Method for producing water-soluble small-molecule organic matter liquid fertilizer through acid hydrolysis method

A water-soluble small molecule and organic matter technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of organic matter and unstable properties, and achieve the effects of stable particle size of organic matter, increased crop yield, and efficient absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

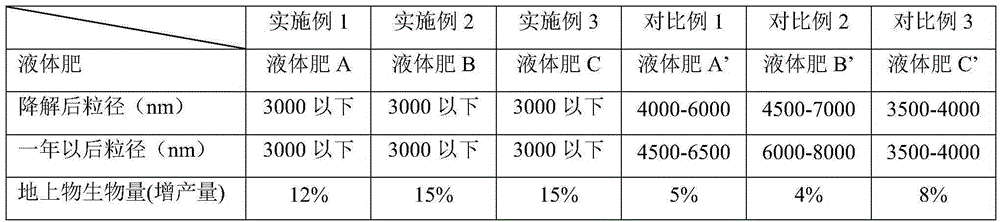

Embodiment 1

[0024] A method for producing water-soluble small molecule organic liquid fertilizer by acid hydrolysis, comprising the following steps: using 200 kg of yeast-producing wastewater as a raw material, injecting the wastewater into a reactor and stirring at a speed of 300 r / min, and performing hydrolysis reaction with compound acid. The compound acid is a mixture of nitric acid with a mass concentration of 85% and hydrochloric acid with a mass concentration of 35%, the mass ratio of the two is 1:2, and the dosage of the compound acid is 10kg. Nitric acid and hydrochloric acid are respectively injected into the reactor from two adjacent feeding ports. The acidolysis reaction time is 30 minutes, and a large amount of heat will be released during the acidolysis process. A reactor with cooling equipment is selected to control the acidolysis reaction temperature at 50-70°C. After the acid hydrolysis reaction, potassium peroxide was added to carry out the oxidation reaction. The reacti...

Embodiment 2

[0026] A method for producing water-soluble small molecule organic liquid fertilizer by acid hydrolysis, comprising the following steps: using 200 kg of waste water fermented to produce alcohol as a raw material, injecting the waste water into a reactor and stirring at a speed of 400 r / min, and performing a hydrolysis reaction with a compound acid. The compound acid is a mixture of nitric acid with a mass concentration of 85% and hydrochloric acid with a mass concentration of 35%, the mass ratio of the two is 1:3, and the consumption of the compound acid is 8 kg of the waste water. Nitric acid and hydrochloric acid are respectively injected into the reactor from two adjacent feeding ports. The acidolysis reaction time is 20 minutes, and a large amount of heat will be released during the acidolysis process. A reactor with cooling equipment is selected to control the acidolysis reaction temperature at 50-70°C. After the acid hydrolysis reaction, potassium peroxide was added to c...

Embodiment 3

[0028] A method for producing water-soluble small molecule organic liquid fertilizer by acid hydrolysis, comprising the following steps: using 200 kg of waste water from amino acid production as a raw material, injecting the waste water into a reactor and stirring at a speed of 300 r / min, and performing hydrolysis reaction with compound acid. The compound acid is a mixture of nitric acid with a mass concentration of 85% and hydrochloric acid with a mass concentration of 35%, the mass ratio of the two is 1:2.5, and the consumption of the compound acid is 4kg. Nitric acid and hydrochloric acid are respectively injected into the reactor from two adjacent feeding ports. The acidolysis reaction time is 30 minutes, and a large amount of heat will be released during the acidolysis process. A reactor with cooling equipment is selected to control the acidolysis reaction temperature at 50-70°C. After the acid hydrolysis reaction, potassium peroxide was added to carry out the oxidation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com