Patents

Literature

53results about How to "Reduce the possibility of corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

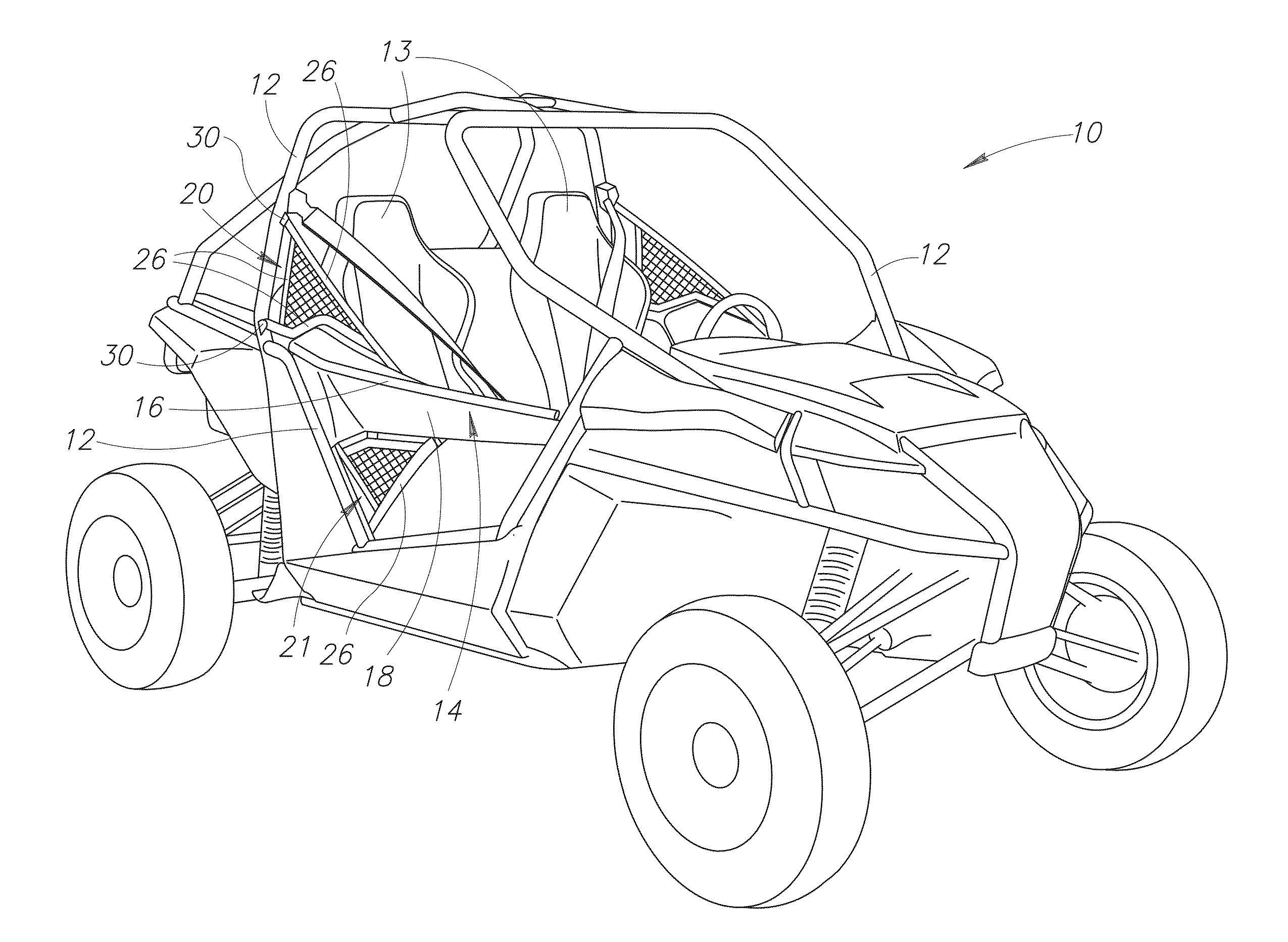

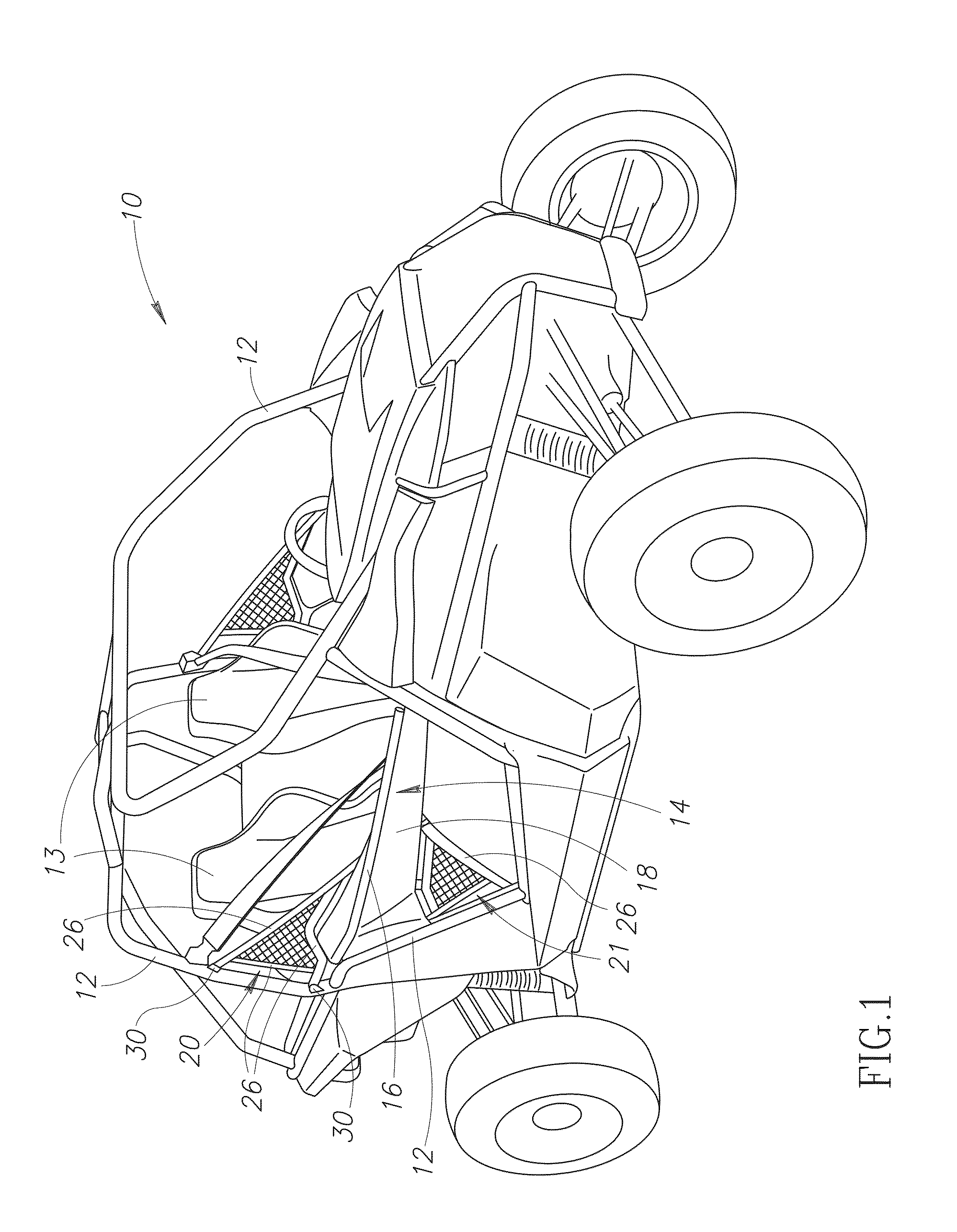

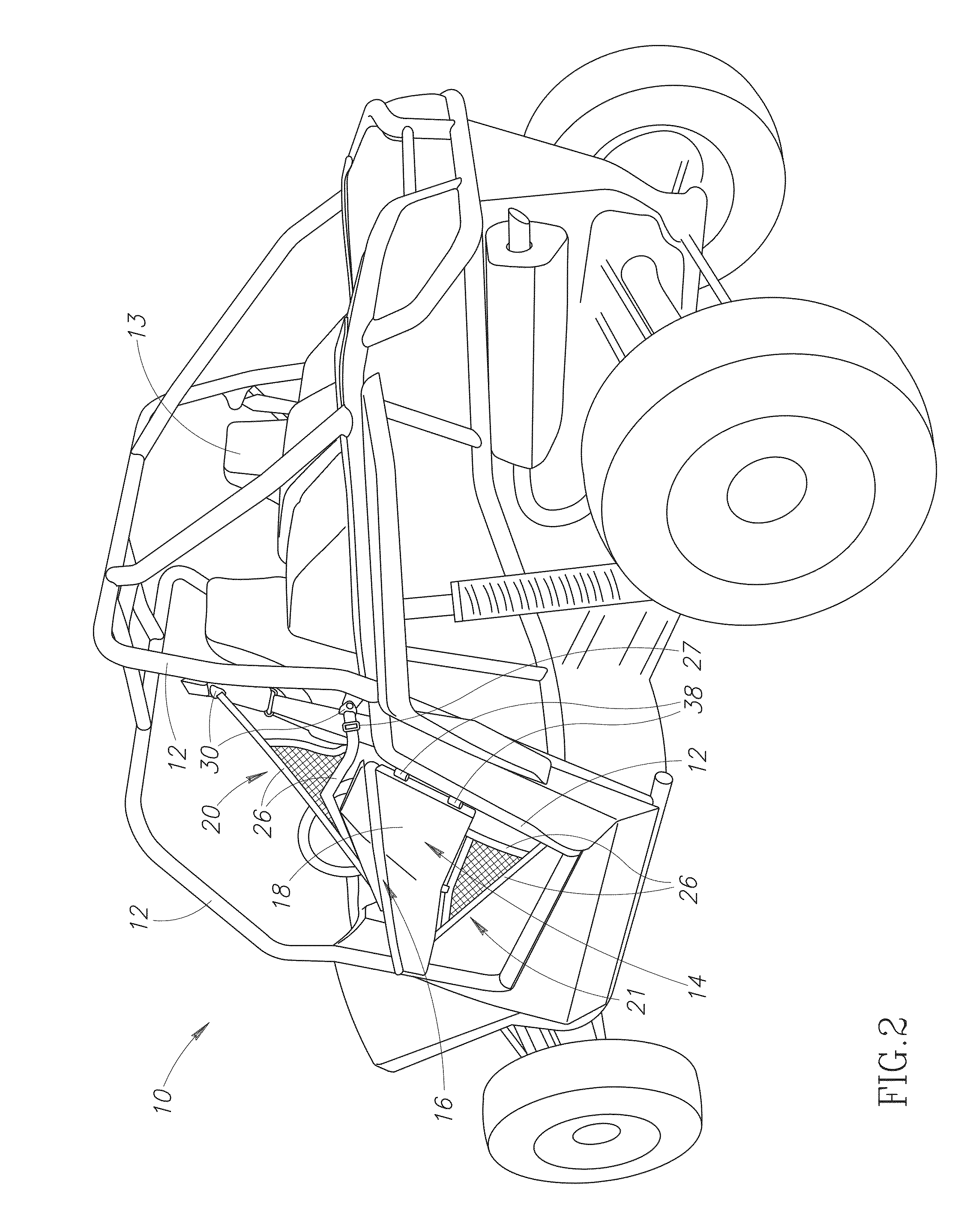

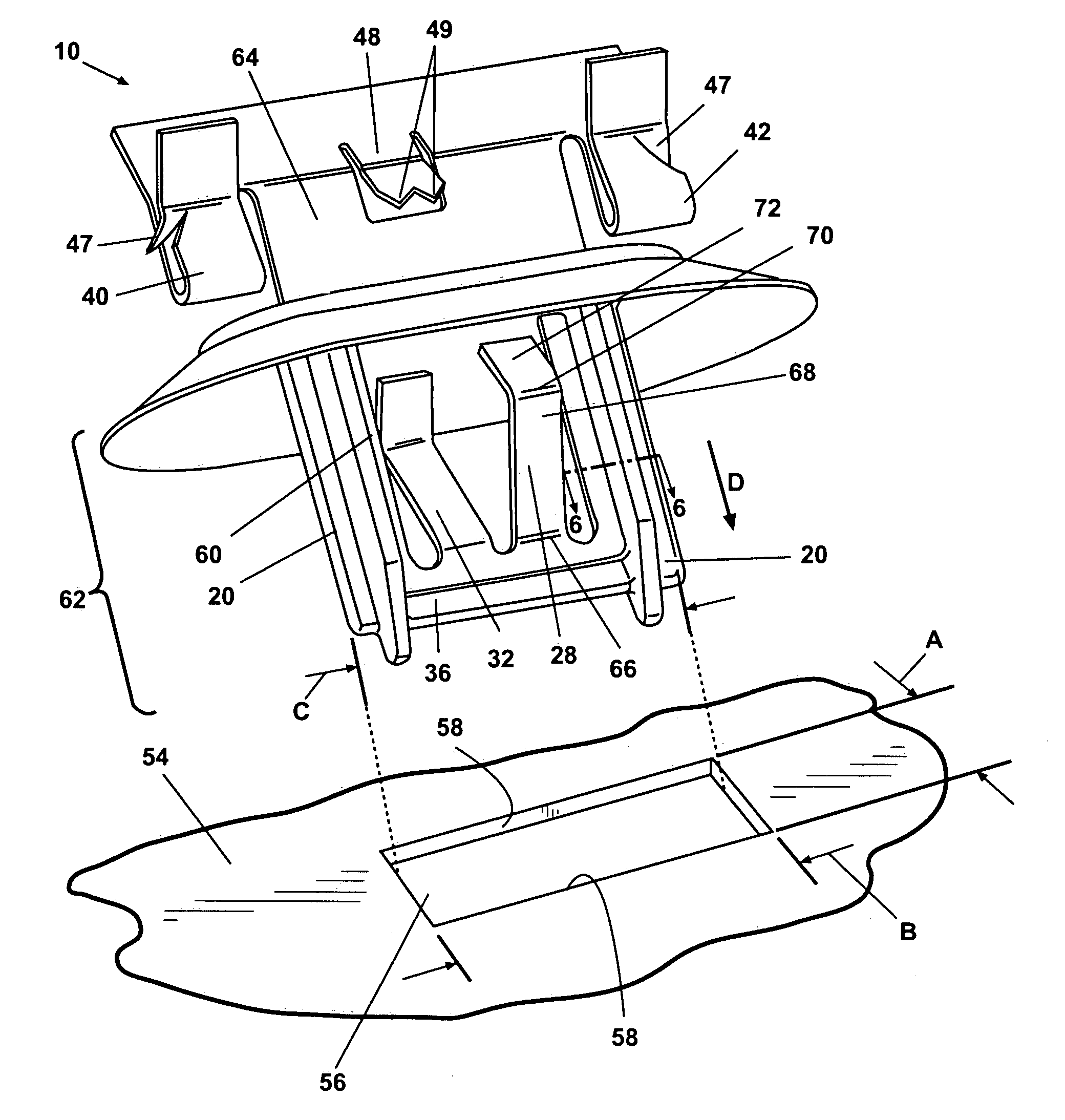

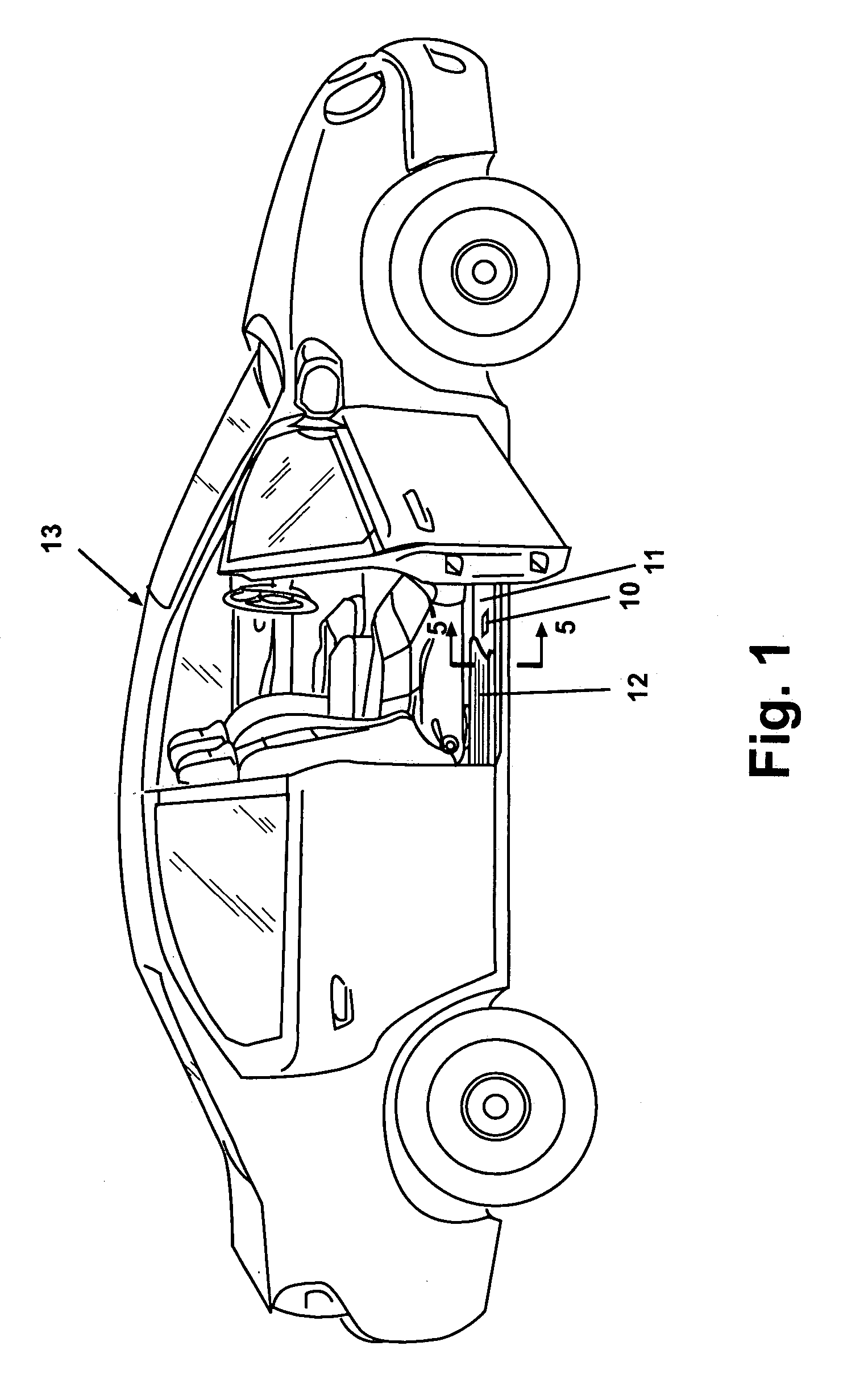

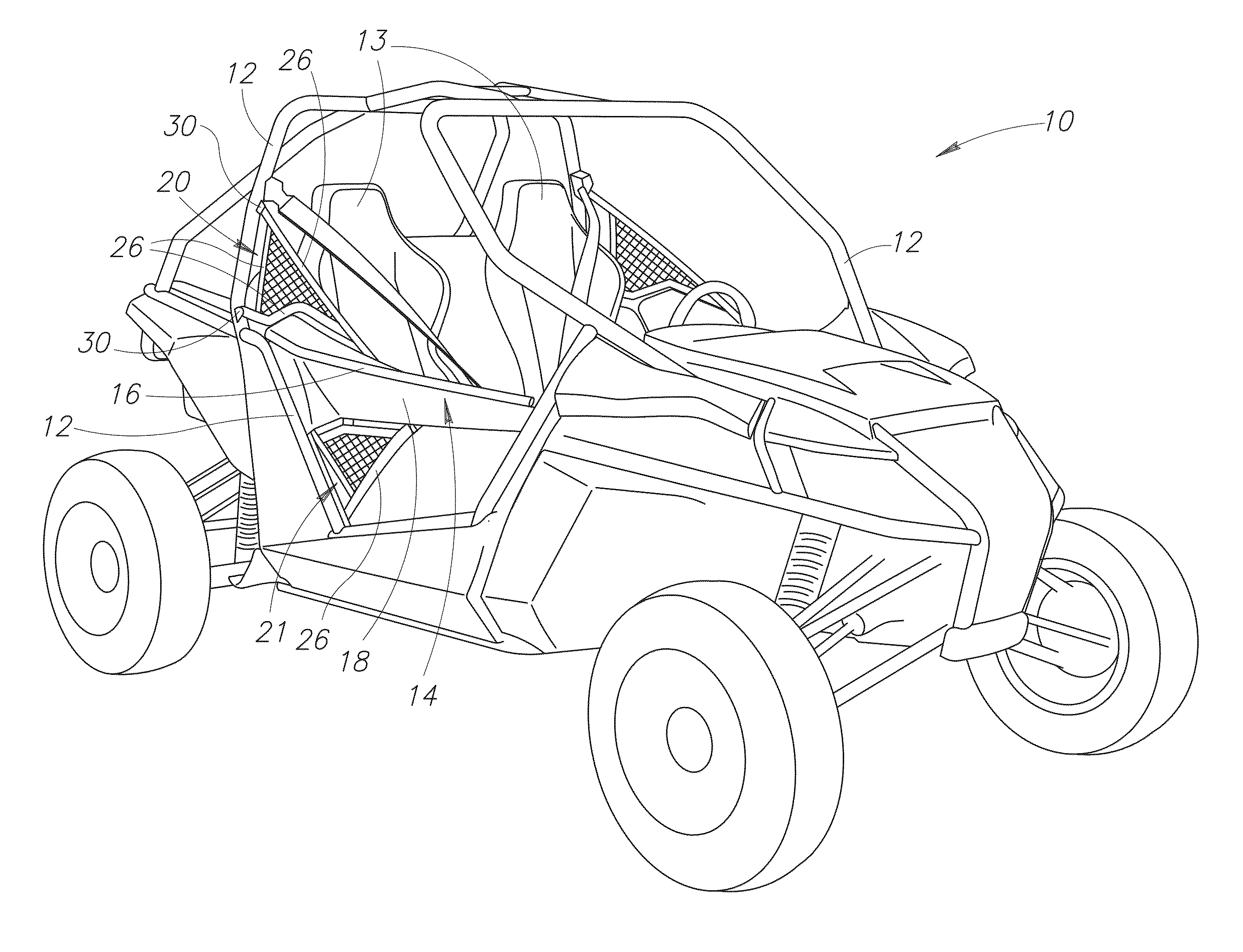

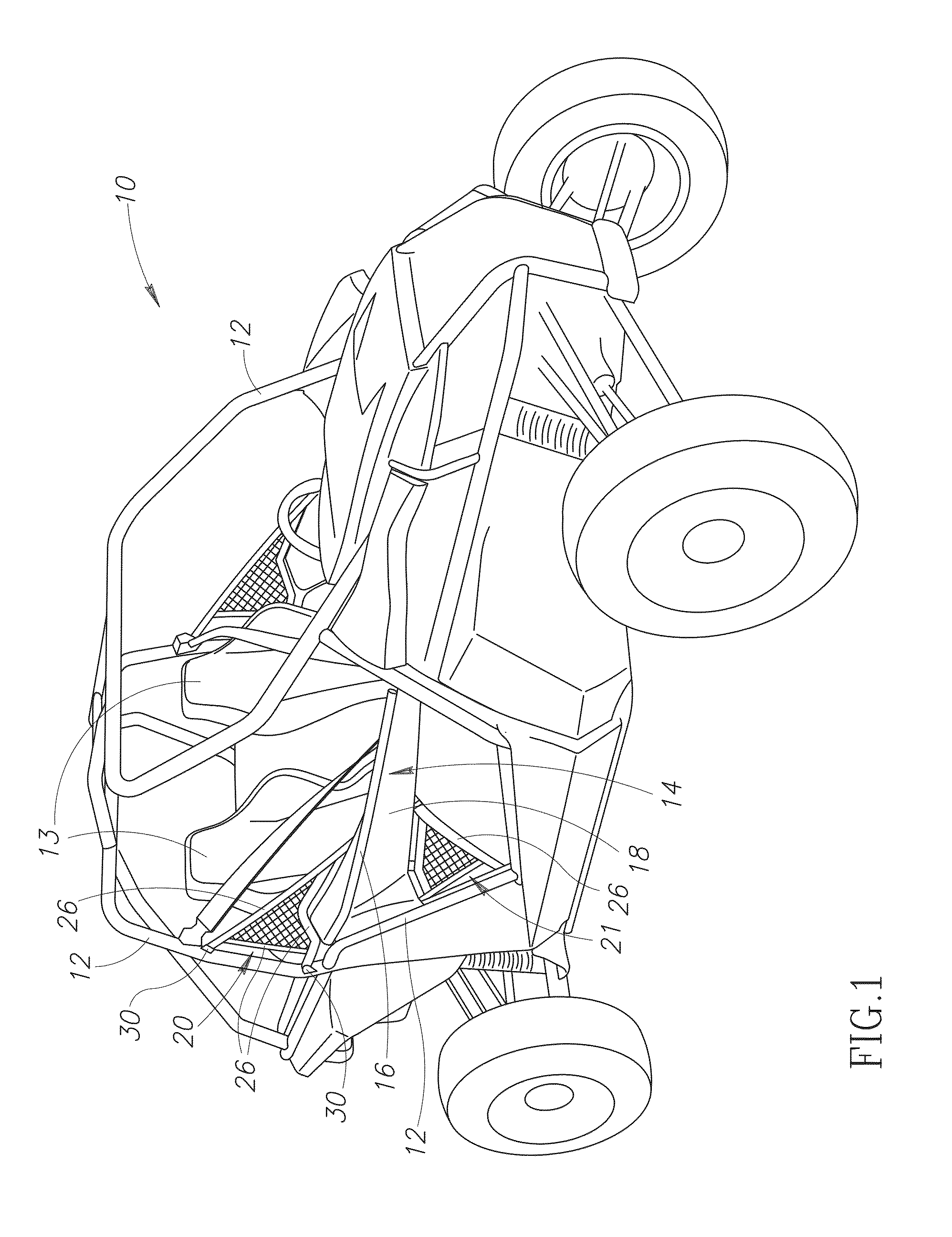

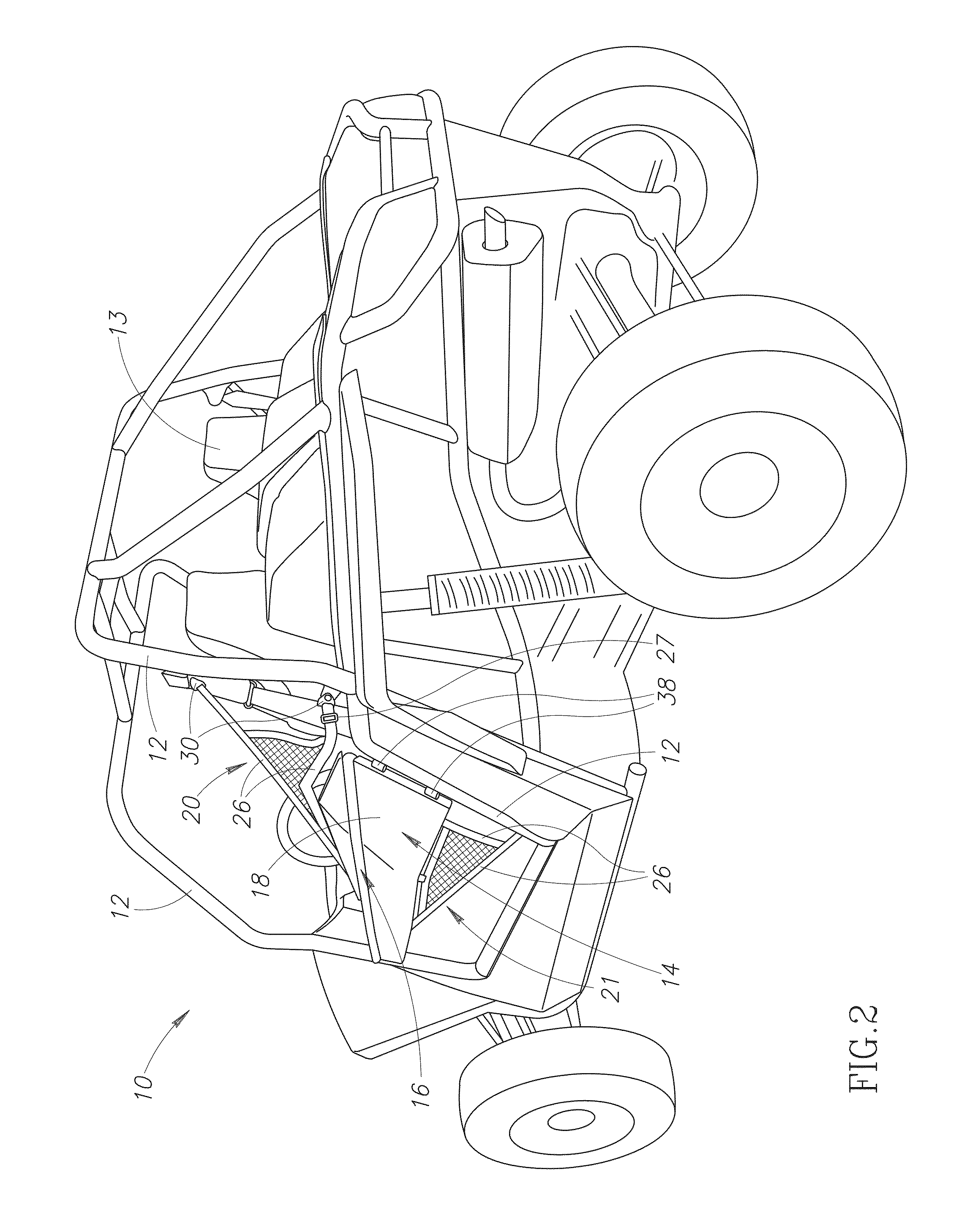

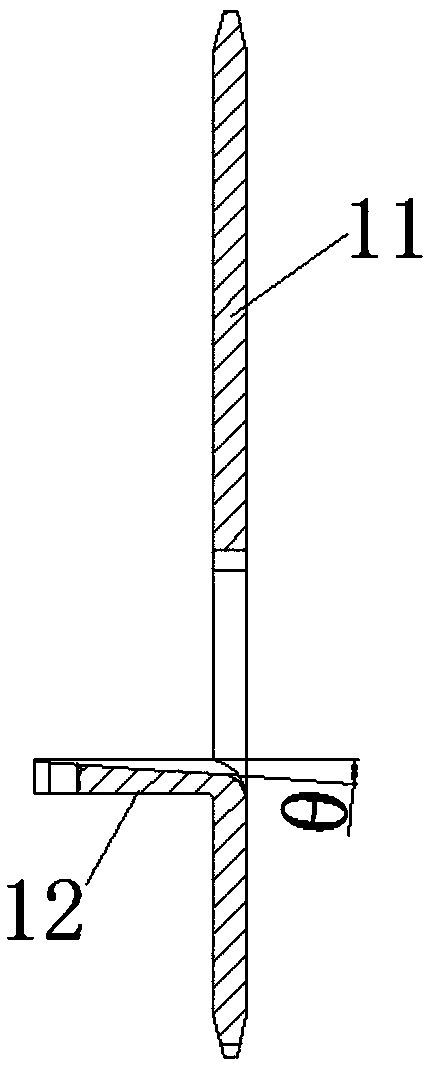

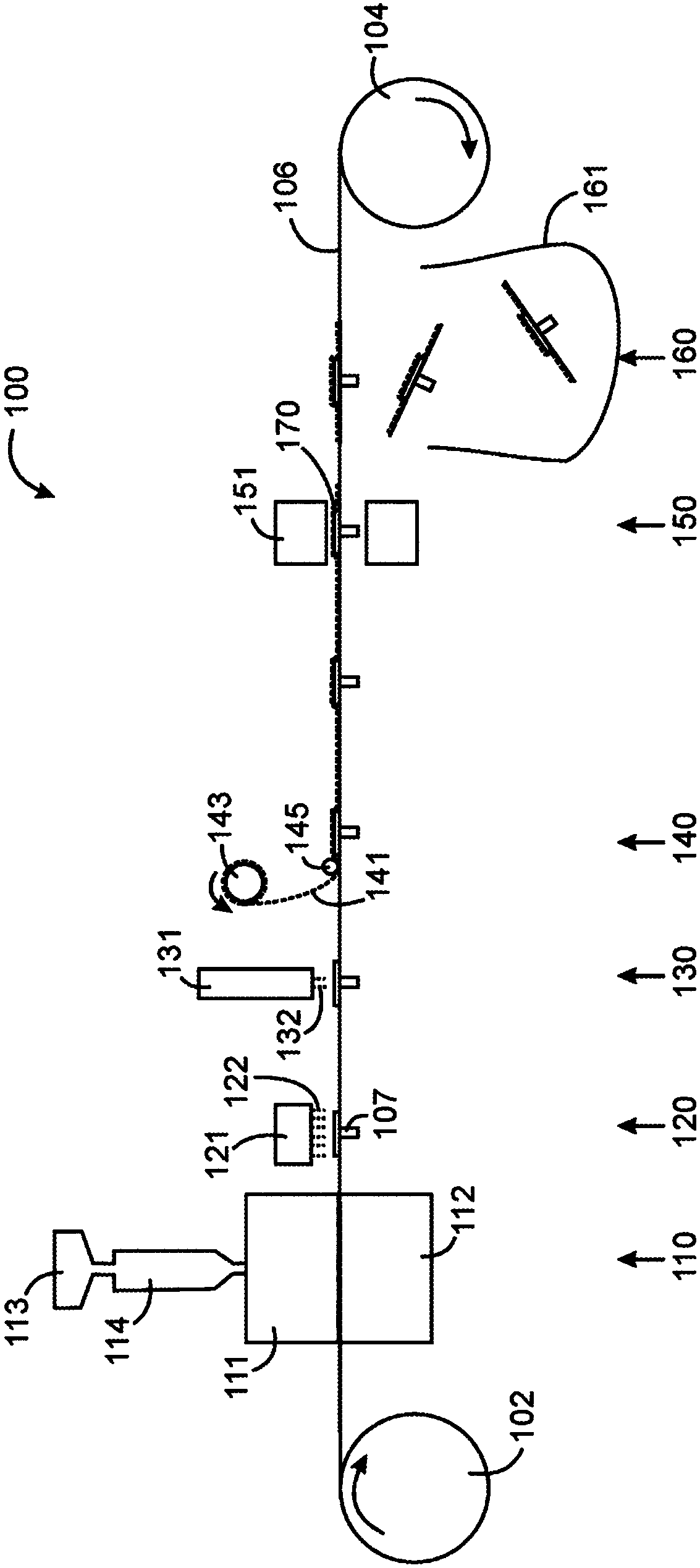

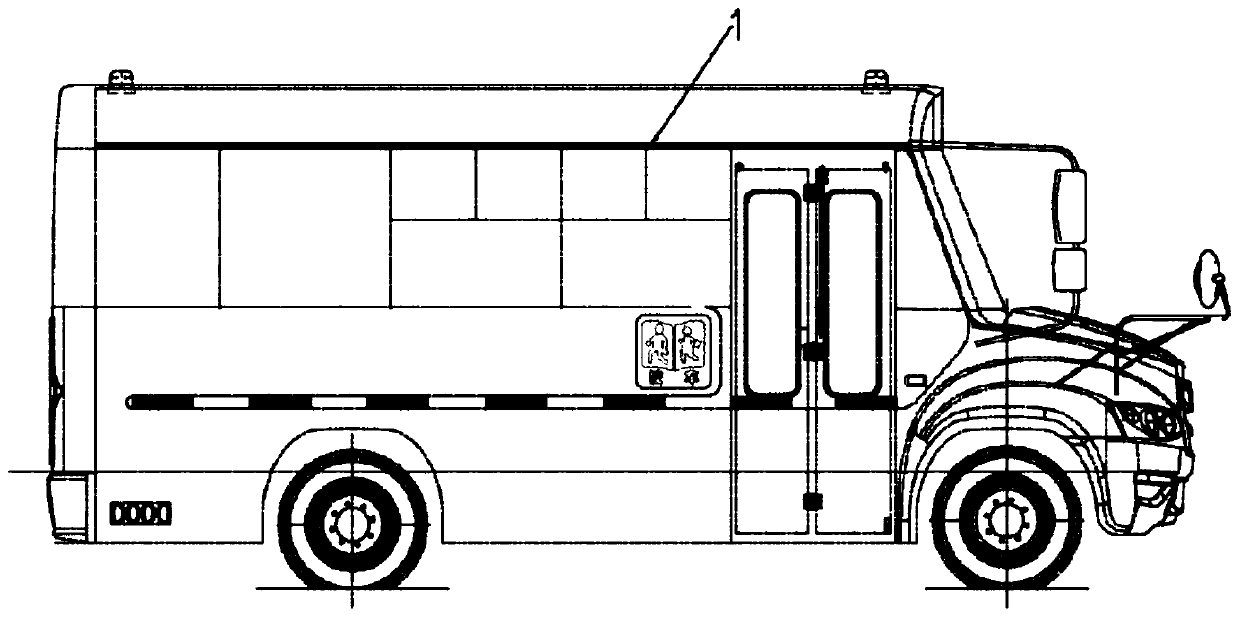

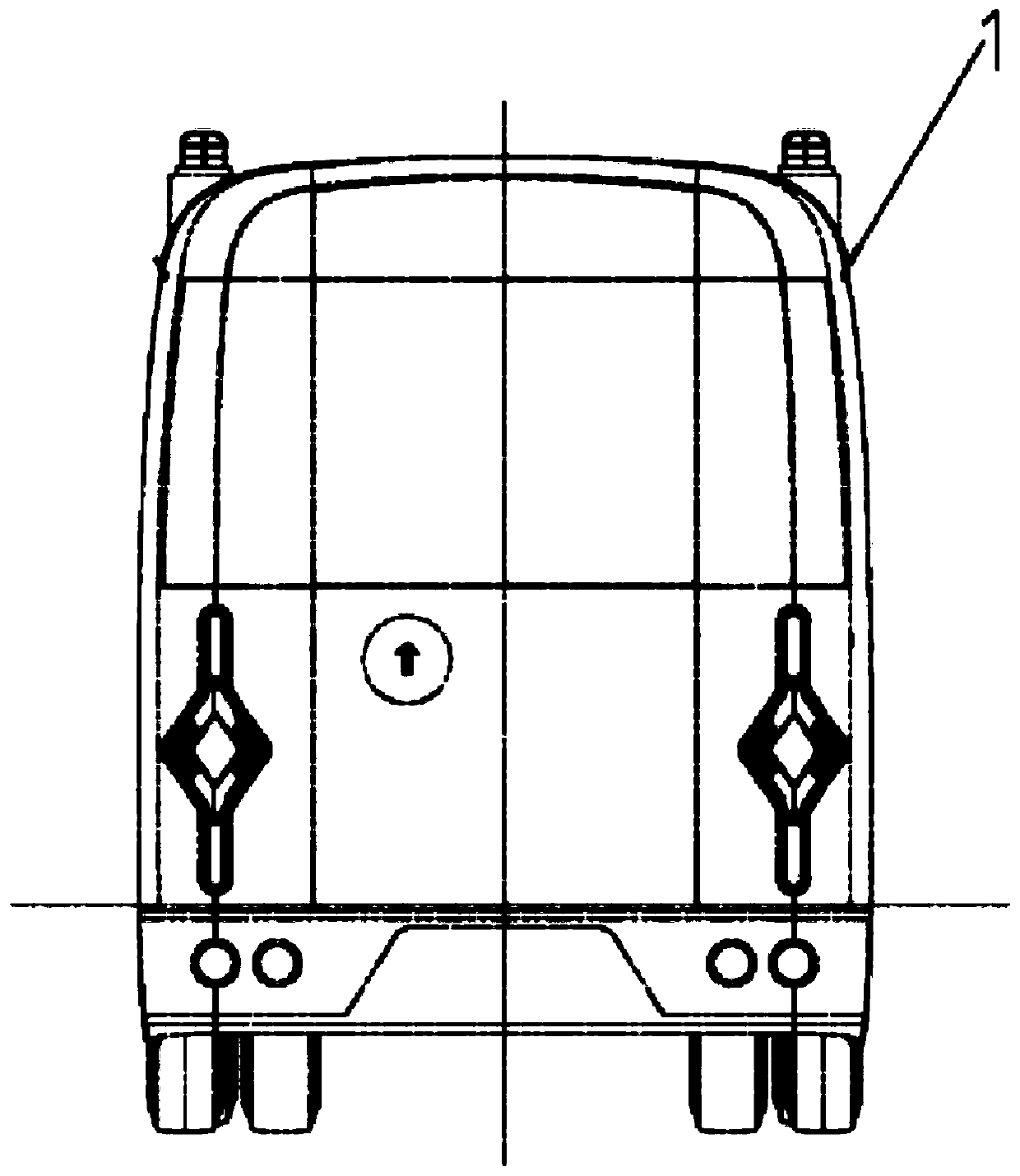

Door for recreational off-highway vehicle

ActiveUS20130199097A1Prevent and reduce and injuryPrevent and reduce likelihoodBuilding locksPedestrian/occupant safety arrangementSafety netBuggy vehicle

A door and an integrated safety net system for a recreational vehicle having a chassis with a step-through door opening. The door includes a forward end and a rearward end, and a hinge coupled between the rearward end of the door and the chassis of the vehicle. A door panel or upper and lower safety nets are coupled to the door frame forward of the hinge and coupled to the chassis of the vehicle on or rearward of the rearward side of the door opening. The safety net and the door are collectively and cooperatively movable as the rear-hinged door moves to the open position or closed position. The door includes a latch at the forward end of the door to provide one operational step to release or secure the door and the integrated safety nets to the chassis upon ingress or egress of the vehicle.

Owner:ARCTIC CAT

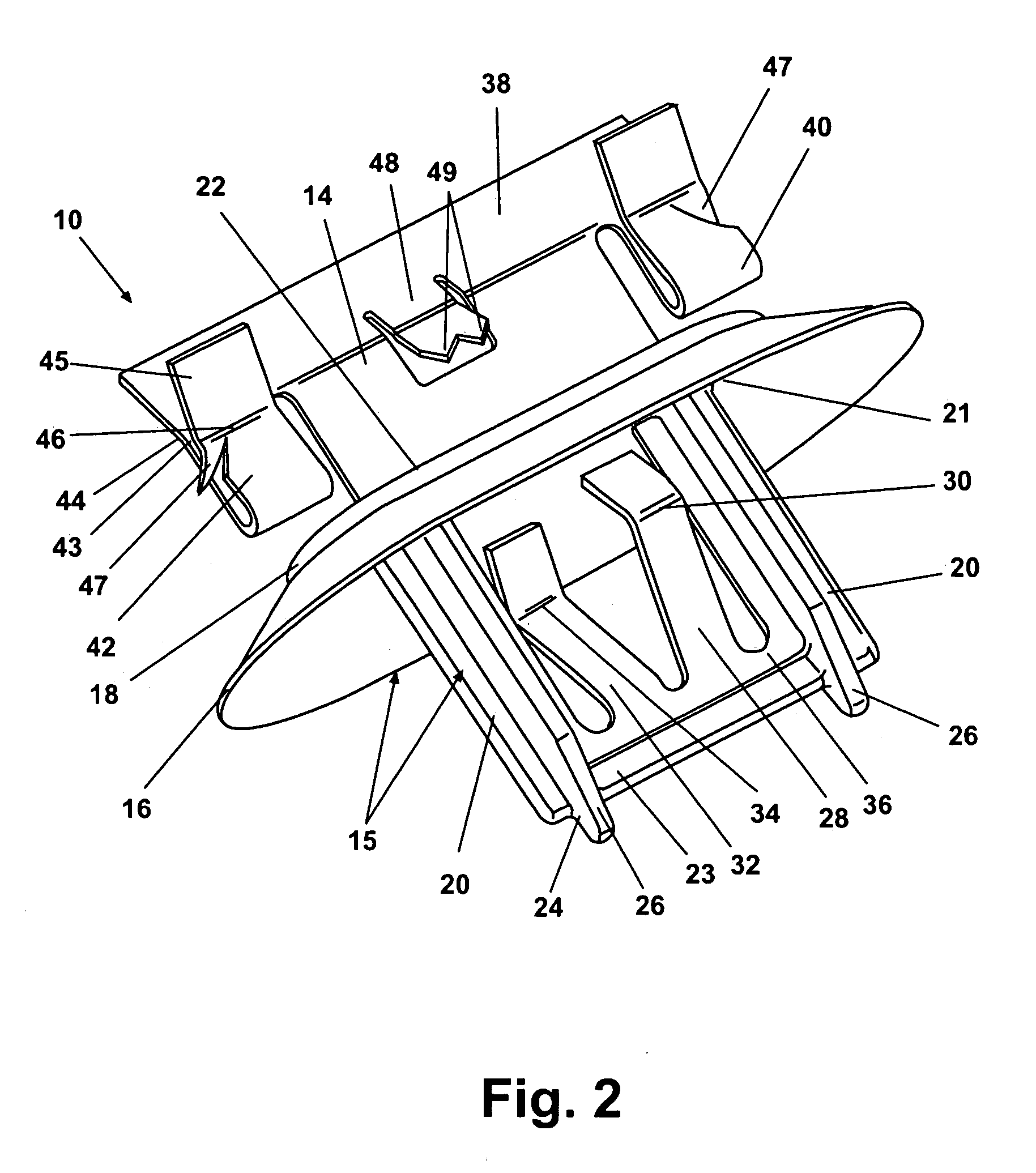

