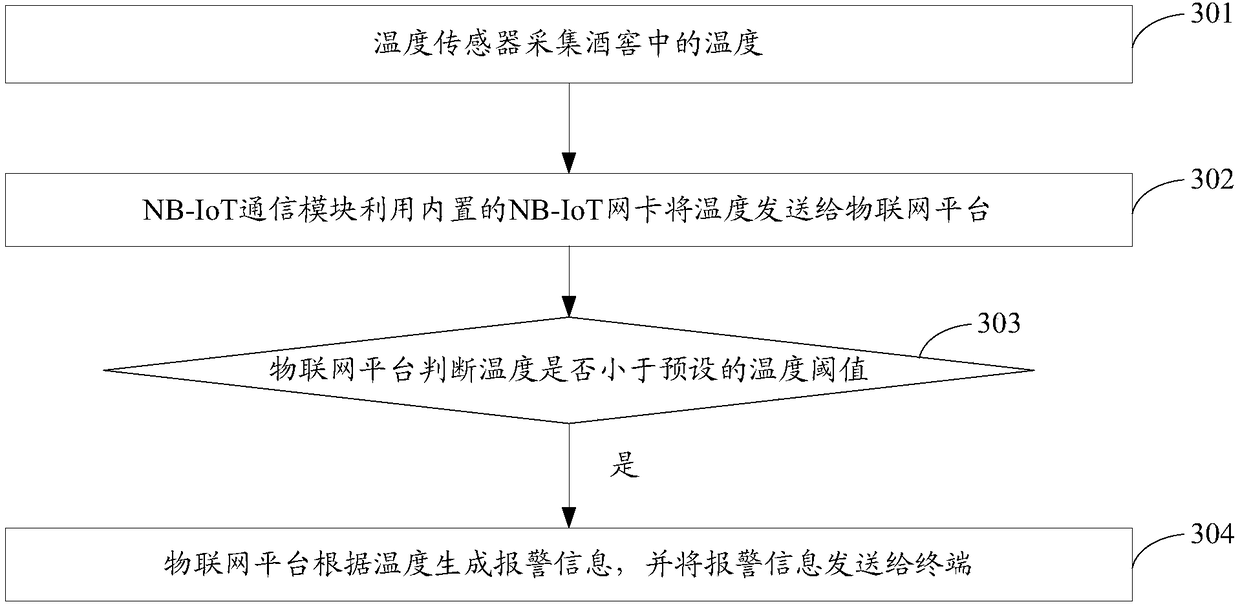

NB-IoT-based wine cellar monitoring method and system

InactiveCN108592983ALow costAdjust the temperature in timeMeasurement devicesTransmission systemsNarrow bandInternet of Things

The invention provides a narrow band-Internet of things (NB-IoT)-based wine cellar monitoring method and system. The method comprises the steps that a sensor collects environmental data in a wine cellar; an NB-IoT communication module utilizes a built-in NB-IoT network card for sending the environmental data to an Internet of things platform; the Internet of things platform judges whether or not the environmental data meets preset warning conditions, and if yes, the Internet of things platform generates warning information according to the environmental data and sends the warning information to a terminal. According to the scheme, the wine cellar monitoring cost can be lowered.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

Adjustable cold compress bag

InactiveCN106389001AEasy to useControl the degree of coolingTherapeutic coolingTherapeutic heatingElectricityCold compresses

The invention discloses an adjustable cold compress bag, which comprises a deformable cold compress bag body, a control body which is fixedly arranged at one side of the cold compress bag body and a control unit which is arranged in the control body, wherein a plurality of cold compress areas are arranged in the cold compress bag body, and some cold compress areas are filled with first reaction mediums; a plurality of accommodating portions are arranged in the control body, and some accommodating portions are filled with second reaction mediums; the cold compress areas and the accommodating ports correspondingly communicate, and switch valves, which are electrical connected to the control unit, are arranged on communicating pipelines; and the first reaction mediums and the second reaction mediums can participate in an endothermic reaction. With the application of the adjustable cold compress bag provided by the invention, a refrigerating degree can be controlled so as to facilitate a user, and temperature can be adjusted timely so as to prevent freezing injury.

