Hierarchical battery temperature control device of supercooled phase change material and temperature control method of hierarchical battery temperature control device

A phase change material, battery temperature control technology, applied in battery temperature control, secondary battery, battery pack components, etc., can solve the problems of limited application scenarios, inability to achieve multiple triggers, and inability to actively trigger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

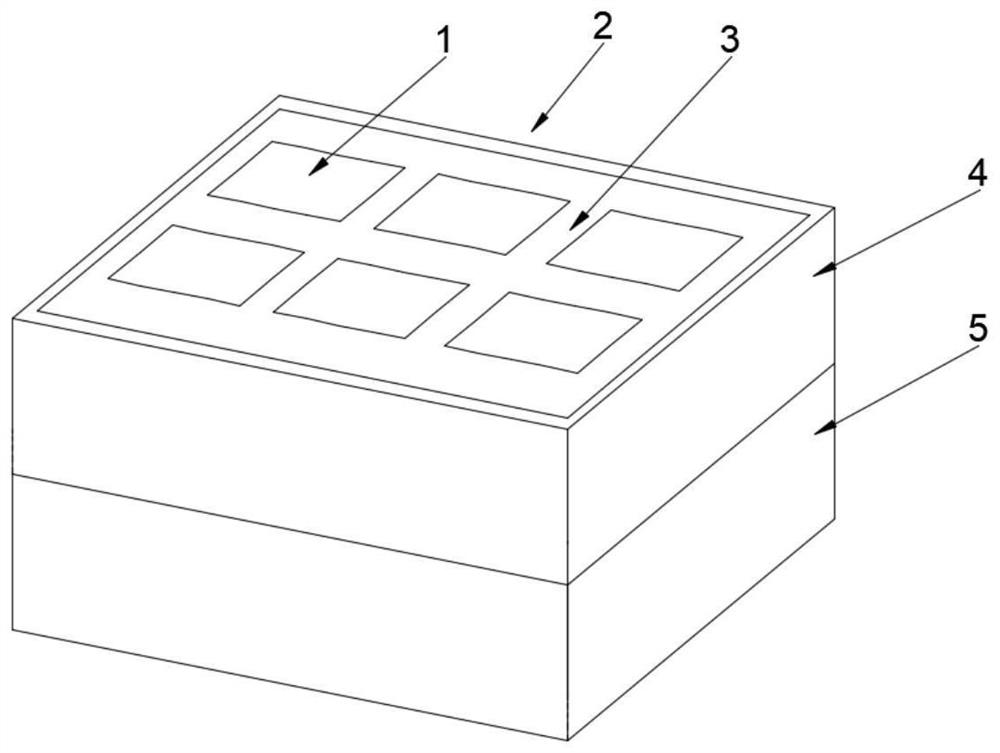

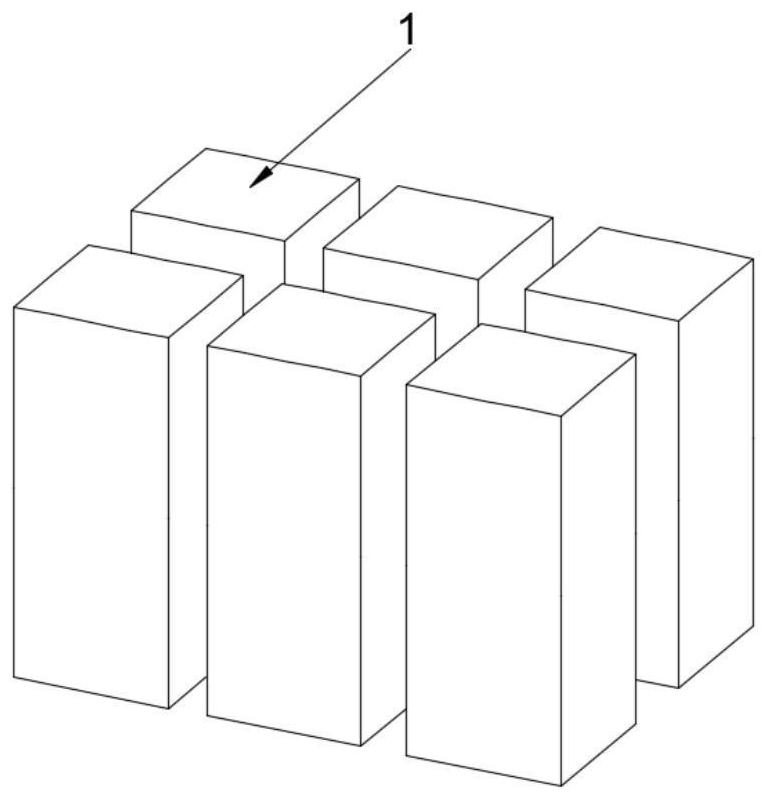

[0031] Such as figure 1 , image 3 As shown, this embodiment includes a battery 1 and a multi-stage cavity 2 sleeved outside the battery. The multi-stage cavity 2 is divided into two stages. Each stage of the cavity is filled with a supercooled phase change material, and the battery 1 is supercooled. Phase change material package. The two-stage chambers 2 are respectively a first-stage chamber 4 and a second-stage chamber 5 , and the first-stage chamber 4 and the second-stage chamber 5 overlap each other in the height direction. The supercooled phase change materials are all Na 2 S0 4 10H 2 0, the melting point is 32.4°C, and the supercooling degree is 20°C, filled in the two stages of the cavity 2. The two-stage bottoms of the cavity 2 are each provided with an active trigger mechanism to break the supercooled state of the supercooled phase change material and release latent heat to heat the battery. The top opening of each stage cavity 2 is sealed by a top cover 3 . T...

