Bidirectional drawing machine for polymide films

A technology of polyimide film and biaxial stretching, which is applied in the field of plastic machinery, can solve the problems of high production equipment requirements, inability to produce, and high product prices, and achieve consistent thickness, energy-saving utilization, and product quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

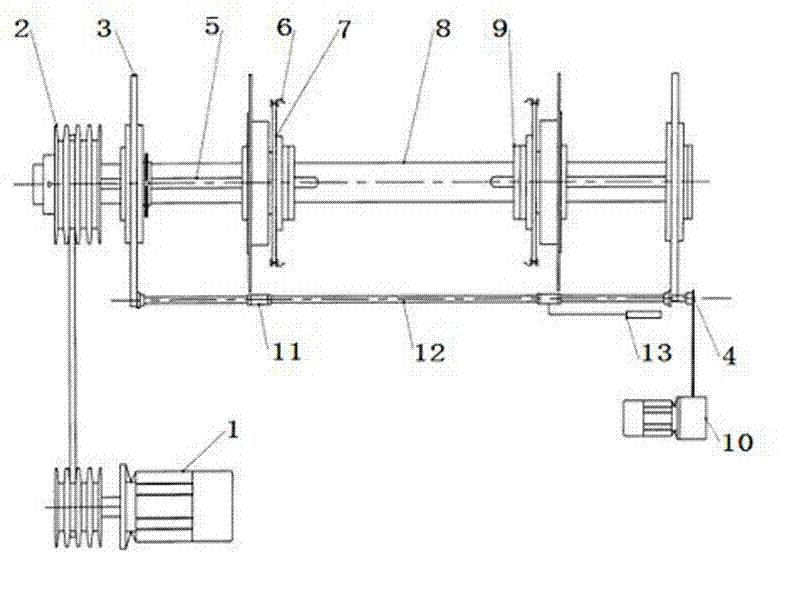

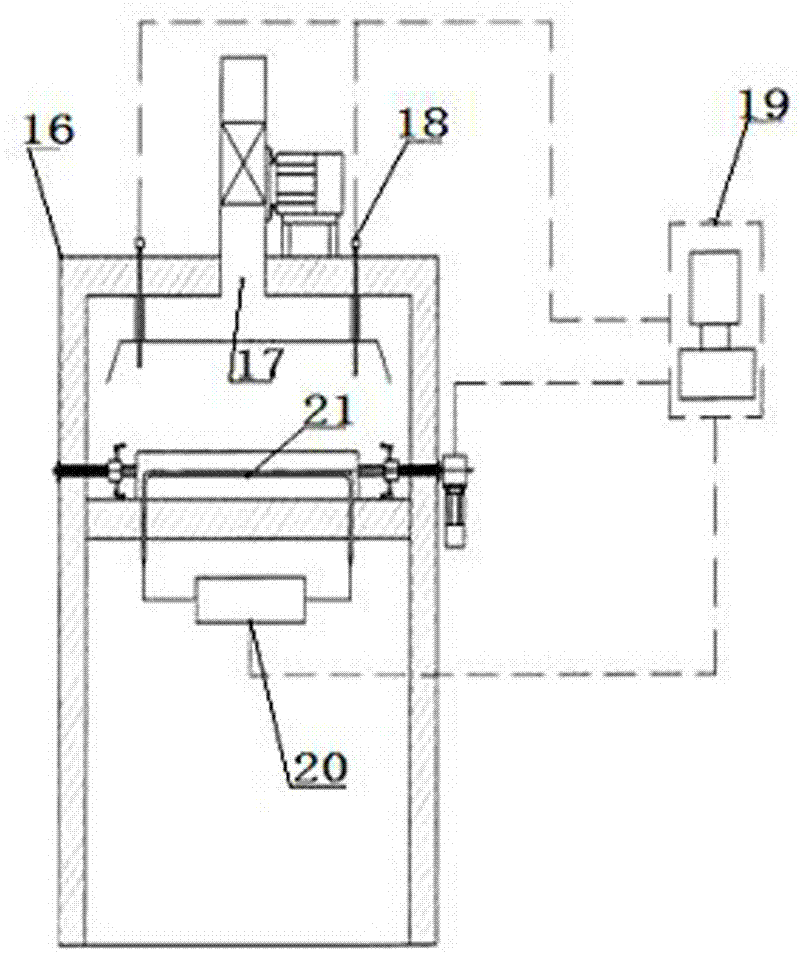

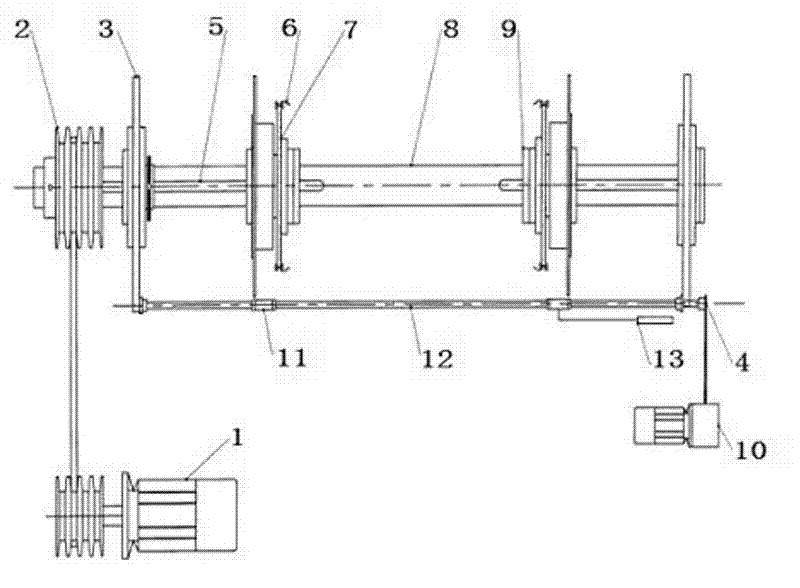

[0010] A bidirectional stretching machine for polyimide film, comprising a pin plate chain mechanism, a stretching machine box 16, a vertical chain and a transmission mechanism, an automatic expansion mechanism, an automatic closed-loop heating system, and an internal circulation bellows, and is characterized in that The extension machine box is made of double-layer stainless steel, and the middle is filled with high-temperature heat-insulating materials; the vertical chain and the transmission mechanism are composed of the main drive motor 1, the pulley 2, the main shaft 8, the guide key 5, and the sprocket 7. The main shaft 8 installed on the wallboard 3 is connected by transmission, and is connected with the sprocket 7 through the guide key 5. The rotation of the sprocket 7 drives the vertical chain 6 to move forward, and then drives the polyimide fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com