Efficient quick connecting device and quick connecting method

A fast connection and high-efficiency technology, applied in the direction of connecting components, flange connections, pipes/pipe joints/fittings, etc., can solve problems such as inconvenience and affect processing efficiency, and achieve the effect of reducing the possibility of corrosion and improving the efficiency of docking work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

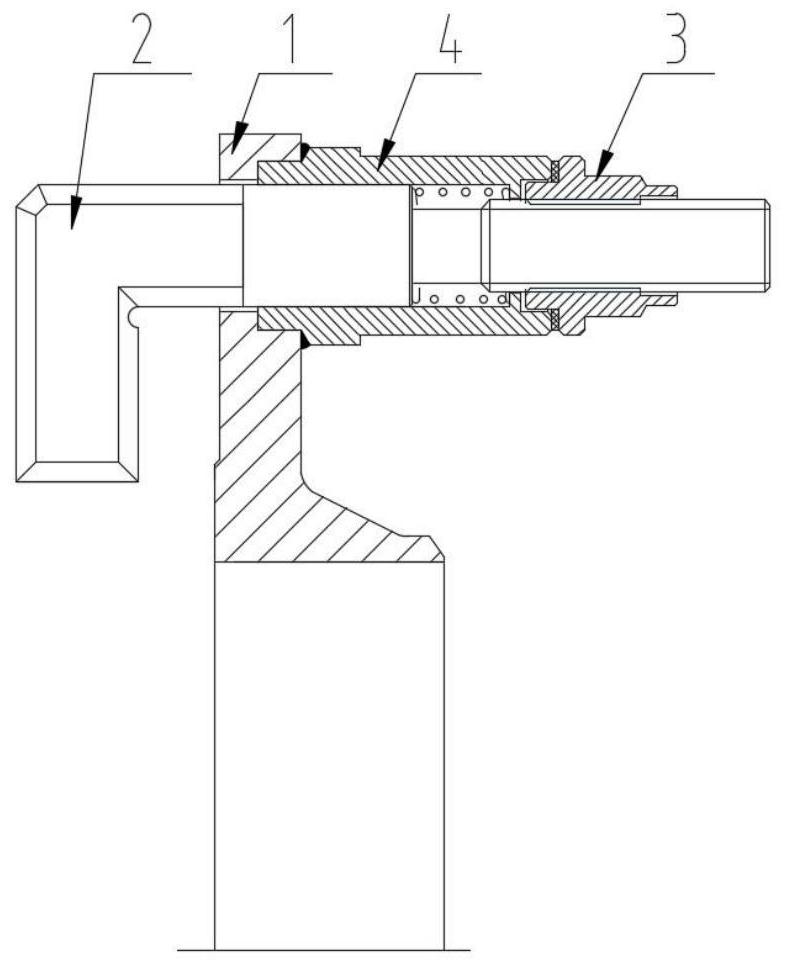

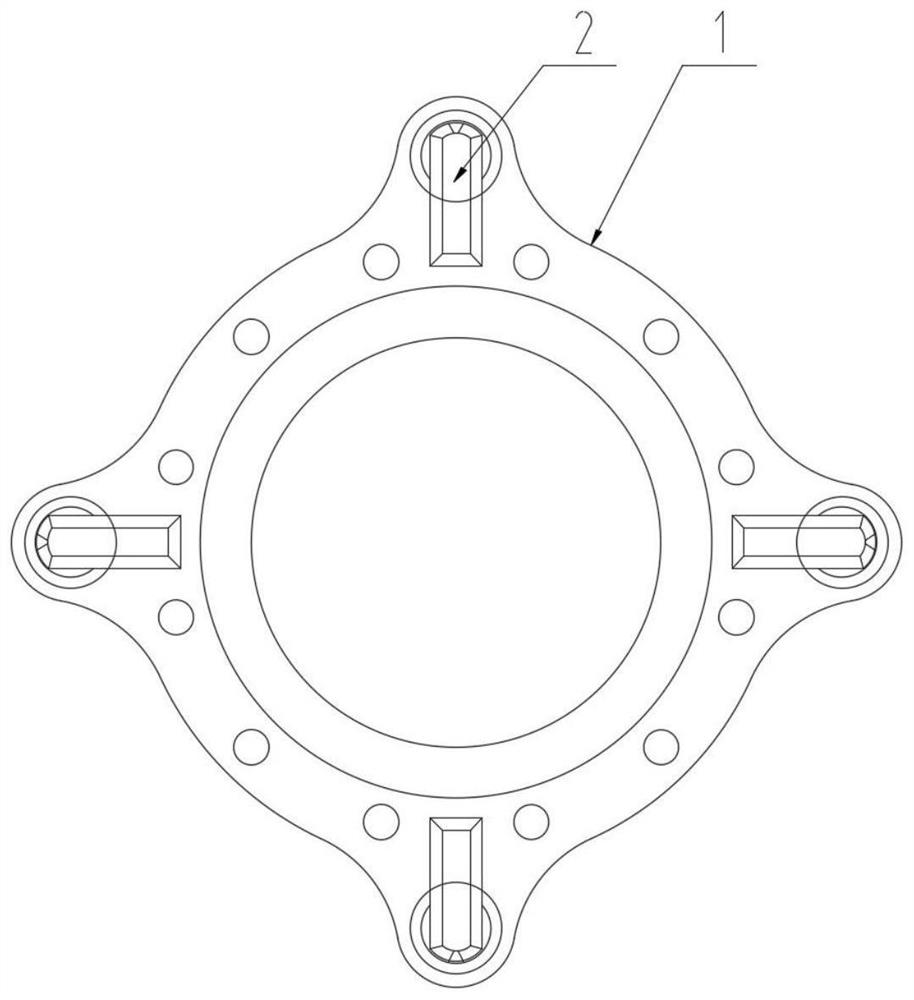

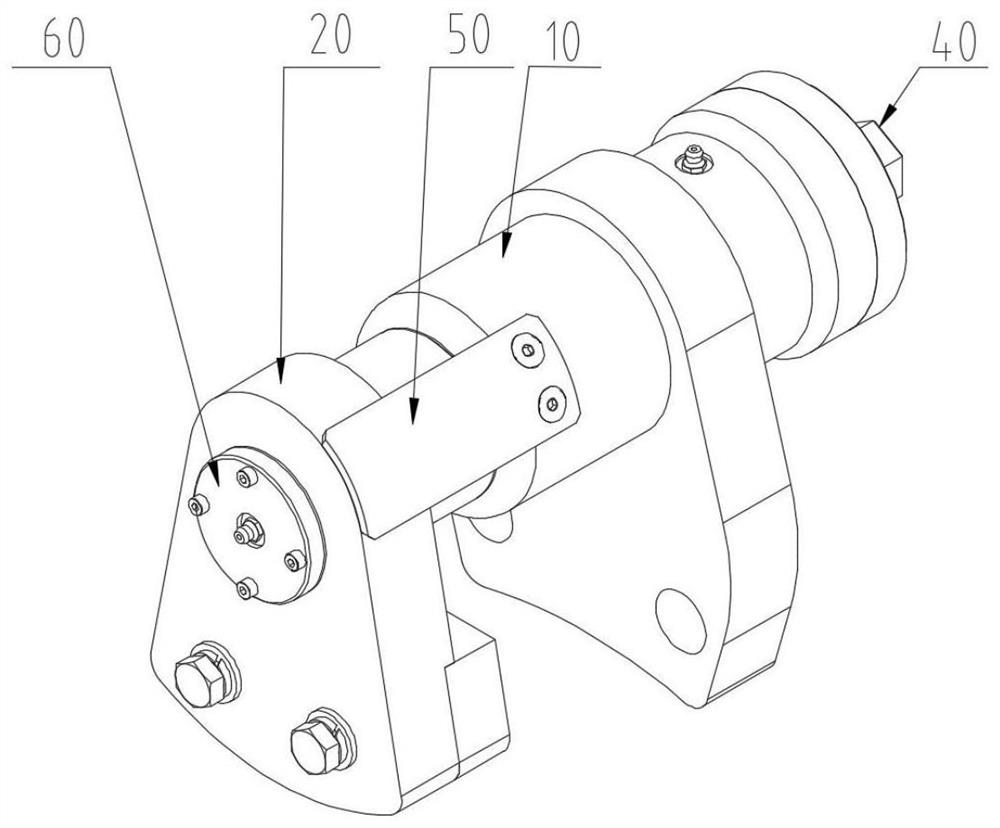

[0051] A high-efficiency quick-connect device, wherein, such as Figure 3-5 As shown, it includes: a housing 10 , a claw 20 , a spring sleeve 30 , a rotating shaft 40 , and a limiting plate 50 .

[0052] The casing 10 has a telescoping chamber 11 therein. The axial part of the claw 20 is slidably connected with the telescoping cavity 11 , and the axial part of the claw 20 has an axial through hole 21 . The spring sleeve 30 is disposed in the axial through hole 21 , and the spring sleeve 30 is in close contact with the sidewall of the axial through hole 21 .

[0053] The rotating shaft 40 is rotatably connected to the housing 10 , the rotating shaft 40 is connected to the spring sleeve 30 , and the rotating shaft 40 is screwed to the axial through hole 21 . The limiting plate 50 is installed on the housing 10 , and the limiting plate 50 is located on one side of the claw 20 .

[0054] During use, after the housing 10 is fixed on the flange of the quick connection device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com