Owner:NANJING JINGZHIQING GREENHOUSE ENG

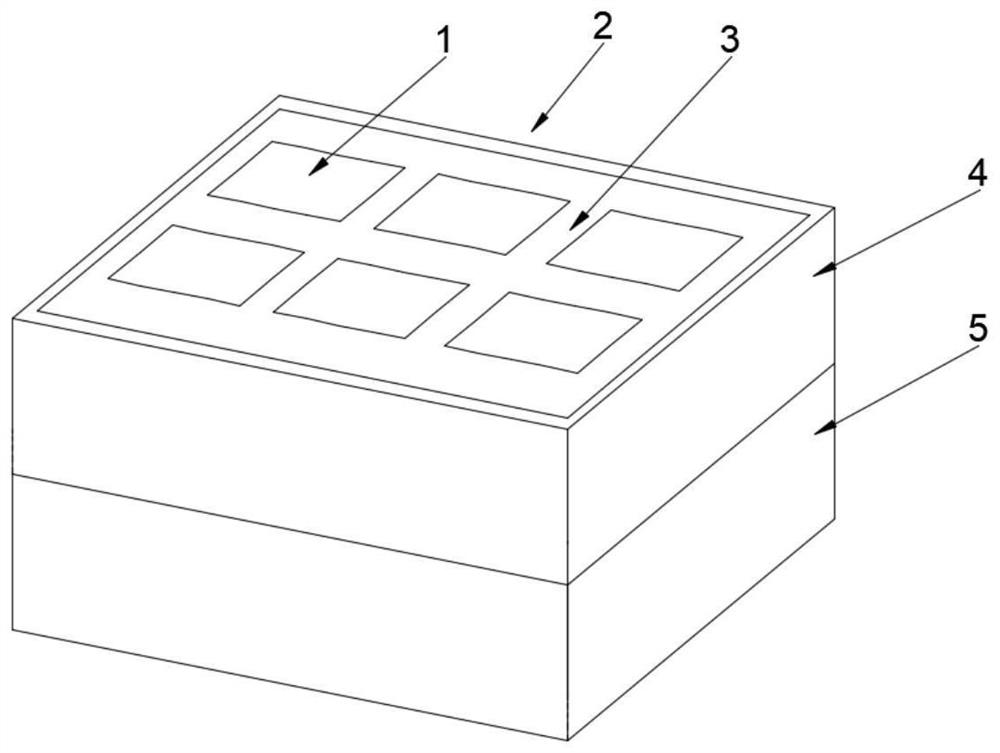

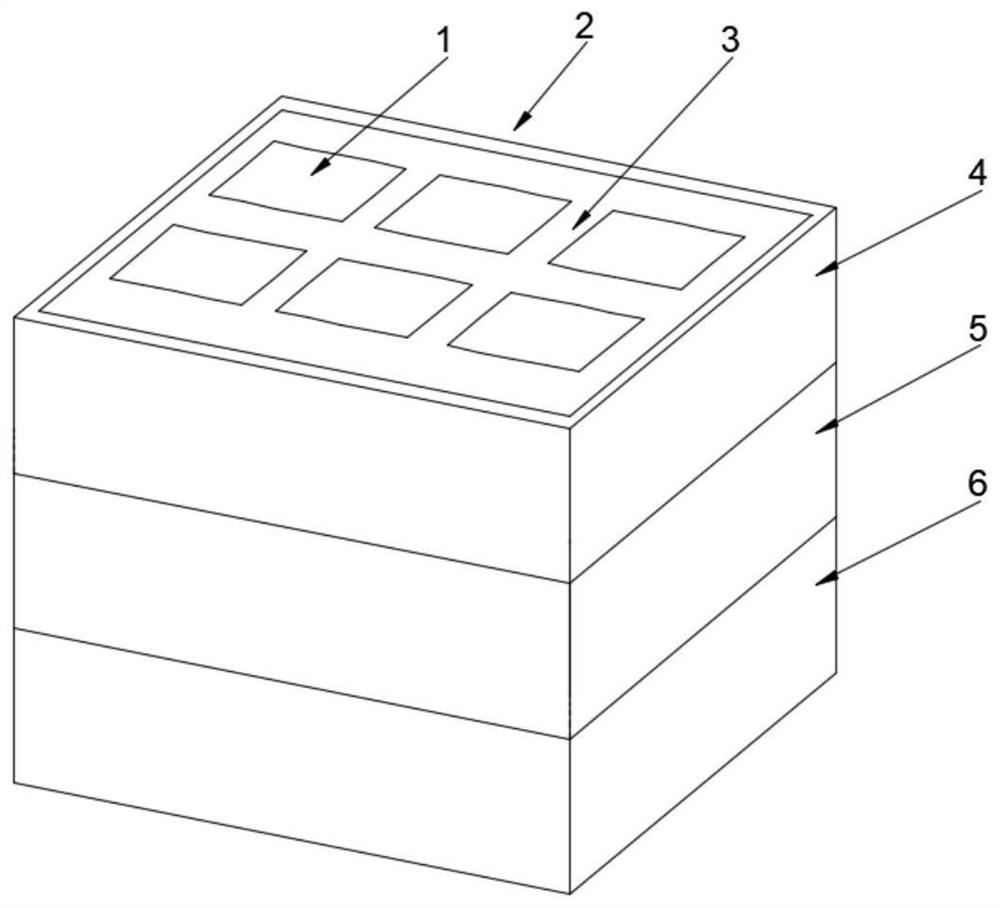

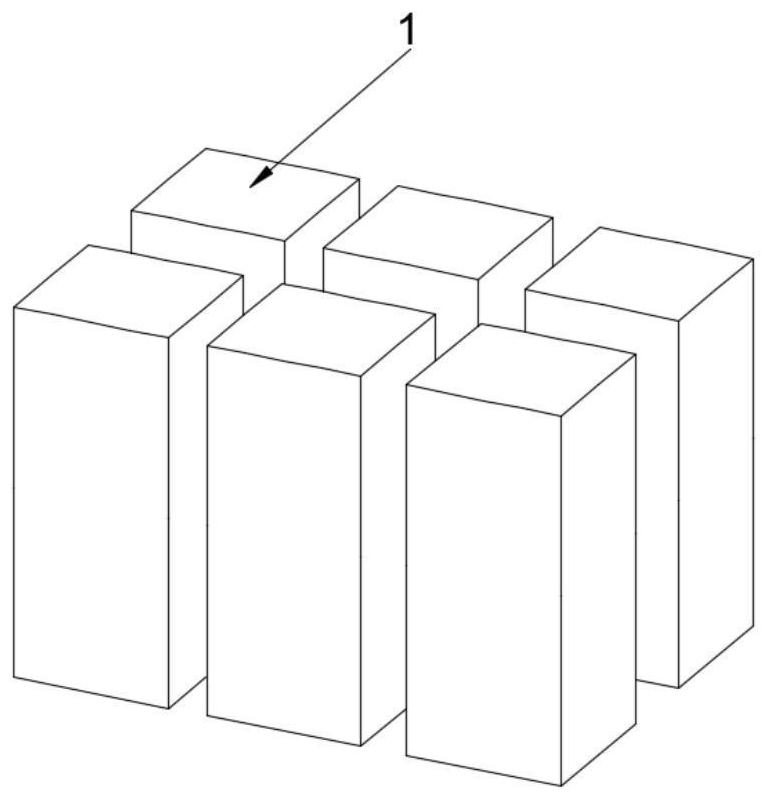

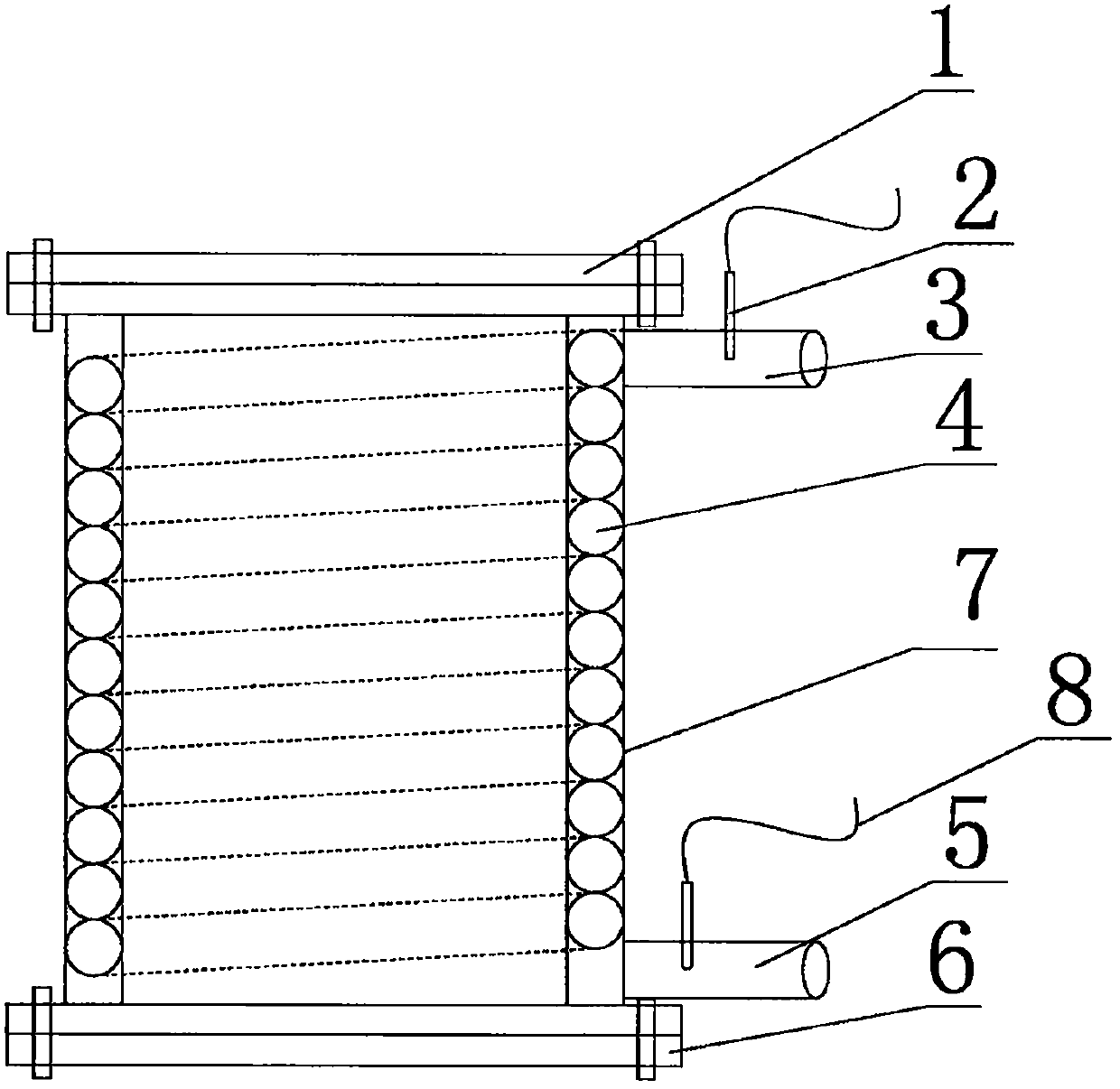

Hierarchical battery temperature control device of supercooled phase change material and temperature control method of hierarchical battery temperature control device

PendingCN114284599ATo achieve the purpose of warming upAdjust the temperature in timeCell temperature controlCell component detailsPower batteryTemperature control mode

The invention belongs to the technical field of thermal management of power batteries, and particularly relates to a graded battery temperature control device of a supercooled phase change material and a temperature control method of the graded battery temperature control device. Each stage of cavity is filled with a supercooled phase change material, and the battery is wrapped by the supercooled phase change material; the supercooled phase change material can be in a supercooled non-solidification state