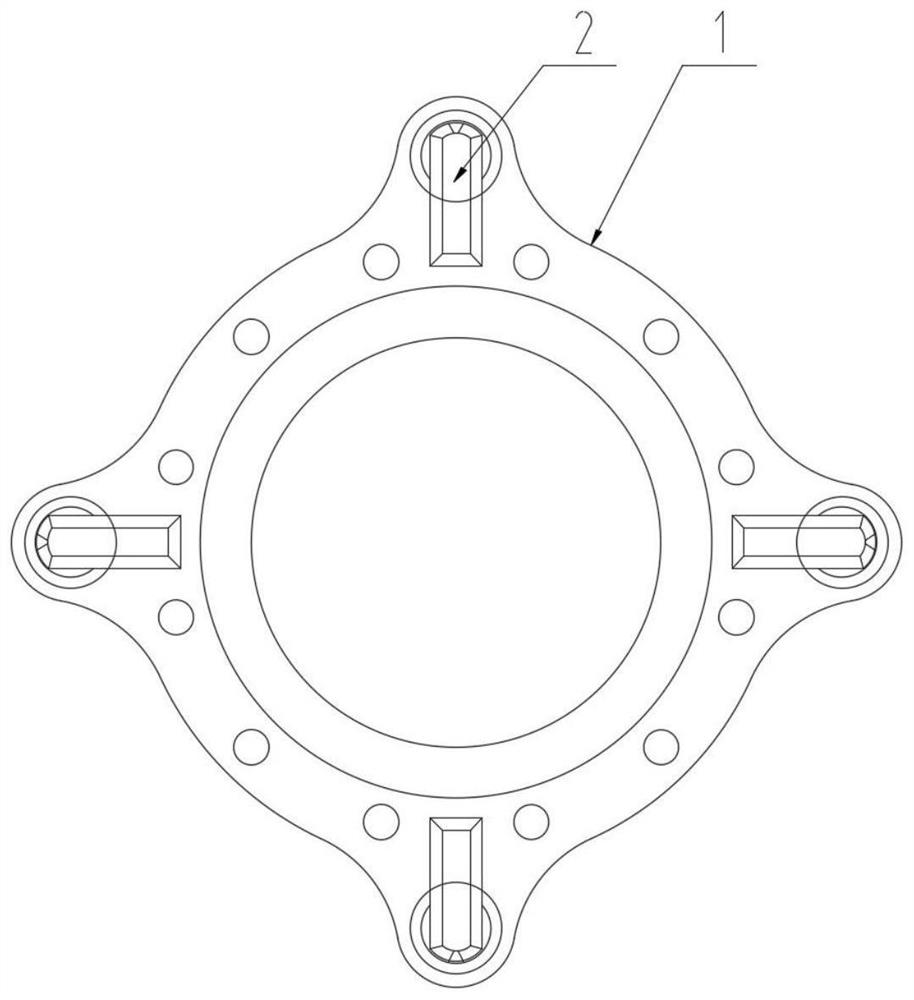

Fastener for fixed rib applications

ActiveUS7204000B2Reduce the possibility of corrosionLow costSnap fastenersSnap-action fastenersEngineeringFastener

A fastener joining accessories to automobiles includes a molded portion having a flexible skirt and two support posts extending from the flexible skirt. A metallic portion insert molded with the molded portion includes both a pair of deflection wings and a pair of looped bights oppositely extending from the flexible skirt.

Owner:NEWFREY

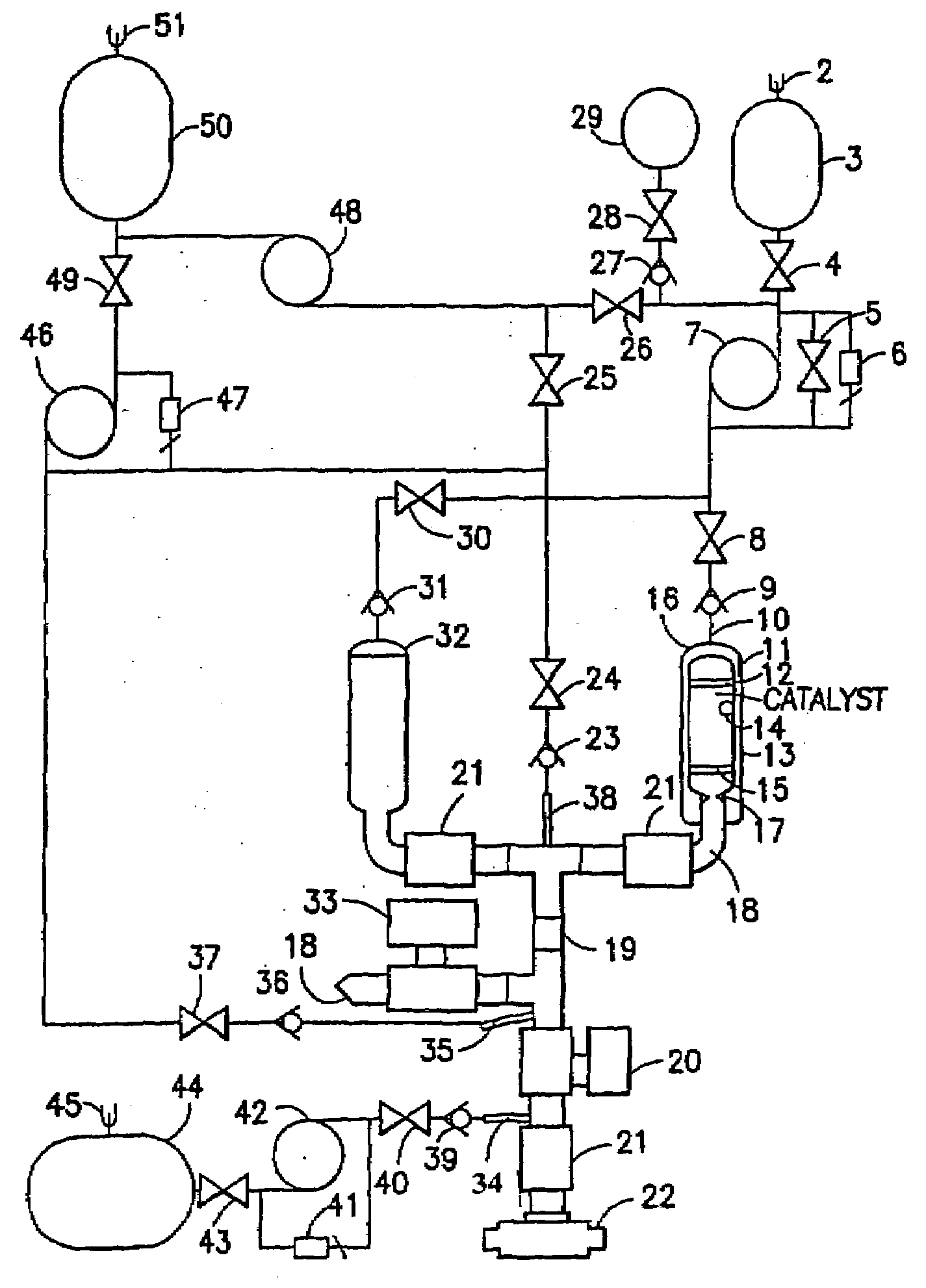

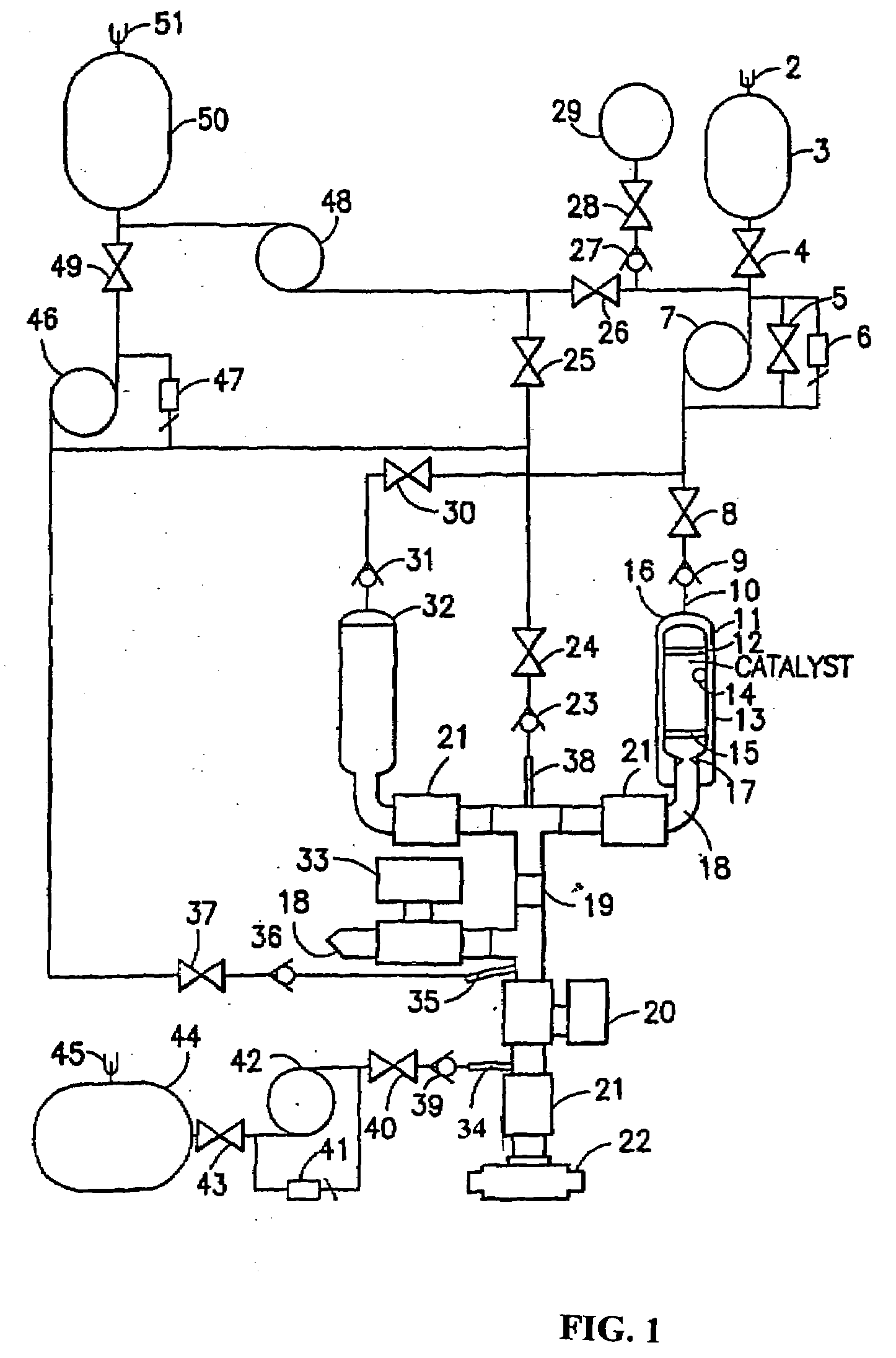

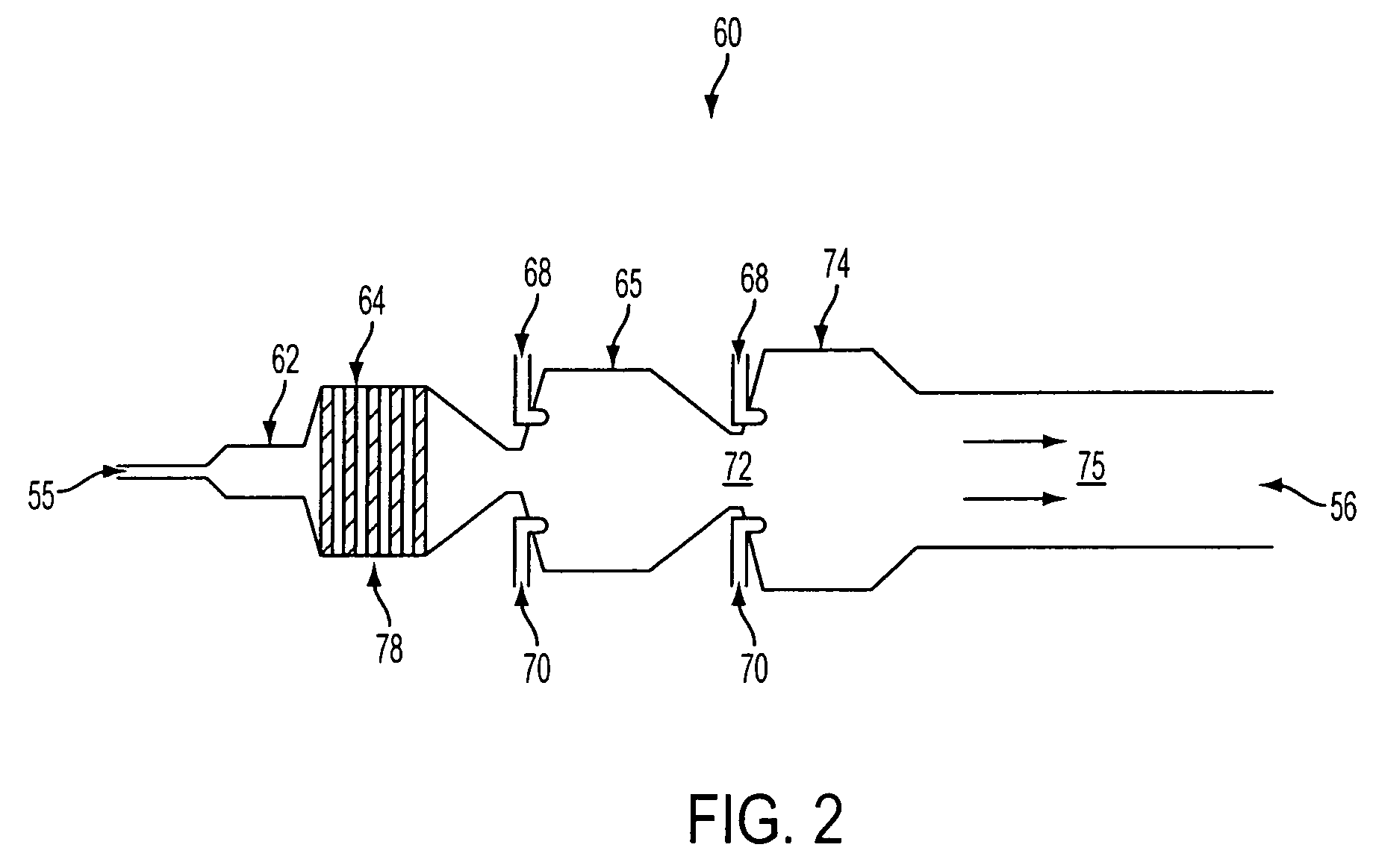

Engine/steam generator with afterburner

InactiveUS20080087434A1Efficient use ofReduce the possibility of corrosionExothermal chemical reaction heat productionDrilling rodsChemical storageCombustion chamber

An engine / steam generator which converts hydrogen peroxide to superheated steam and oxygen and having an afterburner that together with a reducing agent, utilizes the oxygen, thereby supplying oxygen free super-heated steam under pressure for oil well stimulation. Fluids such as water and KH30 can be injected into the engine / stem generator. The invention also relates to an apparatus and methods of incineration, soil remediation, land fill remediation, controlled vault burning, chemical atomization / vaporization, home heating, generation of electricity, diesel engine exhaust cleaning, steam turbine, gas path cleaner for jet engines, steam cleaning, natural gas engine power booster emission reducer, chemical storage tank cleaning, portable gas drive, and metal tempering.

