Connection structure of wiring terminal and enameled wire, method, coil assembly and motor

A technology of terminal and connection structure, which is applied in the parts, connections, circuit/collector parts of connecting devices, etc., can solve the problems such as easy breaking or bumping of enameled wires, defective products, and easy loosening and falling off of enameled wires. , to achieve the effect of removing the length controllable, prolonging the life, and eliminating the hidden danger of pulling and breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

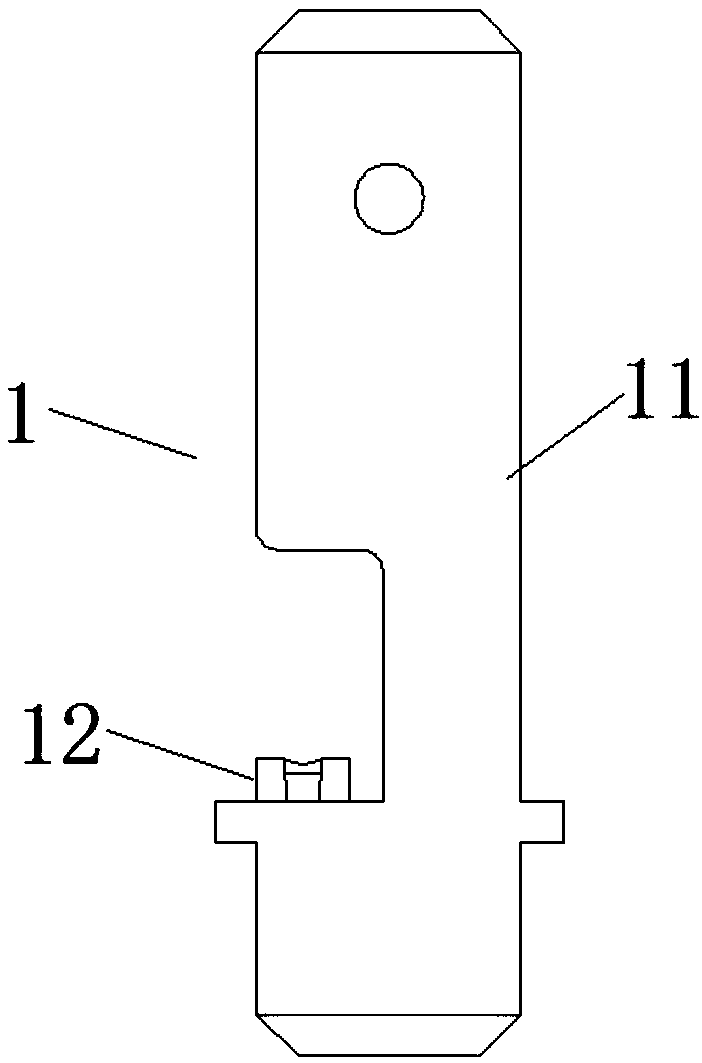

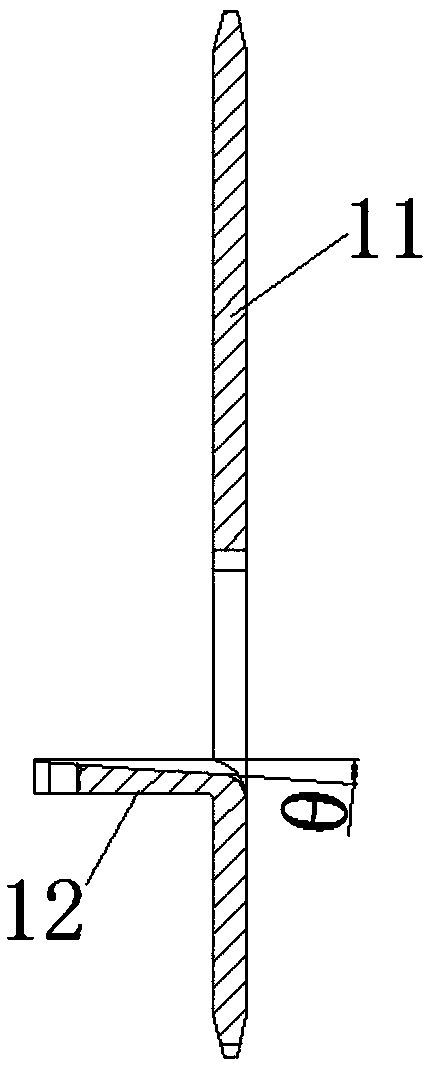

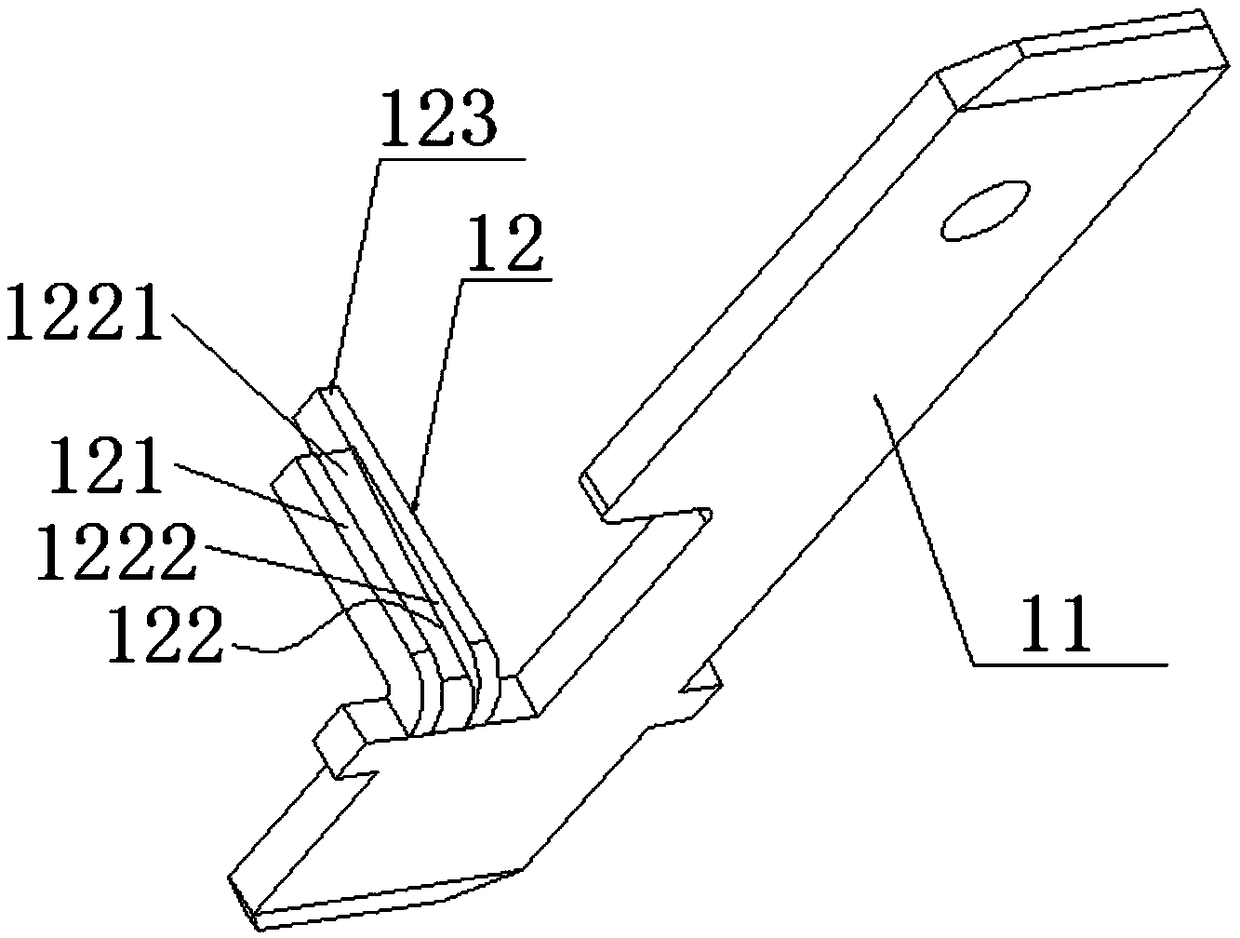

[0065] see Figure 1~3 , which is a schematic structural view of the terminal of the present invention.

[0066] The terminal 1 of this embodiment includes a terminal body 11 and a terminal post 12 . The terminal post 12 is used to connect with the terminal of the enameled wire. The terminal post 12 is fixed on the terminal body 11 and includes a first surface 121 , a first groove 122 and a wire end winding post 123 . The first groove 122 is formed downwardly from the first surface 121 , and includes two side surfaces 1222 and a bottom surface 1221 . In this embodiment, the angle θ between the bottom surface 1221 of the first groove and the first surface 121 is 15°. In other embodiments, the angle θ is preferably in the range of 0-20°, that is, the first groove The bottom surface 1221 of the first surface 121 can be parallel to the first surface 121 or inclined. In this embodiment, the enameled wire is aluminum enameled wire, and in other embodiments, traditional copper ena...

Embodiment 2

