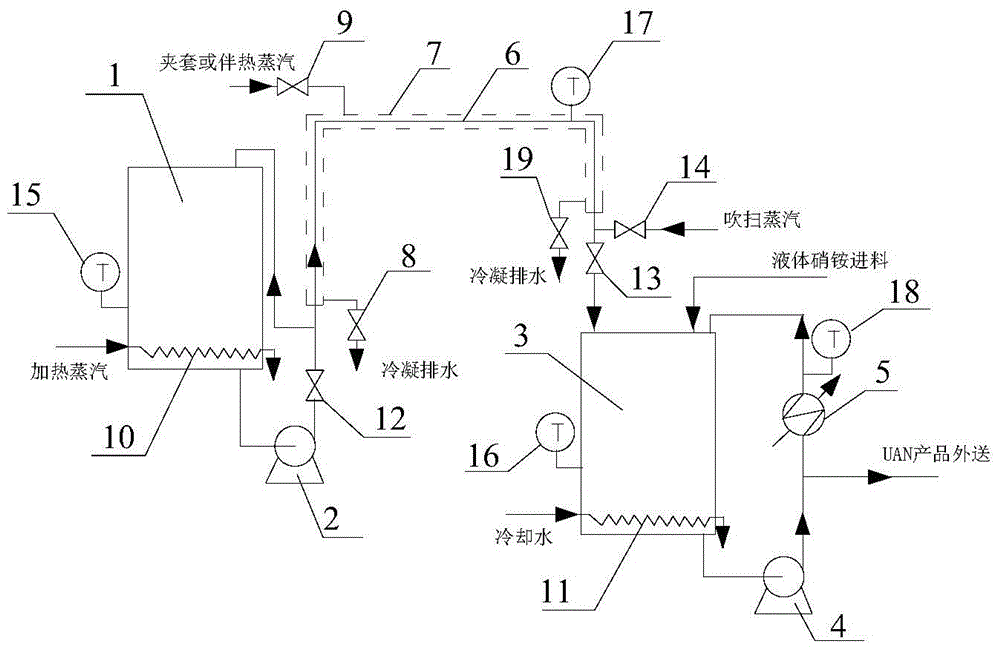

Device and method for industrially producing urea ammonium nitrate solution to reduce biuret formation

A technology of urea ammonium nitrate and biuret, which is applied in the field of chemical fertilizers, can solve the problems of obvious increase, generally reaching 0.5-1.5%, crystallization of urea solution, and long urea residence time, so as to improve product quality and long residence time , Optimize the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] The difference from Example 1 is that the heating steam described in step (a) has a steam pressure of 0.3 MPa and a temperature of 130° C.; the steam heating coil uses a steam pressure of 0.3 MPa and a temperature of 130° C.; the step ( The concentration of the urea solution in c) is 68%, and the temperature of the liquid ammonium nitrate solution is 160°C.

[0045] Sampling and analysis of the UAN solution product shows that the Bi index in the product is less than 0.4%.

Embodiment 3

[0047] The difference from Example 1 is that the heating line 7 is a steam jacketed heating line, and the concentration of the urea solution in step (c) is 68%.

[0048] Sampling and analysis of the UAN solution product shows that the Bi index in the product is less than 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com