Owner:UNITED ENERGY CORP

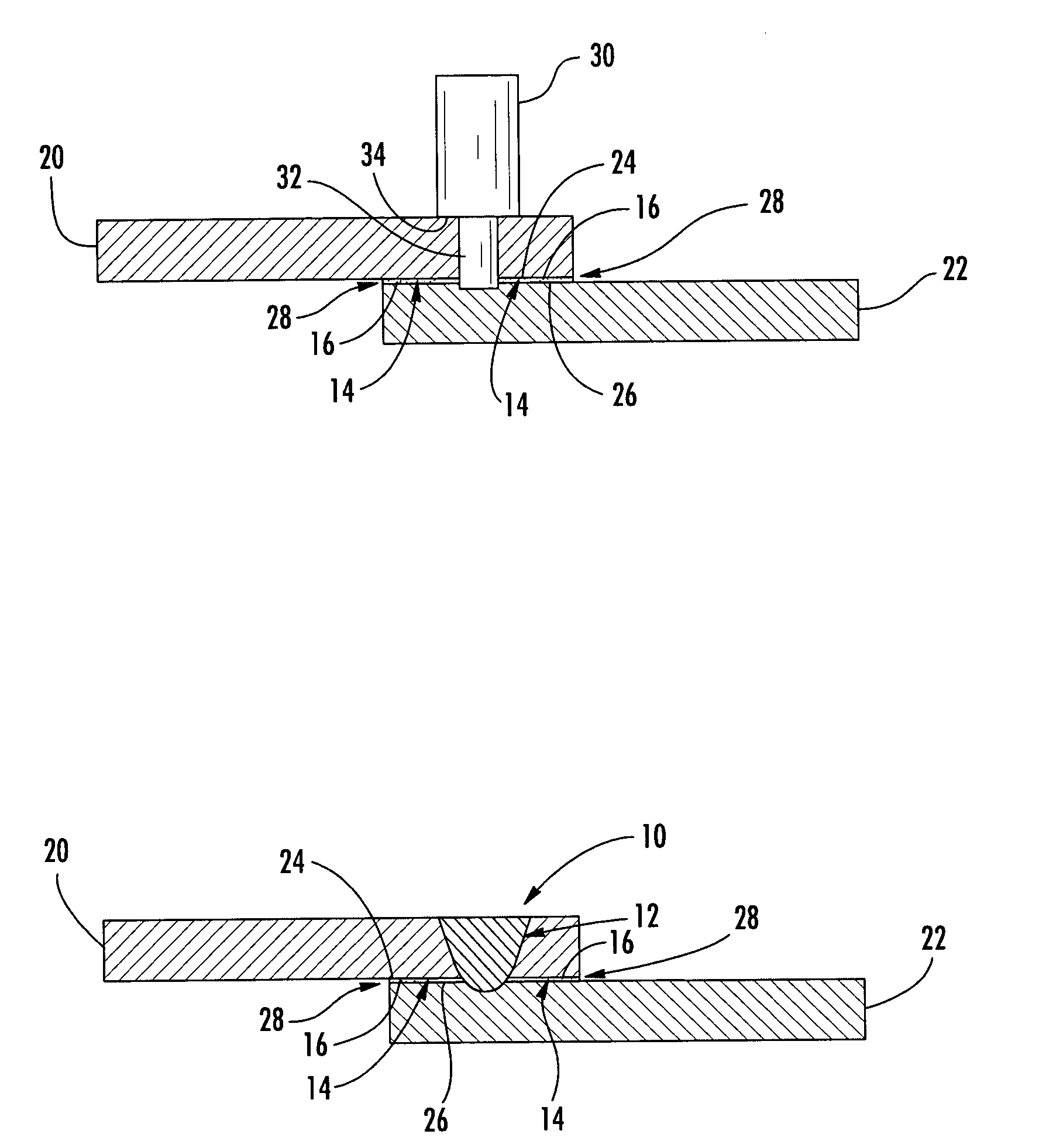

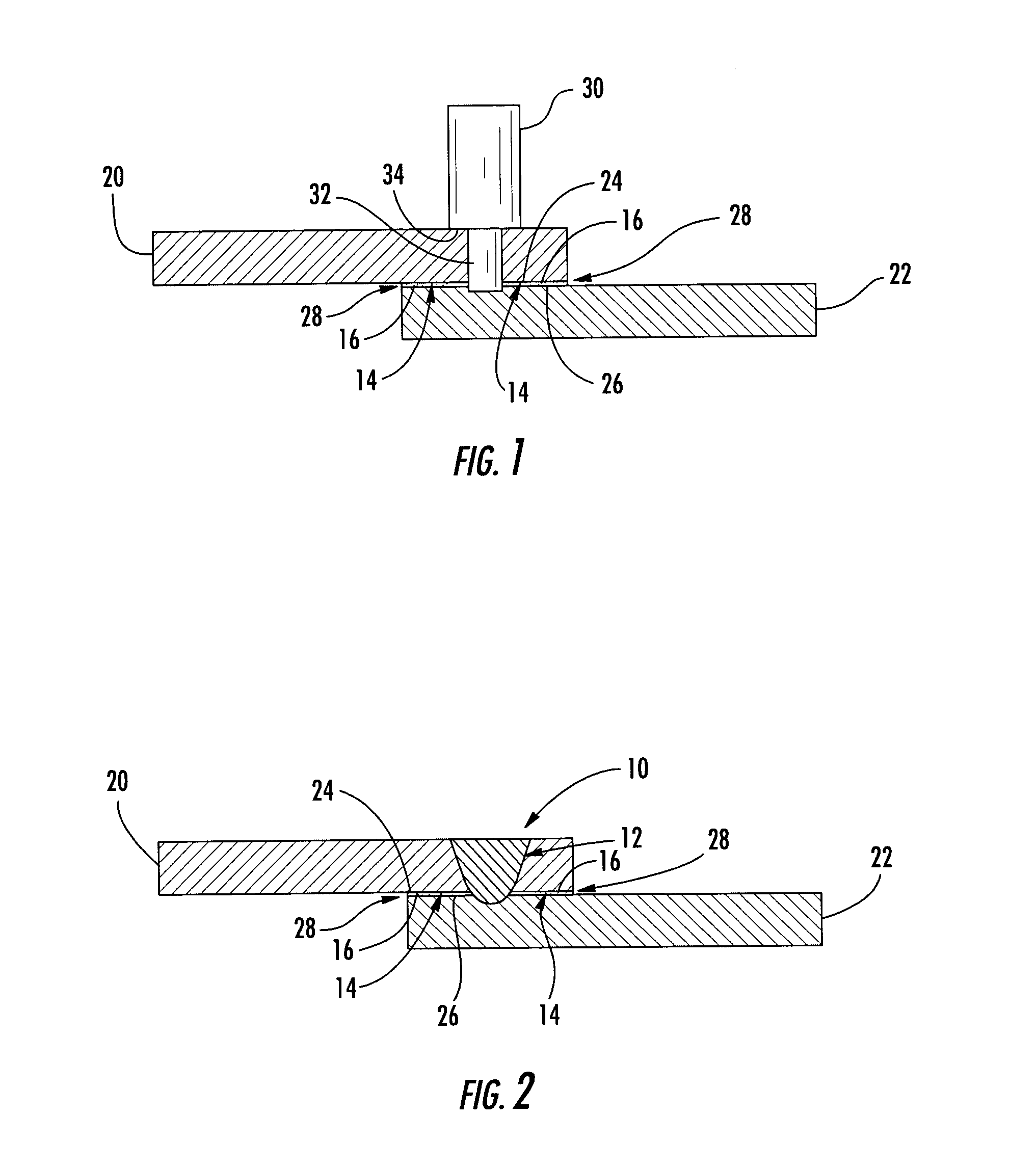

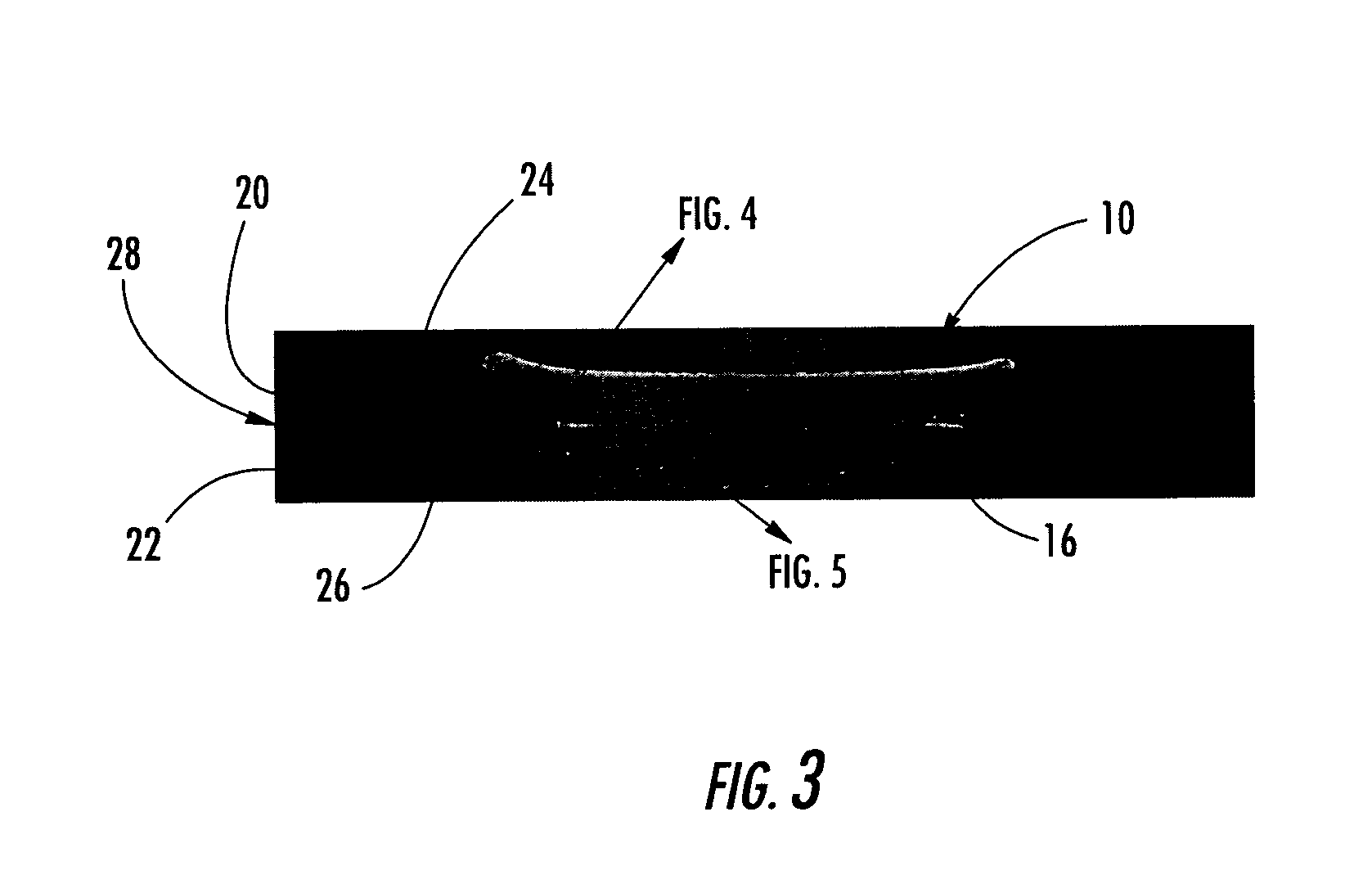

Method and sealant for weld joints

InactiveUS6905060B2Reduce the possibility of corrosionRisk of timeWelding/cutting auxillary devicesAuxillary welding devicesSealantMoisture

A sealant for a weld joint and an associated weld joint and method are provided. The sealant includes aluminum and germanium and is characterized by a melting temperature that is lower than the melting temperature of the structural member that is joined. The sealant, which is disposed between faying surfaces of the structural members, can fill the spaces between the structural members to prevent the entry of chemicals, moisture, debris, and other substances, thereby reducing the likelihood of corrosion of the joint or structural members at the interface. Further, the sealant can be diffusion bonded to the faying surfaces, for example, by the heat generated during the joining process.

Owner:THE BOEING CO +1

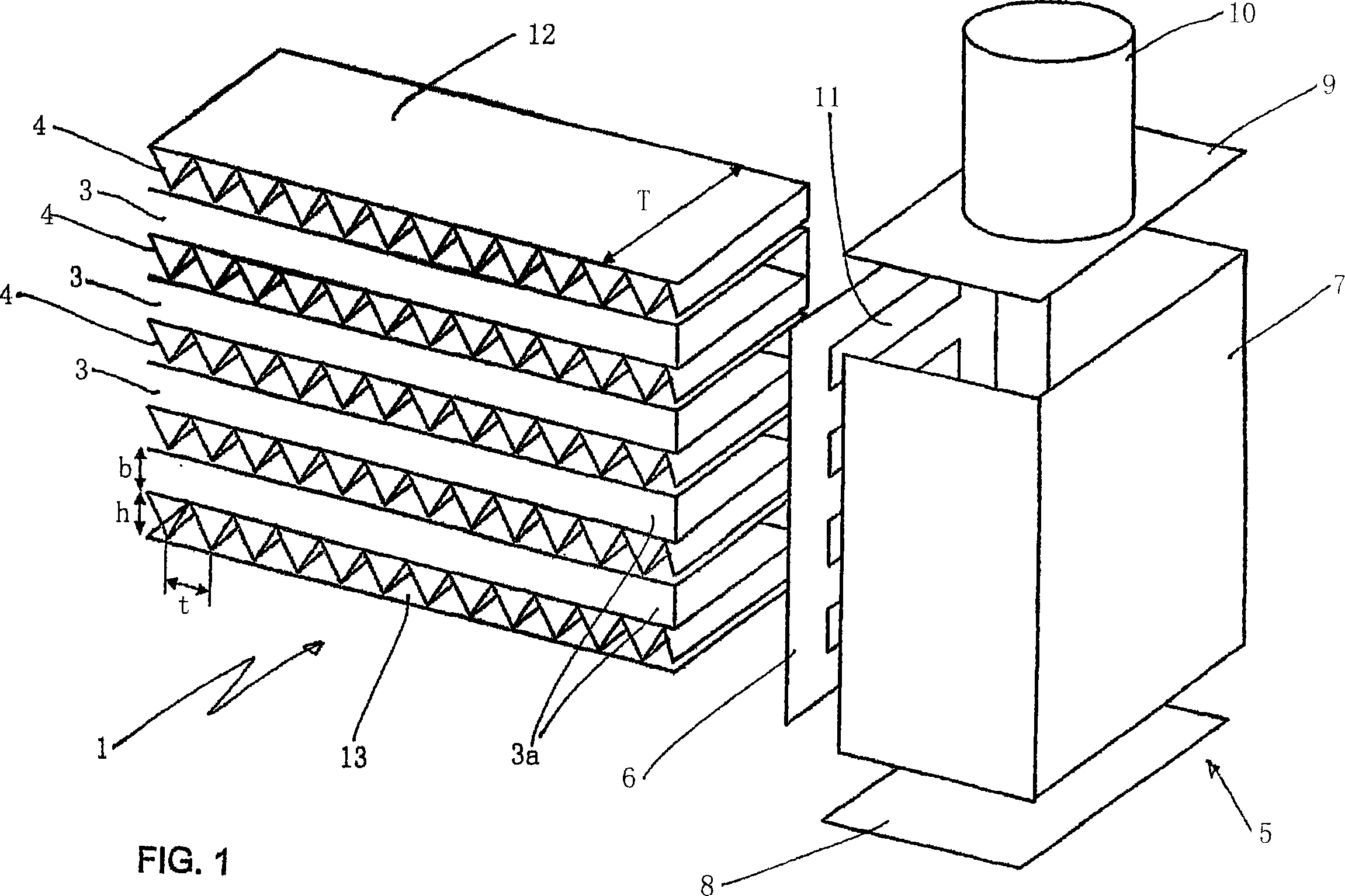

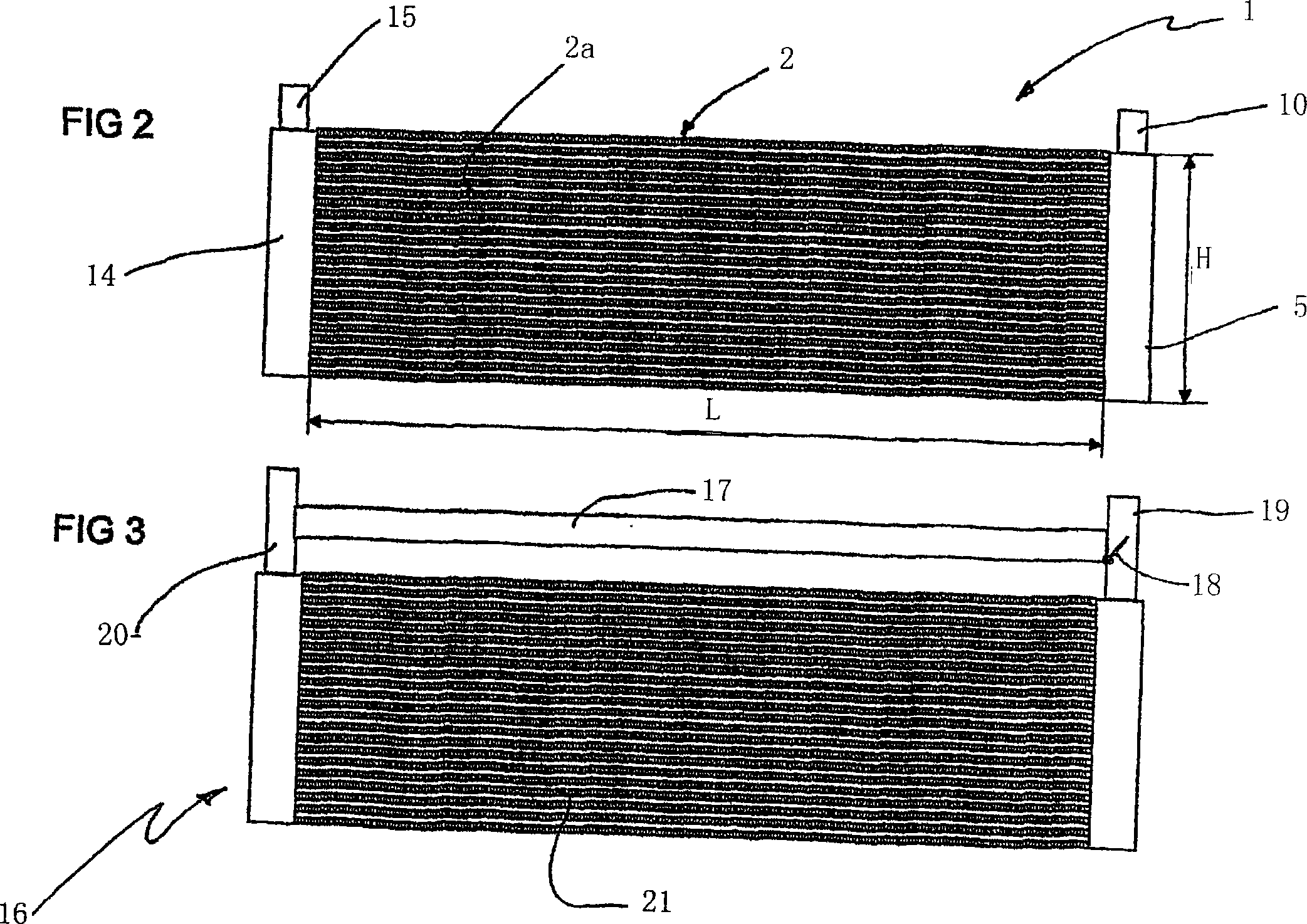

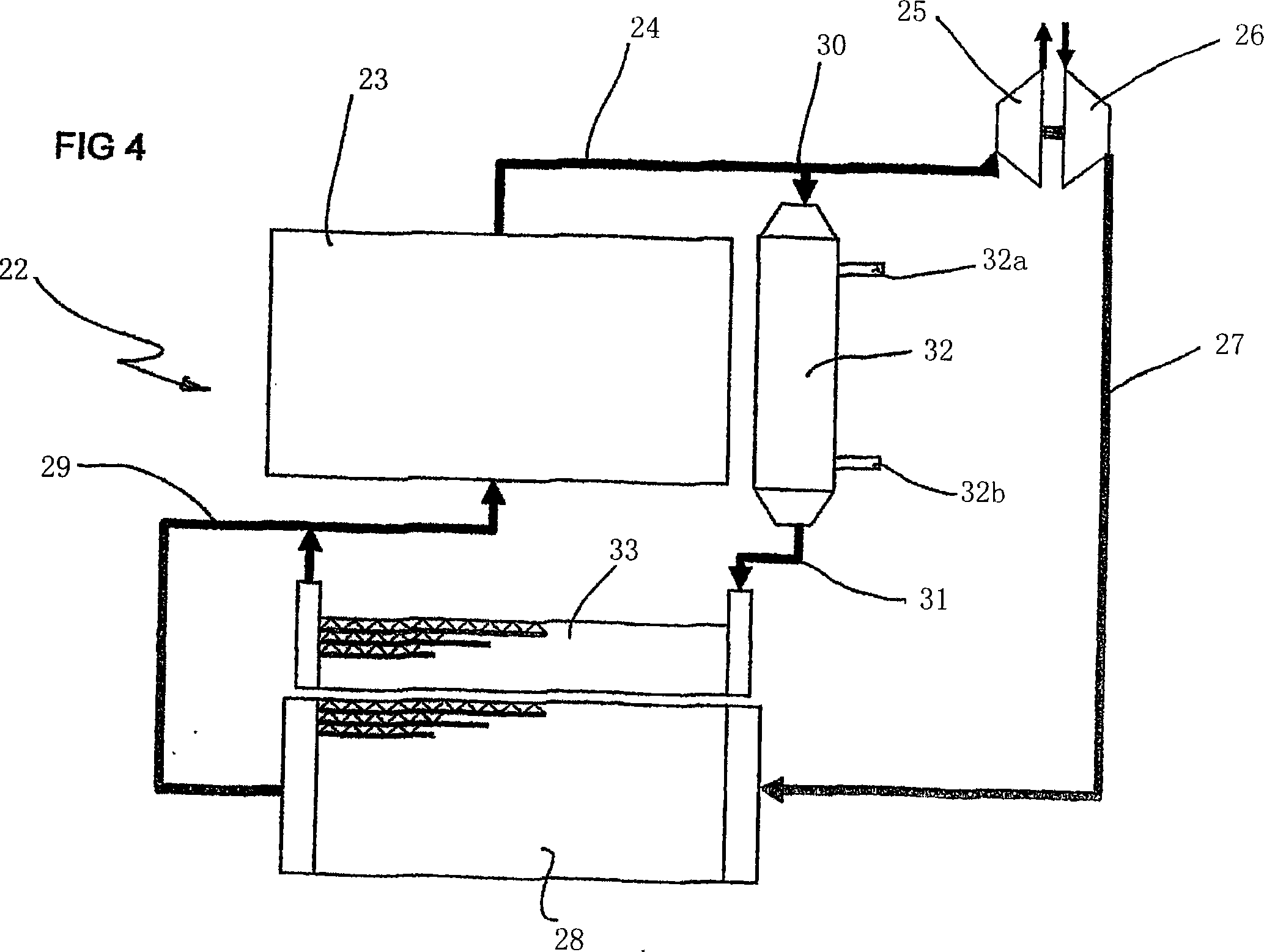

Air-cooled exhaust gas heat exchanger, in particular exhaust gas cooler for motor vehicles

InactiveCN101072976AIncrease powerCompact structureInternal combustion piston enginesStationary conduit assembliesViewpointsImaging processing

To provide an image processing method which easily constructs an indoor space model of high reality in a virtual space and provides a person, who wants to buy a house, with more realistic VR pictures, and also provide a program therefor. Actual pictures of an indoor space photographed with a plurality of photographing devices are obtained, and the obtained actual pictures are compared with virtual pictures obtained by viewing the virtual model of the same indoor model from virtual viewpoints to compute a correlation between the actual pictures and the virtual model. Then, the surface area of the virtual model for mapping the textures of the actual pictures is designated, and the partial areas of the actual pictures after conversion of their forms are mapped to the surface area. Then, the VR images obtained by viewing the virtual model after the texture mapping from arbitrary viewpoints are generated and displayed on a display device.

