System for recovering water vapor in smoke and heat by membrane method and heat exchange module

A heat exchange module, water vapor technology, applied in membrane technology, separation method, gas treatment and other directions, can solve the problems of poor economy, reduce power generation efficiency, reduce steam working ability, etc., to reduce corrosion, improve power generation efficiency, improve The effect of running economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

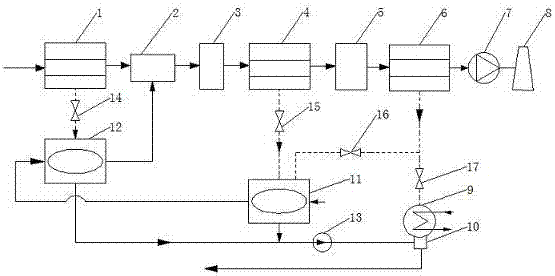

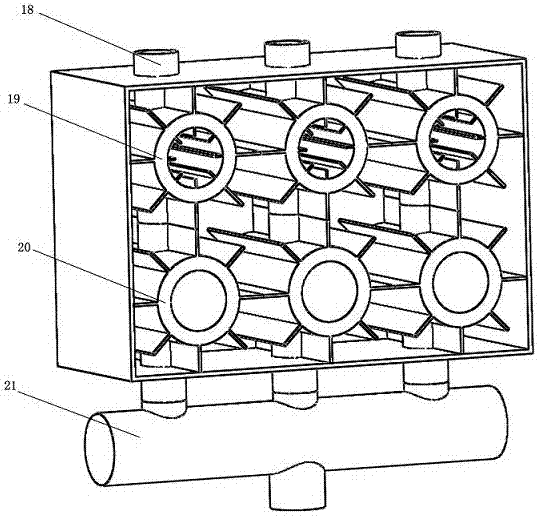

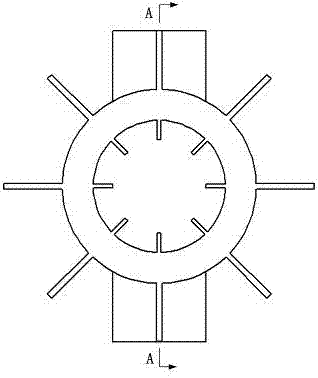

[0017] The present invention designs a system based on the hollow fiber composite membrane method for recovering water vapor and its heat in the flue gas of a thermal power plant and the structure of the heat exchange module of the front heater, with the purpose of realizing the water vapor and its heat in the flue gas of a thermal power plant Recycling, reducing water consumption and coal consumption in thermal power plants, improving the economy of thermal power unit operation, and reducing pollutant emissions from thermal power plants.

[0018] In the water vapor heat recovery system, the moisture recovery device adopts three levels of arrangement: high, medium and low: the high-temperature moisture recovery device (1) is arranged before the air preheater (2), and the recovered water vapor has a higher temperature and can be used as a heating element. The heat source of the blower (12) is drained back to the condenser hot well (10) through the drain pump (13), and the medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com