Through hole reflow soldering device and control method thereof

A technology of reflow soldering and reflow soldering machine, applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of manual repair soldering, heavy manual labor, and high temperature resistance of components, so as to reduce energy loss and be easy to implement , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

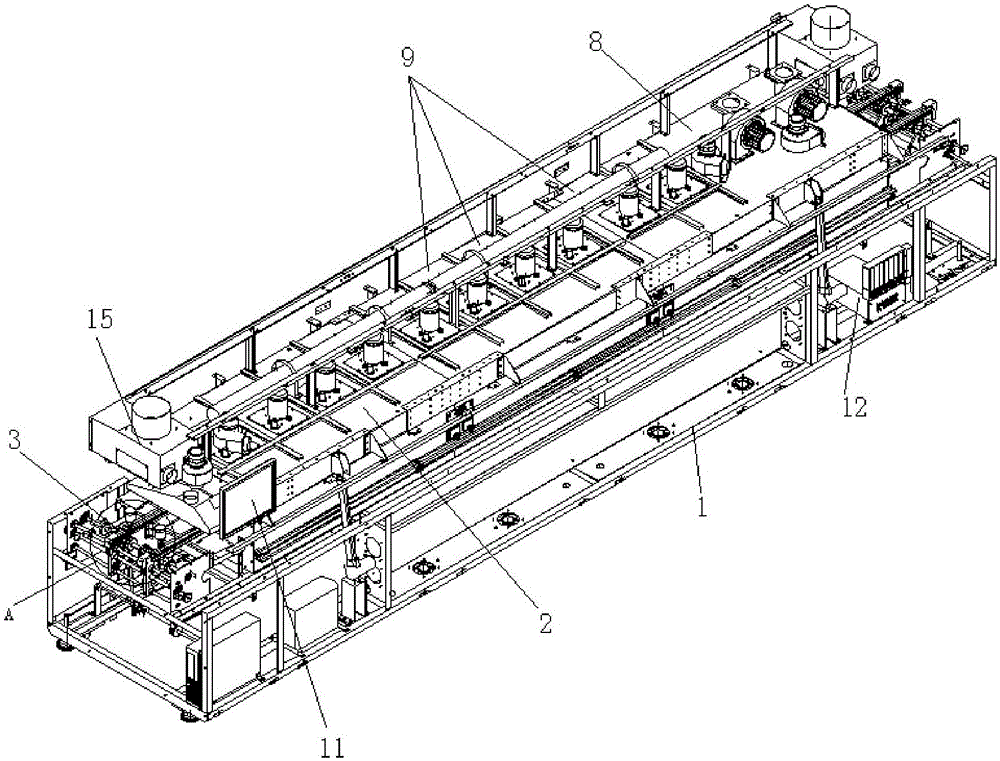

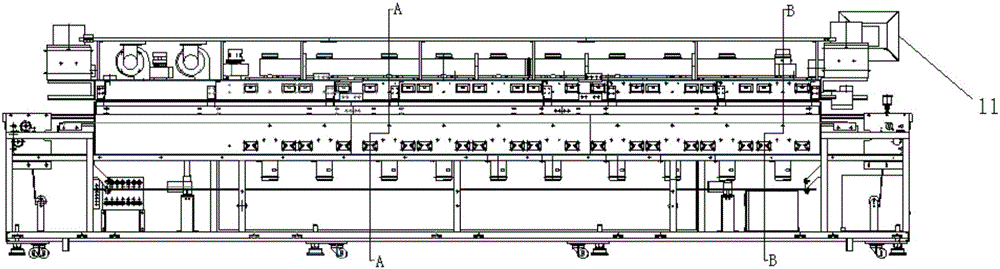

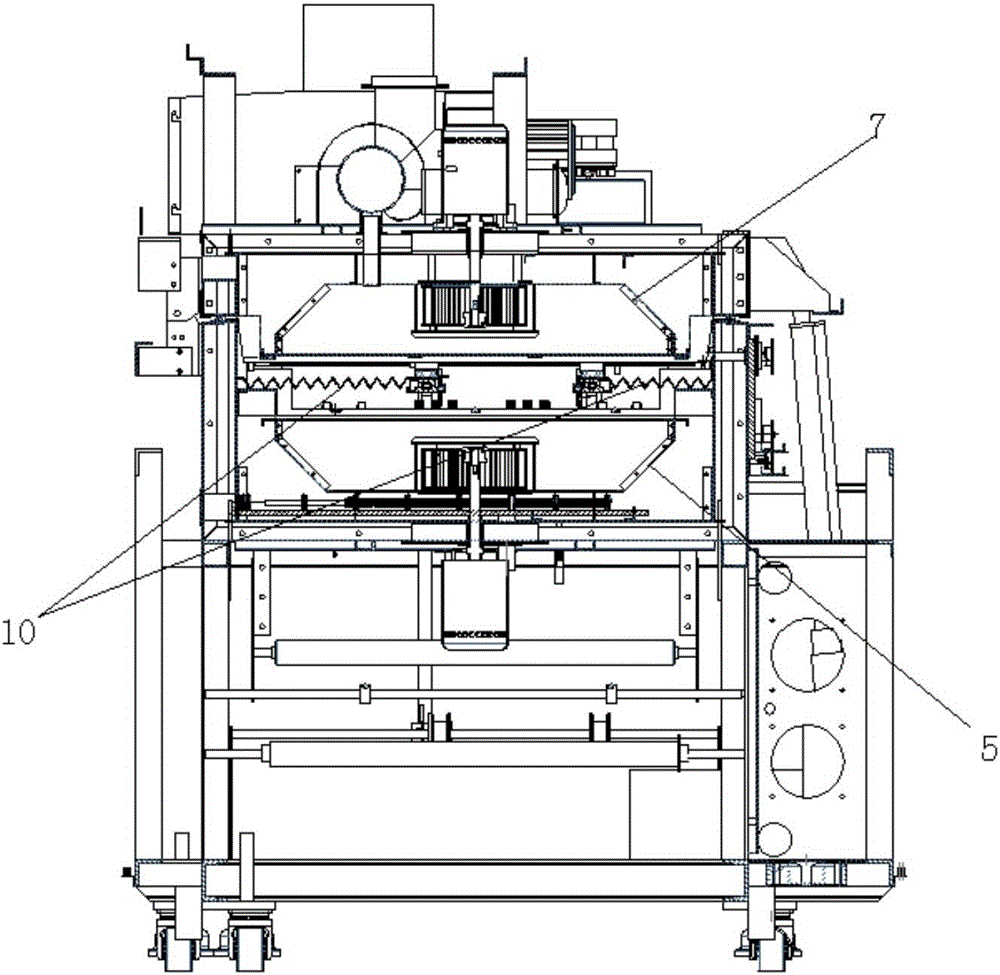

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 11 As shown, a through-hole reflow soldering device includes a reflow soldering machine 1, the upper plane rear edge of the reflow soldering machine 1 is provided with a welding machine cover 2 that can be opened and closed, and the welding machine cover 2 is formed by a The telescopic support arm is connected to control the opening or closing. The upper plane of the reflow soldering machine 1 is provided with a product conveying line 3 that can adjust the width. The reflow soldering machine 1 is provided with two first blowing hot air from left to right. The lower furnace 4 and a second lower furnace 5 blowing upwards, the position corresponding to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com