Drying unit of printing machine

A technology of drying device and printing machine, applied in printing machine, printing machine, general parts of printing machine, etc., can solve the problems of increased hot air humidity, low drying efficiency, easy to paste, etc. Drying efficiency, the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the drawings.

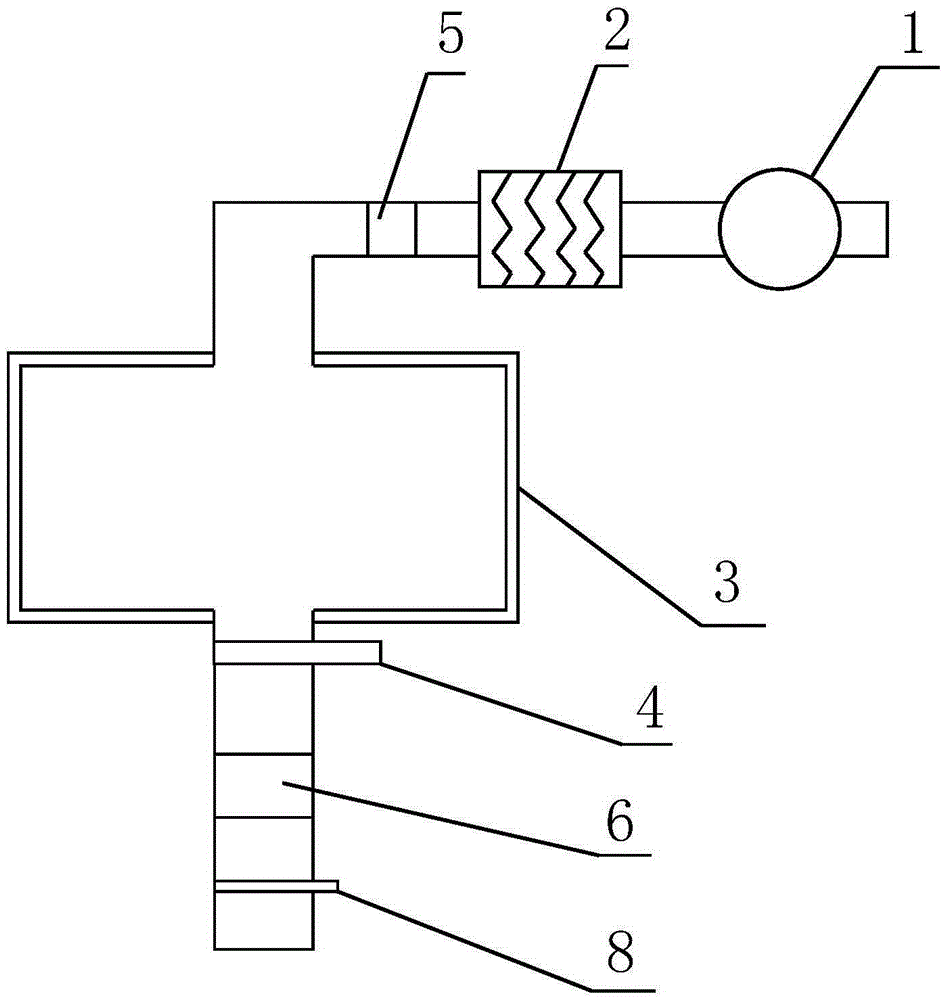

[0014] Such as figure 1 As shown, the printing press drying device provided by the present invention includes a fan 1, a heater 2, and an oven 3 connected in sequence, the outlet of the fan 1 is connected with the inlet of the heater 2, and the outlet of the heater 2 is connected with the inlet of the oven 3. , The oven 3 also has an outlet. The type of the fan 1 is not limited, and it is preferably a blower. The heater 2 is a heater that can adjust the heating temperature.

[0015] The present invention also includes a baffle 4 for changing the area of the outlet of the oven 3, and the baffle 4 is located at the outlet of the oven 3. The baffle 4 is provided with scale marks for easy operation by the operator.

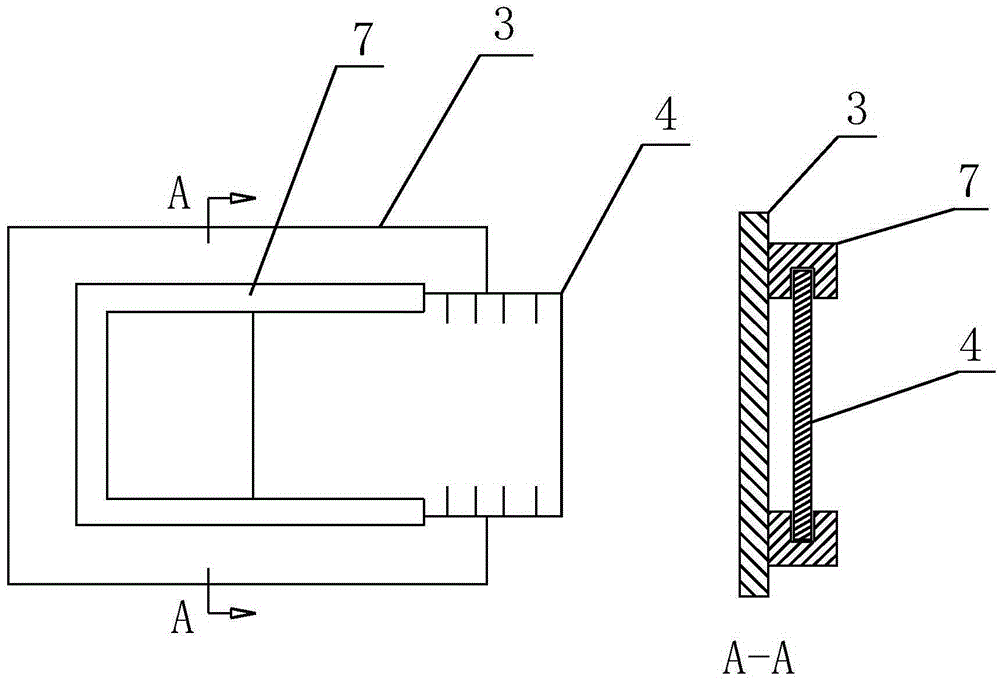

[0016] Such as figure 2 As shown, a limit fixing device 7 is fixedly installed on the outlet of the oven 3, the limit fixing device 7 is located at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com