Air-cooled exhaust gas heat exchanger, in particular exhaust gas cooler for motor vehicles

A technology for exhaust gas coolers and heat exchangers, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, and can solve cooling problems and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

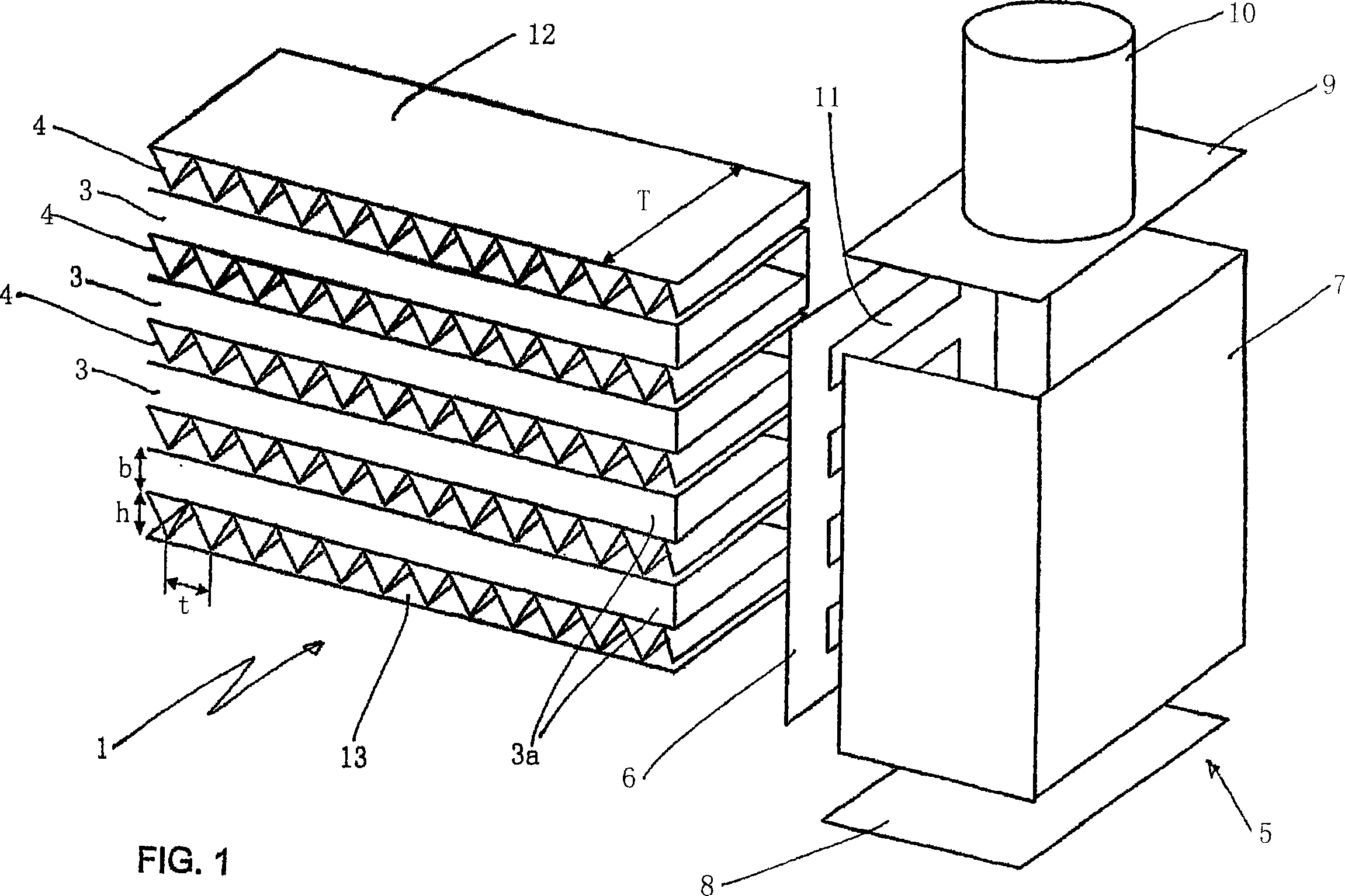

[0039] Fig. 1 is an exploded view of an exhaust gas cooler 1 according to the invention, ie parts or assemblies are disassembled. The exhaust gas cooler 1 is used for cooling the exhaust gas of the exhaust gas recirculation system of the internal combustion engine of the vehicle, and this system will be described in detail in FIG. 4 below. The exhaust gas cooler 1 according to the invention has a tube-fin core 2 consisting of flat tubes 3 and corrugated fins 4 arranged between the flat tubes. The corrugated fins 4 are brazed or welded to the flat tubes to form a compact core 2 . The corrugated fins 4 are penetrated by ambient air and have fish scales (not shown) for improving the heat exchange with the air, which are the same as those on the corrugated fins of known coolant radiators. The corrugated fins 4 can be replaced by so-called plate fins, also not shown, which are curved fins with offset flanges. Generally speaking, the heat exchange efficiency of plate fins is low. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com