Owner:BEHR GMBH & CO KG

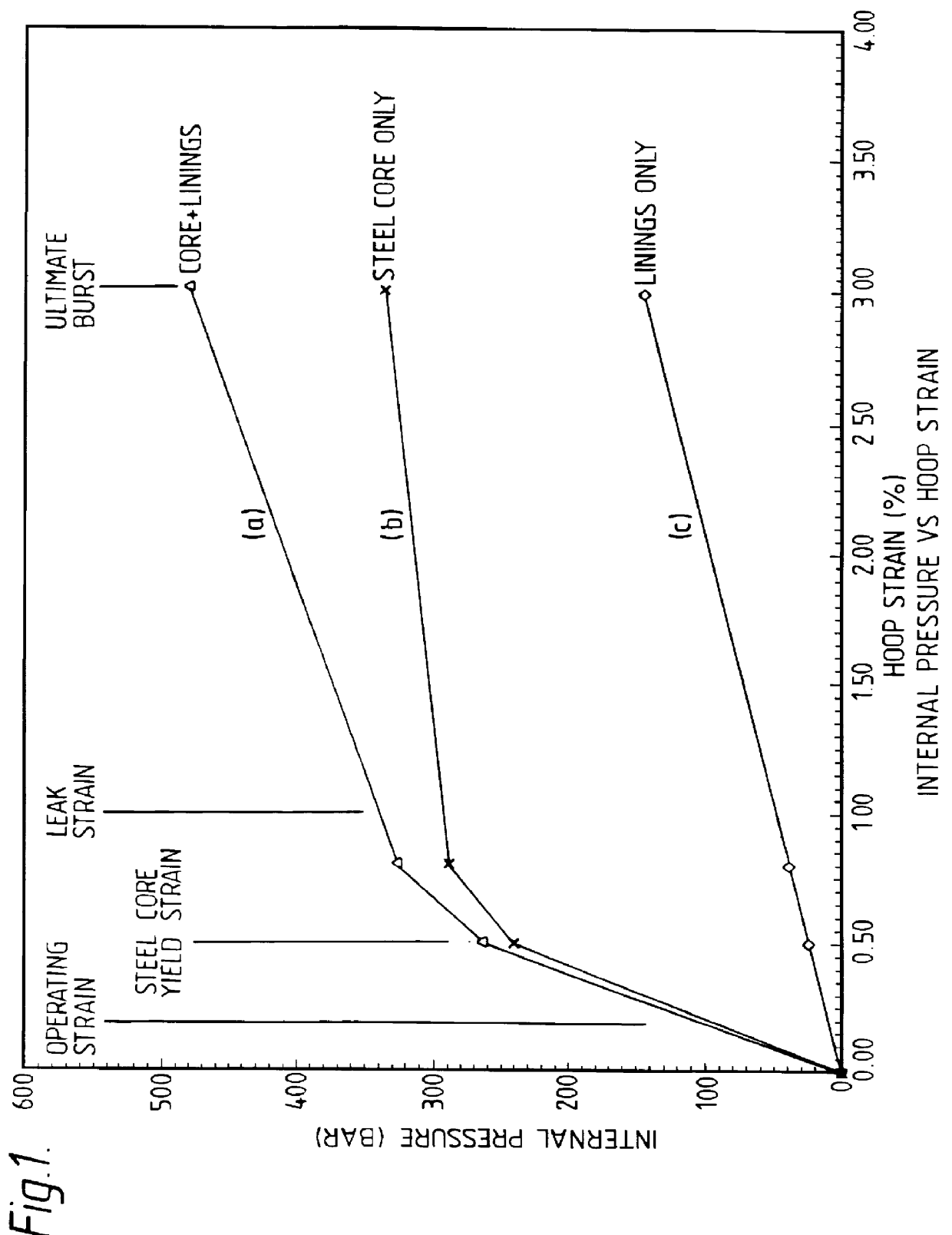

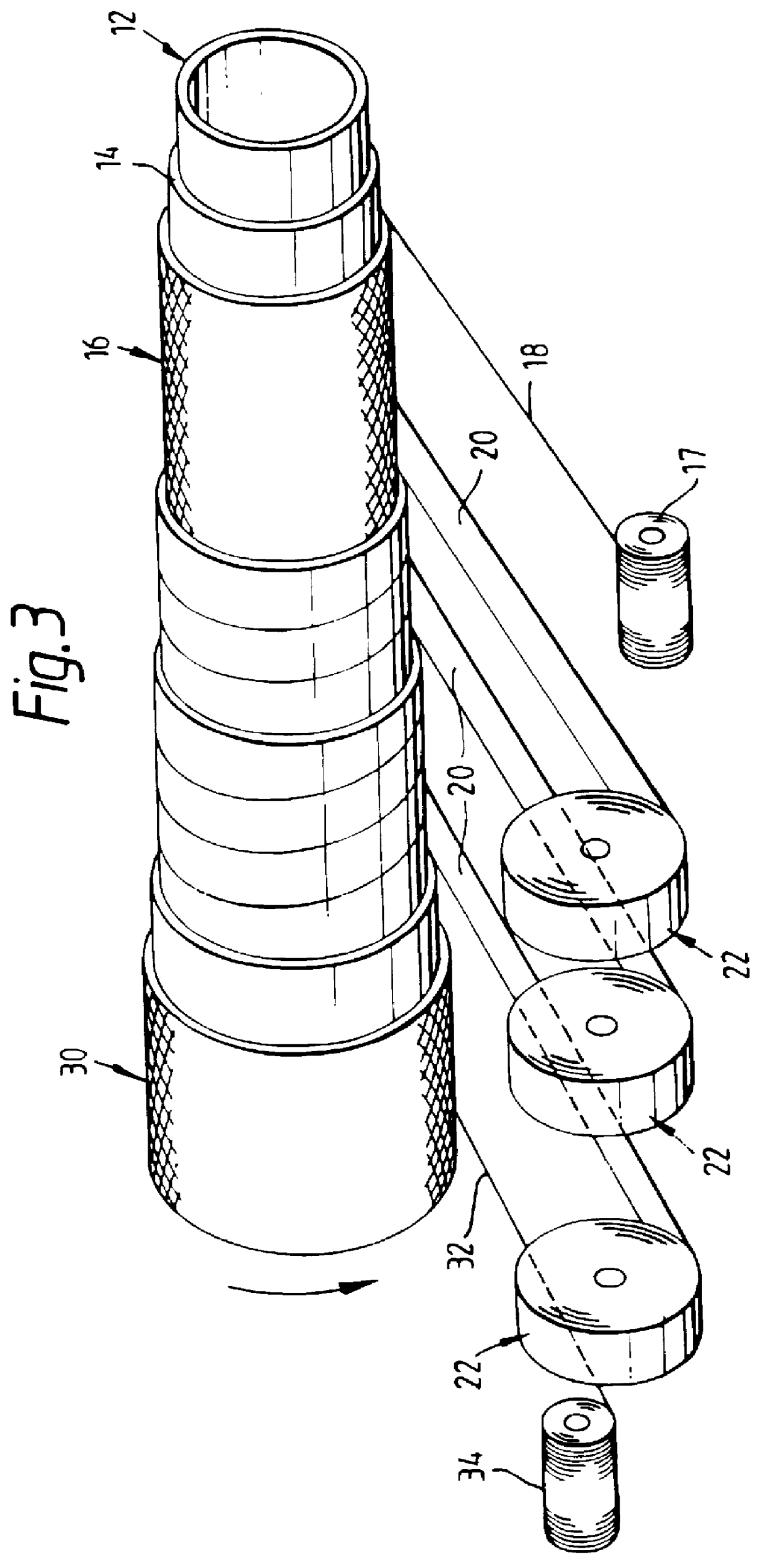

Pipe construction

InactiveUS6048428AImprove the immunityImprove integrityEngine sealsFlanged jointsPlastic materialsEngineering

Owner:BAE SYST LAND SYST MUNITIONS & ORDNANCE

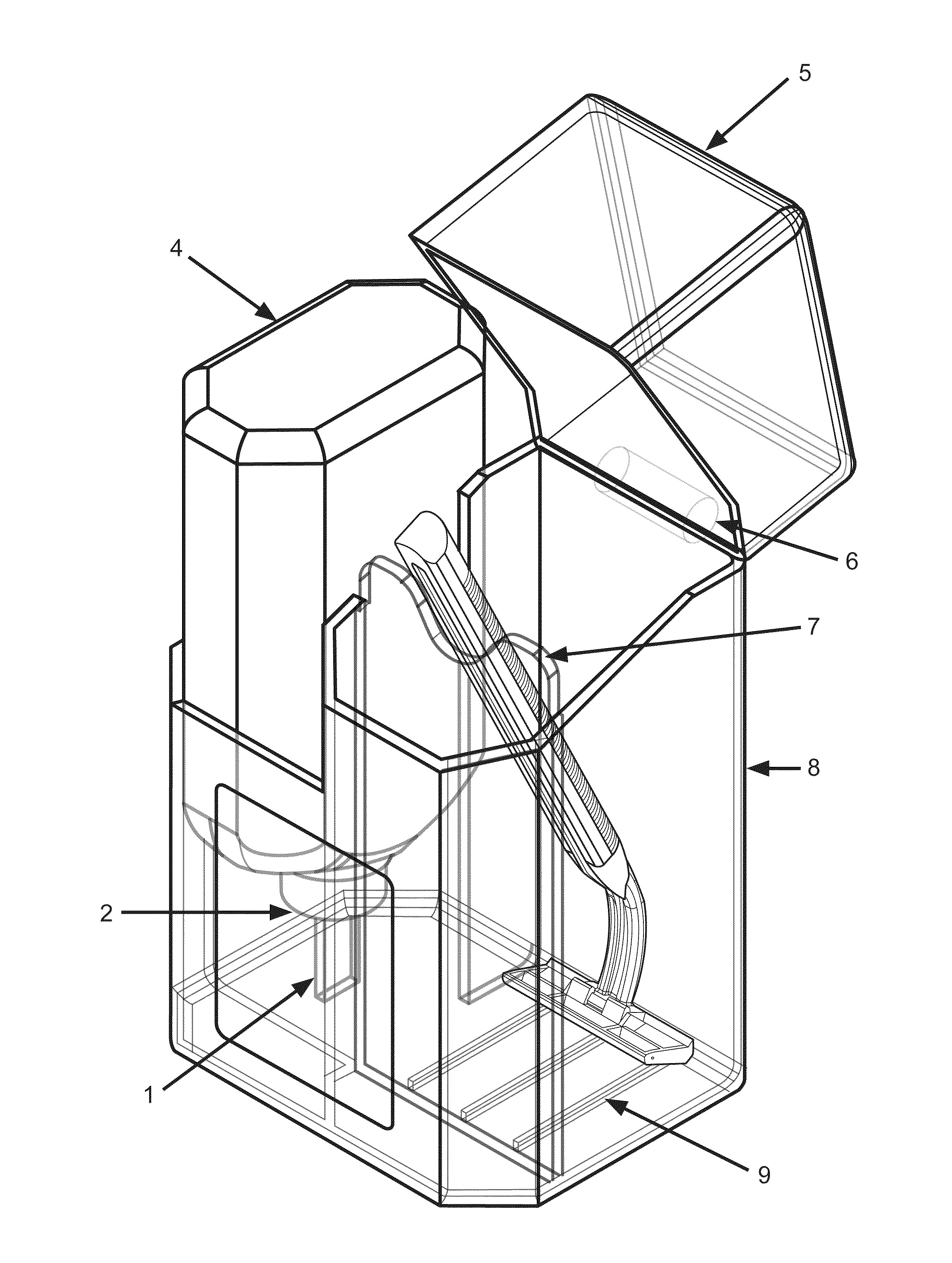

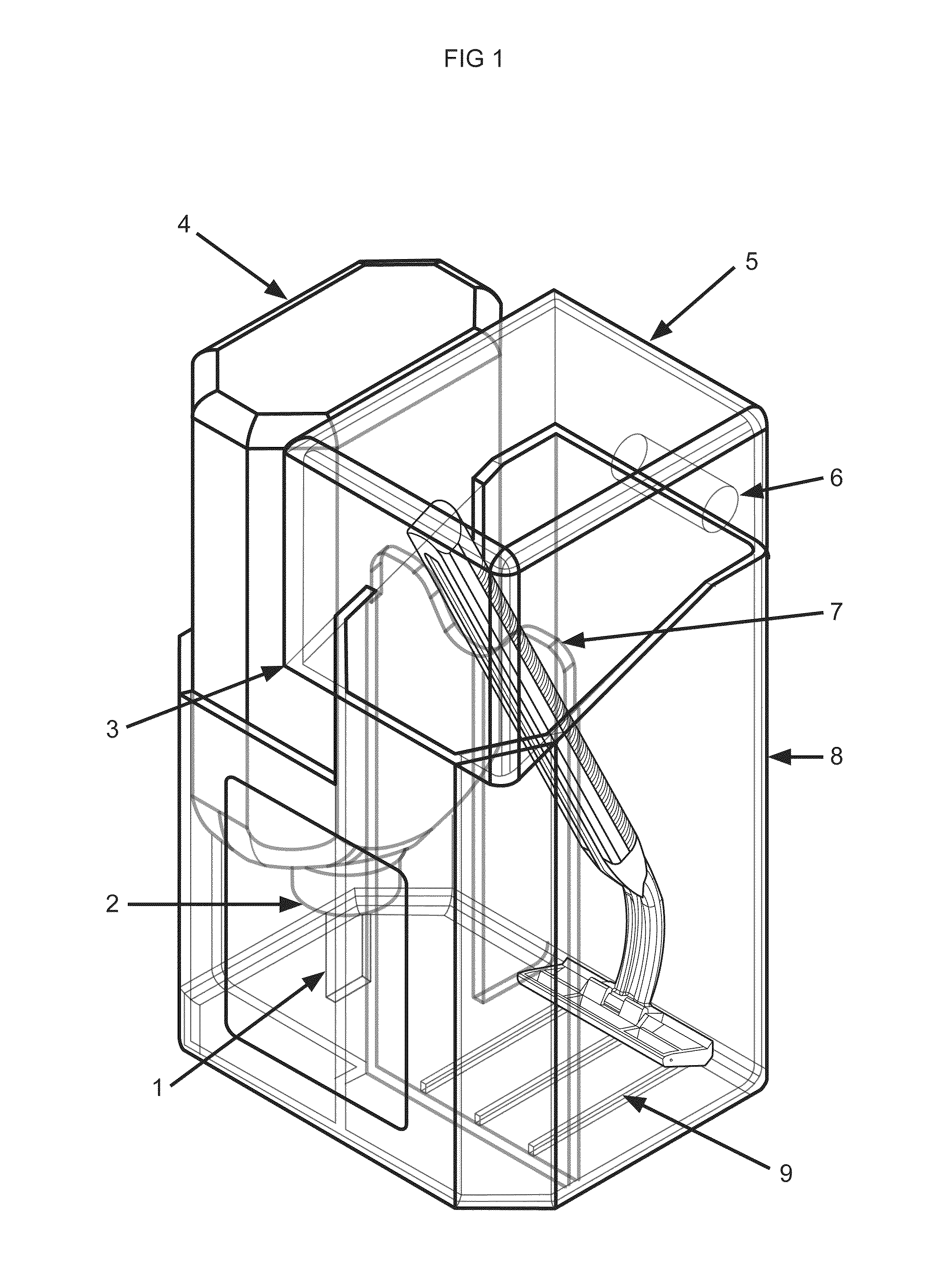

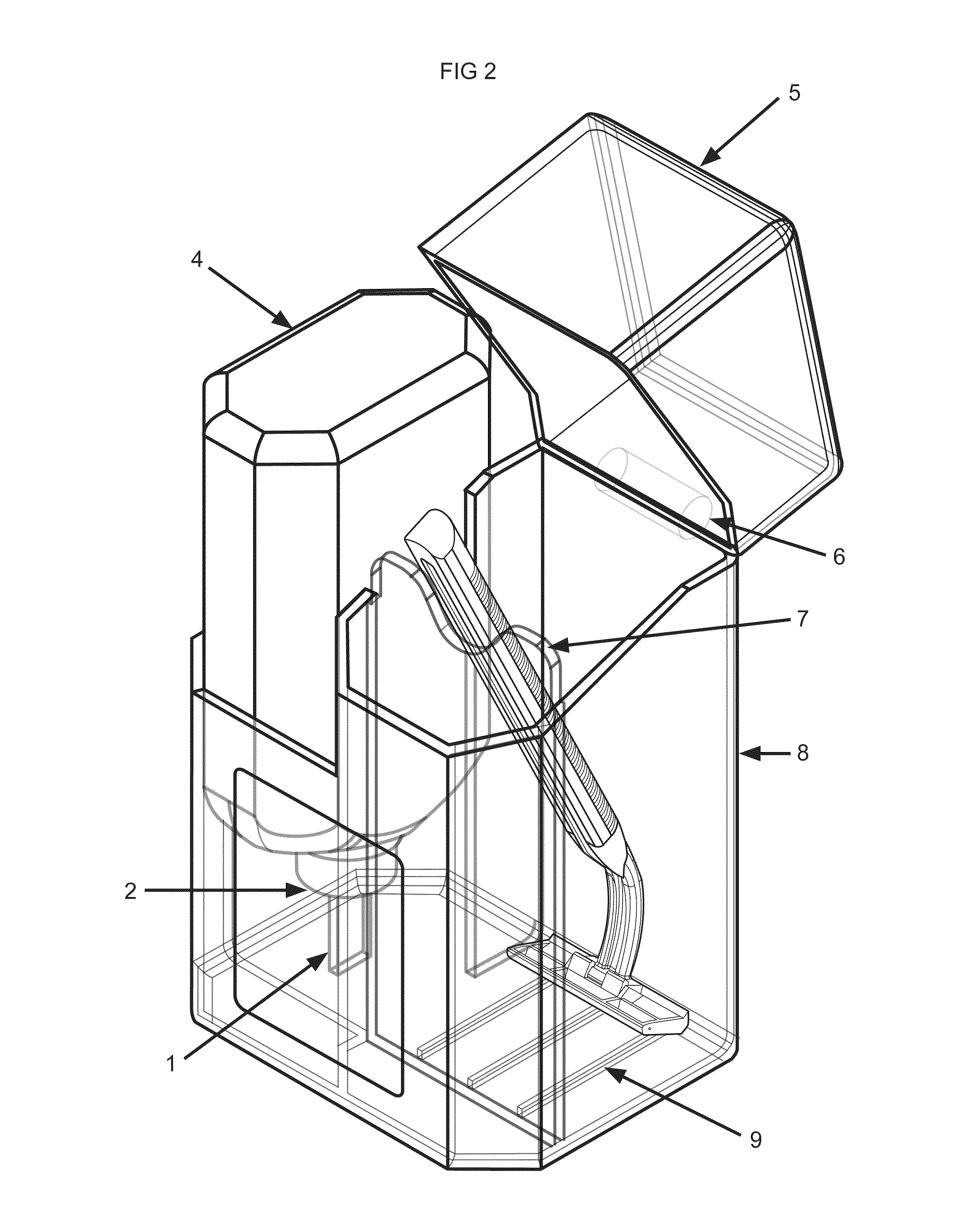

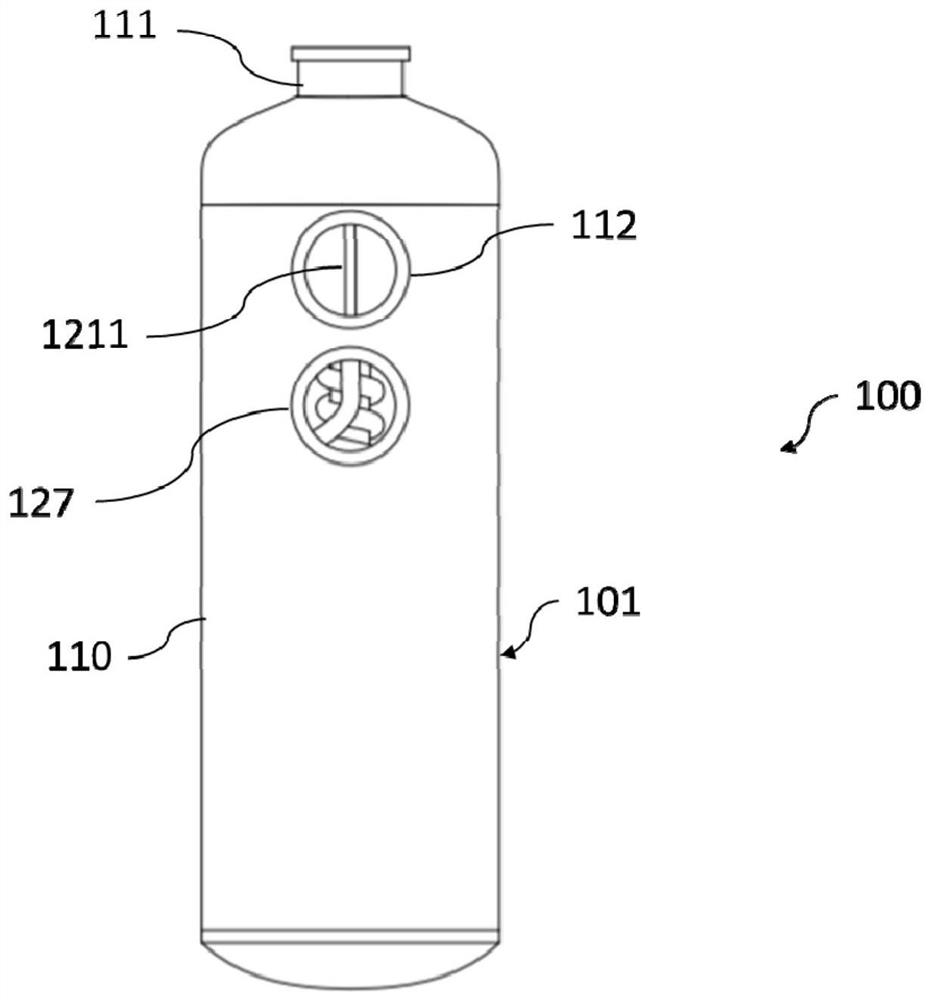

Razor disinfection and storage device

InactiveUS8883075B2Reduce corrosionEasy replenishmentCleaning machinesContainer/bottle contructionAlcoholEngineering

An attractive and compact device and an effective method to store and disinfect a manual shaving razor are disclosed. The method reduces corrosion of the razor's metal blades. A compact container has separate but suitably connected chambers allowing for economy of use of as disinfectant liquid combining alcohol, detergent or soap and skin conditioner. By protecting the razor in one enclosed chamber, oxidative damage and rusting of blades is avoided. A knife edge element is placed at the bottom of another chamber to pierce the foil seal of a suitably inserted bottle within the other chamber. An optional third, drainage chamber below the other two chambers allows for appropriate drainage and removal both of excess fluid used, as well as hair and debris from the blades. The design of the device is compact and attractive, as is the method an extremely effective way of protecting and disinfecting the razor.

