A membrane-type water-cooled wall composite return water condensing natural gas hot water boiler

A membrane-type water-cooled wall and hot water boiler technology, applied in water heaters, fluid heaters, and greenhouse gas reduction, can solve the problems of incomplete recovery of latent heat of vaporization of water vapor, difficulties in discharging boiler pollutants, and public health threats Larger problems, to achieve the effect of reducing initial investment costs, reducing fuel costs, and small foundation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

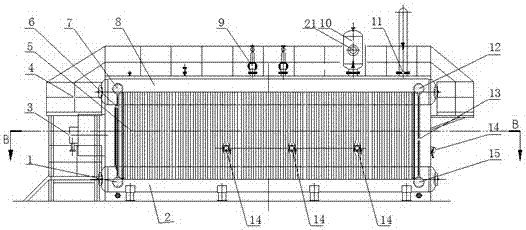

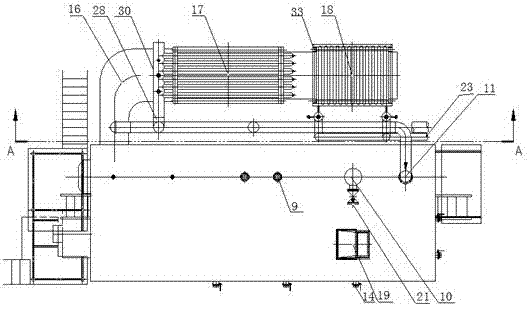

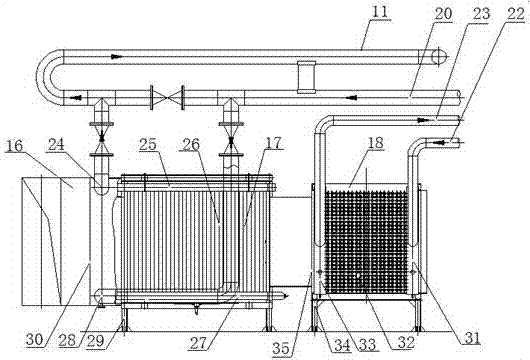

[0021] Such as Figure 1 to Figure 4 As shown, the membrane water wall composite return water condensing natural gas hot water boiler includes an upper drum 8, a lower drum 2, a furnace 5, a turning flue 16, an economizer 17, a condenser 18, a convection tube bundle 38 and pipelines On the upper drum 8, a safety valve 9, a gas collecting tank 10, a body water inlet connecting pipe 11 in the pipeline are successively installed from left to right, and the gas collecting tank 10 is connected with the primary pipe network water supply pipe 21 in the pipeline; The return water of the return water pipe 20 of the primary pipe network passes through the lower water header 28, the lower header 27, the heat exchange tube I 26, the upper header 25, the upper water header 24, and the rear membrane type of the furnace 5 in sequence of the economizer 17 The water wall 13, the membrane w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com