[0068] see Figure 4~5 , the terminal 1 of this embodiment includes a terminal body 11, a terminal 12 and a fixed terminal 13, the terminal 12 does not include a wire end winding column 123, other components and shapes of the terminal 12, the terminal body 11 and the terminal 12 The structural relationship is the same as in Embodiment 1, and the included angle θ is 20° in this embodiment.

[0069] In this embodiment, the section of the fixed terminal 13 is U-shaped, and its inner surface is provided with a plurality of tooth-shaped structures 131 to further prevent the loosening of the enameled wire. In other embodiments, the tooth-shaped structures 131 may not be provided. Structure 131. In the initial state, the fixed terminal 13 and the terminal 12 are separated and independent from each other, and the fixed terminal 13 can be stamped to be fixed with the terminal 12 through a stamping process, and wrapped on the three outer surfaces of the terminal, including the first su...

Embodiment 3

[0072] see Figure 8-9, The terminal 1 of this embodiment includes a terminal body 11 , a terminal post 12 and a fixed terminal 13 . The shape and structure of the terminal 12 in this embodiment, and the structural relationship between the terminal body 11 and the terminal 12 are the same as in Embodiment 1, and the included angle θ in this embodiment is 10°.

[0073] In this embodiment, the fixed terminal 13 is fixed on the terminal 12, and includes a crimping portion 132 and a fixing portion 133 connected to each other. The fixed terminal 13 is fixed on the side wall of the terminal 12 through the fixing portion 133. The crimping portion 132 can pass The crimping covers the first surface 121 of the terminal 12 . The initial state of the fixed terminal 13, such as Figure 8 As shown, the fixed part 133 is fixed to the terminal 12, and the crimping part 132 is located above the terminal 12 and does not contact the terminal 12; after the crimping part 132 is stamped, it looks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com