Improved pulper vertical pipe

A refiner and standpipe technology, applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc., can solve problems such as clogging equipment, large temperature difference between inside and outside refiner standpipe, affecting papermaking process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

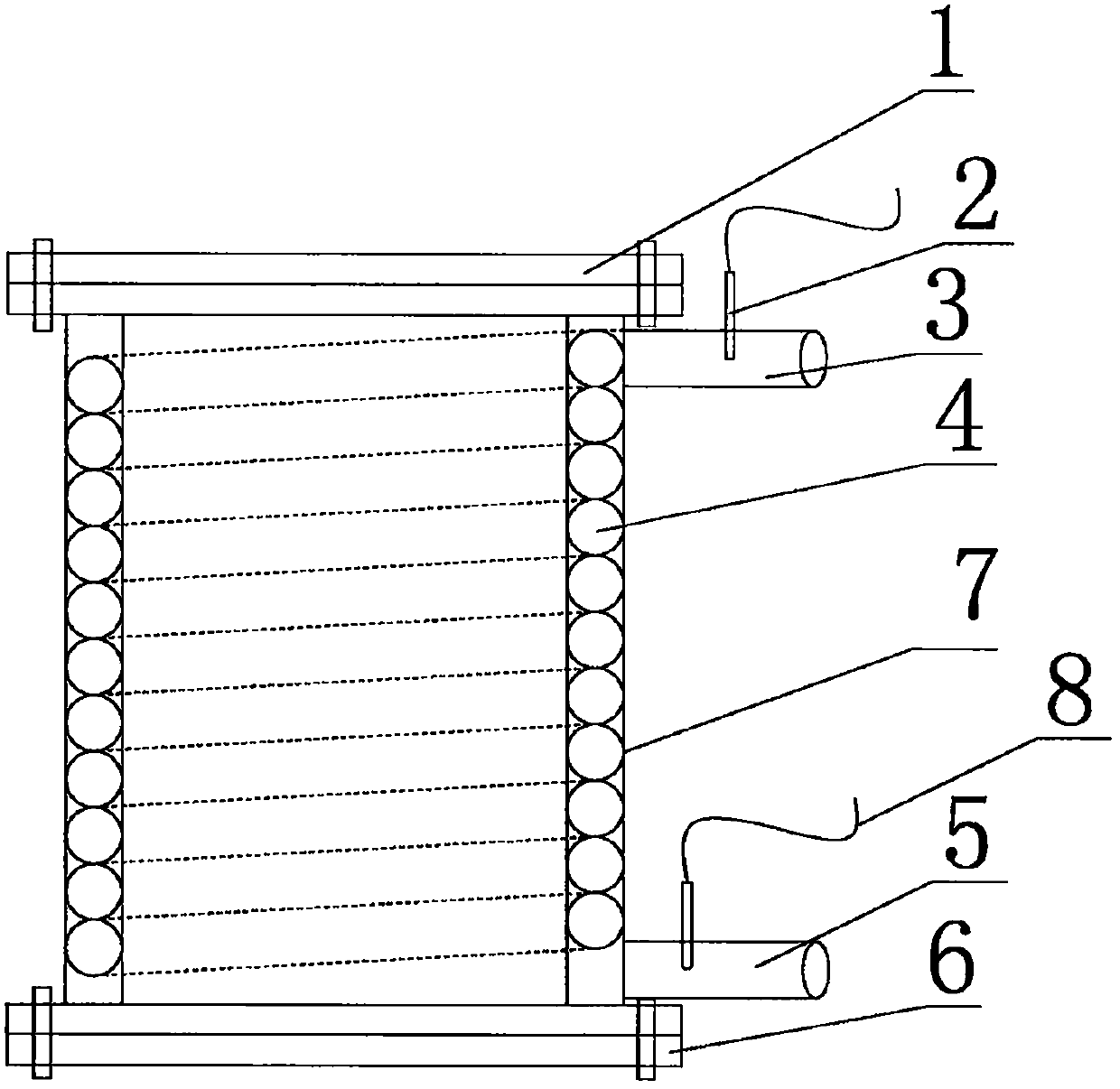

[0012] Such as figure 1 As shown, this embodiment provides an improved refiner standpipe, including a hollow cylindrical standpipe body 7, the upper end of the standpipe body 7 is connected with an upper flange 1 connected to the refiner, and the riser pipe The lower end of the body 7 is connected with the lower flange 6 connected with the screw feeder, the joints of the upper flange 1 and the lower flange 6 and the standpipe body 7 are provided with gaskets, and the riser body 7 The inner wall is provided with an interlayer, and in the interlayer is provided a spirally arranged hot water pipe 4 for passing in hot water. The upper and lower ends of the hot water pipe 4 are respectively provided with a water inlet 3 and a water outlet 5. 80 degrees Celsius Hot water enters from the water inlet 3 and is discharged from the water outlet 5, which effectively ensures that there is no temperature difference between the inside and outside of the standpipe of the refiner.

Embodiment 2

[0014] This embodiment provides an improved standpipe of a refiner, including a hollow cylindrical standpipe body 7, the upper end of the standpipe body 7 is connected with an upper flange 1 connected to the refiner, and the lower end of the standpipe body 7 is The lower flange 6 connected with the screw feeder is connected, and the joints between the upper flange 1 and the lower flange 6 and the standpipe body 7 are provided with gaskets, and the inner wall of the standpipe body 7 is provided with The interlayer is provided with a spirally arranged hot water pipe 4 inside the interlayer for passing in hot water. The upper and lower ends of the hot water pipe 4 are respectively provided with a water inlet 3 and a water outlet 5 . The position of the water inlet 3 is provided with a first temperature sensor 2 for online measurement of the temperature of the water inlet.

Embodiment 3

[0016] This embodiment provides an improved standpipe of a refiner, including a hollow cylindrical standpipe body 7, the upper end of the standpipe body 7 is connected with an upper flange 1 connected to the refiner, and the lower end of the standpipe body 7 is The lower flange 6 connected with the screw feeder is connected, and the joints of the upper flange 1 and the lower flange 6 and the standpipe body 7 are provided with sealing gaskets, and the inner wall of the standpipe body 7 is provided with The interlayer is provided with a spirally arranged hot water pipe 4 inside the interlayer for passing in hot water. The upper and lower ends of the hot water pipe 4 are respectively provided with a water inlet 3 and a water outlet 5 . The position of the water outlet 5 is provided with a second temperature sensor 8 for online measurement of the temperature of the water outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com