Electrode structure, and method for manufacturing thin-film structure

A manufacturing method and structure technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state device manufacturing, microstructure device manufacturing, etc., can solve problems such as strength problems, and achieve the goals of reducing shear stress, improving strength, and suppressing cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] A. Implementation form 1

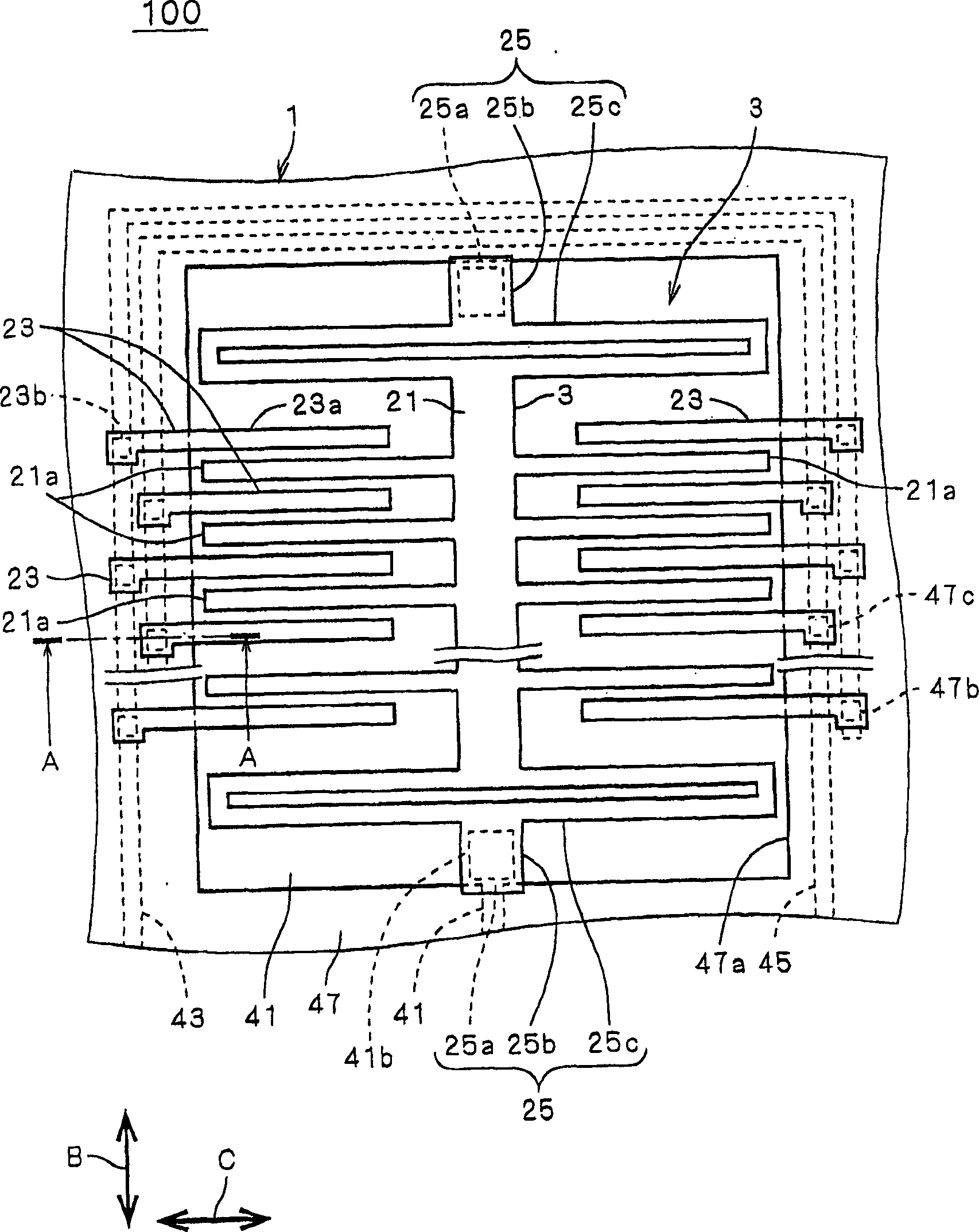

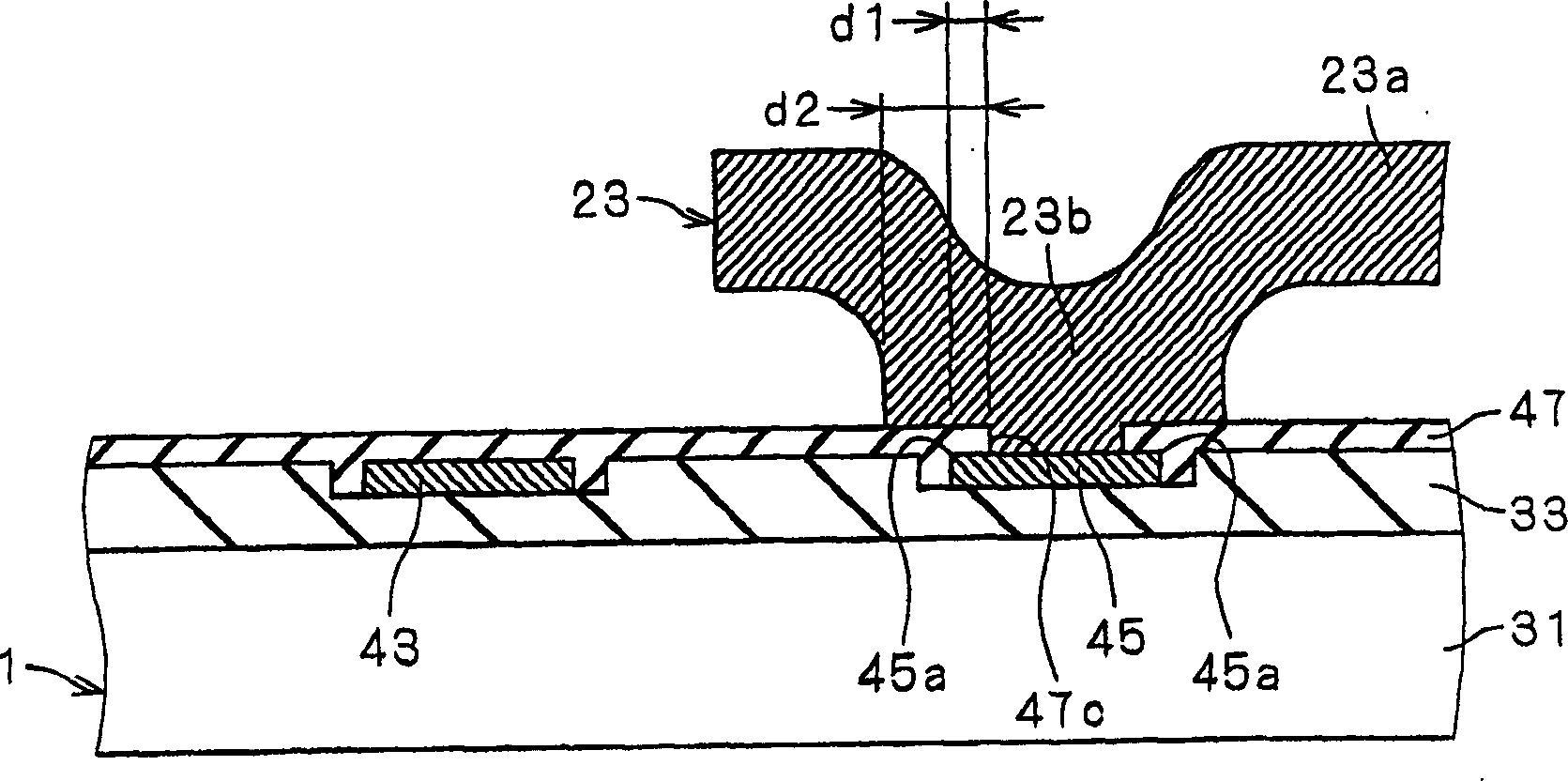

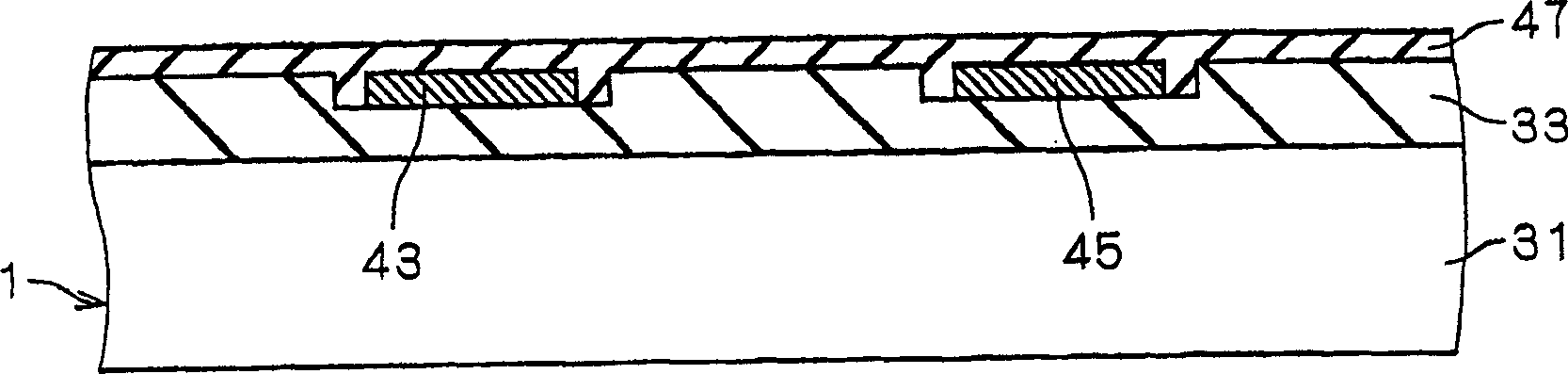

[0054] figure 1 It is a plan view showing the main part structure of the semiconductor acceleration sensor 100 to which the method of manufacturing the thin film structure of the present invention can be applied. figure 2 is along figure 1 The A-A line profile. The semiconductor acceleration sensor 100 includes a substrate 1 as a sensor substrate, and is formed on the substrate 1 ( figure 1 The center is the front side of the paper), and the sensor part 3 has the function of detecting acceleration.

[0055] The sensor unit 3 includes a movable mass body 21, several fixed structures 23, and several beams 25, and is formed as a thin film structure. The thin film structure is formed of a conductive material, for example polysilicon doped with impurities, for example doped polysilicon doped with phosphorus.

[0056] The mass body 21 has a plurality of movable electrode portions 21 a extending along a direction C perpendicular to the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com