Multilayer ceramic substrate, electronic component, and method of manufacturing multilayer ceramic substrate

一种多层陶瓷、陶瓷衬的技术,应用在多层电路制造、印刷电路制造、印刷电路零部件等方向,能够解决变窄等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

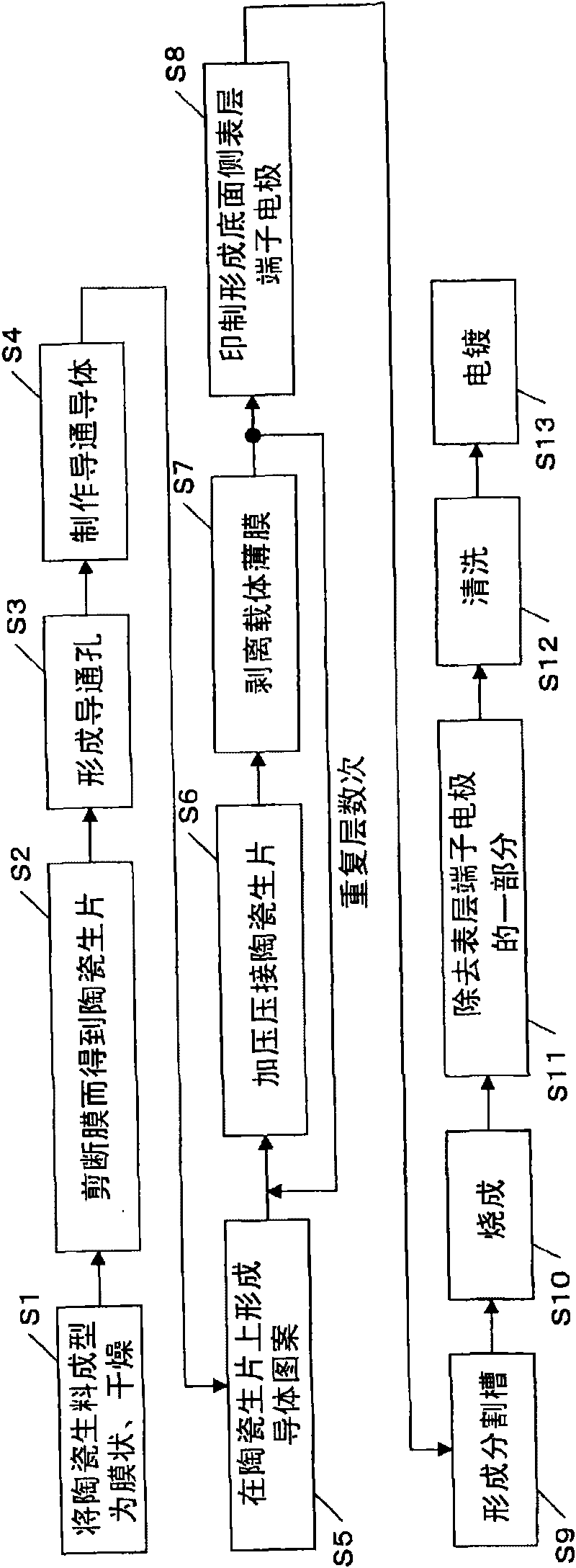

[0029] Embodiments of the present invention will be described with reference to the drawings. figure 1 It is a flowchart showing the manufacturing steps of the multilayer ceramic substrate of this embodiment.

[0030] (manufacturing of multilayer ceramic substrates)

[0031] In the step of forming the multilayer ceramic substrate of this embodiment, first, a plurality of ceramic green sheets are produced. For this reason, on the organic carrier film (carry film) (for example PET film) by doctor blade method, will be made of the ceramic material powder that can be fired at low temperature, the powder of glass component, organic binder, plasticizer and A slurry made of a mixture of solvents is formed into a film with a predetermined thickness and dried (S1). The dried thickness of the raw material varies depending on the purpose, but is about 20 to 200 μm in the example here.

[0032] In addition, as the low-temperature sinterable ceramic material used for ceramic green sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com