Preparation method of lithium ion battery ternary cathode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of uneven particle size distribution, affecting high temperature cycle performance, secondary spherical particle breakage, etc., to achieve uniform morphology, improve High temperature cycle performance, the effect of suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

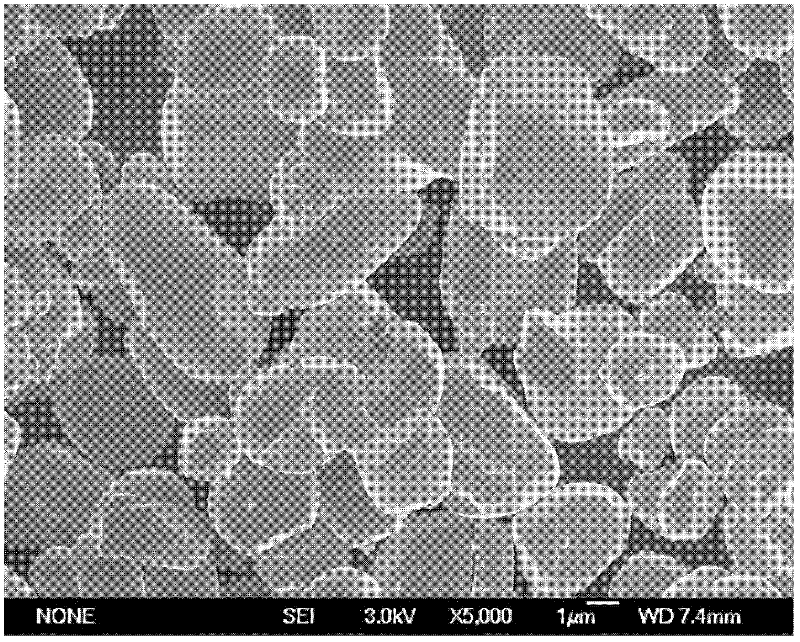

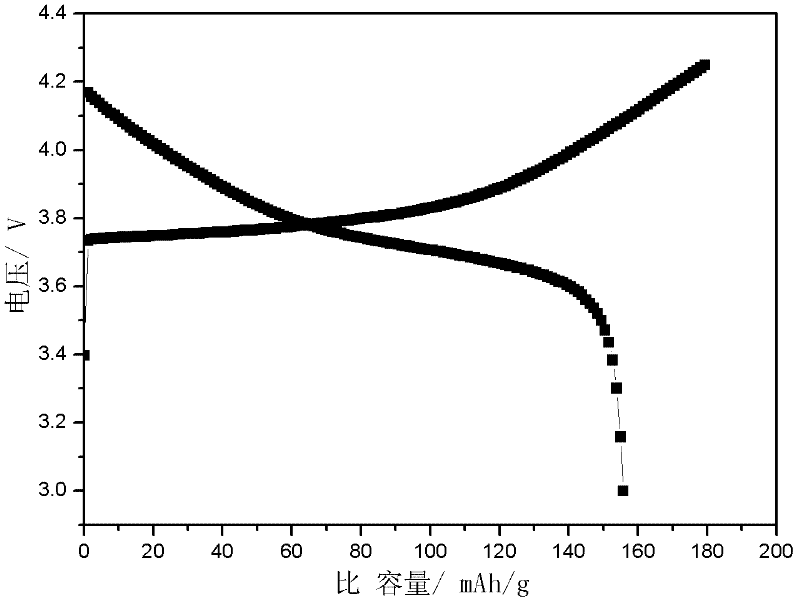

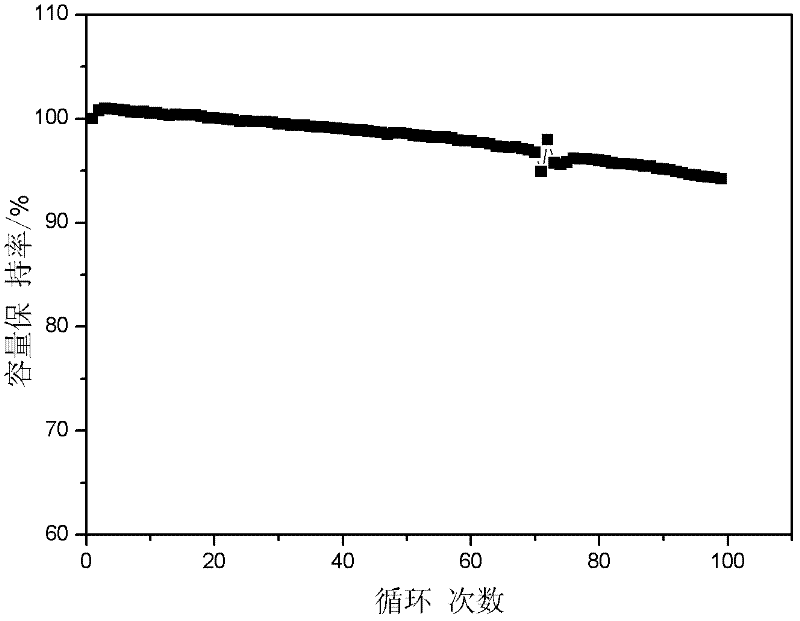

Image

Examples

Embodiment 1

[0024] 1. Prepare the coated ternary cathode material Li according to the following steps 1.03 [Ni 0.5 co 02 mn 0.3 ] 0.90 Ti 0.05 al 0.05 o 2

[0025] 1) According to the molar ratio of Li:(Ni+Co+Mn):Ti:Al=1.03:0.90:0.05:0.05, accurately weigh 86.53g LiOH·H 2 O, 165.41gNi 0.5 co 0.2 mn 0.3 (OH) 2 , 7.99g TiO 2 , 7.8g Al 2 o 3 . 5.35 g of soluble starch was ball-milled for 1 hour, then added to a colloid mill for grinding for 8 hours, dried in vacuum at 100° C., and then pressed into tablets using a tablet machine.

[0026] 2) The molding material obtained in step 1) is heated to 950° C. at a heating rate of 3° C. / min, kept for 16 hours, cooled naturally to room temperature, and crushed by an air jet mill.

[0027] 3) Weigh 38.77g of zirconium isopropoxide according to the molar ratio of Zr:(Ni+Co+Mn+Ti+Al)=0.05:1, dissolve in isopropanol, and slowly add 201.22g of jet mill to crush The final step 2) product was stirred at room temperature for 1 h, filtered, wa...

Embodiment 2

[0033] Prepare the coated ternary cathode material Li according to the following steps 1.06 [Ni 0.5 co 0.2 mn 0.3 ] 0.95 Mg 0.025 al 0.025 o 2 :