Owner:HENRY CHRISTOPHER J +1

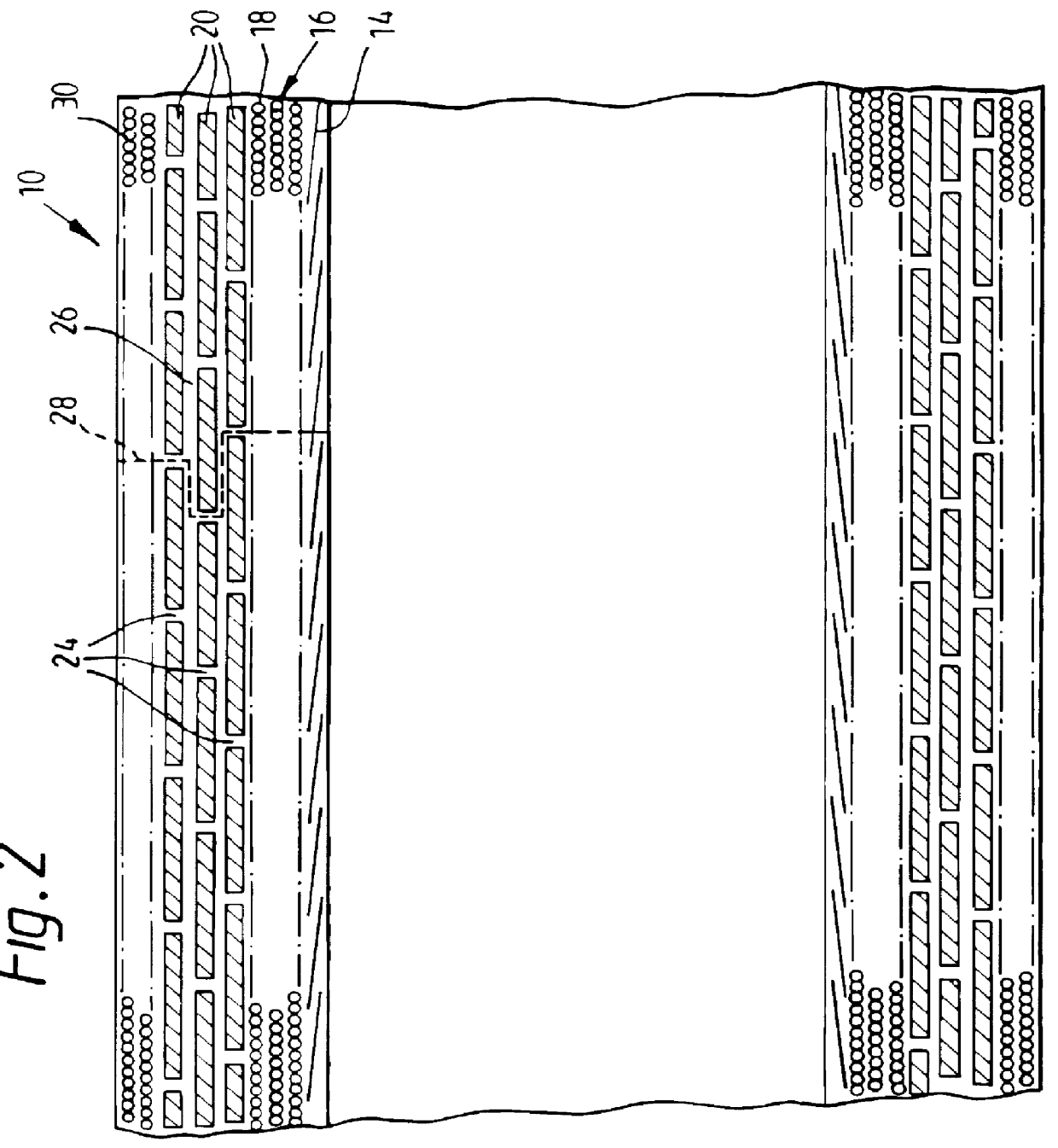

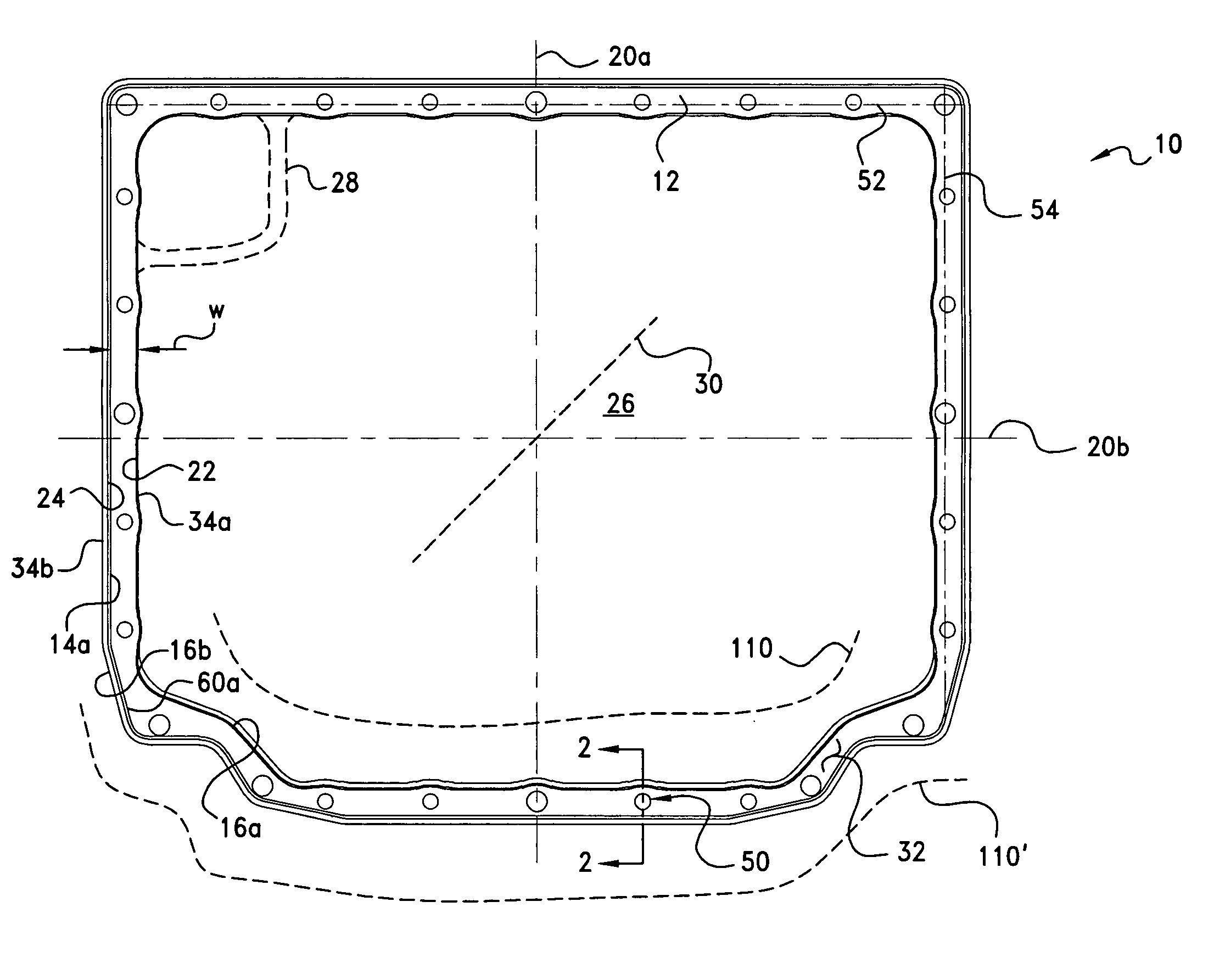

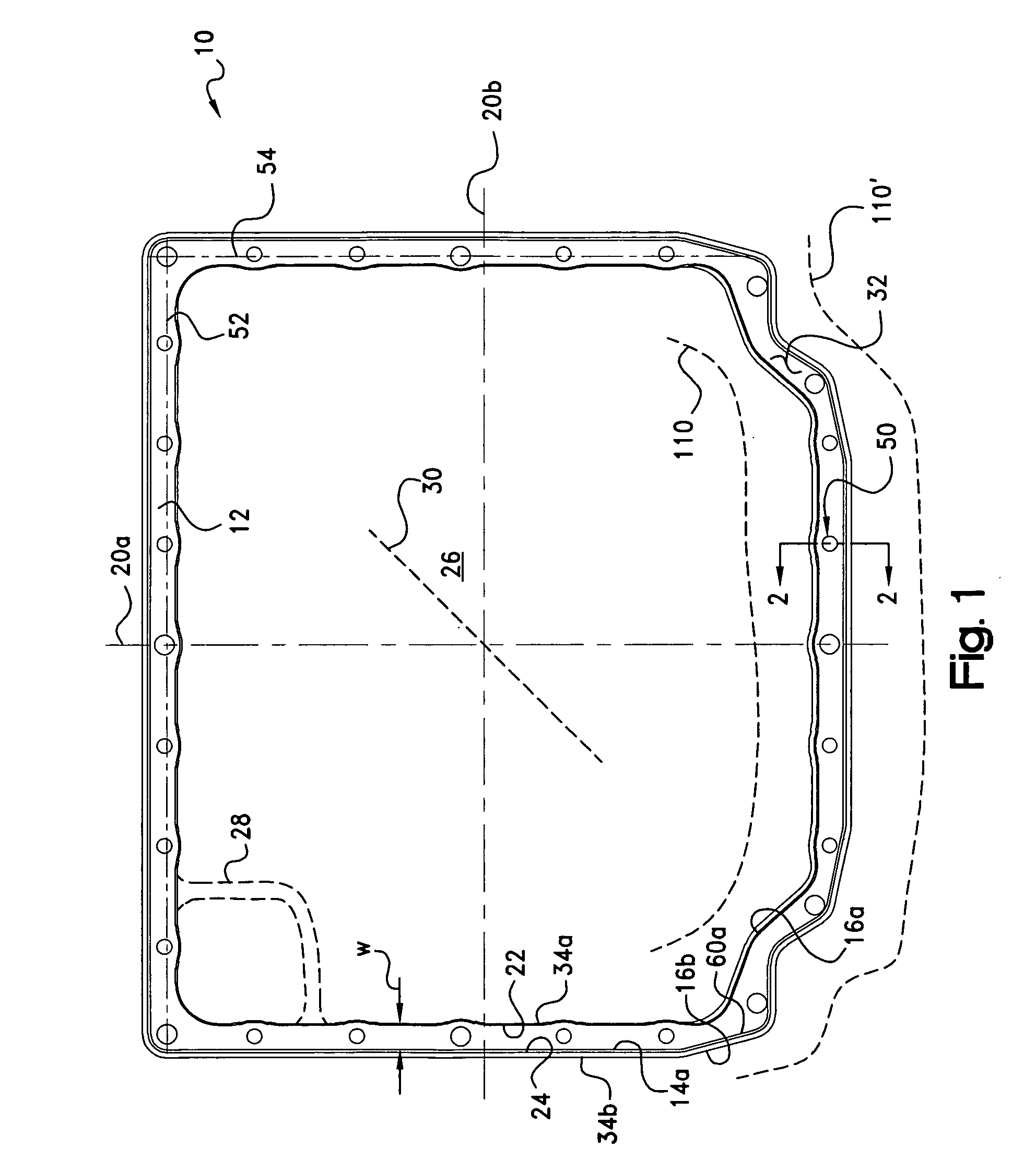

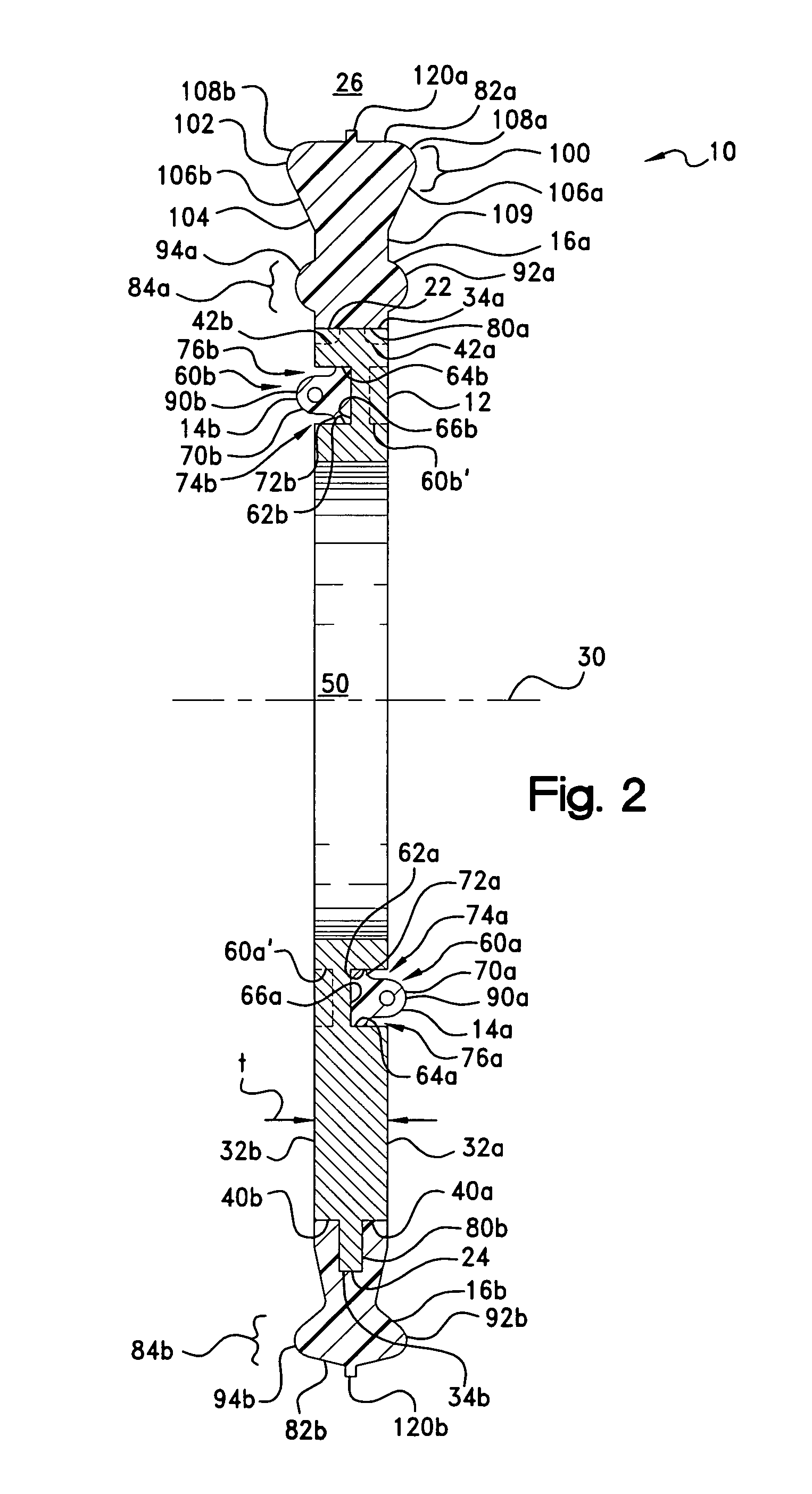

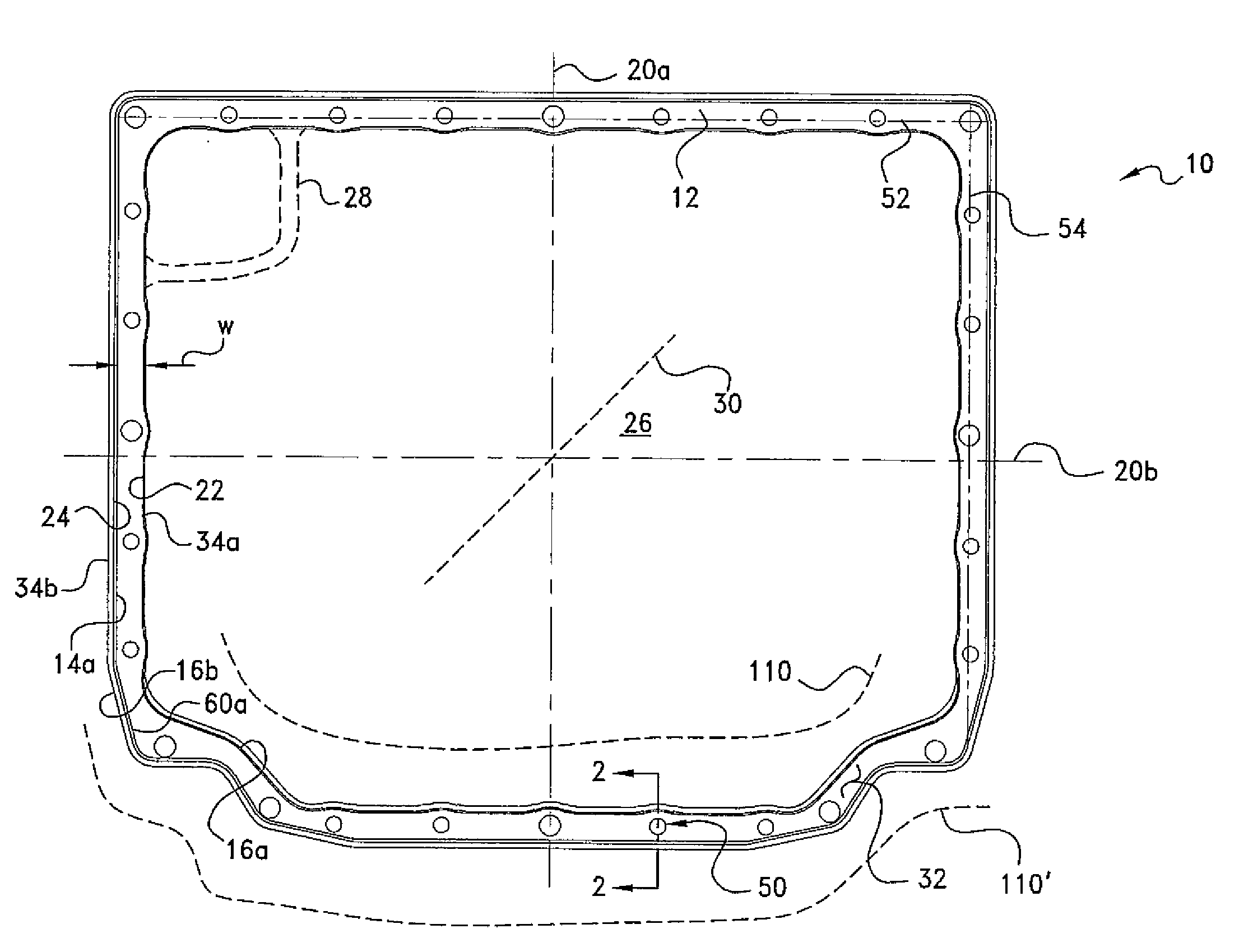

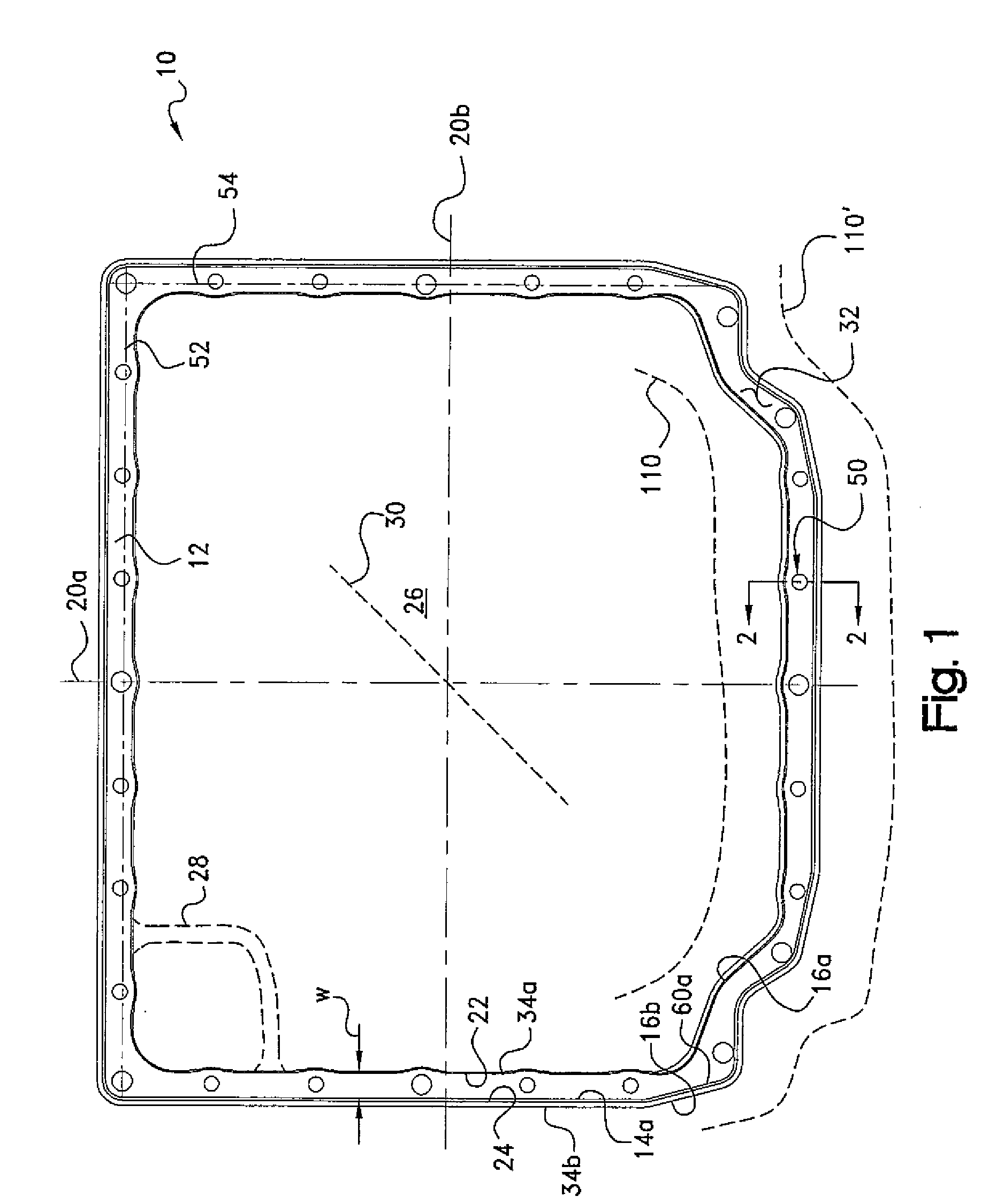

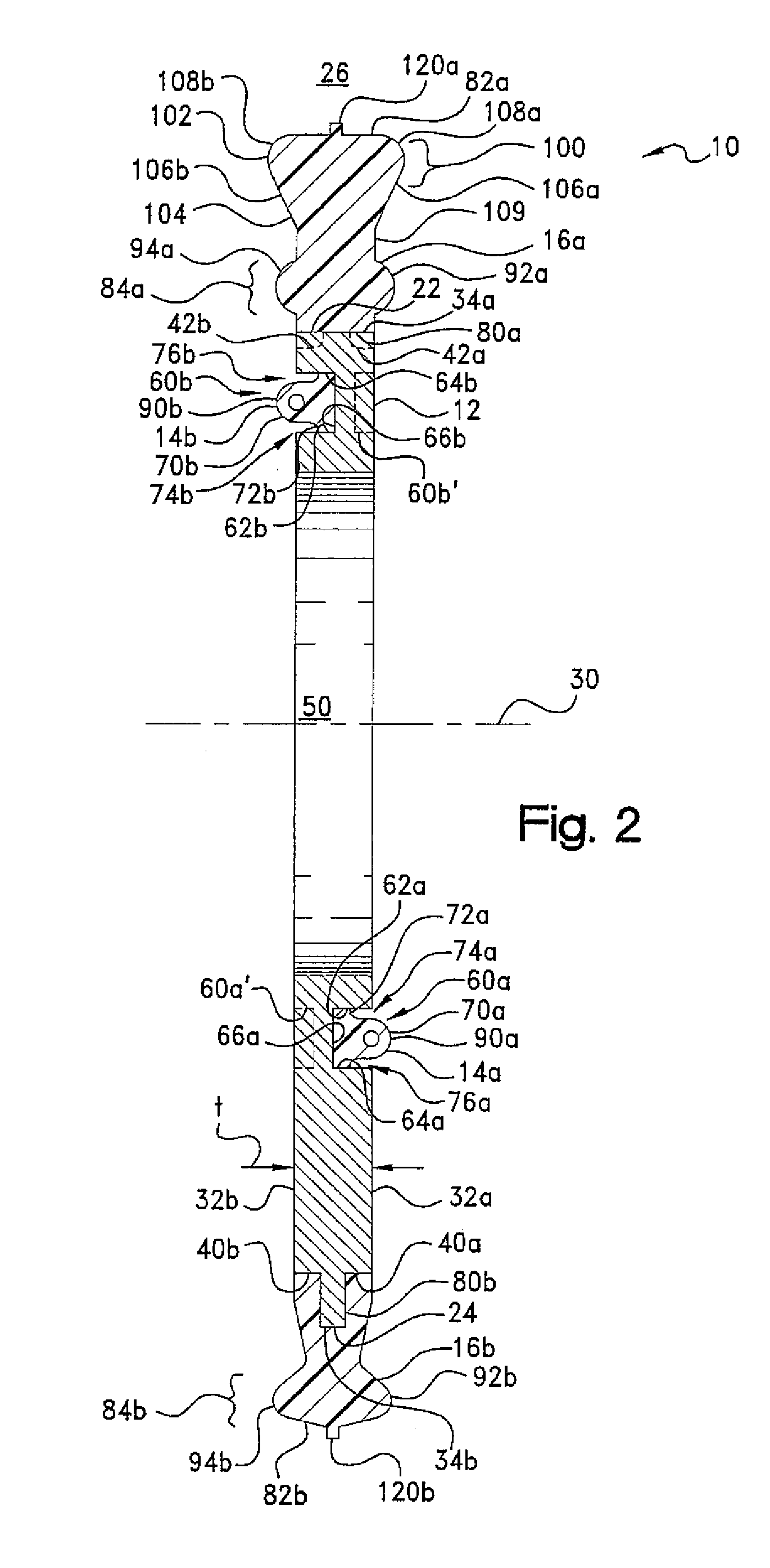

Wedging retainer gasket construction

InactiveUS20060038357A1Increased potential for corrosionLoss of service lifeEngine sealsSealing arrangements for enginesFree stateVoid space

Sealing gasket construction for providing a fluid seal intermediate a pair of opposed, mating parts or structures, one of the parts having an edge and a void space defined along the edge. The gasket includes a retainer and a resilient seal element having a wedging portion extending radially beyond one of the retainer inner or outer perimeter. The wedging portion is configured in a free state to extend into the area of the void space and to be wedged against the other one of the interfacing parts, and thereby made to occupy at least a portion of the void space.

Owner:KAMIBAYASHIYAMA JULIAN F

Wedging retainer gasket construction

InactiveUS20110072634A1Increased potential for corrosionLoss of service lifeEngine sealsMetal working apparatusFree stateEngineering

Sealing gasket construction for providing a fluid seal intermediate a pair of opposed, mating parts or structures, one of the parts having an edge and a void space defined along the edge. The gasket includes a retainer and a resilient seal element having a wedging portion extending radially beyond one of the retainer inner or outer perimeter. The wedging portion is configured in a free state to extend into the area of the void space and to be wedged against the other one of the interfacing parts, and thereby made to occupy at least a portion of the void space.

Owner:KAMIBAYASHIYAMA JULIAN F

Door for recreational off-highway vehicle

ActiveUS9061569B2Reduce stress and tensionMinimizes retention of moisturePedestrian/occupant safety arrangementBuilding locksSafety netBuggy vehicle

Owner:ARCTIC CAT

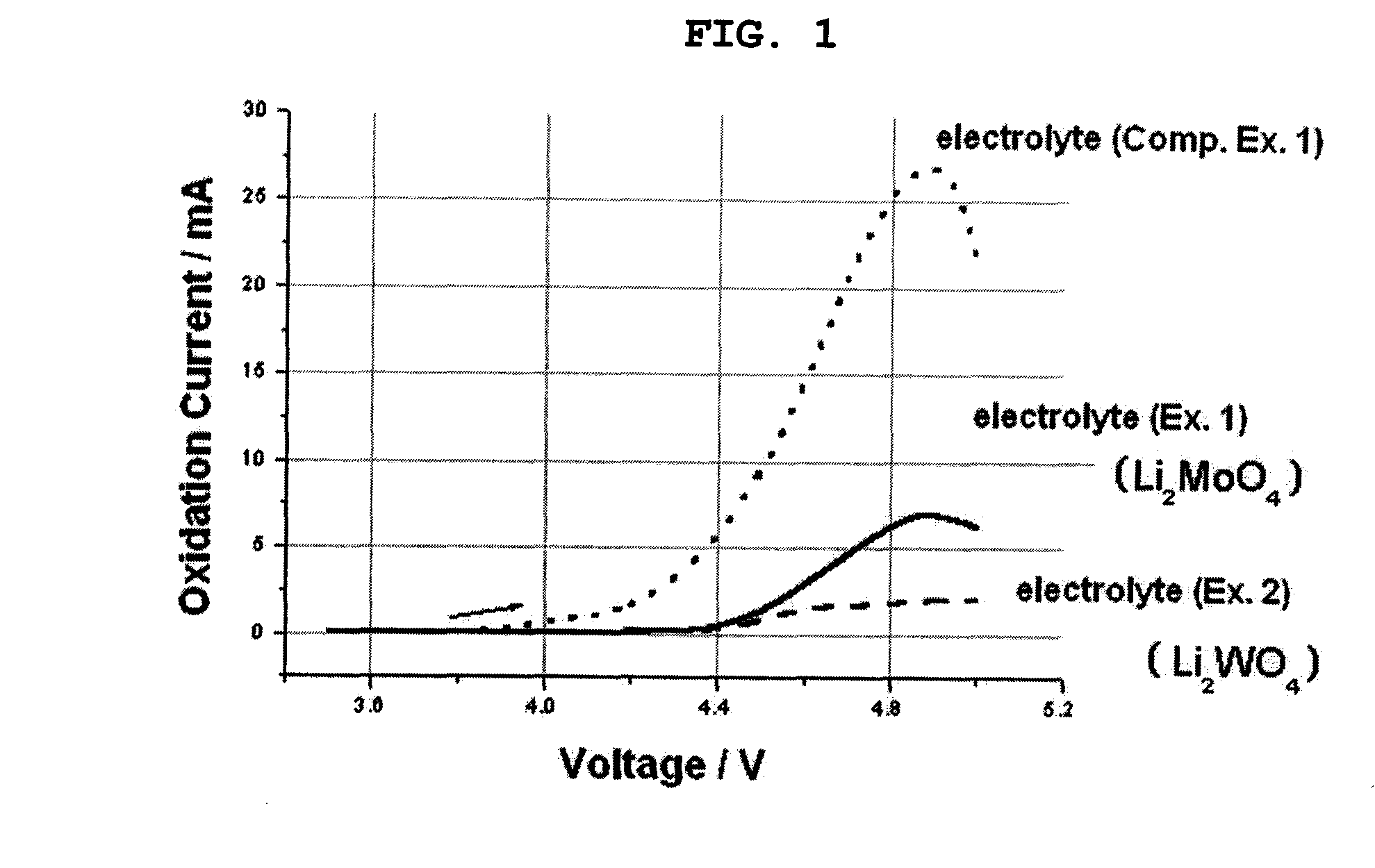

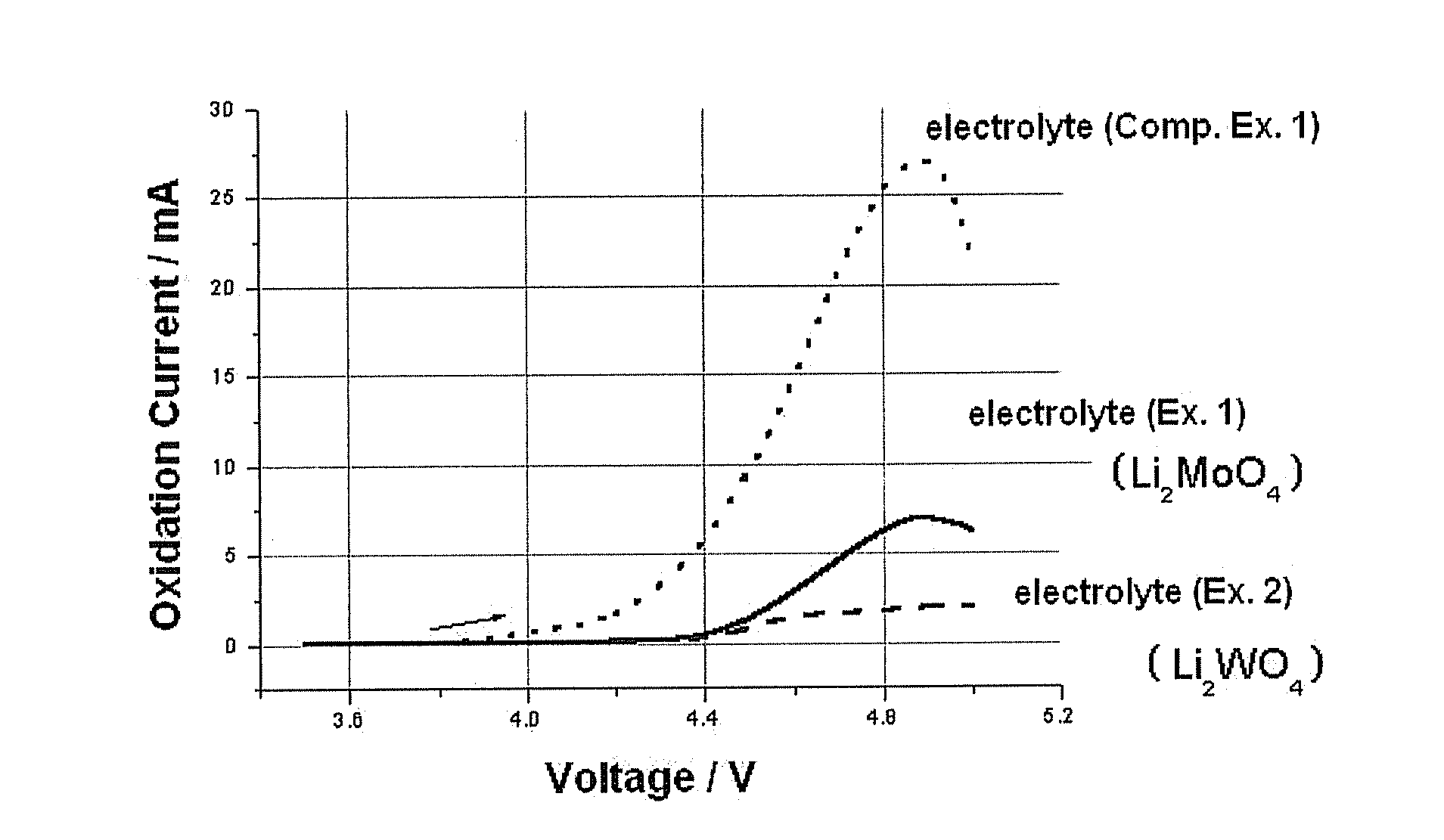

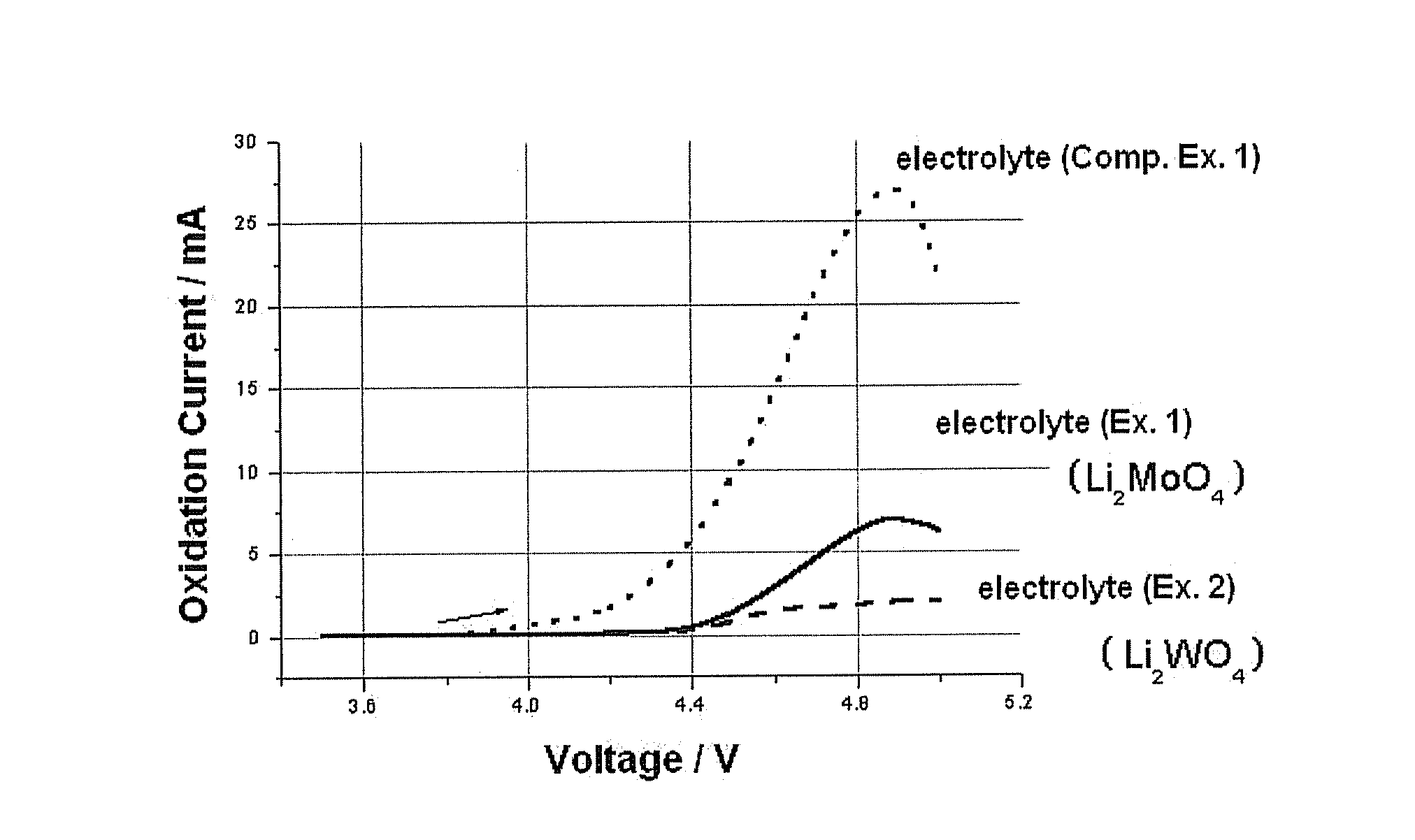

Nonaqueous Eletrolyte Comprising Oxyanion and Lithium Secondary Battery Using the Same

ActiveUS20080254370A1Avoid corrosionPrevent materialElectrolytic capacitorsCell electrodesHigh temperature storageOxyanion

Disclosed is an electrolyte comprising: (a) an electrolyte salt; (b) a non-aqueous electrolyte solvent; and (c) a binary or multinary metal oxide salt. An electrochemical device comprising the same electrolyte is also disclosed. The metal oxide salt used in the electrolyte is dissolved in a non-aqueous solvent and generates oxyanions capable of improving corrosion resistance of metals. Therefore. the electrolyte prevents corrosion of metallic materials present in an electrochemical device, caused by extreme conditions, such as overcharge, overdischarge and high-temperature storage conditions, to which the device is exposed. Further, the electrolyte prevents degradation in the quality of an electrochemical device, caused by corrosion of metallic materials.

