Cold flow passage multi-mould-hole mould flow passage balance structure

A balanced structure, multi-cavity technology, applied in the field of mold manufacturing, can solve the problems of lowering the quality of the finished product, slow filling of the outer cavity, and fast filling of the inner cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

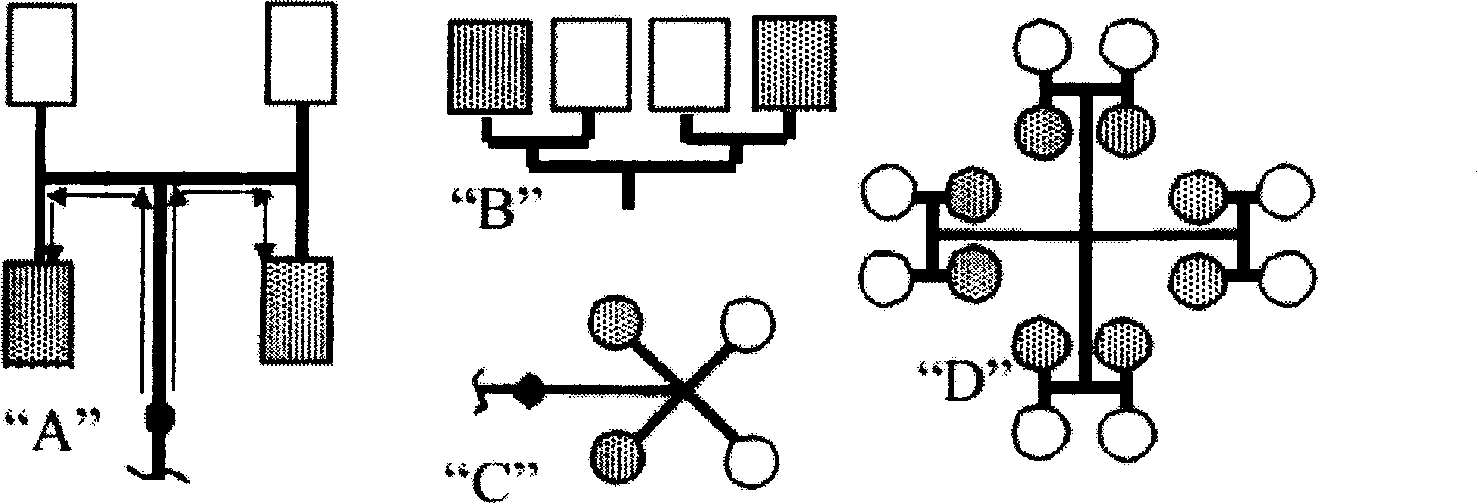

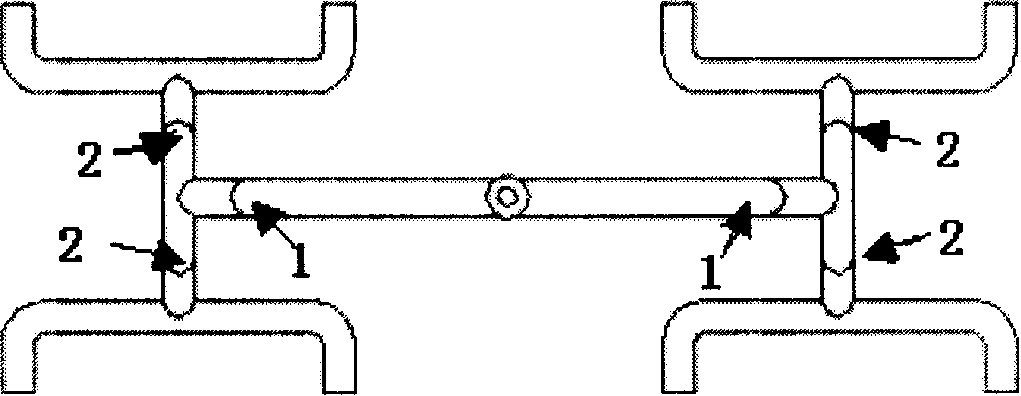

[0023] see Figure 2-9 , the cold runner multi-cavity mold runner balance structure, including the main channel and the runner; also includes the turning structure, the turning structure is set at the junction between the main channel and the runner.

