Device for reducing generation of biuret in urea ammonium nitrate solution industrial production process and application method thereof

A technology of urea ammonium nitrate and biuret, which is applied in the direction of fertilization equipment, ammonium nitrate fertilizer, urea compound fertilizer, etc., can solve the problem of obvious increase, generally reaching 0.5-1.5%, crystallization of urea solution, long urea residence time, etc. problems, to achieve the effect of improving product quality, long residence time, and optimizing production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

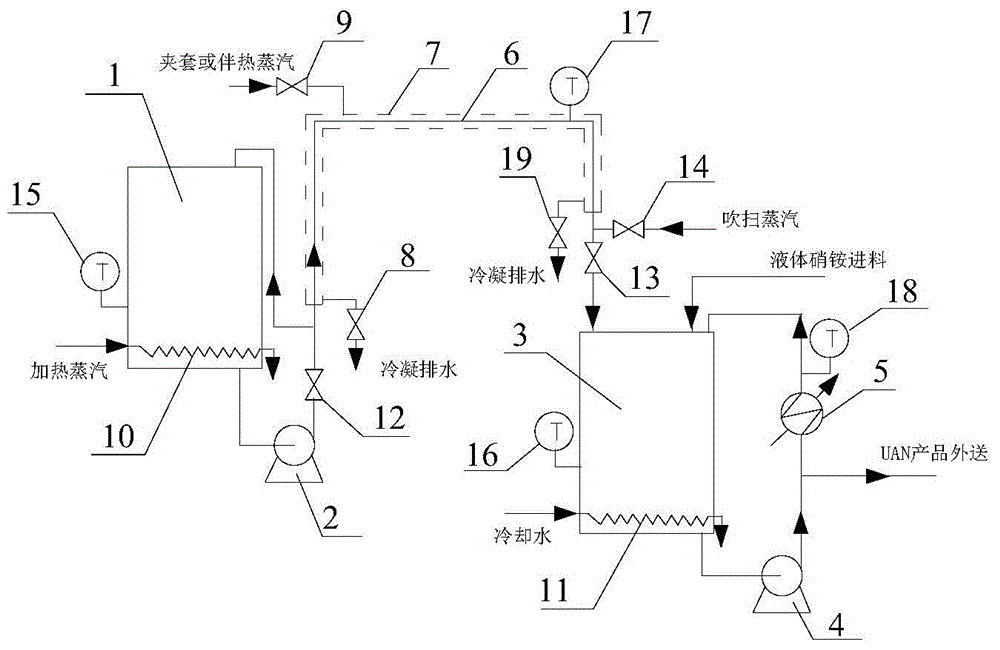

Image

Examples

Embodiment 2

[0044] The difference from Example 1 is that the heating steam described in step (a) has a steam pressure of 0.3 MPa and a temperature of 130° C.; the steam heating coil uses a steam pressure of 0.3 MPa and a temperature of 130° C.; the step ( The concentration of the urea solution in c) is 68%, and the temperature of the liquid ammonium nitrate solution is 160°C.

[0045] Sampling and analysis of the UAN solution product shows that the Bi index in the product is less than 0.4%.

Embodiment 3

[0047] The difference from Example 1 is that the heating line 7 is a steam jacketed heating line, and the concentration of the urea solution in step (c) is 68%.

[0048] Sampling and analysis of the UAN solution product shows that the Bi index in the product is less than 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com