Owner:LG ENERGY SOLUTION LTD

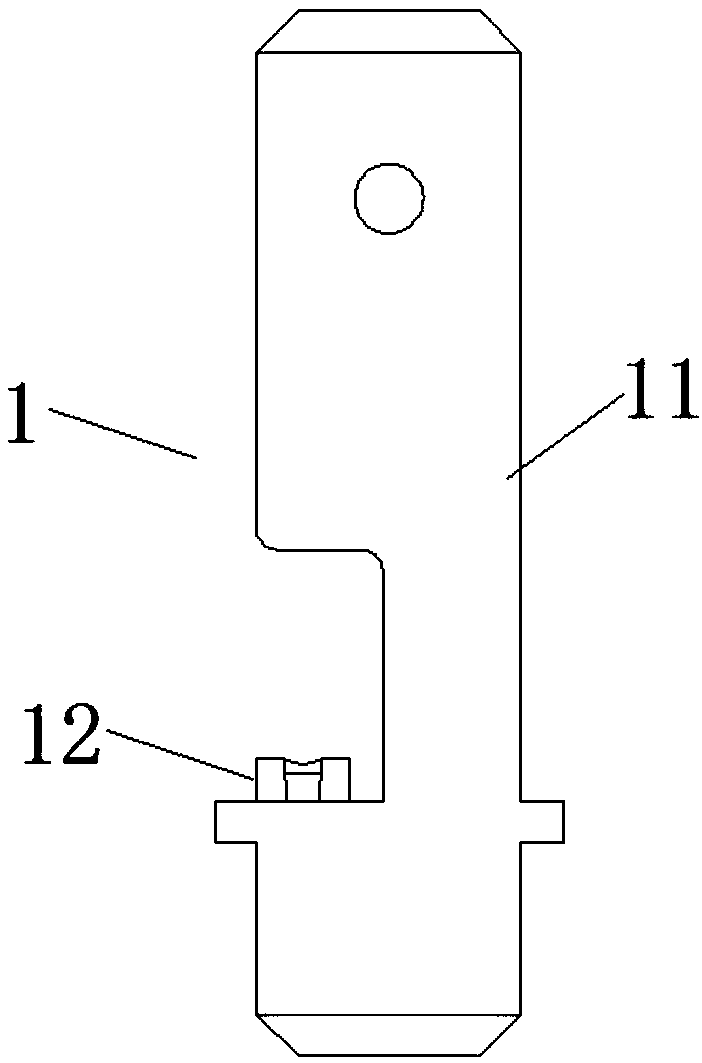

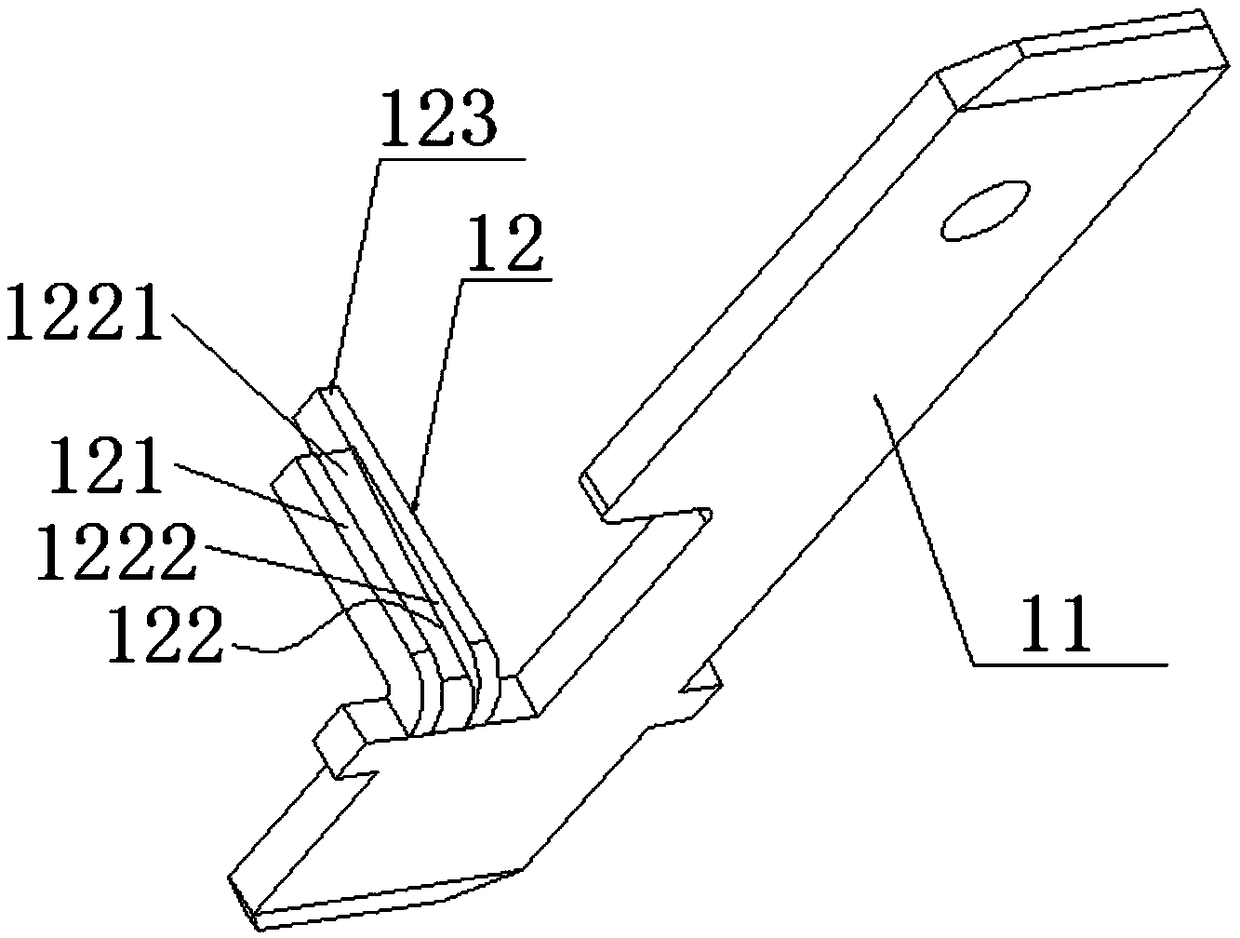

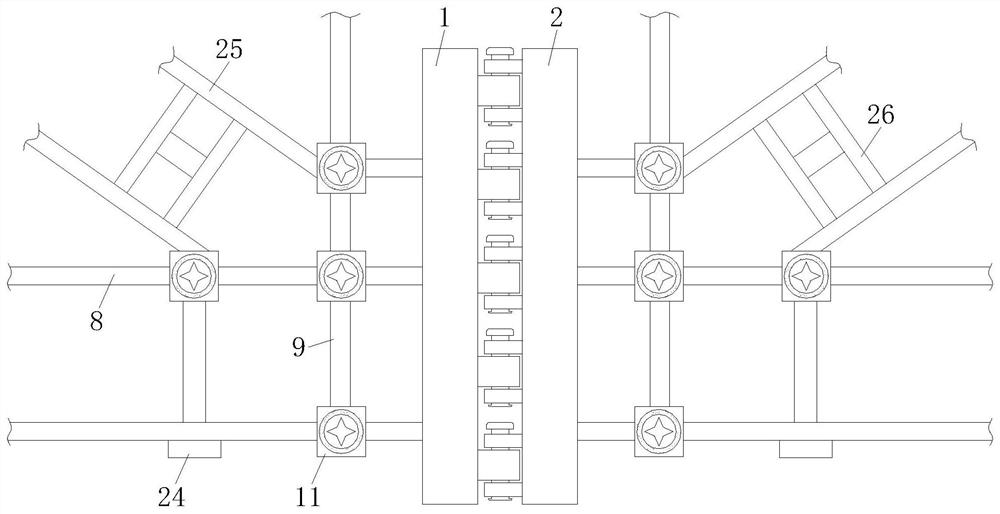

Connection structure of wiring terminal and enameled wire, method, coil assembly and motor

PendingCN109301567ARealize butt welding connectionReduce the possibility of corrosionLine/current collector detailsCoupling device detailsBinding postEngineering

The invention provides a connection structure of a wiring terminal and an enameled wire, a connection method, a coil assembly and a motor. The wiring terminal of the present invention comprises a wiring terminal body, and a wiring post which is connected with the wiring end of the enamel wire; the wiring post is fixed to the wiring terminal body and includes a first surface, and a first groove which is formed in the first surface and faces downwardly; the connection structure of the wiring terminal and the enameled wire includes the enameled wire and the wiring terminal; the wiring end of theenameled wire is arranged in the first groove; a fixing terminal is crimped and is fixed to the wiring end of the enameled wire and the wiring post; and the wiring end of the enameled wire is butt-welded to the fixing terminal and the wiring post. With the connection structure, and the connection method of the invention adopted, the enameled wire can be arranged and fixed on the wiring post more conveniently and firmly, the enameled wire can be favorably protected, and the enameled wire is unlikely to be damaged due to external forces; the butt-welded connection of the enameled wire and the wiring post is realized, and therefore, the length of the removed sheath of the enameled wire can be controlled, and the service life of the coil assembly or motor can be prolonged.

Owner:HANYU GRP CO LTD

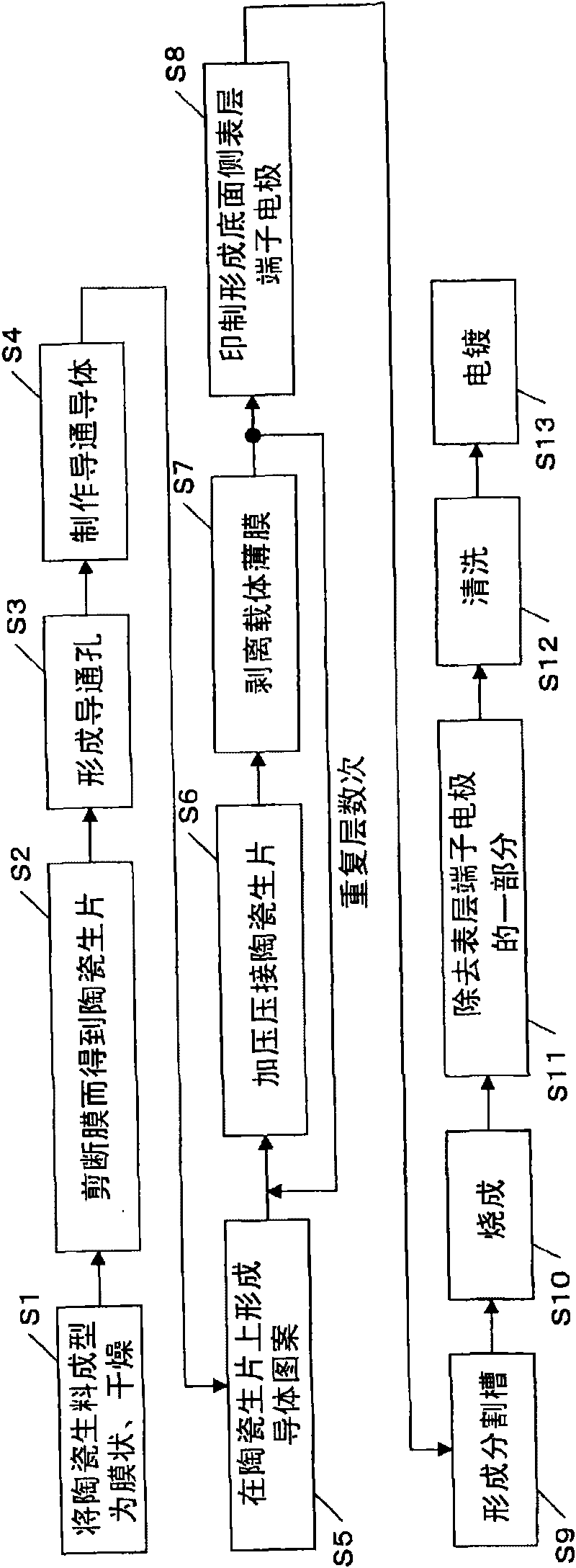

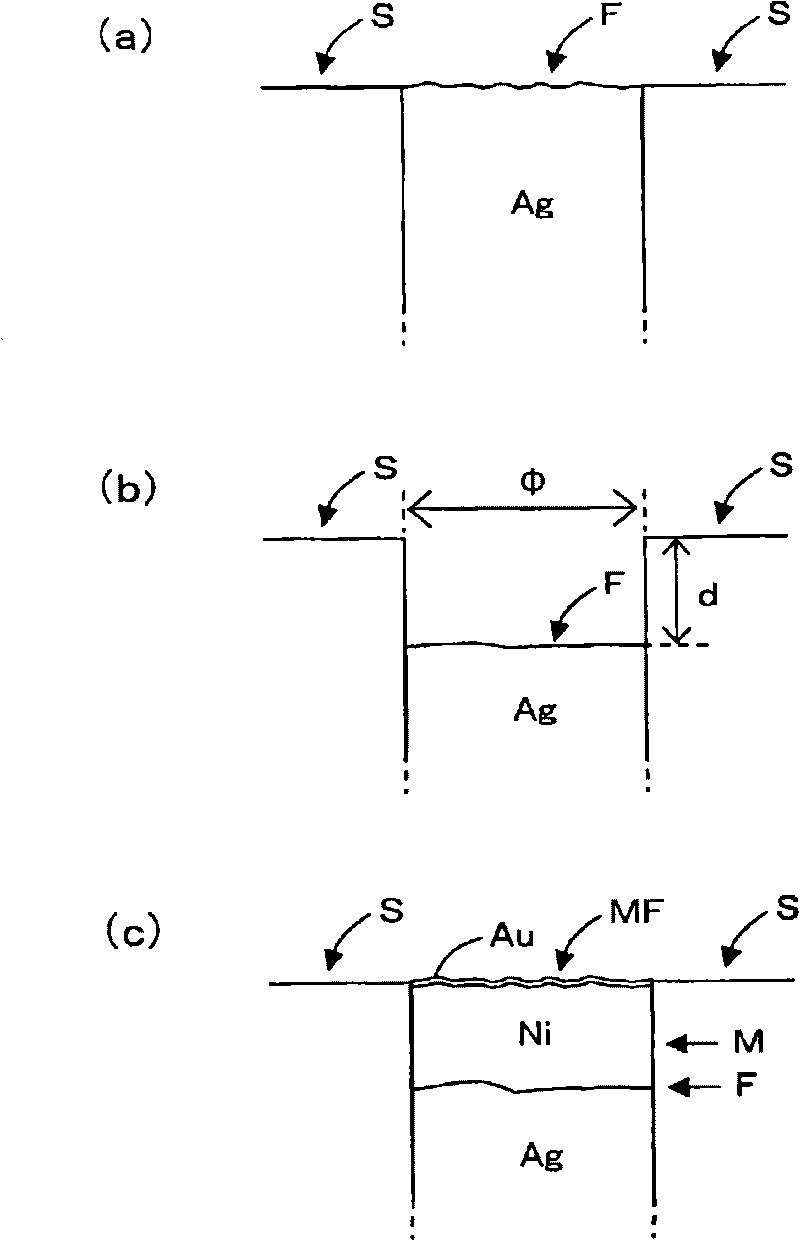

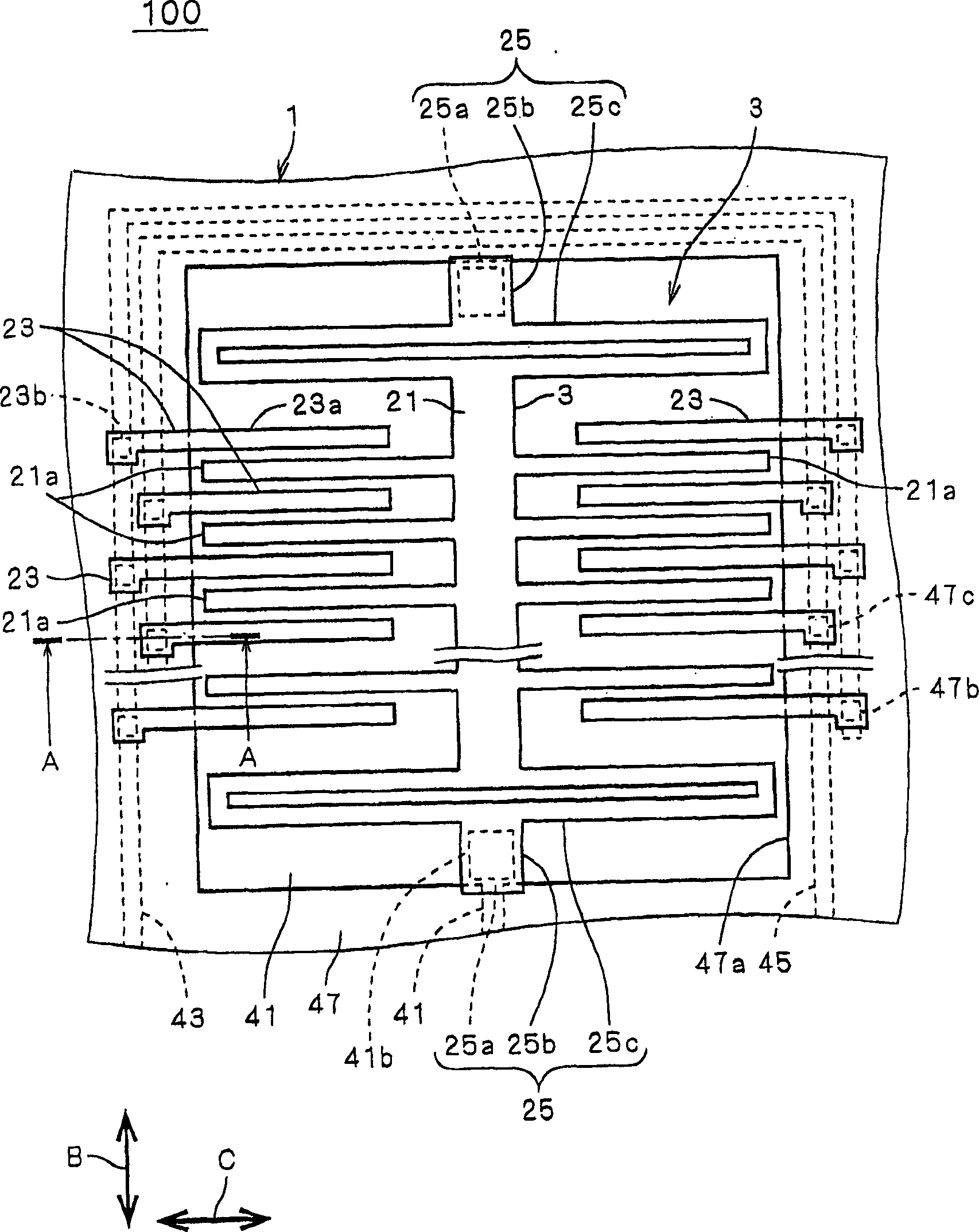

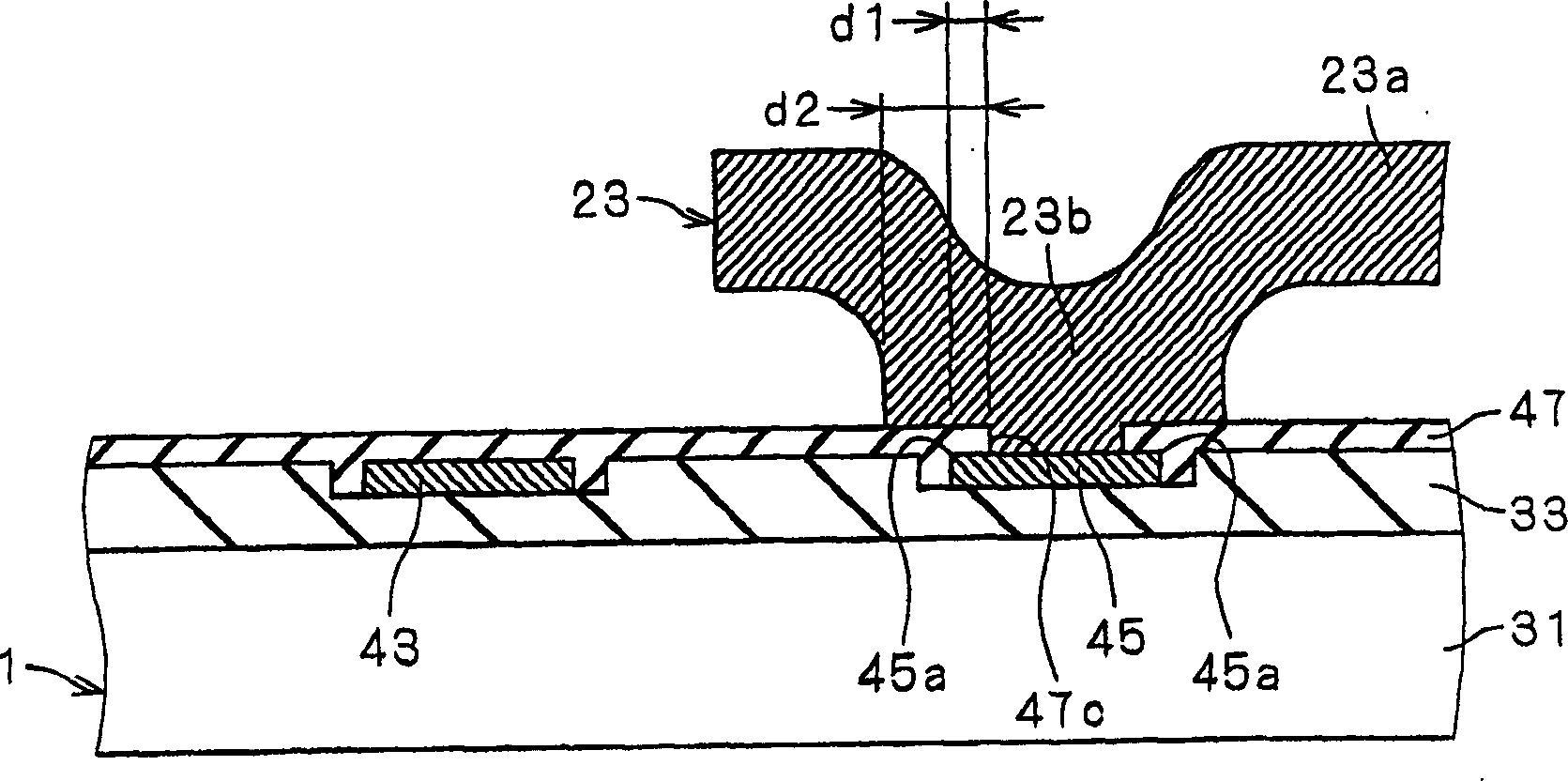

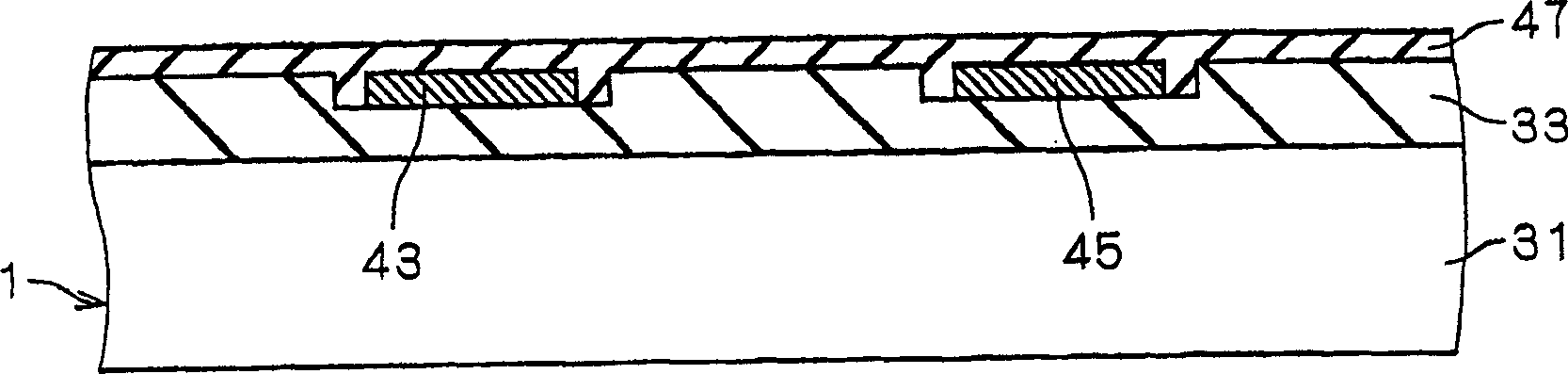

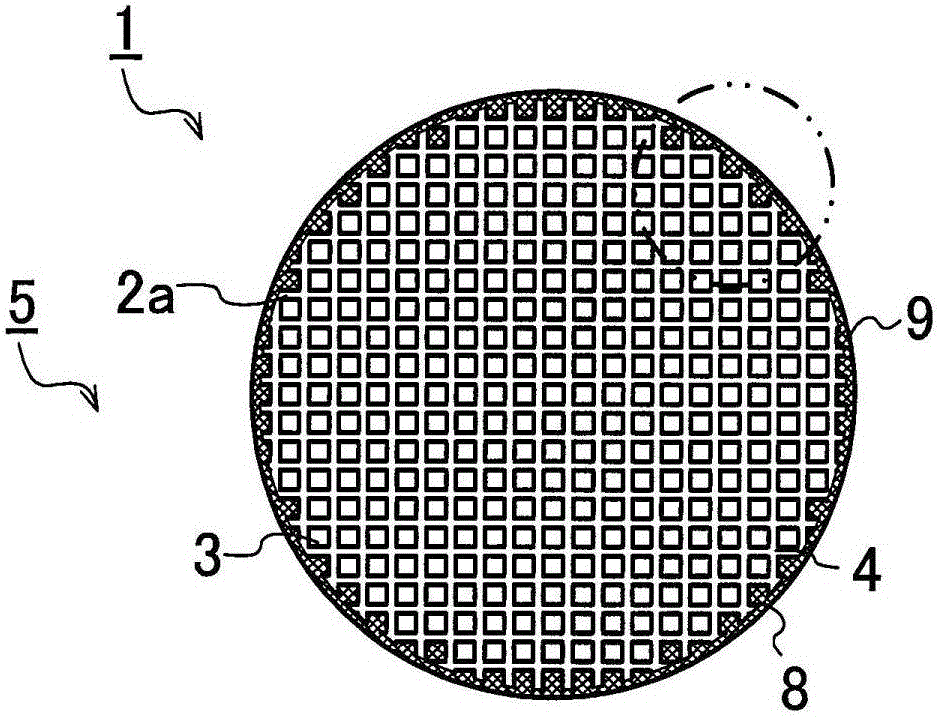

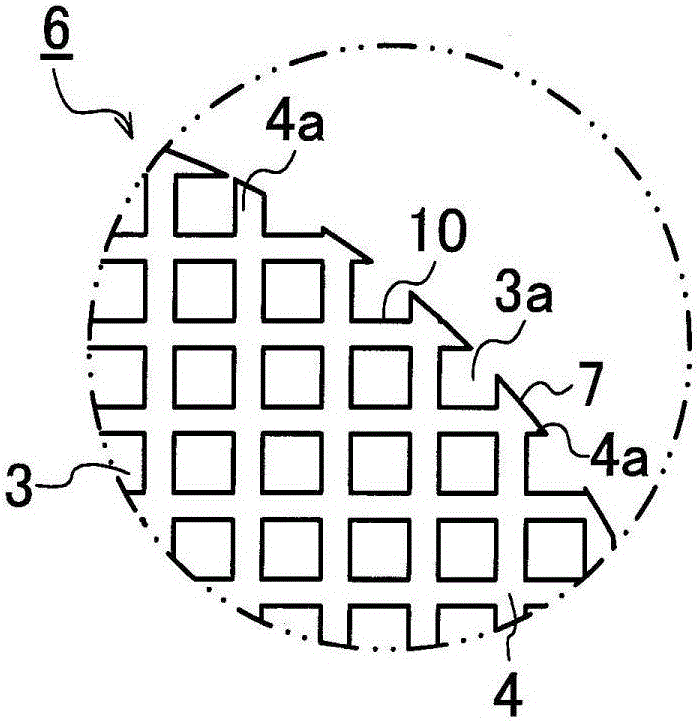

Multilayer ceramic substrate, electronic component, and method of manufacturing multilayer ceramic substrate

ActiveCN101692442ANarrow downSmall size and high densityPrinted circuit detailsSemiconductor/solid-state device detailsSurface layerSurface mounting

A multilayer ceramic substrate in which an active element and a passive element are surface-equipped over the outermost surface on one side is provided. The multilayer ceramic substrate comprises a plurality of laminated ceramic substrate layers, a surface layer terminal electrode provided in a via hole of an outermost ceramic substrate layer on at least one side and having a surface layer via electrode and a metal plating layer deposited over an end surface of the surface layer via electrode, and a via conductor which connects the surface layer terminal electrode and circuit patterns over the ceramic substrate layer at the inside, wherein a via hole size of a surface layer terminal electrode for connection of the active element is smaller than a via hole size of a surface layer terminal electrode for connection of the passive element.

Owner:PROTERIAL LTD

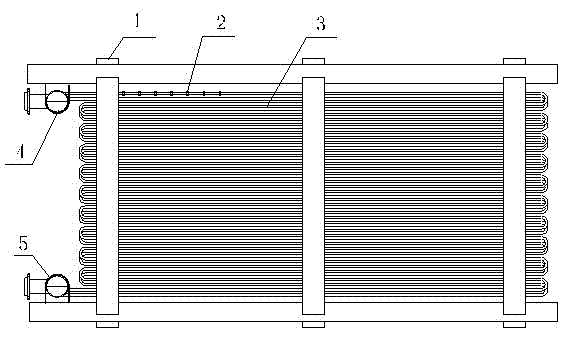

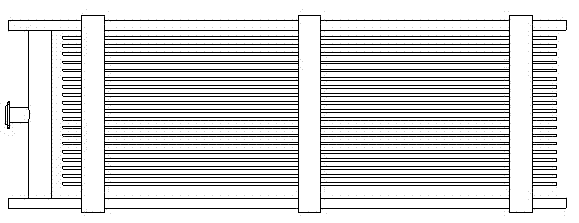

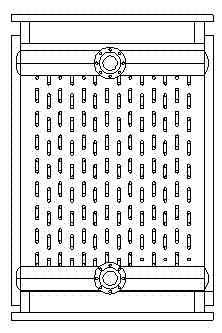

Anti-corrosive anti-scaling high-efficiency heat exchanger

InactiveCN102654363AEasy maintenanceEasy to cleanCorrosion preventionStationary conduit assembliesHeat conductingMetallic materials

The invention discloses an anti-corrosive anti-scaling high-efficiency heat exchanger, mainly consisting of a support, descaling rings, a heat exchange coiled pipe, a heat exchanger inlet header and a heat exchanger outlet header, wherein the heat exchange coiled pipe is formed by stacking and alternatively arranging a plurality of heat exchange coiled pipe units, each heat exchange coiled pipe unit is manufactured through location of a location strip after two layers of snake-shaped coiled pipes are staggered, the heat exchange coiled pipe is made of a nonmetal material, and the nonmetal material includes but is not limited to polymer composite materials and modified heat-conducting composite materials. A plurality of descaling rings are suspended on each horizontal section of the heat exchange coiled pipe. The anti-corrosive anti-scaling high-efficiency heat exchanger has the advantages of effectively preventing corrosion of a heat exchanger used in different mediums, slowing down the time of scaling outside the heat exchange coiled pipe due to the arrangement of the descaling rings, and also improving the heat exchange effect of the heat exchanger, also has the advantages of compact structure, capability of mounting in a stacking manner, small overhaul space and the like, and can be widely applied to heat exchange occasions of different fluids.