in a low-temperature environment and absorbs heat to be melted in a high-temperature environment; an active triggering mechanism is arranged at the bottom of each stage of cavity and is used for triggering the solidification process of the supercooled phase change material in the cavity; and the controller is used for controlling the start and stop of the active triggering mechanism of the one-stage or multi-stage cavity according to the battery temperature. The working mode in winter is a preheating mode and a temperature control mode, the working mode in summer is a single temperature control mode, and by means of grading setting, refined temperature control over the battery is achieved, and the purpose of preventing the temperature of the battery from being too high is achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Improved pulper vertical pipe

InactiveCN107780279ATemperature online monitoringAdjust the temperature in timePulp beating/refining methodsWater circulationPapermaking

The invention relates to an improved standpipe of a refiner, which comprises a hollow cylindrical standpipe body, the upper end of the standpipe body is connected with an upper flange connected with the refiner, and the lower end of the standpipe body is connected with a screw feeder. The lower flange connected to the feeder, the joints between the upper flange and the lower flange and the standpipe body are provided with gaskets, the inner wall of the riser pipe is provided with interlayers, and a spiral arrangement is arranged in the interlayers. The hot water pipe is used for passing in hot water, and the upper end and the lower end of the hot water pipe are respectively provided with a water inlet and a water outlet. In the present invention, a hot water circulation system is arranged on the inner wall of the standpipe of the refiner, and the standpipe of the refiner is insulated with hot water, which prevents the formation of condensed water due to the temperature difference between the inside and outside, thereby solving the problem of fiber falling and affecting the papermaking process.

