Fly ash product sintering furnace and method and formula thereof

A sintering method and fly ash technology, applied in ceramic products, furnaces, muffle furnaces, etc., can solve the problems of low production efficiency, scale failure, environmental pollution, etc., and achieve convenient operation, simple structure, and balanced furnace temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the drawings, the same components are denoted by the same reference numerals.

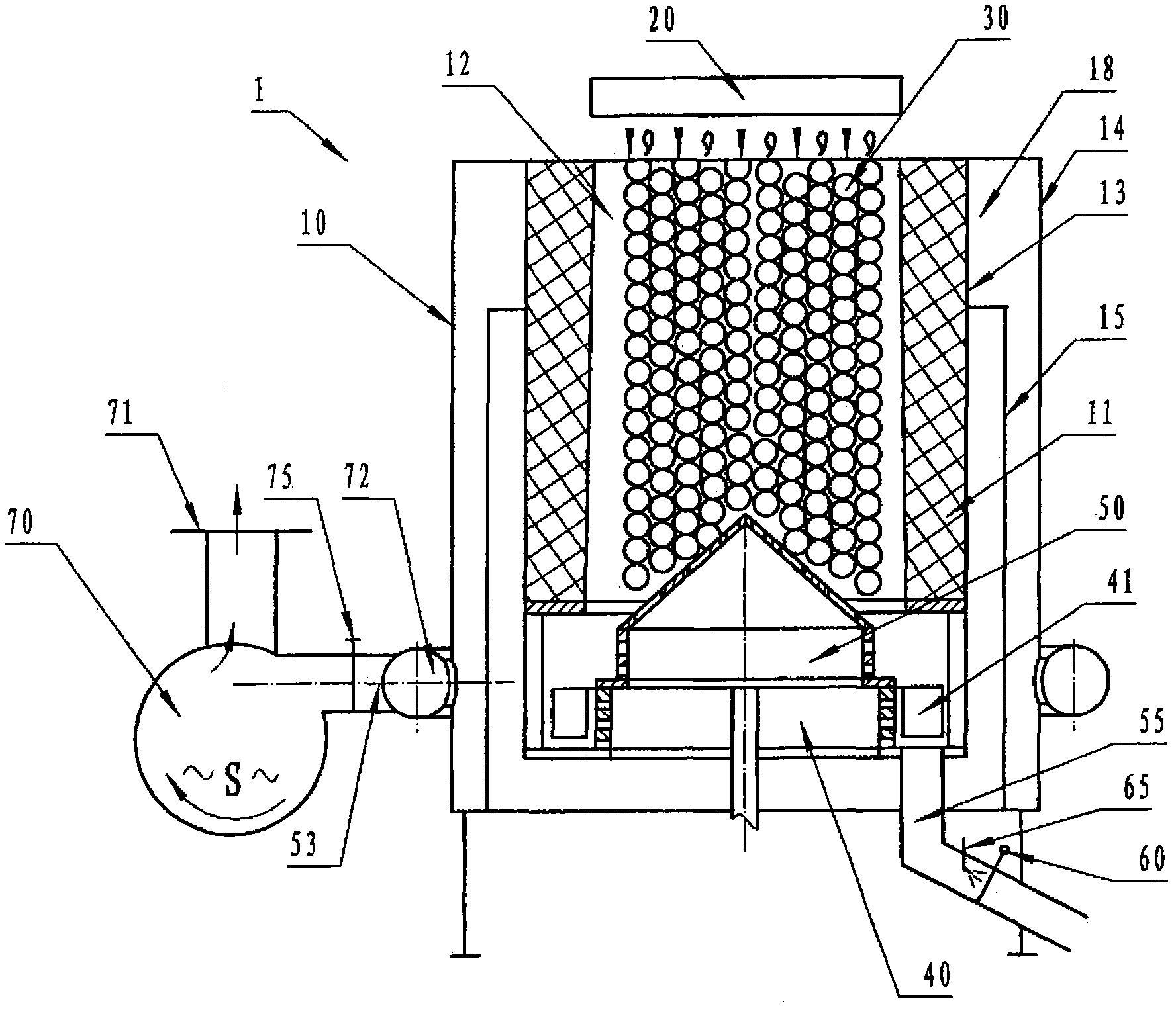

[0031] figure 1 It is a structural schematic diagram of a fly ash product sintering furnace 1 according to a preferred embodiment of the present invention. As shown in the figure, the sintering furnace 1 includes a furnace body 10, a tower grate discharge ventilation device 40, an annular air duct 72 and an upper chute 55.

