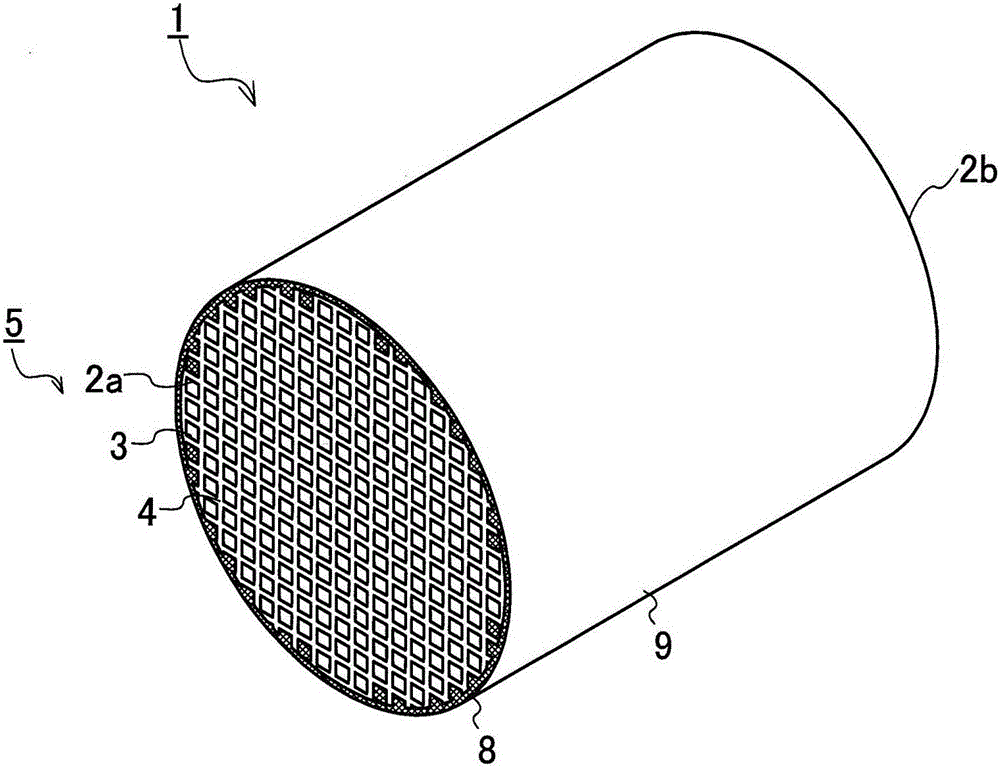

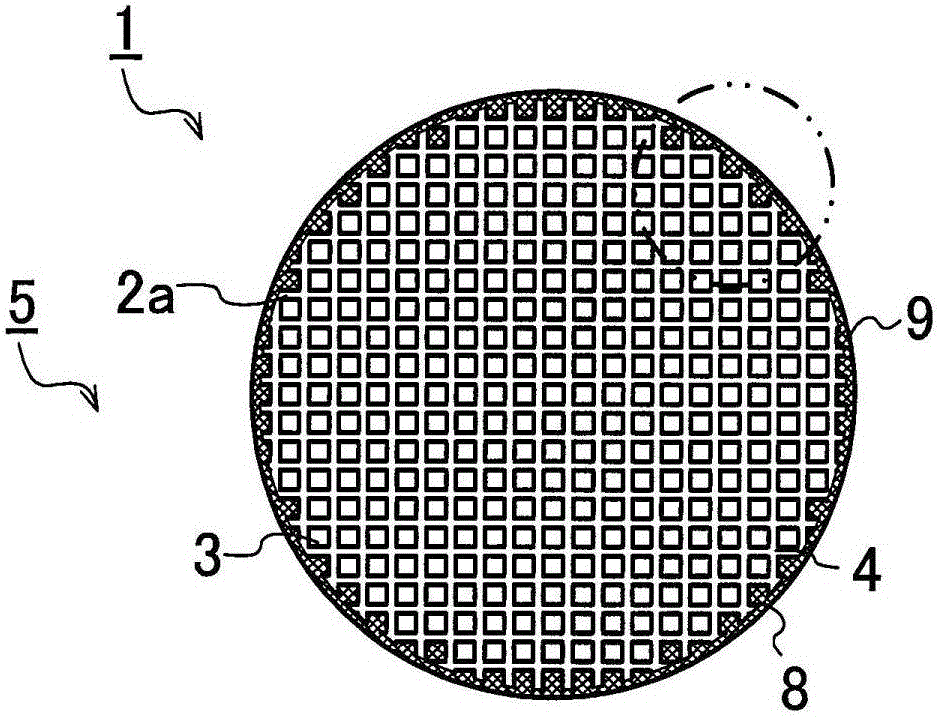

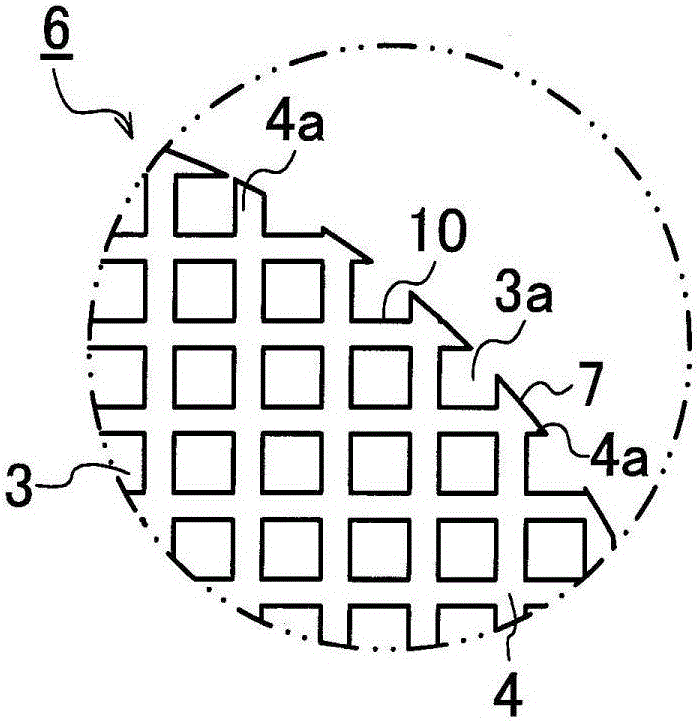

Circumference coating material, bonding material, honeycomb structure, and method of producing honeycomb structure

一种蜂窝结构体、涂层材料的技术,应用在涂层、化学仪器和方法、层压等方向,能够解决隔壁剥离等问题,达到降低腐蚀的可能性、减少氯浓度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] (1) Silica gel, chlorine concentration of outer peripheral coating material before and after drying, and influence of heat treatment The outer peripheral coating material was prepared using silica gels (Examples 1 to 7, Comparative Example 1) with different chlorine concentrations. The measurement results of the chlorine concentration of the silica gel used, the chlorine concentration of the outer peripheral coating material before drying, and the chlorine concentration of the outer peripheral coating material after drying are shown in Table 1 below. In addition, with regard to Examples 6 and 7, the chlorine concentration of the outer peripheral coating material at each heating temperature after the above-mentioned heating process is also shown.

[0059] The measurement of the chlorine concentration was carried out using a thermal hydrolysis-ion chromatography analysis method. Specifically, a sample to be measured under an inert atmosphere is thermally decomposed (therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com