Owner:顾亚萍

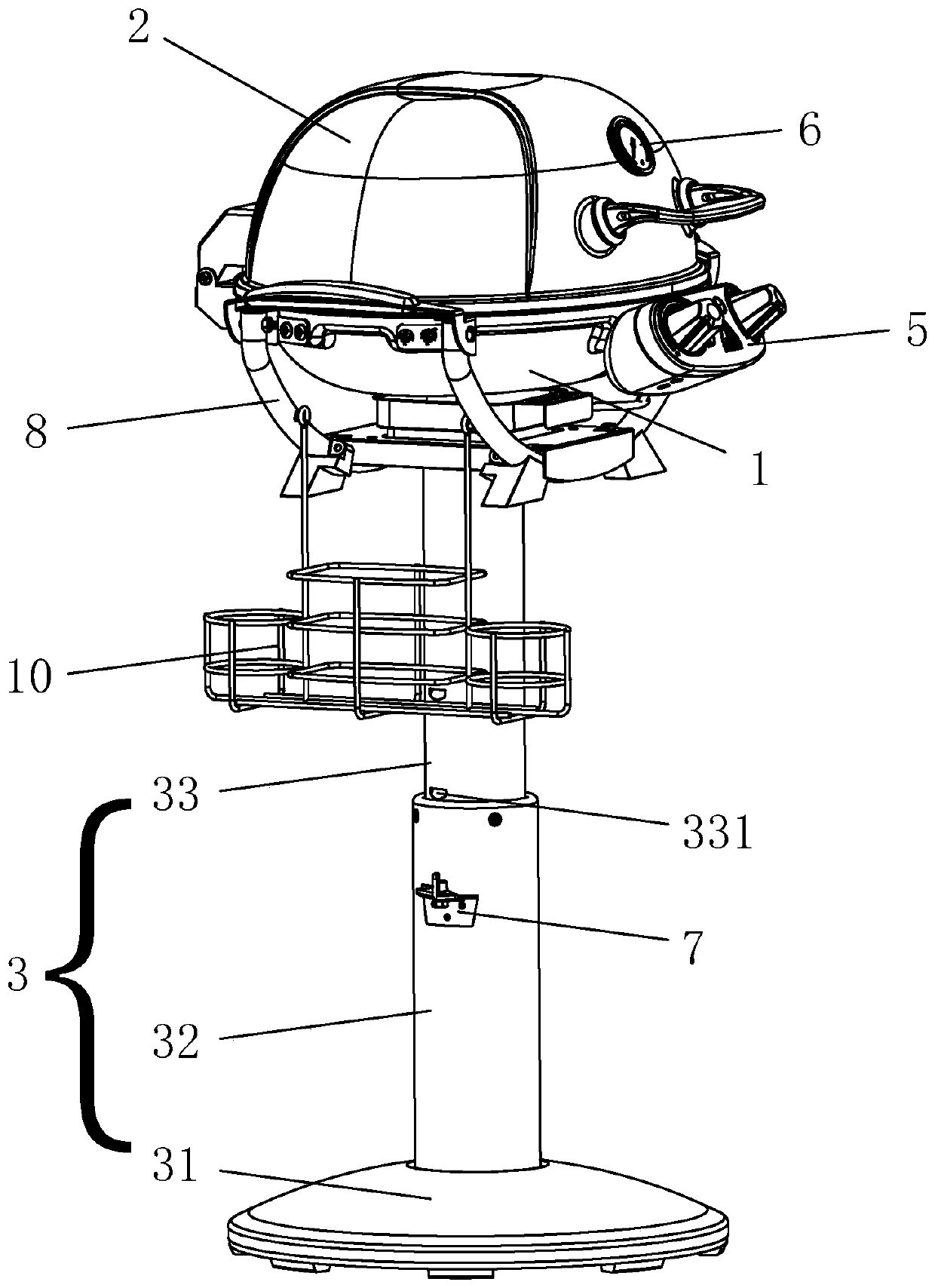

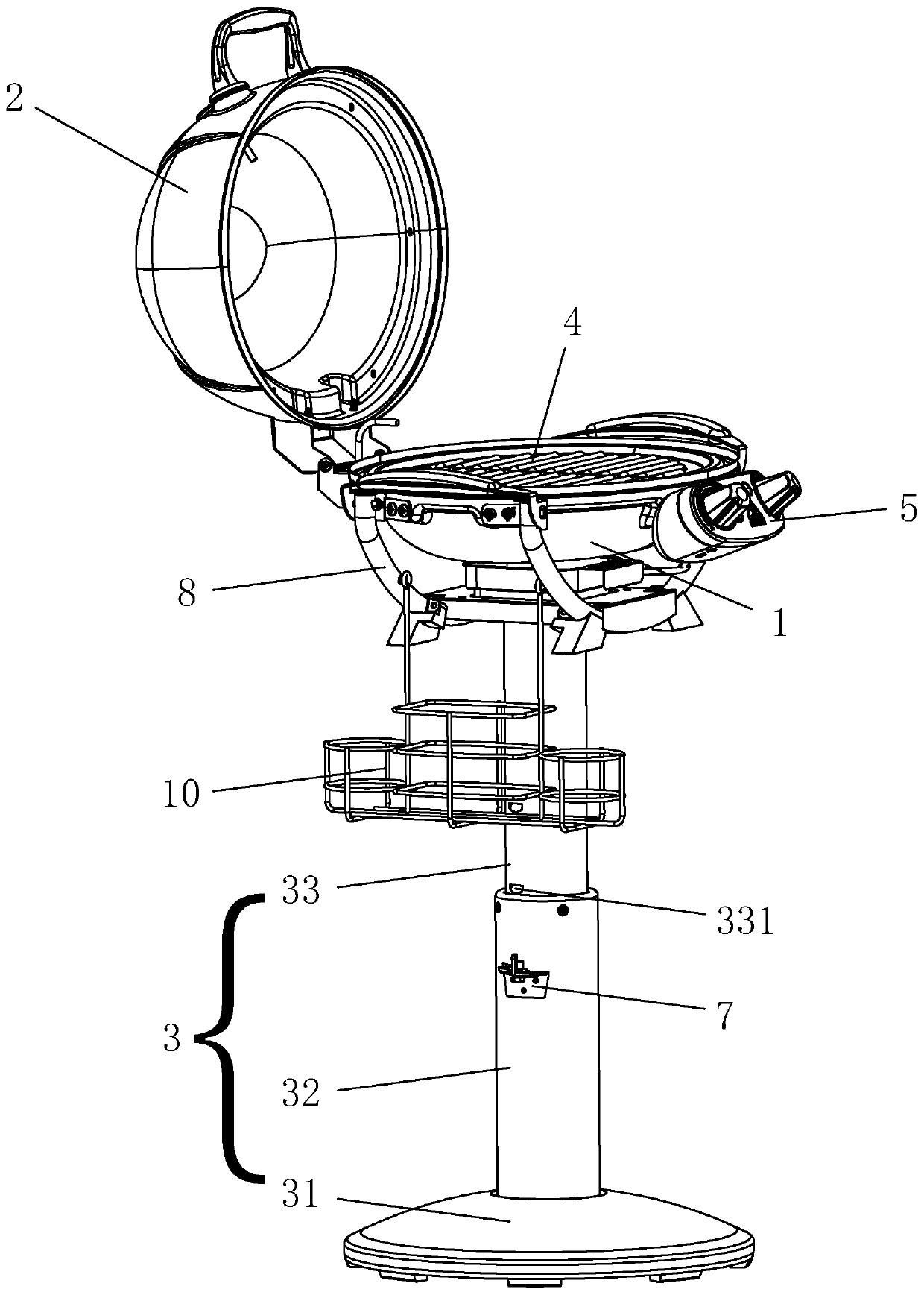

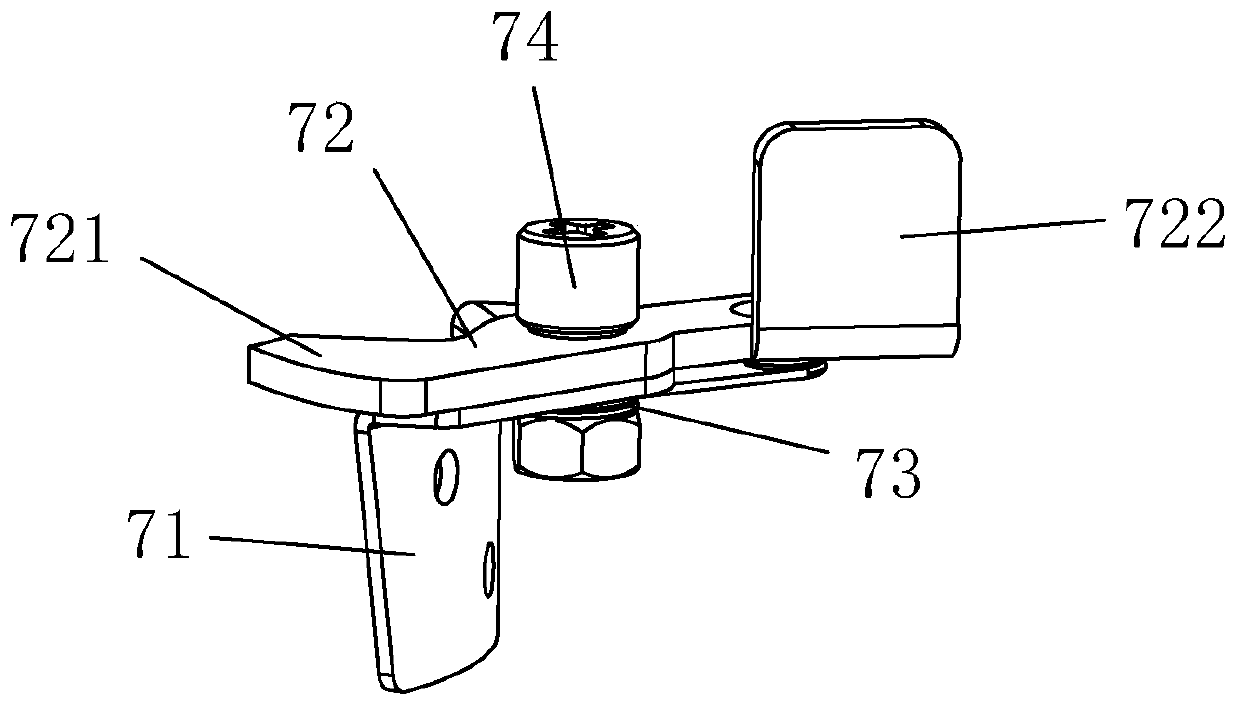

Standing type electric oven

PendingCN110916524ARealize standing liftHeight adjustableRoasters/grillsEngineeringMechanical engineering

The invention relates to a standing type electric oven which comprises a bottom shell and a top cover hinged to the bottom shell, a liftable supporting leg assembly is arranged at the lower end of thebottom shell, standing type lifting can be achieved, the height can be rapidly adjusted, the standing type electric oven can be used without being placed on a table, and the standing type electric oven is particularly suitable for outdoor use. The bottom shell is detachably connected with the supporting leg assembly, the electric oven can be placed on an indoor table to be used after the supporting leg assembly is detached, and the universality is high; a baking tray and a first heating assembly located at the lower end of the baking tray are arranged in the bottom cover, a second heating assembly located at the upper end of the baking tray after the top cover covers the bottom shell is