Owner:陈建伟

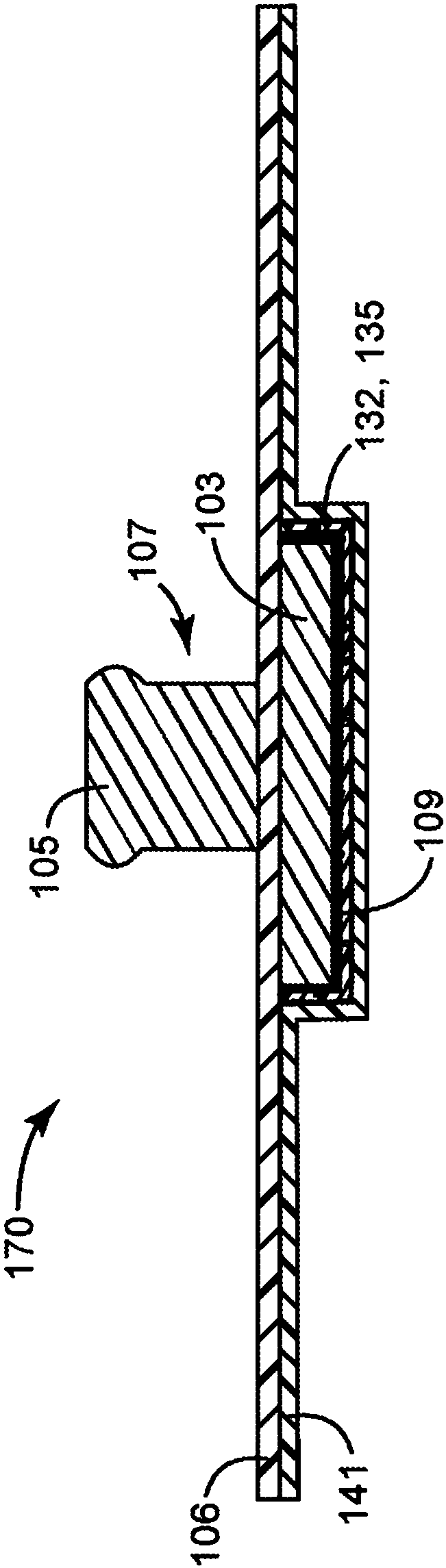

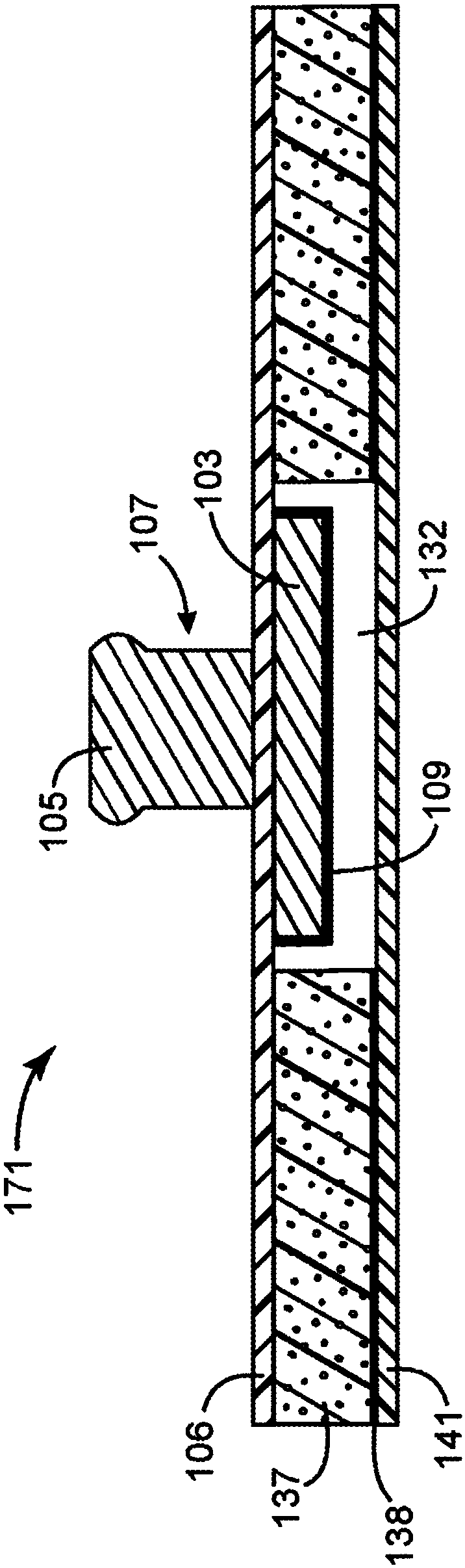

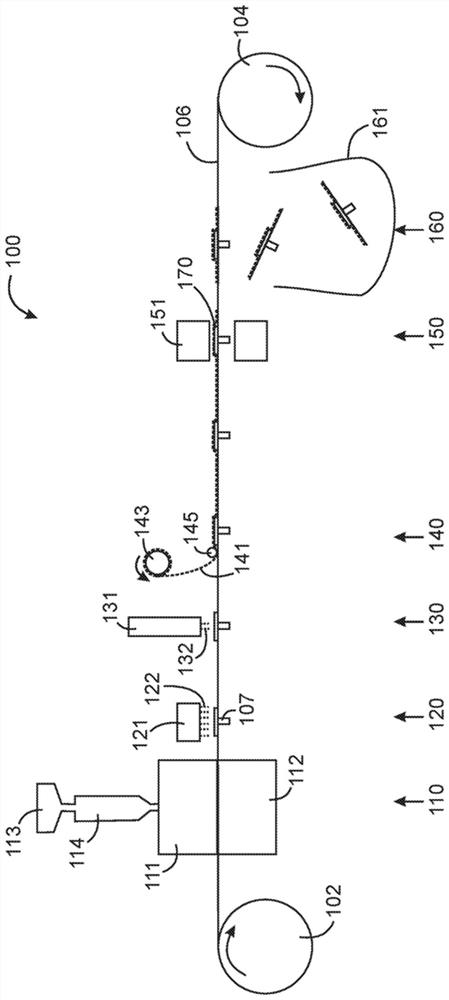

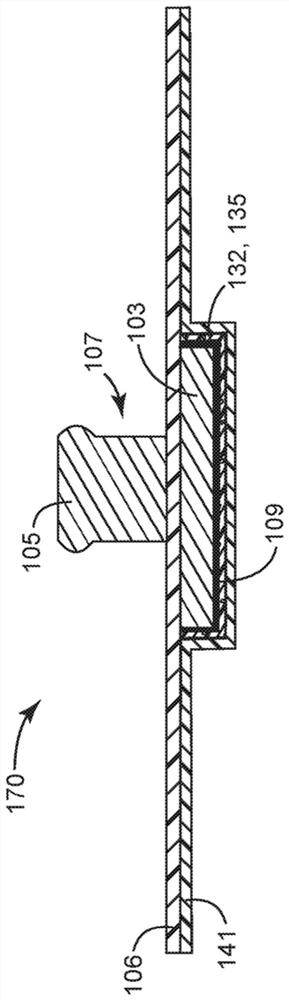

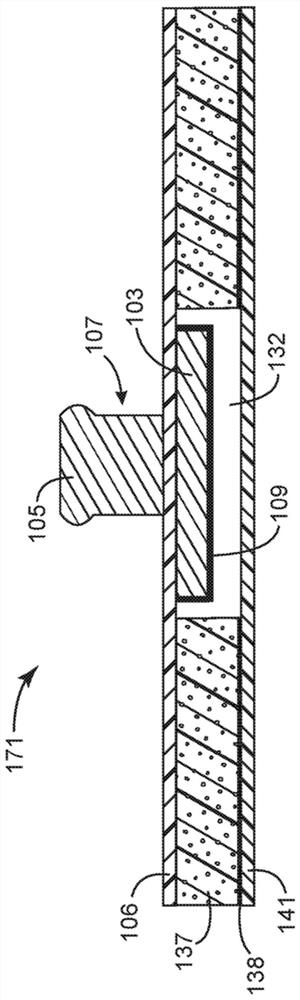

One-piece sensor for bioelectrode and processes for production

InactiveCN108472846AKeep dryReduce the possibility of corrosionSensorsDomestic articlesPhysical chemistryEngineering

A process for producing a sensor (107) for a biomedical electrode (170) (e.g. an ECG electrode) involves injection molding an electrically conductive resin through a film (106) of a backing material to form the sensor directly in the backing material and coating the contact face of the sensor with a non-polarizable conductive material (109) (e.g. silver-containing material). Additional steps of applying an electrolyte (132) over the non-polarizable conductive material coated on the contact face and applying a liner (141) over the electrolyte results in the biomedical electrode. Biomedical electrodes produced thereby have the sensor secured in a film of the backing material with a contact face (103) of the sensor disposed on a first side of the film and a post (105) of the sensor protrudingfrom a second side of the film opposite the first side. The process permits production of one-piece sensors for bioelectrodes in a continuous fashion without the need for studs to retain sensors in afilm of the backing material.

Owner:3M INNOVATIVE PROPERTIES CO

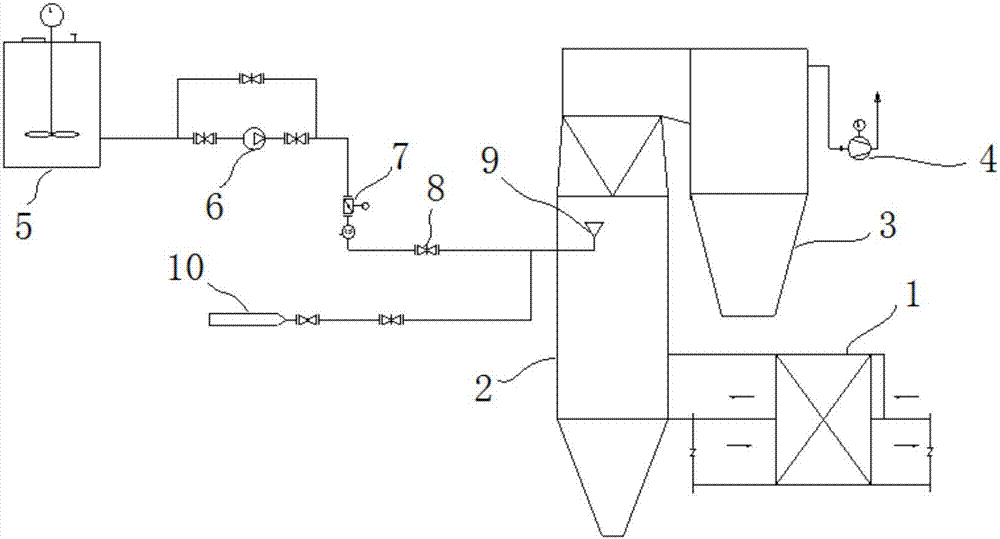

Desulfurization wastewater treatment method

InactiveCN106986401AAchieve pollutionNo corrosion problemsGeneral water supply conservationWaste water treatment from gaseous effluentsGas phasePhase change

The invention discloses a desulfurization wastewater treatment method, and belongs to the field of desulfurization wastewater treatment. A hot air unit introduces hot air into a phase change generator; meanwhile, a wastewater system conveys desulfurization wastewater to an atomizer in the phase change generator for atomization, hot wind formed by the desulfurization wastewater and the hot air is changed into a gas phase from a liquid phase through mass and heat exchange and the gas phase is discharged from an outlet of the phase change generator along with the hot wind; a solid formed by impurity crystal in the desulfurization wastewater enters the hot air unit at a solid outlet of the phase change generator under the action of gravity. According to the desulfurization wastewater treatment method, hot air in the phase change generator and atomized desulfurization wastewater drops are subjected to mass and heat exchange, and the desulfurization wastewater drops are evaporated and crystallized and then subjected to gas-solid separation. The problems that an original desulfurization balance is broken and equipment corrosion is caused in the desulfurization wastewater treatment process in a flue are solved, so that zero pollution and zero emission of the desulfurization wastewater are achieved.

Owner:张玉君

Electrode structure, and method for manufacturing thin-film structure

InactiveCN1466775AReduce the possibility of corrosionPrevent infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilm structure

An electrode structure where a sacrifice film is removed without removing another insulating film and a method for manufacturing a thin-film structure. There are formed anchor holes for opening the surface of a wiring line which is covered with a sacrifice film and a nitride film. The anchor hole is formed of a hole portion of the nitride film and an opening of the sacrifice film. The diameter ofthe hole portion is smaller than the width of the wiring line by a first predetermined distance from the edge of the surface of the wiring. The diameter distance from the hole portion. Because of thepresence of the first and second predetermined distances, the distance by which the etchant for removing the sacrifice film penetrate into an oxide film.

Owner:MITSUBISHI ELECTRIC CORP

Steel-bar rust inhibitor based on radish extract, and preparation method and application thereof

InactiveCN109279800AInhibition of direct erosion damageGood antirust effectEnvironmental resistanceRebar

The invention discloses a steel-bar rust inhibitor based on a radish extract, and a preparation method and an application thereof. The steel-bar rust inhibitor comprises the following raw materials bymass: 98% to 100% of the radish extract and 0% to 2% of an anti-corrosion additive. Compared with the prior art, the steel-bar rust inhibitor provided by the invention has the following advantages: raw materials are green and environmentally-friendly, have low carbon and low cost, are widely-available and have high yield, so industrial production can be easily realized; the traditional disadvantages of pollution of nitrite to the environment and complicated preparation process of an organic rust inhibitor are avoided; rust-inhibiting components contained in a raw material namely the radish extract is utilized to generate interaction with a steel bar, so an adsorption film is formed on the surface of the steel bar, and direct erosion damage of chlorine ions to the steel bar is inhibited; the rust inhibitor prepared by using the method provided by the invention has excellent rust-inhibiting effect; and the steel-bar rust inhibitor has simple preparation method and application method andbroad prospects.

Owner:HOHAI UNIV

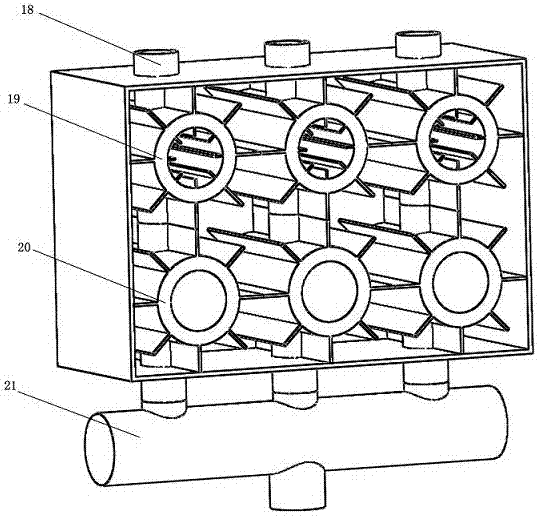

System for recovering water vapor in smoke and heat by membrane method and heat exchange module

PendingCN107062298AReduce low temperature corrosionRaise the cold junction temperatureGas treatmentCombustion processWater recoveryAir heater

The invention discloses a system for recovering water vapor in smoke of a thermal power plane and heat based on a composite membrane, and a heat exchange module with a front-loaded air heater. A water recovery device adopts three-grade arrangement, and is provided with the front-loaded air heater for recovering the heat of the water vapor. A high-temperature water recovery device is arranged in front of an air preheater; the temperature of the recovered water vapor is higher; the recovered water vapor serves as a heat source of the air heater; a medium-temperature water recovery device is arranged in front of a desulfurization tower; the heat of the recovered water vapor serves as a heat source of the front-loaded air heater for heating environmental air; a low-temperature water recovery device is arranged behind the desulfurization tower; the temperature of the recovered water vapor is lower; and the recovered water vapor can be directly fed in a steam condenser for condensation. The heat exchange module with the front-loaded air heater mainly consists of a water vapor conveying pipe, an I-grade heat exchange module, an II-grade heat exchange module and a dewatering header. The system is huge in application potential on the aspects of water conservation and energy conservation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

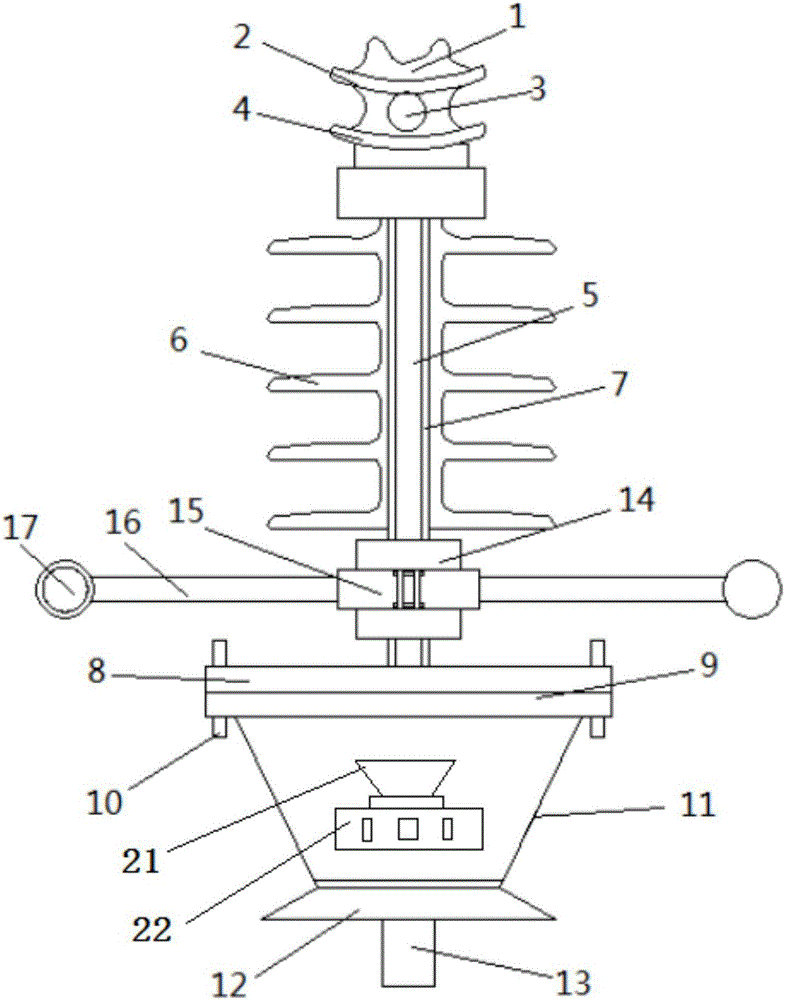

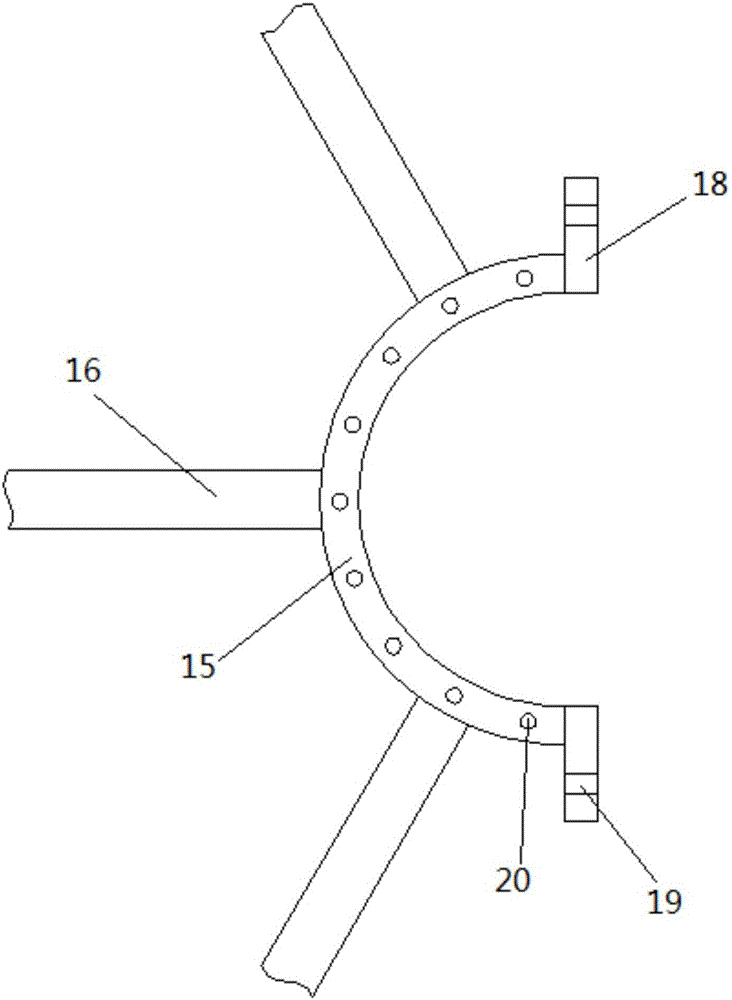

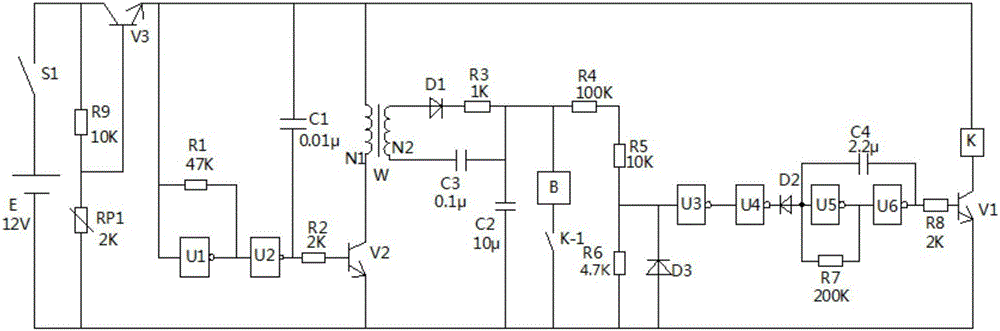

Anti-bird insulator for intelligent power grid

The invention discloses an anti-bird insulator for an intelligent power grid. The anti-bird insulator comprises a lower body, an upper body and a bird repelling structure, the lower body is in the shape of a bellmouth with big end up, the upper portion of the lower body is provided with a lower flange, the upper body is arranged above the lower body and comprises an umbrella skirt and an upper fitting positioned above the umbrella skirt, the upper fitting comprises an upper convex disc and a lower convex disc which are integrally arranged and parallel to each other, a through hole is formed between the upper convex disc and the lower convex disc, and a positioning groove is formed in the upper convex disc; a cylindrical core rod is arranged inside the umbrella skirt. The lower body and the upper body are connectedly mounted through an adjusting screw penetrating the upper flange and the lower flange, so that adjustment on distance between the upper body and the lower body can be realized quite conveniently; during mounting, mounting can be performed after the distance between contact faces of the upper body and the lower body is adjusted to a proper position according to mounting needs and mounting position of a bus, so that the anti-bird insulator is quite convenient to use.

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

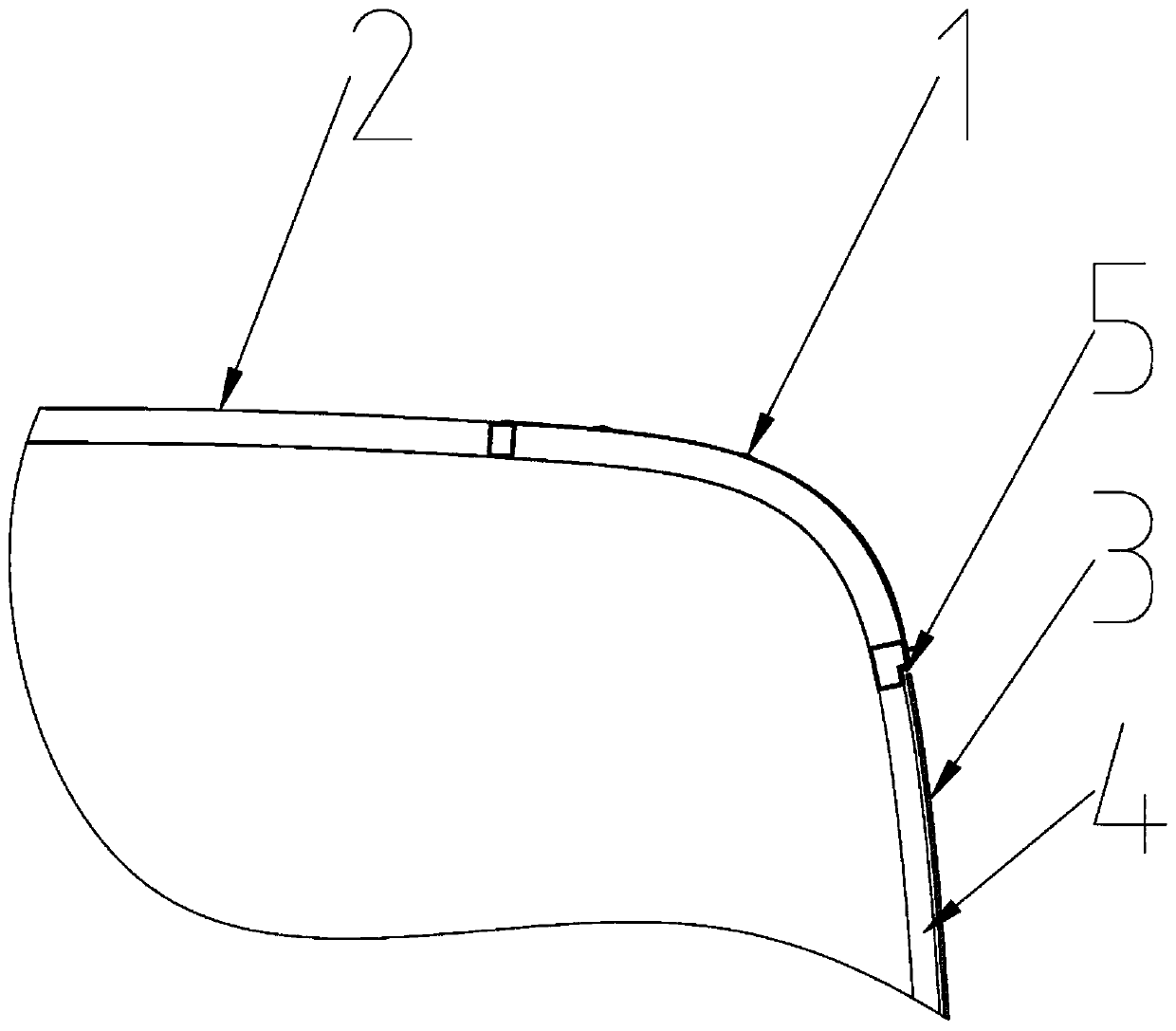

Integral rolling rain gutter side top covering part

PendingCN110435771AImprove the ability to resist thermal deformationImprove the ability to resist thermal deformation, and the appearance quality of the side roof skinSuperstructure subunitsVehiclesThermal deformationEngineering

The invention discloses an integral rolling rain gutter side top covering part, which includes an integral rain gutter side top skin covering part body, a first rib line, a second rib line, a seam allowance flange and a rain gutter. The integral rain gutter side top skin covering part body, a vehicle roof frame assembly, side window glass, a side wall frame and a glass pasting caulking compound form a side wall closed structure. The integral rolling rain gutter side top covering part has the beneficial effects that through a scheme of replacing a self-tapping screw with an integral rolling rain gutter for fixing aluminum alloy rain gutter, rainwater is prevented from entering a vehicle roof frame through a fixing hole of the self-tapping screw, and the possibility of the vehicle roof framecorroded by the rainwater is decreased. According to the integral rolling rain gutter side top covering part, through the built-in first rib line and second rib line, integral internal stress of theintegral rain gutter side top skin covering part is enhanced, the ability resistant to thermal deformation of high-temperature electrophoretic fluid applied to side top skin during vehicle electrophoresis is improved, the vehicle appearance quality of the side top skin is improved, and then the purpose of improving the reliability of parts by adjusting the process and tools of the parts is achieved.

