Nickel-gold depositing device

A technology of immersion nickel gold and nickel immersion, applied in the field of immersion nickel gold, can solve the problems of high cost, low degree of automation, poor solderability, etc., and achieve the effect of improving quality, high degree of automation, and eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

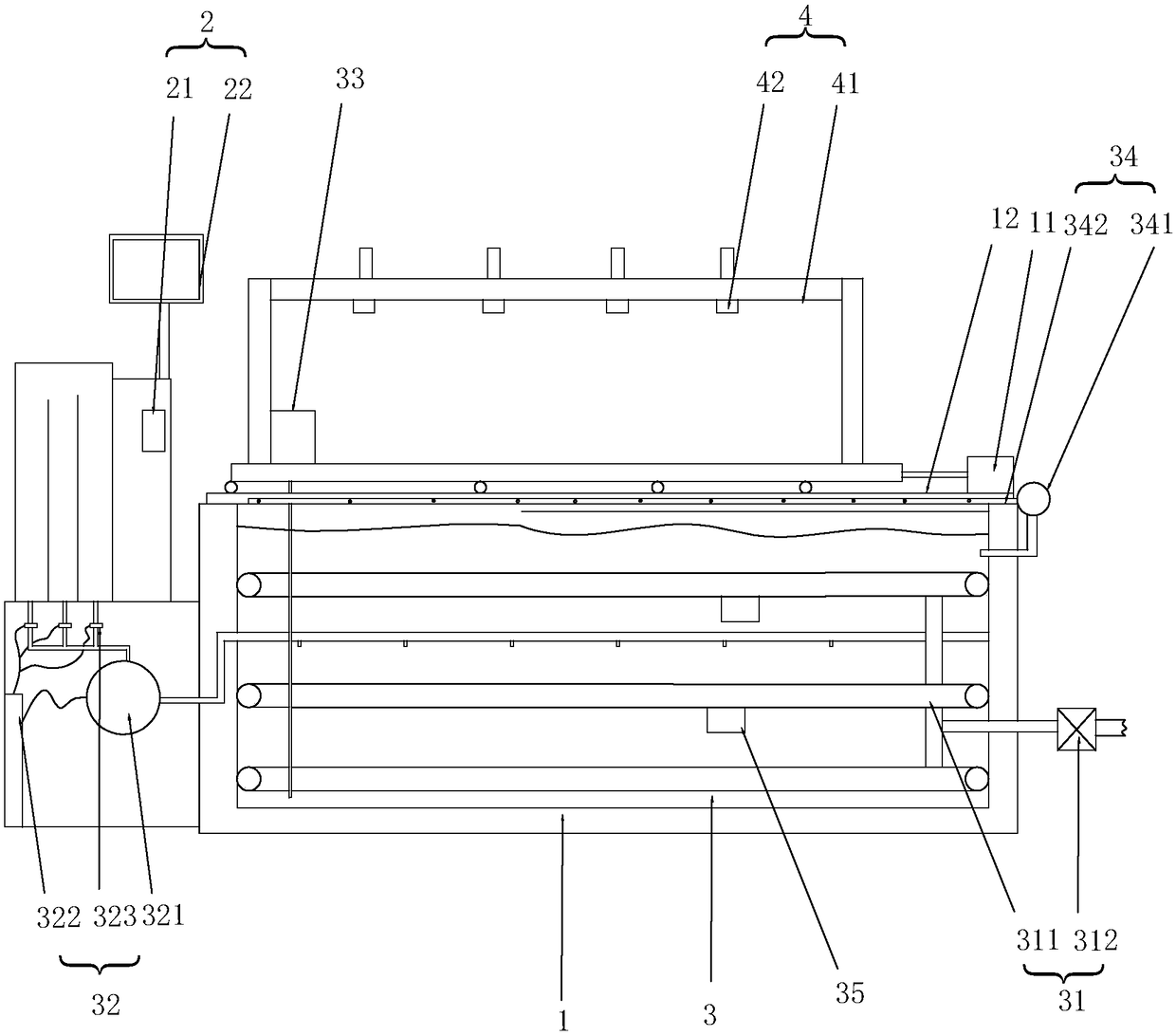

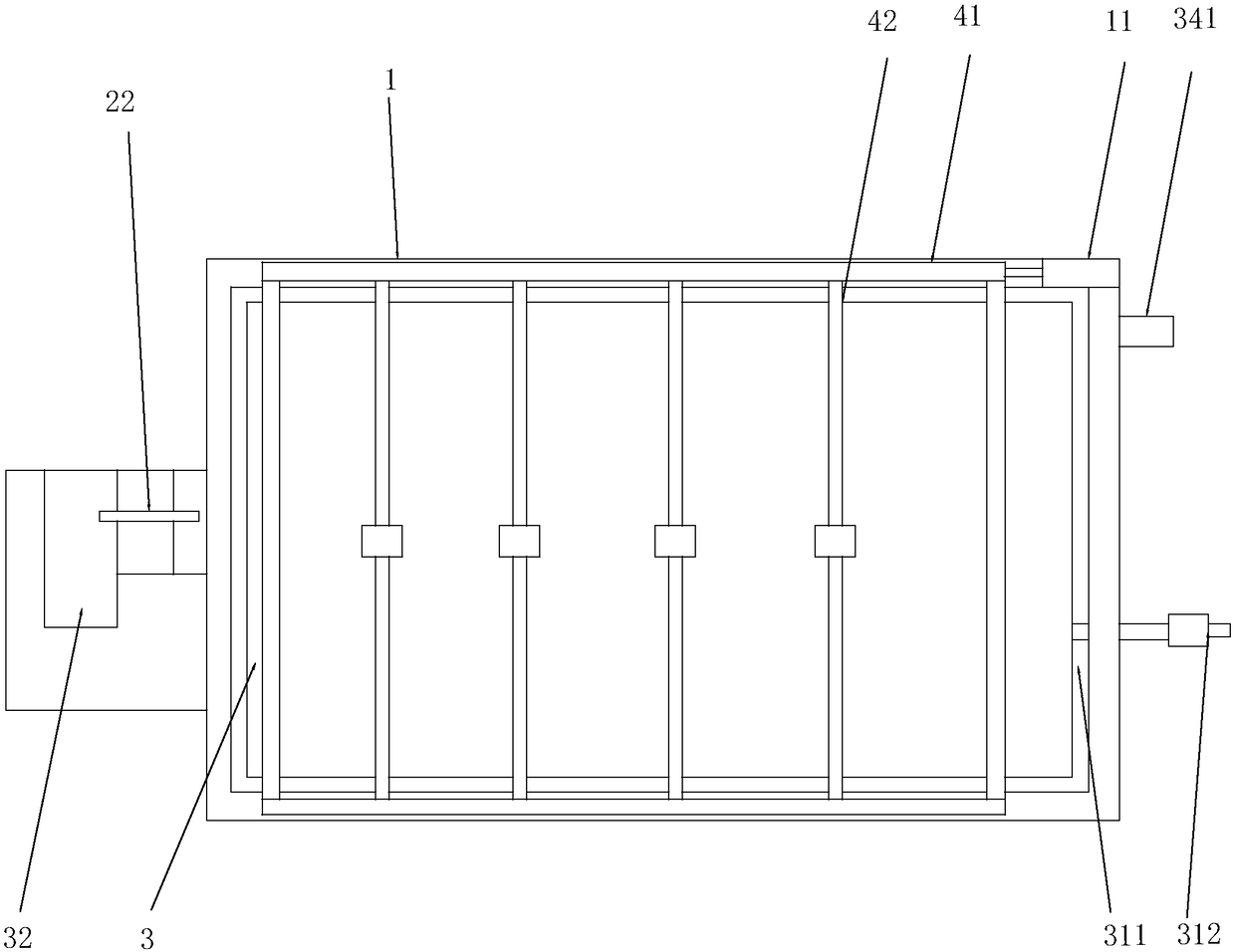

[0019] see figure 1 and figure 2 , a kind of immersion nickel gold device of the present invention, comprises support 1, control group 2, is arranged on support 1 nickel cylinder 3 and is used for conveying and shakes the material frame 4 of circuit board, and described material frame 4 is arranged on nickel cylinder 3 On the upper part, the support 1 is provided with a shaking group 11 for shaking the material rack 4, the support 1 is provided with a guide rail 12, and the material rack 4 can slide back and forth to set the guide rail 12, and the shaking group 11 can drive the material rack 4 slide back and forth on the guide rail 12. The shaking group 11 is used to realize the reciprocating sliding of the material rack 4, and then shake and hang on the circuit board, so as to improve the adhesion ability of nickel ions on the circuit board.

[0020] In this embodiment, the control group 2 includes a microprocessor 21, a memory for recording the feedback information of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com