arranged in the top cover, and a control device used for controlling the first heating assembly and thesecond heating assembly is further arranged on the outer side of the bottom shell. Simultaneous heating of the upper surface and the lower surface is realized through respective control of the control device, so that food can be quickly baked without turning over, and convenience and quickness are realized; in addition, the temperature displayer is arranged on the top cover, the temperature in the oven is monitored in real time, and a user can conveniently adjust the temperature in time.

Owner:ZHONGSHAN FENGYE ELECTRICAL APPLIANCE CO LTD

Carbon roaster preheating area volatile component monitoring and temperature controlling device and method

PendingCN110207502ATo achieve the purpose of warming upAdjust the temperature in timeDesign optimisation/simulationControl devices for furnacesAir doorPressure range

The invention relates to a carbon roaster preheating area volatile component monitoring and temperature controlling device and method. On the basis of an existing roaster flame control system, a detecting control device is additionally arranged in a preheating area, the control device comprises a rack which is provided with a cross arm beam frame body, a temperature measuring device, a pressure measuring device and an image collecting device are arranged on the cross arm beam frame body, and a pulse igniter is further arranged on the cross arm beam frame body. Under control of the control device, with a certain negative pressure range, by adjusting the opening degree of an air door of a smoke exhausting frame, the temperature of a flame path is controlled, and when the negative pressure reaches the range limit value, and the temperature in the preheating area does not reach the target value, by means of a self-absorbing type pulse combustor inserted into the flame path and provided with ignition and flame detection, the purpose of setting the temperature curve of the flame path of the preheating area according to the technology for temperature rising can be achieved. The device andthe method have the advantages of accurately analyzing the escape and combustion circumstances of volatile components in the preheating area online in real time, and adjusting the temperature of thepreheating area in time.