Owner:ANHUI ANKAI AUTOMOBILE

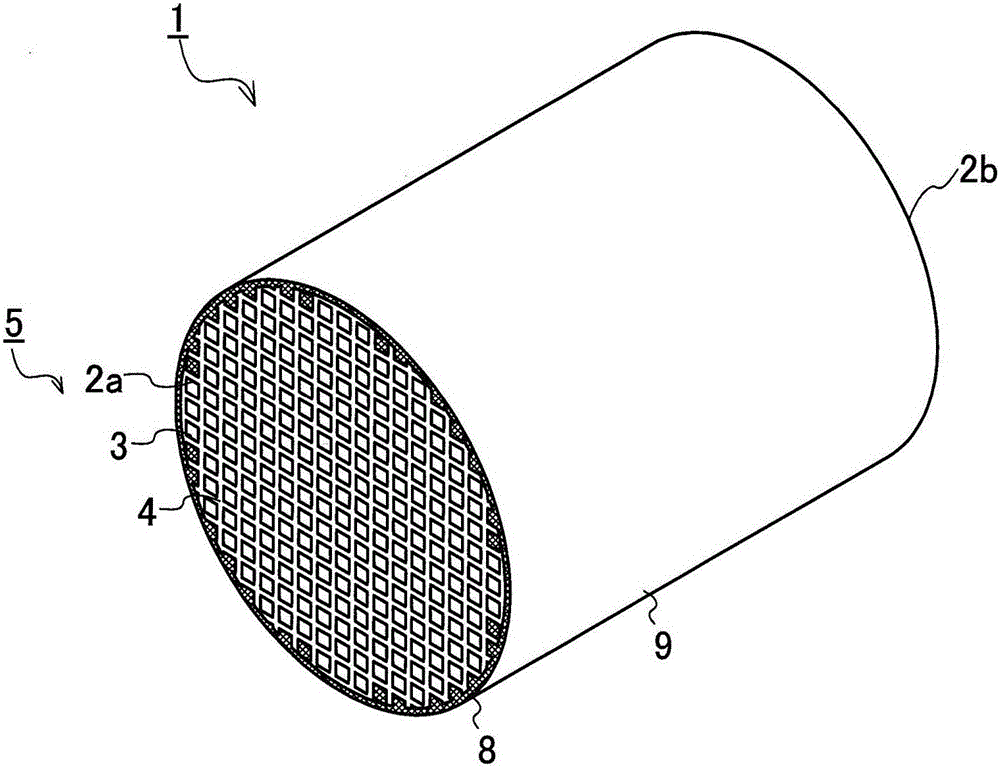

Circumference coating material, bonding material, honeycomb structure, and method of producing honeycomb structure

ActiveCN106014557AChlorine concentration decreasedReduce the possibility of corrosionSilencing apparatusLaminationColloidal silicaPhosphoric acid

Owner:NGK INSULATORS LTD

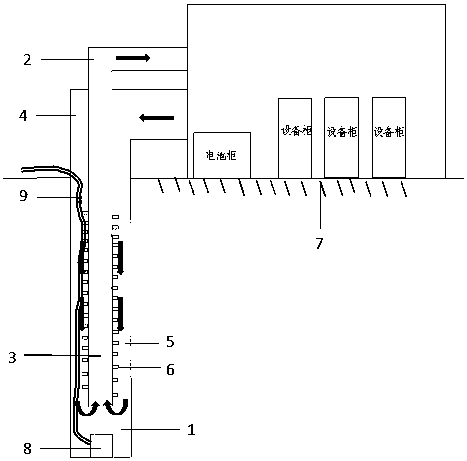

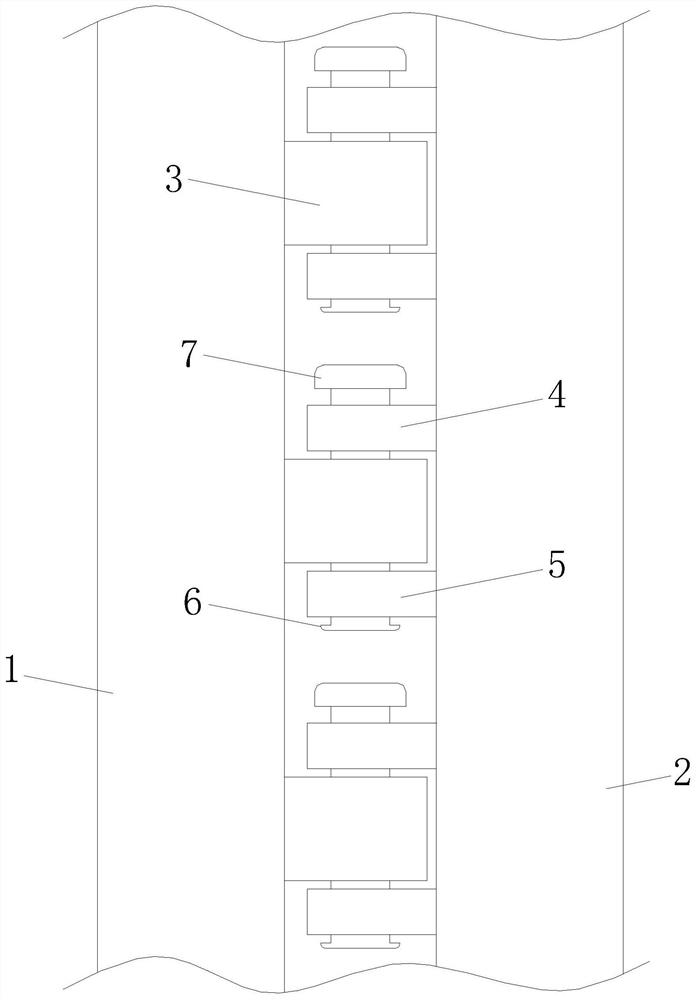

Underground casing pipe type heat exchanging device based on air medium

PendingCN108302669AImprove practicalityGood effectLighting and heating apparatusGeothermal collectorsTerrainWater source

The invention provides an underground casing pipe type heat exchanging device based on an air medium. The underground casing pipe type heat exchanging device based on the air medium is different froman earth energy heat exchanging structure based on a water source medium, and the practical performance and effect are further improved in the aspects of energy consumption indexes and the building cost of the underground casing pipe type heat exchanging device based on the air medium. The underground casing pipe type heat exchanging device based on the air medium comprises an inner heat insulating pipe, an outer heat exchanging pipe and a bottom communicating cavity used for being buried underground by 10 meters to 100 meters. According to the underground casing pipe type heat exchanging device based on the air medium, due to the constant temperature feature that underground soil is 20 DEG C or so, it is only needed to adopt a draught fan to provide power, influences by the terrain and climate are avoided, and a good energy saving effect and adaptability are achieved. Because of adoption of the inner and outer casing pipe type structure, the arrangement of spiral protrusions or fins,and the arrangement of a heat preserving layer, contact between the inner heat insulating pipe and the outside environment is effectively reduced, and the heat exchanging efficiency and the constant temperature effect are substantially improved; and according to the actual testing, the underground casing pipe type heat exchanging device based on the air medium is adopted, and is used as a temperature adjusting source on the basis of the constant temperature feature that the underground soil is 20 DEG C or so, it is only needed to adopt the draught fan to provide power, and influences by the terrain and time are avoided, and the good energy saving effect and adaptability are achieved.

Owner:SICHUAN HUINENG ENERGY INVESTMENT MANAGEMENT +1

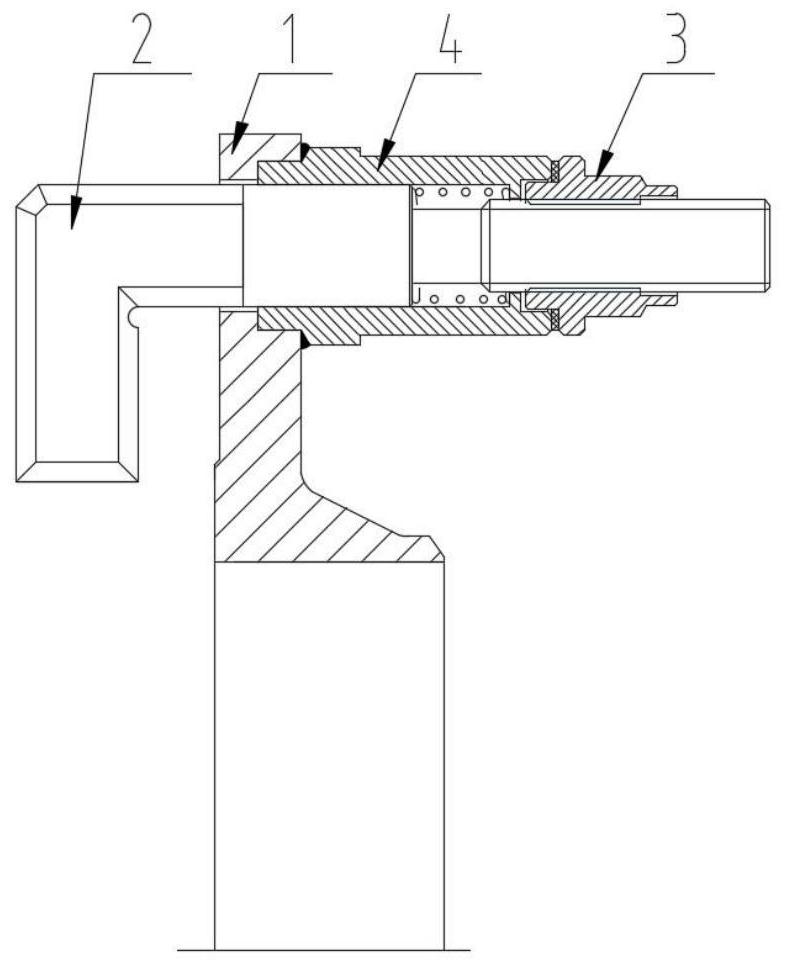

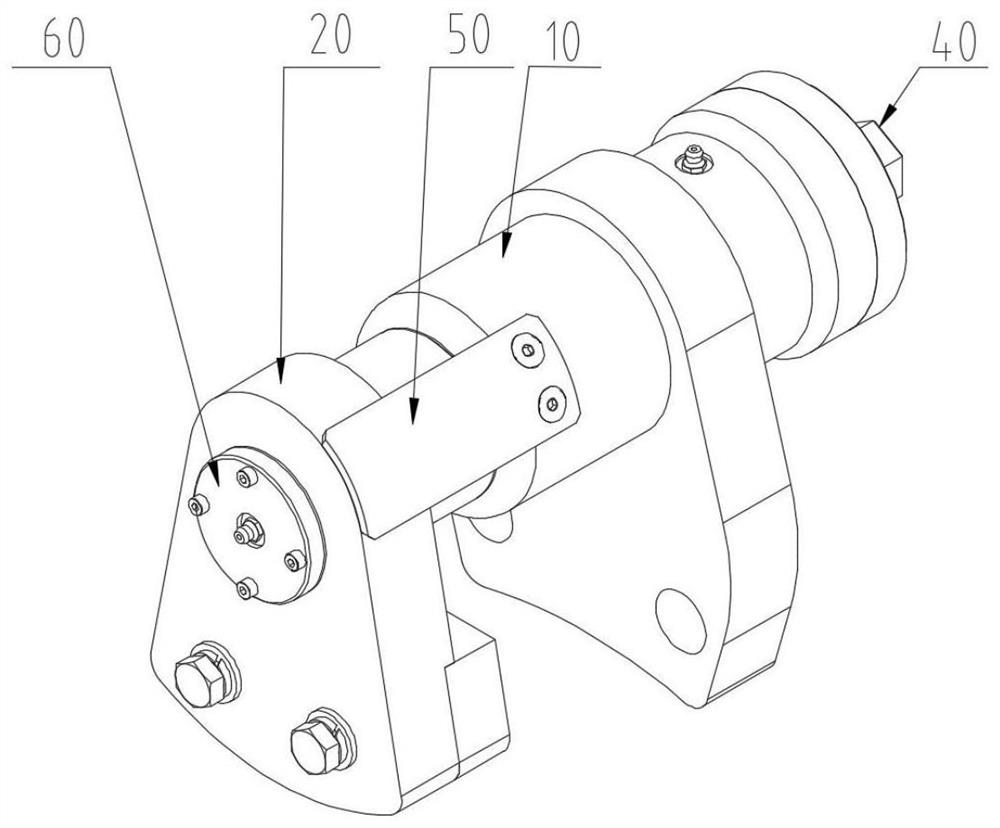

Efficient quick connecting device and quick connecting method

InactiveCN112082019AImprove docking efficiencyReduce the possibility of corrosionFlanged jointsNutsButt jointFluid loading

The invention discloses an efficient quick connecting device and a quick connecting method, and relates to the technical field of equipment special for fluid loading and unloading. The efficient quickconnecting device comprises a shell, a clamping jaw, a spring sleeve, a rotating shaft and a limiting plate. The rotating shaft is in threaded connection with the clamping jaw, and the clamping jaw is tightly pressed by the spring sleeve connected with the rotating shaft, so that when the rotating shaft rotates, the clamping jaw can rotate under the influence of the friction force of the spring sleeve, after rotating by a certain angle, the clamping jaw is limited by the limiting plate to be just aligned to a ship manifold flange, thus the rotating shaft continues to be rotated, the clampingjaw is separated from the influence of rotating acting force of the spring sleeve, thus the clamping jaw and the rotating shaft generate threaded motion, and the clamping jaw is promoted to axially move to clamp or loosen the ship manifold flange. The butt joint of the ship manifold flange can be realized or canceled only by rotating the rotating shaft forwards or reversely, and the butt-joint work efficiency is greatly improved.

Owner:JIANGSU CHANGLONG PETROCHEM EQUIP

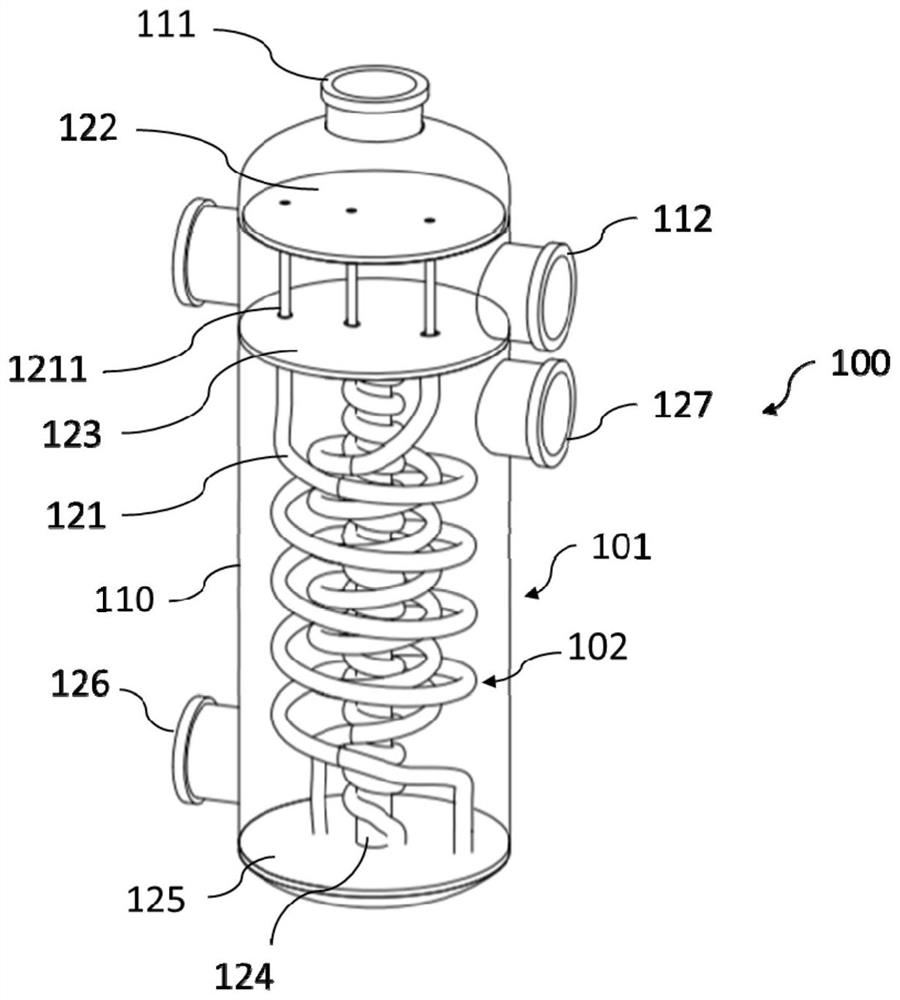

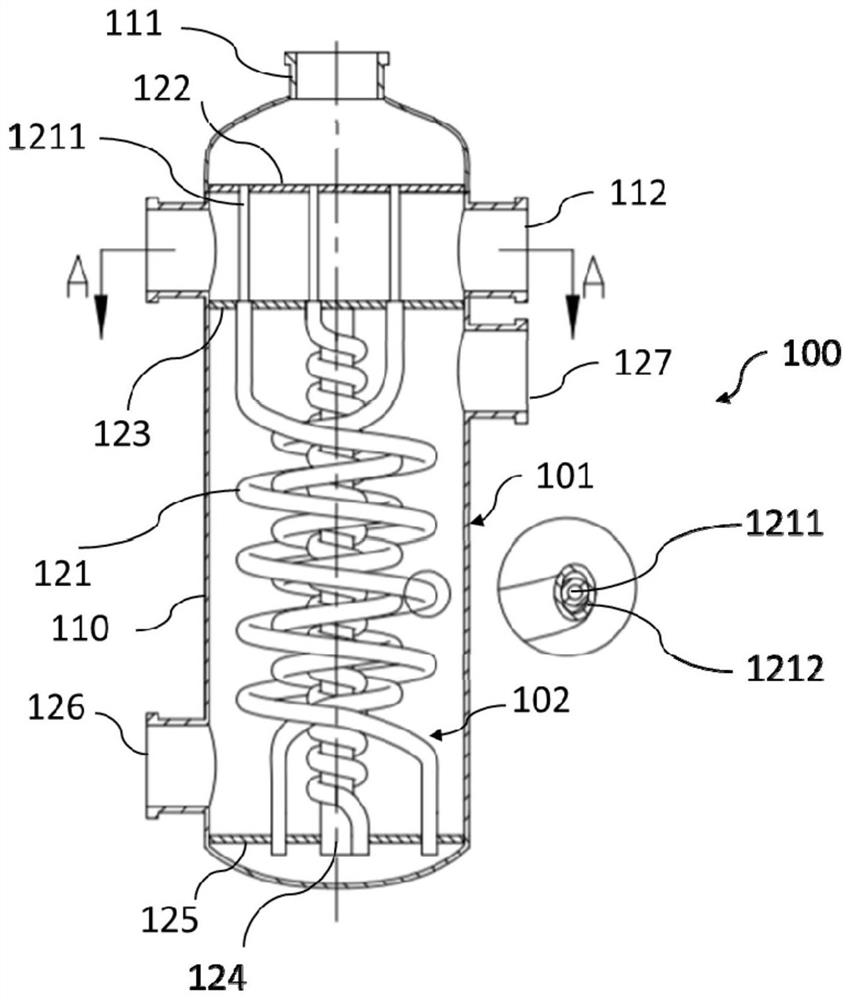

Heat exchange tube, heat exchanger tube core, heat exchanger and manufacturing method

PendingCN112082404AIncrease the heat exchange areaImprove heat transfer efficiencyCorrosion preventionHeat exhanger sealing arrangementHeat pipe heat exchangerEngineering

The application discloses a heat exchange tube comprising a first hollow tube and a second hollow tube, and the first hollow tube comprises a first end and a second end; the second hollow pipe comprises an open end and a closed end, and the first hollow tube is arranged in the second hollow tube; a gap is formed between the outer wall of the first hollow tube and the inner wall of the second hollow tube, and the first end of the first hollow tube extends out of the open end of the second hollow tube; the second end of the heat exchange tube is separated from the inner wall of the closed end ofthe second hollow tube; and the open end of the second hollow tube of the heat exchange tube and the middle part of the second end of the first hollow tube are wound into a spiral shape around a center. The application further discloses a heat exchanger tube core using the heat exchange tube, a heat exchanger and a manufacturing method thereof. By adopting the spiral winding type and sleeve typeheat exchange tubes, the heat exchange area can be increased, so that the heat exchange efficiency is improved; meanwhile, stress deformation and weld joint cracking due to heat expansion of the heatexchange tubes in use of the heat exchanger tube core and the heat exchanger are avoided; and the possibility of dew point corrosion can be reduced.

Owner:洛阳超蓝节能技术有限公司 +2

Integrated sensor for bioelectrode and method for production

InactiveCN108472846BKeep dryReduce the possibility of corrosionSensorsDomestic articlesMedicineConductive materials

The present invention discloses a method of producing a sensor (107) for a biomedical electrode (170), such as an ECG electrode, which involves injecting a conductive resin through a film (106) of a backing material to form directly in the backing material The sensor and the contact surface of the sensor are coated with a non-polarizable conductive material (109), such as a silver-containing material. The additional steps of applying the electrolyte (132) on the non-polarizable conductive material coated on the contact surface and applying the liner (141) on the electrolyte result in a biomedical electrode. The biomedical electrode thus produced has a sensor fixed in a film of a backing material, wherein the contact surface (103) of the sensor is arranged on a first side of the film and the posts (105) of the sensor extend from the side facing away from the first side. The second side of the membrane is convex. This method permits the production of integrated sensors for bioelectrodes in a continuous manner without the need for studs to hold the sensors in the film of backing material.

Owner:3M INNOVATIVE PROPERTIES CO

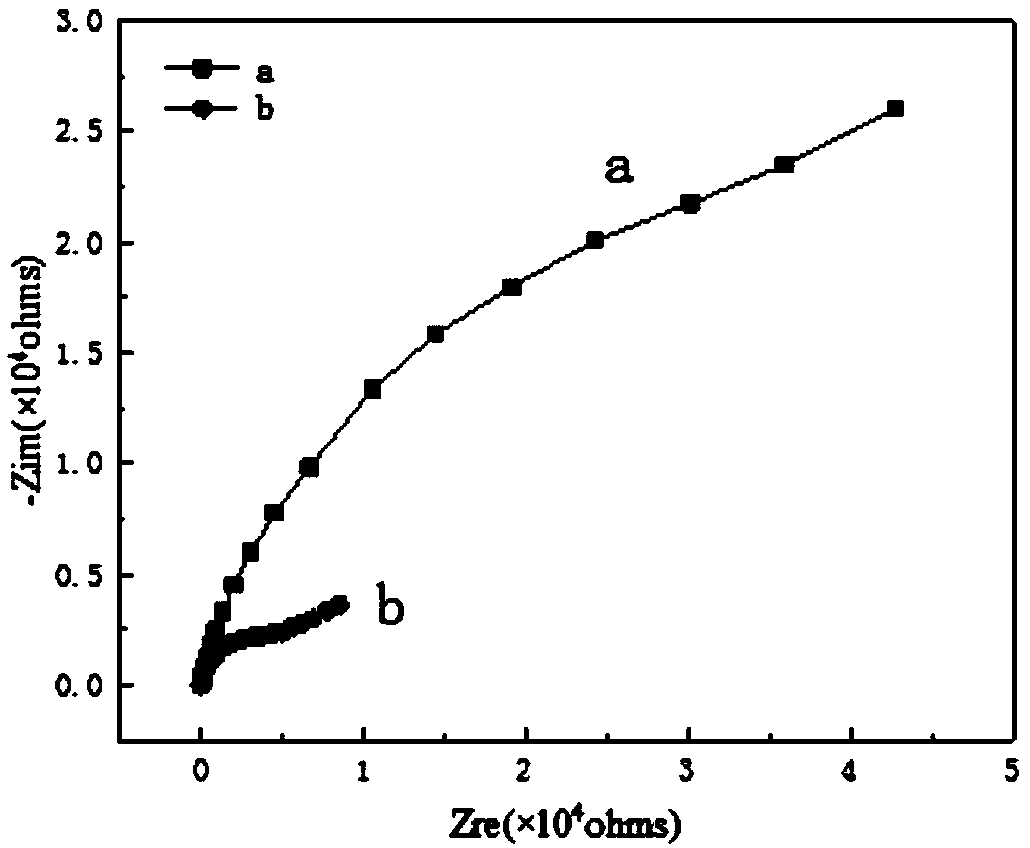

Nonaqueous electrolyte comprising oxyanion and lithium secondary battery using the same

ActiveUS8597826B2Avoid corrosionPrevent materialElectrolytic capacitorsCell electrodesHigh temperature storageElectrical battery

Disclosed is an electrolyte comprising: (a) an electrolyte salt; (b) a non-aqueous electrolyte solvent; and (c) a binary or multinary metal oxide salt. An electrochemical device comprising the same electrolyte is also disclosed. The metal oxide salt used in the electrolyte is dissolved in a non-aqueous solvent and generates oxyanions capable of improving corrosion resistance of metals. Therefore, the electrolyte prevents corrosion of metallic materials present in an electrochemical device, caused by extreme conditions, such as overcharge, overdischarge and high-temperature storage conditions, to which the device is exposed. Further, the electrolyte prevents degradation in the quality of an electrochemical device, caused by corrosion of metallic materials.

Owner:LG ENERGY SOLUTION LTD

Steel structure with anti-corrosion function and anti-corrosion process thereof

InactiveCN112709327AWith anti-corrosion functionReduce contact areaBuilding insulationsMetallurgyEngineering

The invention discloses a steel structure with an anti-corrosion function and an anti-corrosion process of the steel structure, and belongs to the technical field of steel structure assemblies, the steel structure with the anti-corrosion function comprises a left connecting piece, a right connecting piece, a transverse frame beam and a longitudinal frame beam. An upper lock hole and a lower lock hole are formed in the surface of the side, close to the left connecting piece, of the right connecting piece, the lock block is located between the upper lock hole and the lower lock hole, and the lock block, the upper lock hole and the lower lock hole are movably connected together through a fixing rod. The joints of the transverse frame beams and the longitudinal frame beams are protected, the contact area with the outside is reduced, the possibility of being corroded by the outside environment is greatly reduced, through the four-layer anti-corrosion design, the anti-corrosion capacity of the steel structure is improved, the anti-corrosion performance is high, the adhesive force is high, the sealing performance is good after colloid film forming is enhanced, and the service life of the steel structure is prolonged. The permeability of water vapor and oxygen is reduced, and the service life of the steel structure is prolonged.

Owner:澧县华丰建筑环保节能材料有限责任公司

Connection structure of monomer sodium-sulfur cell in sodium-sulfur cell module and method

InactiveCN103165849AReduce contact resistanceReduce the possibility of corrosionCell component detailsBusbarSodium–sulfur battery

The invention discloses a connection structure of a monomer sodium-sulfur cell in a sodium-sulfur cell module, which belongs to the energy storage field, and comprises a first monomer sodium-sulfur cell and a second monomer sodium-sulfur cell, a first cathode tab and a first anode tab are provided on a first monomer sodium-sulfur cell, a second cathode tab and a second anode tab are provided on a second monomer sodium-sulfur cell; and the first cathode tab and the second anode are connected through two roots of busbars. A technical effect is characterized in that the first cathode tab on two roots of busbars and the first monomer sodium-sulfur cell as well as the second anode tab on the second monomer sodium-sulfur cell form a sandwich structure, the contact resistance in the connection structure is effectively reduced, because the cross section of the busbars is in a rectangular shape, under the condition that the cross section areas are same, the surface area of the busbars is smaller, thereby the possibility that the busbars is corroded by sulfur steam or sodium polysulfide steam is reduced, and the contact resistance of the connection structure can keep long time constancy.

Owner:SHANGHAI ELECTRIC SODIUM SULFUR ENERGY STORAGE TECH +2

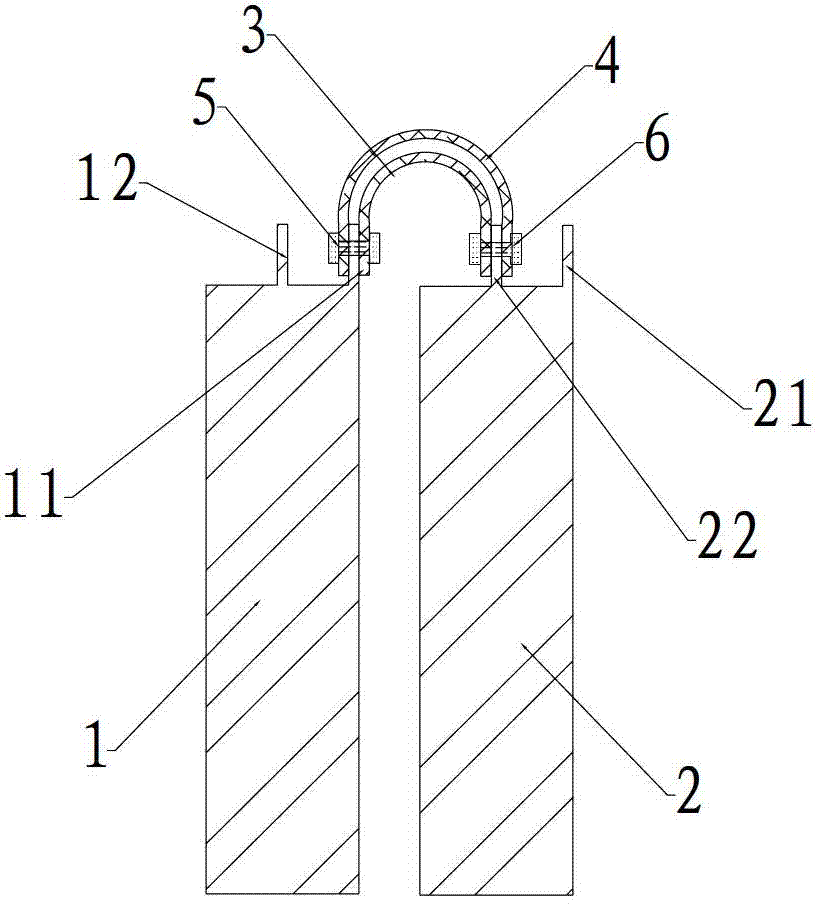

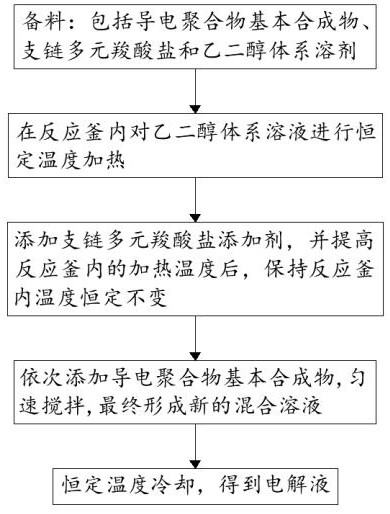

High-temperature-resistant long-service-life electrolyte for aluminum electrolytic capacitor

ActiveCN112133562ALower impedanceImprove conductivityElectrolytic capacitor manufactureElectrolytic agentHydration reaction

The invention discloses a high-temperature-resistant long-service-life electrolyte for an aluminum electrolytic capacitor. The preparation process comprises the steps of S01, preparing materials whichcomprise a conductive polymer basic composition, branched chain polycarboxylate and an ethylene glycol system solvent. According to the invention, the electrolyte is developed through the cooperationof the conductive polymer, the branched chain polycarboxylate and the ethylene glycol system, wherein the branched chain polycarboxylate has the effects of providing oxygen ions and repairing an anodic oxide film, and the conductive polymer has the effects of reducing the impedance of the electrolyte and improving the conductivity of the electrolyte; the anode oxide film is reinforced and protected, the impedance of the anode oxide film is reduced, and the conductivity of the anode oxide film is improved, so that the use temperature and the working voltage of the aluminum electrolytic capacitor are improved, the hydration reaction of electrolyte due to high temperature is reduced, the degradation of the oxide film is reduced, and the possibility of aluminum corrosion is reduced; and the electrolyte for the aluminum electrolytic capacitor is resistant to high temperature and long in service life.

Owner:CHANGZHOU HUAWEI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com