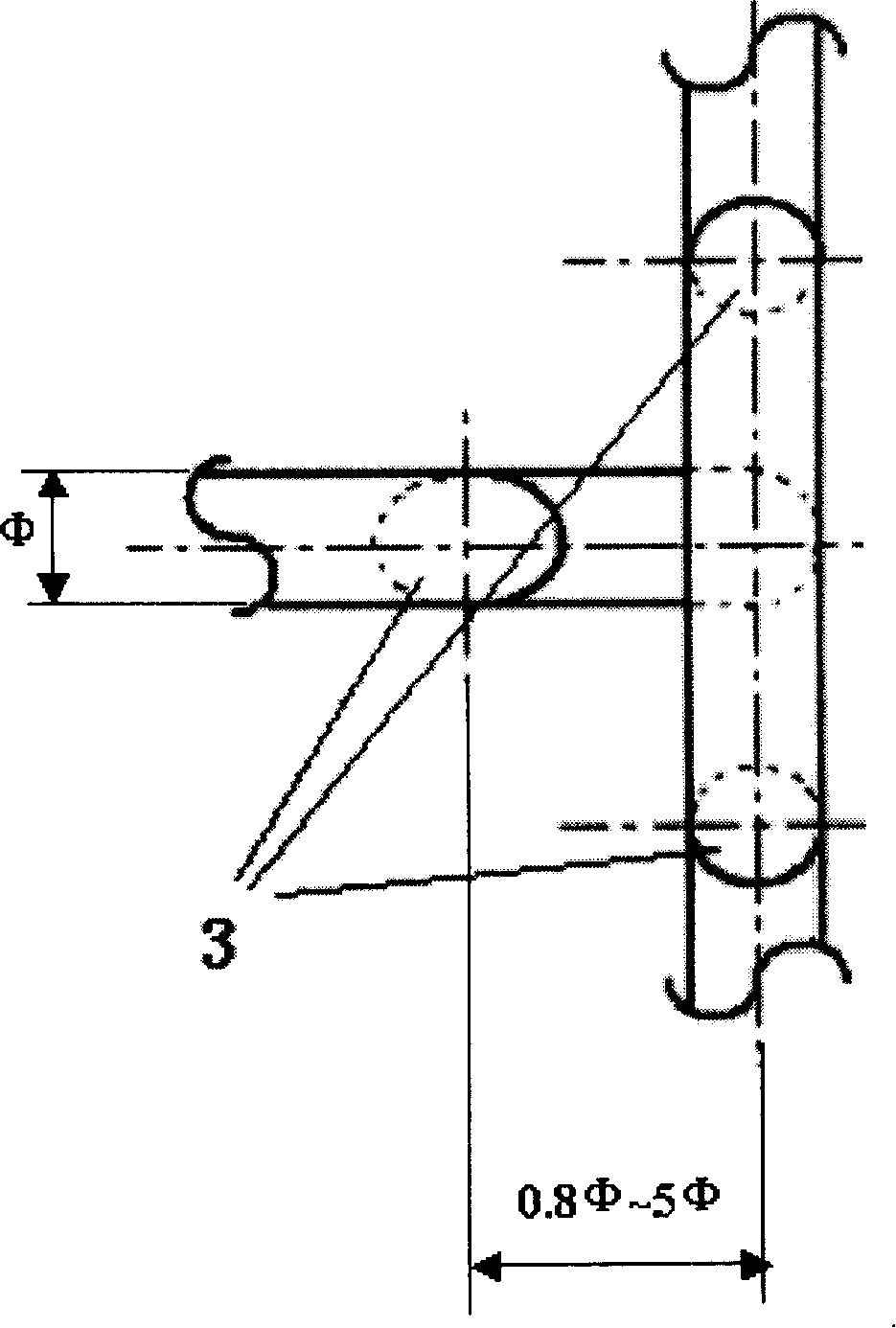

[0024] The turning structure is a circular arc surface structure; a natural arc transition is adopted between the turning structure and the main flow channel and the flow distribution channel. Such as Figure 9 shown.

[0025] The diameter of the flipping structure is 1 to 3 times the diameter of the channel where the structure is located, such as Figure 5 shown.

[0026] The length of the flip structure is 0.8 to 5 times the diameter of the flow channel; generally 1.5 to 5 times; as image 3 shown.

[0027] The translational height of the axis line of the turning structure is 0.5 to 1.5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com