Temperature control method for optical fiber preform acceleration mold base, computer medium and computer

A temperature control method and optical fiber preform technology, applied in the direction of temperature control, control/regulation system, non-electrical variable control, etc., can solve the problem of long response time of water bath, untimely adjustment of mold base temperature, and coating diameter of optical fiber preform. the reduction of the compliance rate, etc., to achieve the effect of shortening the response time and improving the compliance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

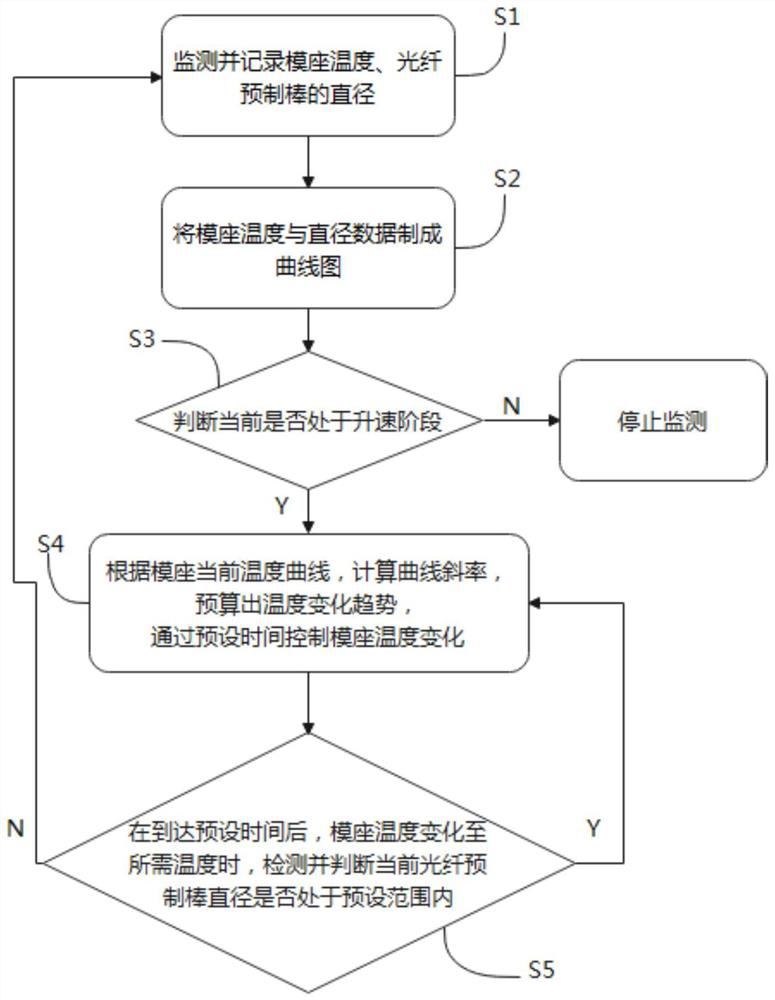

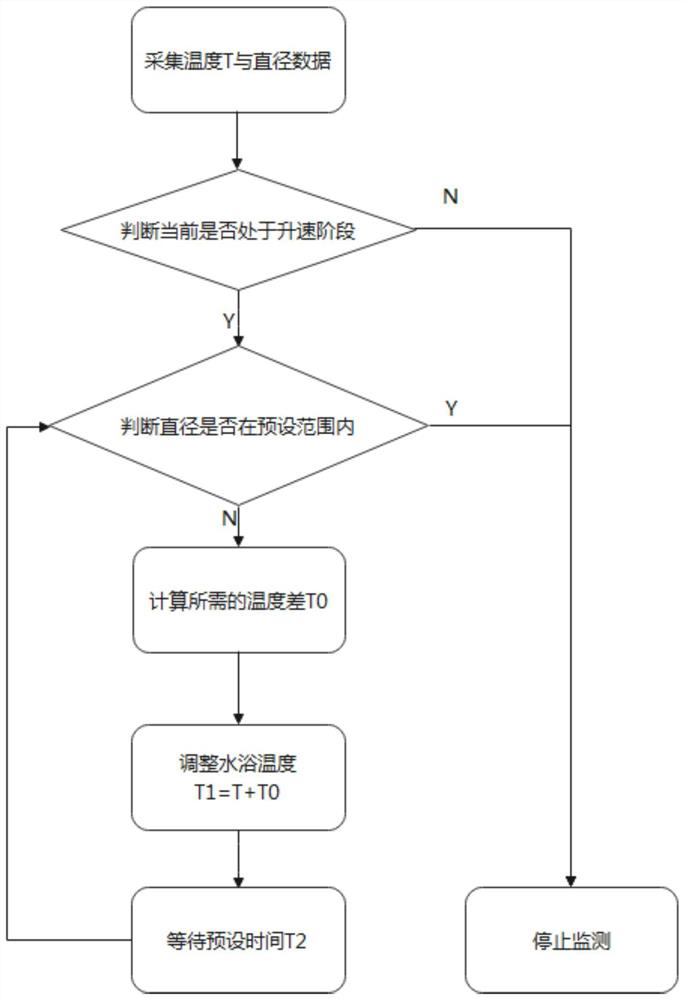

[0032] In some embodiments, referring to figure 1 As shown, a method for controlling the temperature of an optical fiber preform speed-up mold base of the present invention comprises the following steps:

[0033] S1: Monitor and record the mold base temperature and the diameter of the optical fiber preform;

[0034] S2: Make a graph of the mold base temperature and diameter data;

[0035] S3: Judging whether it is currently in the speed-up stage, if not, stop monitoring, if so, execute step S4;

[0036] S4: According to the current temperature curve of the mold base, calculate the slope of the curve, estimate the temperature change trend, and control the temperature change of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com