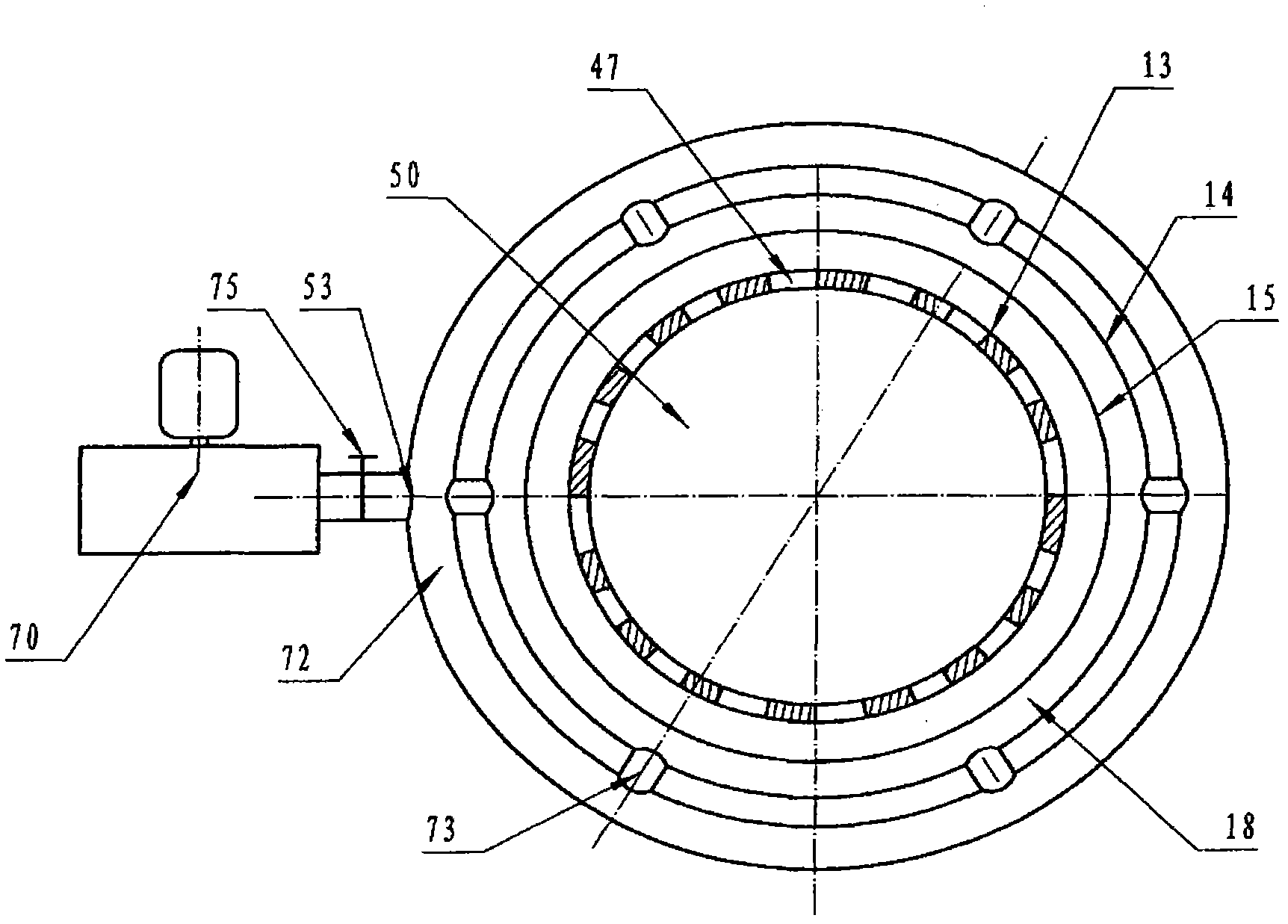

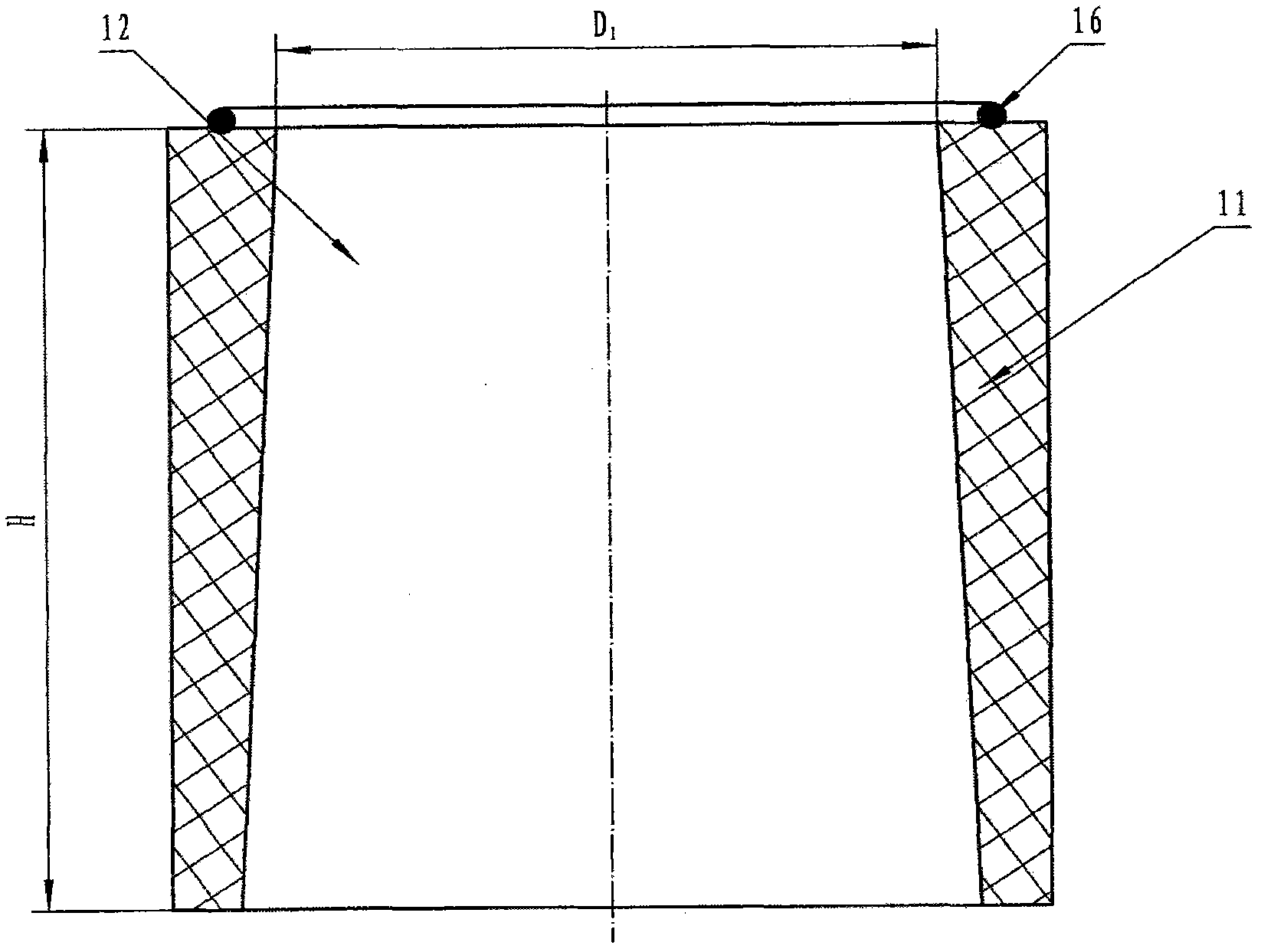

[0032] The furnace body 10 includes: a furnace inner shell 13, a furnace outer shell 14, and a furnace lining 11, wherein a furnace cavity 12 is formed inside the furnace lining 11, and the furnace inner shell 13 surrounds the outer side of the furnace lining 11, and the furnace inner shell 13 and the furnace outer shell 14 form a The space is the hot air jacket 18, the hot air jacket 18 is provided with a guide ring 15, the guide ring 15 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com