Carbon roaster preheating area volatile component monitoring and temperature controlling device and method

A technology for temperature control devices and carbon roasting furnaces, applied in furnace control devices, furnace monitoring devices, furnaces, etc., can solve the problems of untimely adjustment and control, large fluctuations, low volatile concentration, etc., and achieve the effect of system optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

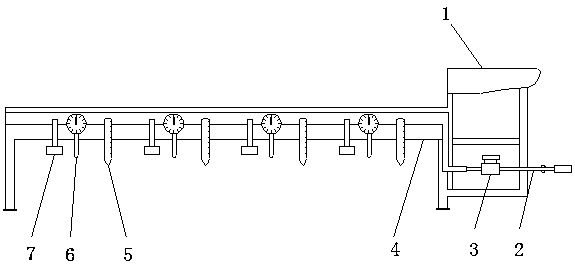

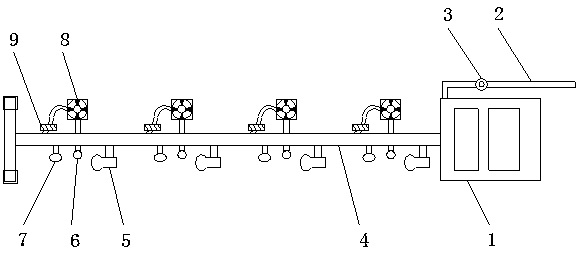

[0026] Such as Figure 1-4 As shown, during implementation, the pulse igniter 8 is inserted into the fire wellhead of the corresponding roasting furnace. After the interface is sealed, the ignition and on-off operation of the pulse igniter 8 is controlled according to the instructions of the control device; the image acquisition device 7 is inserted into the upstream of the burner of the corresponding roasting furnace. In the fire well mouth, after the interface is sealed, the volatile matter combustion situation and state image in the fire channel will be collected in real time and transmitted to the control device. After sealing, the temperature and pressure in the fire channel will be collected in real time, and the control device will communicate with the original flame control system through the industrial Ethernet, and the on-site working conditions such as the temperature and pressure of the fire channel and the opening of the smoke exhaust rack valve will be obtained th...

Embodiment 2

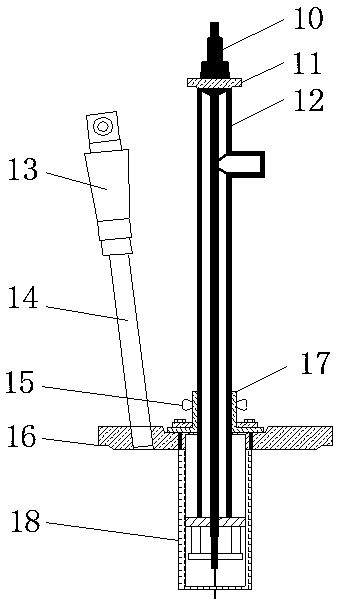

[0030] Such as Figure 1-4As shown, the volatile matter monitoring and temperature control device and method in the preheating zone of a carbon roasting furnace are suitable for roasting furnaces with no more than twenty fire channels in the furnace chamber. The control device includes a frame 1, and the frame 1 is provided with a cross-arm frame body 4, and the cross-arm frame body 4 is provided with a temperature measuring device 5, a pressure measuring device 6 and an image acquisition device 7, and the cross-arm frame body 4 is also provided with a pulse An igniter 8, the pulse igniter 8 is connected with a pulse type solenoid valve 9, the pulse igniter 8 includes an ignition electrode 10, the bottom of the ignition electrode 10 is connected to a gas protection tube 12 through a connection plate 11, the gas protection The lower side of the tube 12 is provided with a fixed disc 16, the fixed disc 16 is provided with a flame detector 13, and the detector protection tube 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com