Ultralow loss optical fiber production system and technology used for production

A technology for producing systems and optical fibers, applied in the directions of cladding optical fibers, optics, light guides, etc., can solve problems such as the destruction of the silicon-oxygen tetrahedron structure, the expansion of the scope of micro-cracks, and the influence of the strength of the optical fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

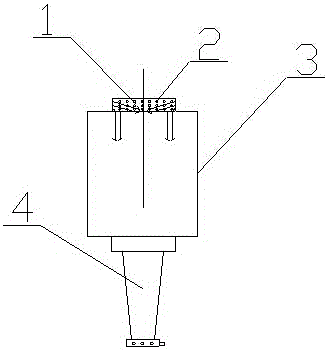

[0023] Ultra-low-loss optical fiber is the material basis for the future development of large-capacity optical communication, and it is an important medium for my country to implement the "One Belt, One Road" and "Broadband China" strategies to achieve 400G ultra-high-speed bandwidth. In order to respond to the national call, conform to the development trend of optical communication, break the foreign technology monopoly of ultra-low loss optical fiber, and promote the development of my country's submarine long-distance optical cable and land long-distance backbone network communication, it is necessary to carry out research on ultra-low loss optical fiber products and their industrialization platforms. studied.

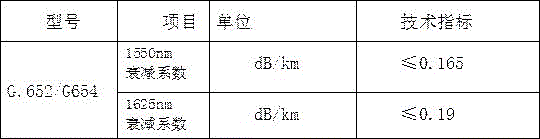

[0024] Ultra-low loss optical fiber consists of inner and outer acrylate coatings, fluorine-doped cladding and pure silica core. The following table lists the main technical specifications of the two types of optical fibers:

[0025]

[0026] Optical fiber strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com