[0034] 1) Accurately weigh 78.32g Li according to the molar ratio of Li:(Ni+Co+Mn):Mg:Al=1.06:0.95:0.025:0.025 2 CO 3 , 174.06g Ni 0.5 co 0.2 mn 0.3 (OH) 2 , 2g MgO, 3.9g Al 2 o 3 12.8g of PVP was ball milled and mixed for 1 hour, then added into a colloid mill to grind for 5 hours, dried in vacuum at 100°C, and then pressed into tablets using a tablet machine.

[0035] 2) The molding material obtained in step 1) is heated to 970° C. at a heating rate of 5° C. / min, kept for 12 hours, cooled naturally to room temperature, and crushed by a jet mill.

[0036] 3) Weigh 18.79g of titanium chloride according to the molar ratio of Ti:(Ni+Co+Mn+Mg)=0.05:1, dissolve it in water, slowly add the product of step 2) after being broken by the jet mill under stirring, and add dropwise Adjust the pH to 11 with ammonia water, stir at...

Embodiment 3

[0039] Prepare the coated ternary cathode material Li according to the following steps 1.03 [Ni 0.5 co 0.2 mn 0.3 ] 0.95 Ti 0.05 o 2 :

[0040] 1) Accurately weigh 86.53g LiOH·H according to the molar ratio of Li:(Ni+Co+Mn):Ti=1.03:0.95:0.05 2 O, 174.06gNi 0.5 co 0.2 mn 0.3 (OH) 2 , 7.99g TiO 2 , 5.38g of soluble starch was ball-milled for 1 hour, then added to a colloid mill for grinding for 8 hours, dried in vacuum at 100°C, and then pressed into tablets using a tablet machine.

[0041] 2) The molding material obtained in step 1) is heated to 950° C. at a heating rate of 3° C. / min, kept for 16 hours, cooled naturally to room temperature, and crushed by an air jet mill.

[0042] 3) Weigh 37.51g of aluminum nitrate according to the molar ratio of Al:(Ni+Co+Mn+Ti)=0.05:1, dissolve it in water, and under stirring, slowly add the product of step 2) after being crushed by the jet mill, and add dropwise Adjust the pH to 9 with ammonia water, stir at 60°C for 2h, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com