Vibration soaking pit furnace

A soaking furnace and furnace body technology, which is applied in the field of aluminum melting furnaces, can solve problems such as burning of molten aluminum, polluting the environment, increasing alumina content, etc., and achieves the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

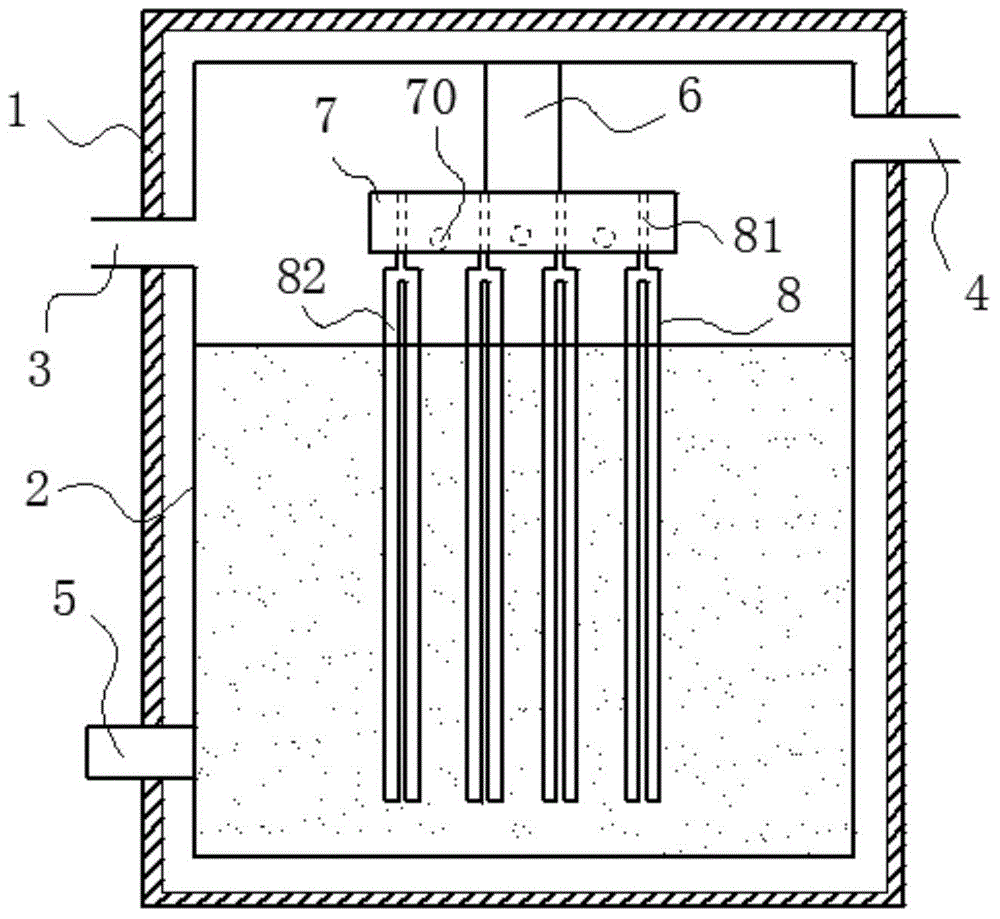

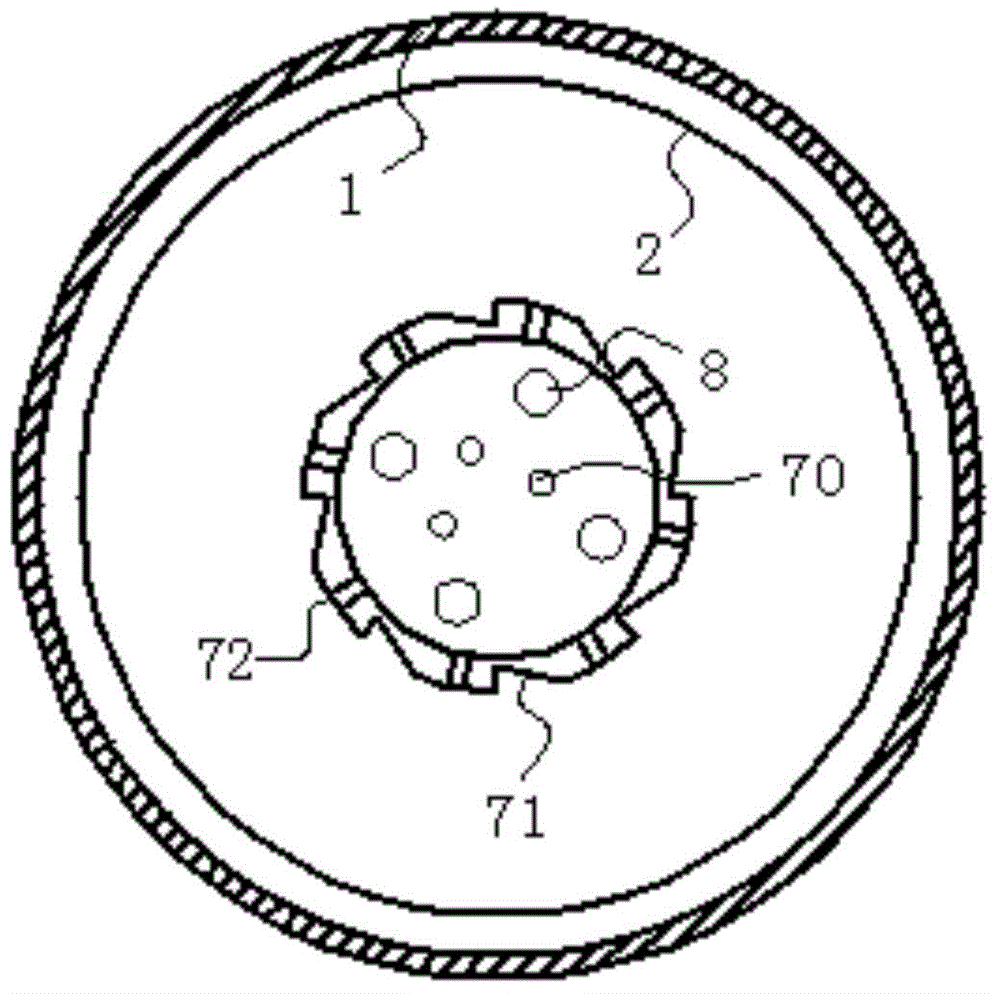

[0012] exist figure 1 , figure 2 In the embodiment shown, the vibrating aluminum melting furnace includes a furnace body 2, a heat insulating shell 1, a burner 3, a smoke exhaust pipe 4 and a liquid outlet 5; the furnace body 2 is wrapped by the heat insulating shell 1, and the burner The nozzle 3 and the smoke exhaust pipe 4 are installed on the upper end of the side wall of the furnace body 2, and the liquid outlet 5 is opened at the lower end of the side wall of the furnace body 2; the inner wall of the top of the furnace body 2 is fixedly installed with an air disc rotating shaft 6 ; On the rotating shaft 6 of the air plate, a hollow air plate 7 is provided inside, and the air plate 7 is located above the molten aluminum, and the top surface of the air plate 7 is parallel to the top of the furnace body 2; Four needle bars 8 are installed on the lower bottom surface of the wind disc 7, and each of the needle bars 8 is parallel to each other and perpendicular to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com