Owner:河南华索科技有限公司

A nickel-gold device

ActiveCN108149291BRealize automated productionQuality improvementCellsPrinted circuit manufactureTemperature controlElectricity

The invention discloses a nickel-gold depositing device. The nickel-gold depositing device comprises a support, a control assembly, a nickel cylinder arranged on the support, and a material frame; thematerial frame is arranged on the upper portion of the nickel cylinder; the nickel cylinder is internally provided with a temperature control system, a charging assembly and an electroplating assembly; the temperature control system, the charging assembly and the electroplating assembly are all electrically connected with the control assembly; and a defoaming device is further arranged on the nickel cylinder. According to the nickel-gold depositing device, the temperature control system used for controlling the temperature of a solution in the nickel cylinder, the charging assembly used for adding nickel ions and the electroplating assembly used for increasing the electroplating speed are arranged in the nickel cylinder and all electrically connected with the control assembly, nickel depositing automatic production can be effectively achieved by controlling the temperature control system, the charging assembly and the electroplating assembly through the control assembly so that the solution temperature can be adjusted timely, the nickel ion solution can be added automatically and the magnitude of the electroplating current can be adjusted according to the solution temperature andthe nickel ion concentration in the nickel cylinder in the nickel depositing process of a circuit board, thus, the nickel-gold depositing device can adapt to electroplating work of the different circuit boards automatically, and the automation degree is high.

Owner:珠海市鸿天万达电子科技有限公司

A kind of radiofrequency ablation electrode and radiofrequency ablation system for renal sympathetic nerve

The present invention relates to a radiofrequency ablation electrode for renal sympathetic nerve and a radiofrequency ablation system. The radiofrequency ablation electrode for renal sympathetic nerve includes a first electrode and a second electrode, and the first electrode and the second electrode have opposite polarity. Two electrodes with opposite polarities can effectively control the flow direction and range of the current, so that the radiofrequency ablation energy is more concentrated, so it can accurately burn the renal sympathetic nerves on the outer wall of the renal artery without damaging organs and tissues outside the target treatment range Cause unnecessary damage and have the advantage of being less destructive. And because the radiofrequency ablation energy is concentrated, the renal sympathetic nerves on the outer wall of the renal artery can be burned accurately and quickly, which greatly shortens the operation time and is beneficial to the postoperative recovery of the patient.

Owner:CARDEA MEDSYST TIANJIN

Production process of health-care beer

InactiveCN113462495ARich in nutritional valueHighlight the role of medicine and health careWort preparationBeer fermentationBiotechnologyChaptalization

The invention relates to the technical field of health-care beer, in particular to a production process of health-care beer. The production process comprises the following steps: storing Tibetan highland barley, feeding the Tibetan highland barley into a screening mechanism through a feeding machine, and performing crushing treatment: crushing the Tibetan highland barley and Chinese wolfberry fruits through a crusher; performing a gelatinization process: adding the crushed Tibetan highland barley and Chinese wolfberry fruits into a gelatinization device for uniform gelatinization; adding fermentation yeast: transferring the gelatinized Tibetan highland barley and medlar into a stirring device, and adding distiller's yeast into the stirring device; performing a saccharification process: mixing the product of the previous process in a saccharification chamber for saccharification, then filtering, and a fermentation process: cooling the boiled liquid in a cooling chamber, and fermenting in a fermentation chamber; filtering: performing secondary filtering on the fermented product, and filling. The invention provides the production process of the health-care beer which is good in drinking taste, has a health-care effect and brews the Tibetan highland barley and the Chinese wolfberry fruits.

Owner:朱许洪

A kind of small size and slender special carbon material one-time molding roasting furnace material box

ActiveCN108106430BEffective vertical fixationNo need to worry about bending, softening and damageFurnace componentsFurnace typesBrickMaterials science

The invention discloses a small-specification slender special carbon material once molding roasting burden box. The small-specification slender special carbon material once molding roasting burden boxcomprises a furnace body and a fixed box; the furnace body is built by lattice bricks, and four corners adopt corner lattice bricks; the furnace body is of a rectangular structure opened at the upperpart, and is provided with transverse brackets at the middle part and the bottom; the bracket at the middle part serves as a two-layer bracket; the bracket at the bottom serves as a one-layer bracket; multiple bases in rectangular matrixes are mounted above the one-layer bracket and the two-layer bracket; fixed boxes are mounted on the inner sides, and are of long cylinder structures; fixed gridsare mounted in the fixed boxes, and are rectangular lattice frames consisting of multiple metal pieces to form fixed holes; the outer ends of the fixed grids are tightly bonded with the inner walls of the fixed boxes; a bottom fire way is arranged below the furnace body; lower temperature measuring heads are arranged below the bases; and middle temperature measuring heads and upper temperature measuring heads are arranged at the middle parts and the tops of the fixed boxes. The small-specification slender special carbon material once molding roasting burden box can effectively realize fixation of finished products, and improves the yield.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com