Development of rotating miniature combustion bomb

A technology of miniature incendiary and incendiary bombs, applied in the direction of material thermal development, etc., can solve the problems of temperature lag, single technology, large sample size, etc., to ensure smooth conduction, overcome circuit connection failure, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

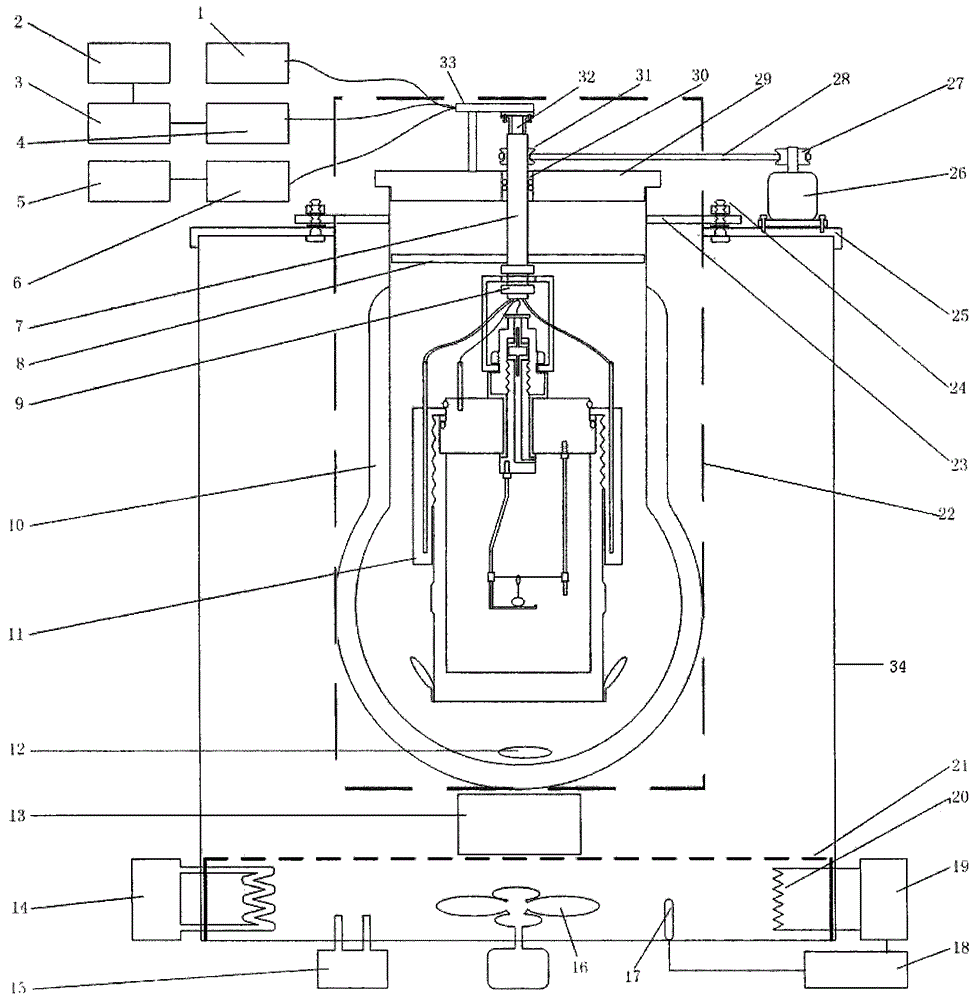

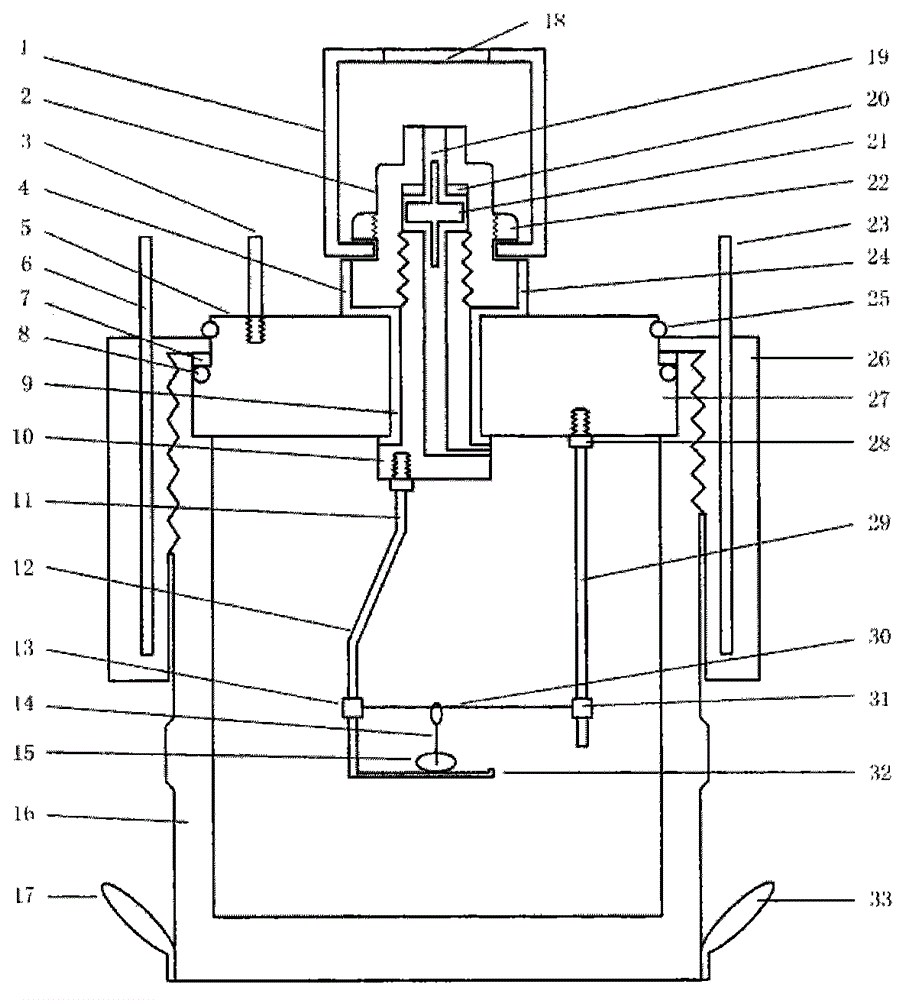

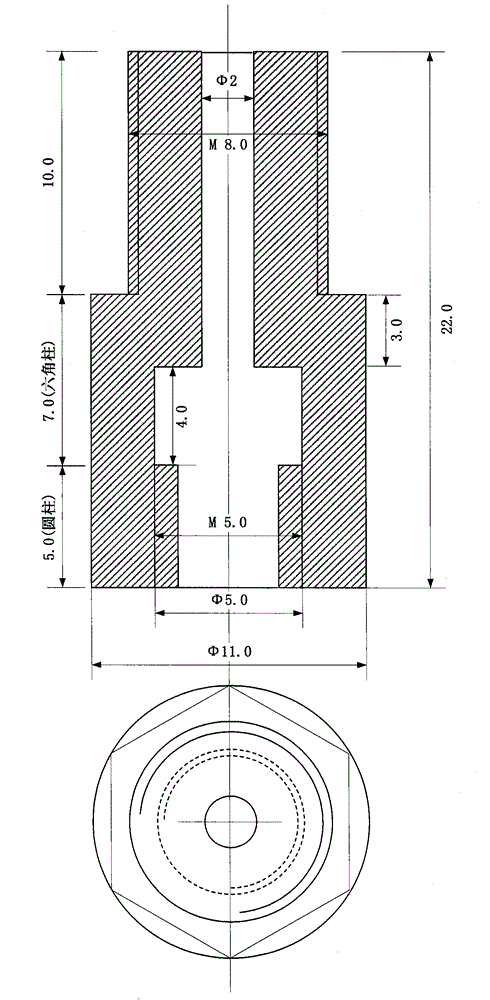

[0044] "Multi-functional high-precision miniature isothermal environment combustion-dissolution-reaction calorimeter" consists of the following components: 1. Oxygen bomb ignition system, 2. Computer, 3. Power amplifier or A / D converter, 4. Weston electric Bridge, 5. precision steady current power supply, 6. time counter, 7. suspender, 8. heat shield, 9. firm nut for suspension ring, 10. Dewar bottle, 11. miniature oxygen bomb (see the section diagram of miniature oxygen bomb for details ), 12. Glass stirrer, 13. Submersible magnetic stirrer, 14. Refrigeration system, 15. Automatic water inlet and drainage system, 16. Electric stirrer for constant temperature tank, 17. Temperature sensor for constant temperature tank, 18. Weston bridge , 19. Temperature controller, 20. Heater, 21. Teflon support frame, 22. The red frame indicates replacement parts for different functions, 23. Dewar bottle fixing plate, 24. Thermostat cover plate and Du Tile bottle plate fixing screw, 25, const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com