Embodiment 2

[0036] Such as figure 1 , image 3 As shown, this embodiment includes a battery 1 and a multi-stage cavity 2 sleeved outside the battery. The multi-stage cavity 2 is divided into two stages. Each stage of the cavity is filled with a supercooled phase change material, and the battery 1 is supercooled. Phase change material package. The two-stage chambers 2 are respectively a first-stage chamber 4 and a second-stage chamber 5 , and the first-stage chamber 4 and the second-stage chamber 5 overlap each other in the height direction. The supercooled phase change material is Na 2 S0 4 10H 2 0 and CaCl 6 ·6H 2 O, with melting points of 32.4°C and 29°C, and supercooling degrees of 20°C and 30°C, are respectively filled in the first-stage cavity 4 and the second-stage cavity 5 of the cavity 2 . The two-stage bottoms of the cavity 2 are each provided with an active trigger mechanism to break the supercooled state of the supercooled phase change material and release latent heat to...

Embodiment 3

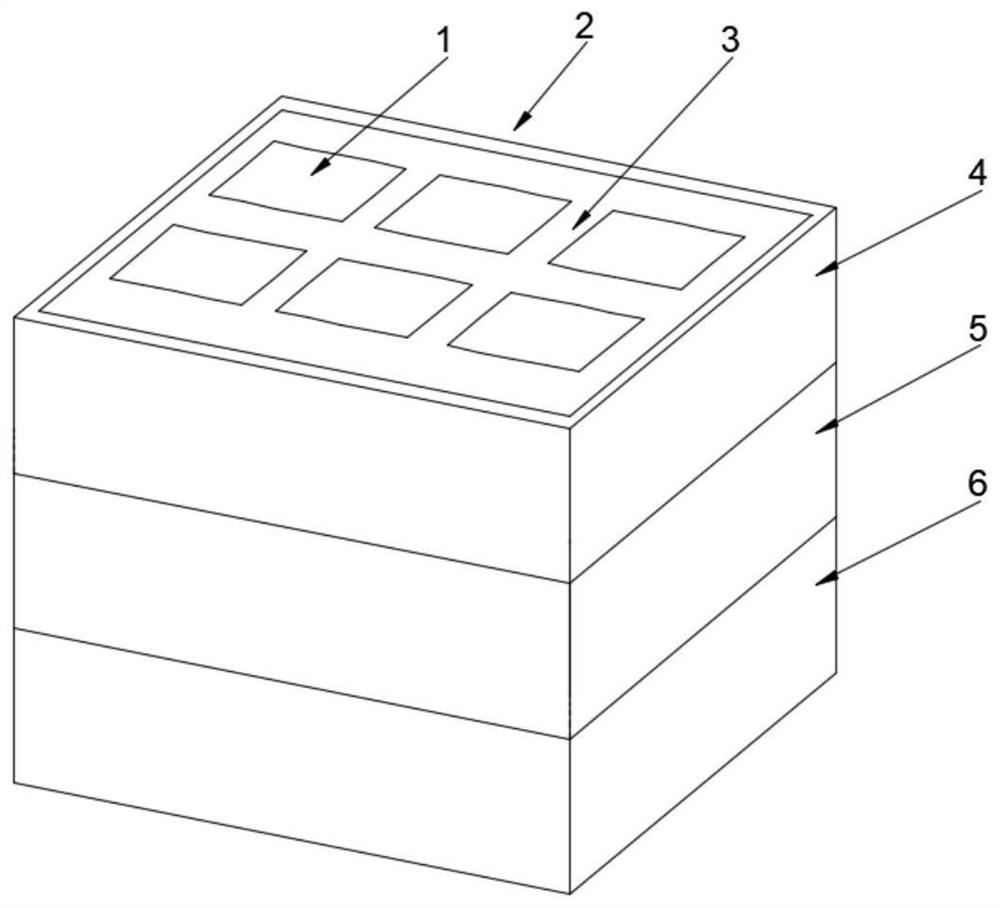

[0041] Such as figure 2 , image 3 As shown, this embodiment includes a battery 1 and a multi-stage cavity 2 sheathed outside the battery, and the multi-stage cavity 2 is divided into three stages. Each cavity is filled with a supercooled phase change material, and the battery 1 is wrapped by the supercooled phase change material. The tertiary cavity 2 is respectively the first level cavity 4, the second level cavity 5 and the third level cavity 6, the first level cavity 4, the second level cavity 5 and the third level cavity 6 are at the height superimposed on each other. The supercooled phase change material is CaCl 2 ·6H 2 0, its melting point is 29°C, and its supercooling degree is 30°C, which are respectively filled in the three stages of the cavity 2. Each of the three bottoms of the cavity 2 is provided with an active trigger mechanism to break the supercooled state of the supercooled phase change material and release latent heat to heat the battery. The top open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com