Biomass gasification device and process

A biomass and equipment technology, applied in the field of biomass gasification equipment and gasification process, can solve the problems of inability to continuously and stably generate electricity by gas generator sets, inconvenient storage and transportation for large-scale promotion and application, damage and corrosion of terminal application equipment, etc. Controllable leveling operation, improving gasification efficiency and gas calorific value, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings.

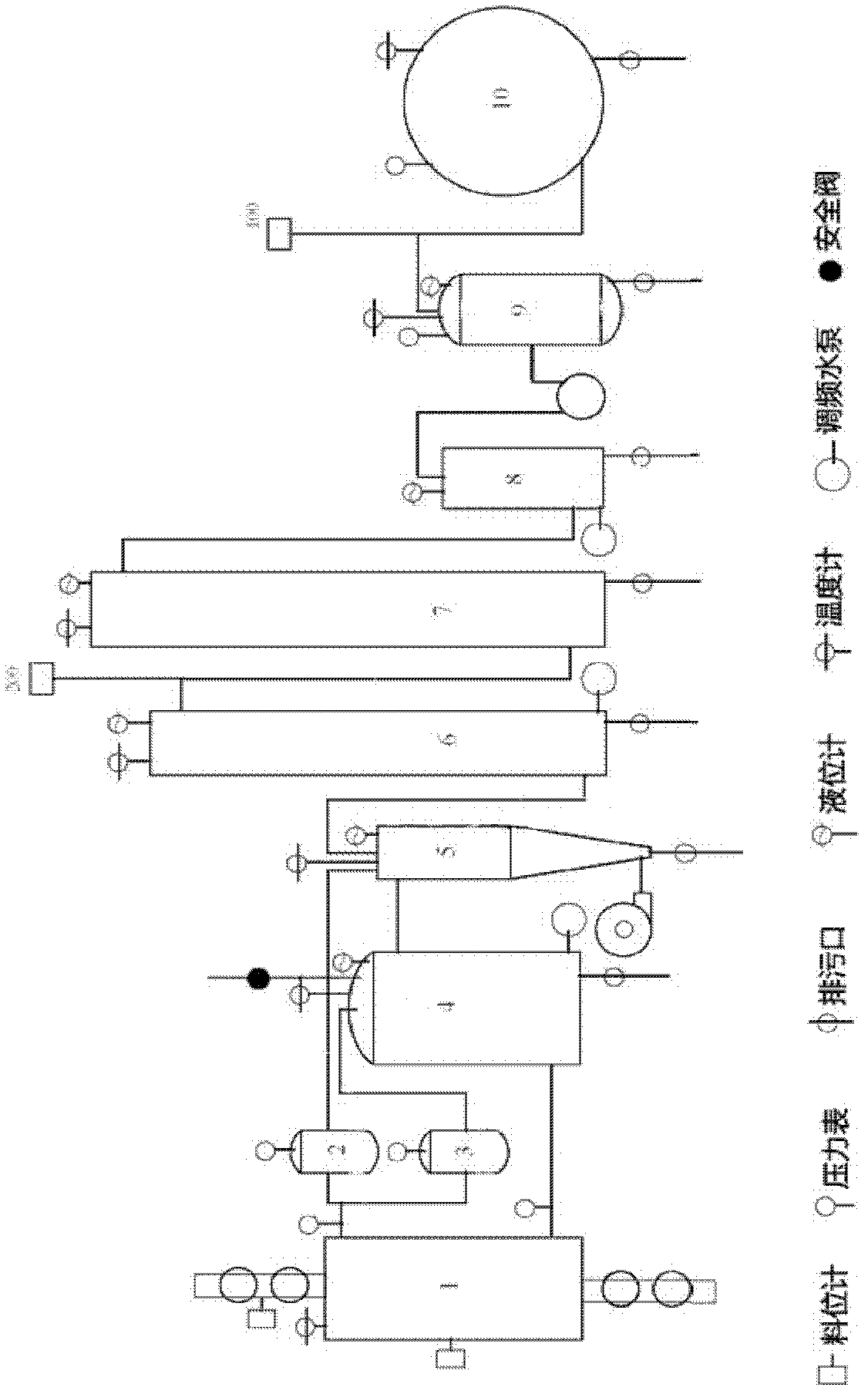

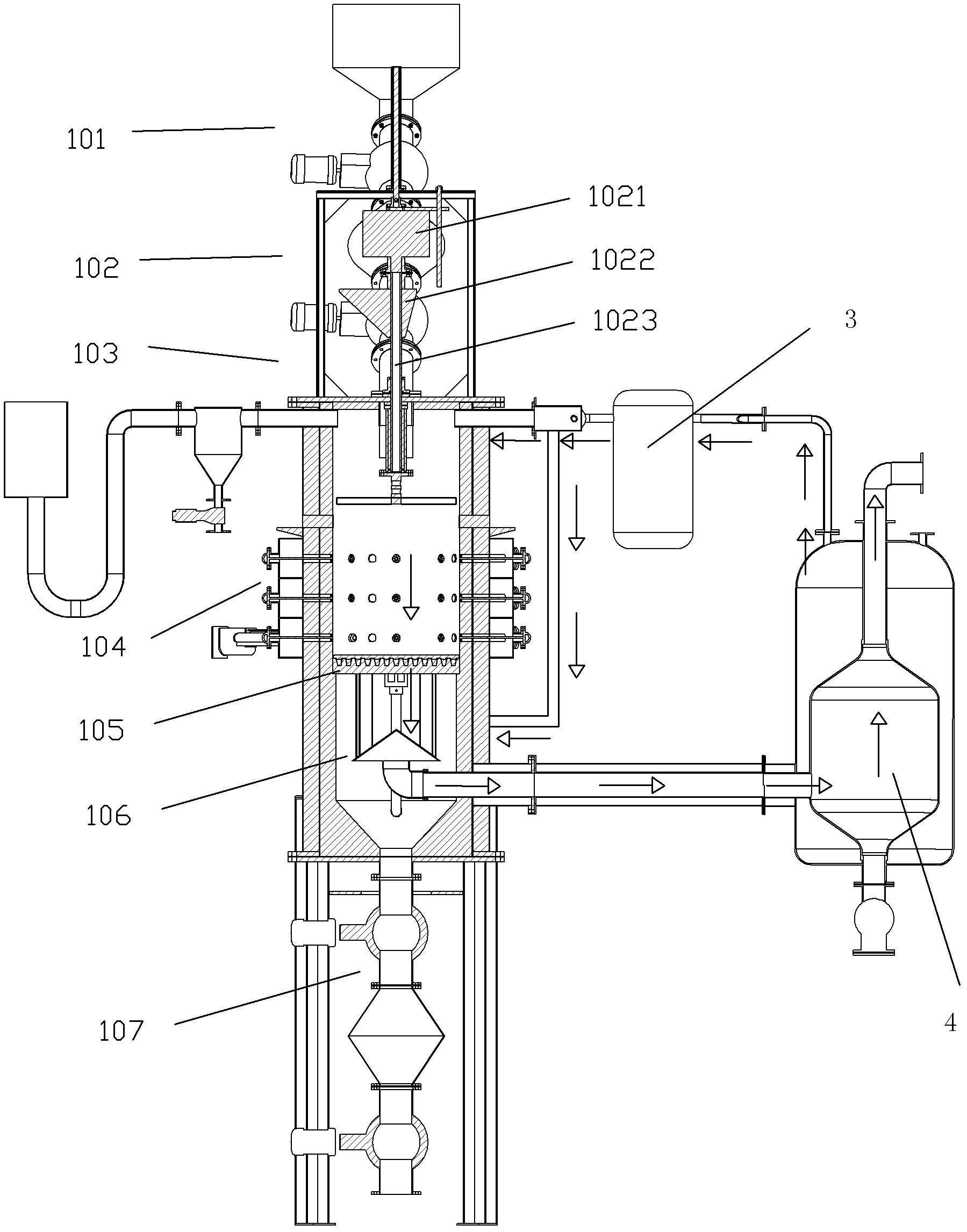

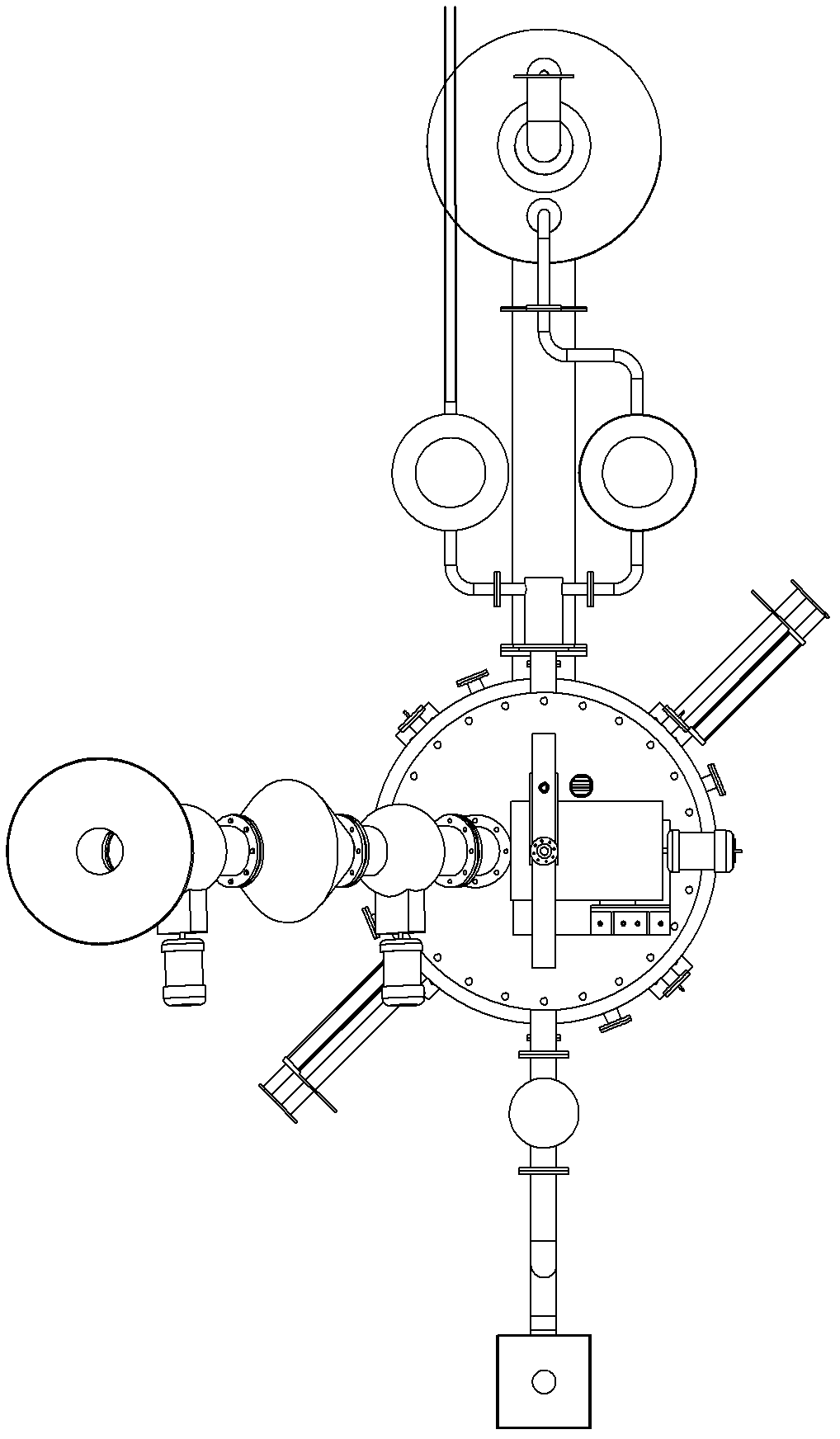

[0061] A biomass gasification equipment, such as figure 1 As shown, it includes gasification reaction chamber 1, air buffer tank 2, steam buffer tank 3, steam heat exchanger 4, internal and external double cyclone heat exchange dust collector 5, cooling tower 6, electric tar catcher connected in sequence by gas pipeline 7. Hydrogen sulfide removal sprayer 8, gas-water separator 9 and gas storage tank 10;

[0062] The steam heat exchanger 4, the steam buffer tank 3, and the gasification reaction chamber 1 are connected in sequence through a steam pipeline; the blower, the inner and outer double cyclone heat exchange dust collector 5, the air buffer tank 2, and the gasification reaction chamber 1 are connected in sequence through an air pipeline; Gas) The gas storage tank 10 is connected to the user end gas application equipment or the gas pipeline network thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com