Electric cable

一种电缆、质量份的技术,应用在缆、绝缘电缆、电路等方向,能够解决低温耐受性和耐磨性恶化、不能同时满足阻燃性电池液耐受性、低温耐受性耐磨性和剥皮性能等问题,达到满足低温耐受性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 48

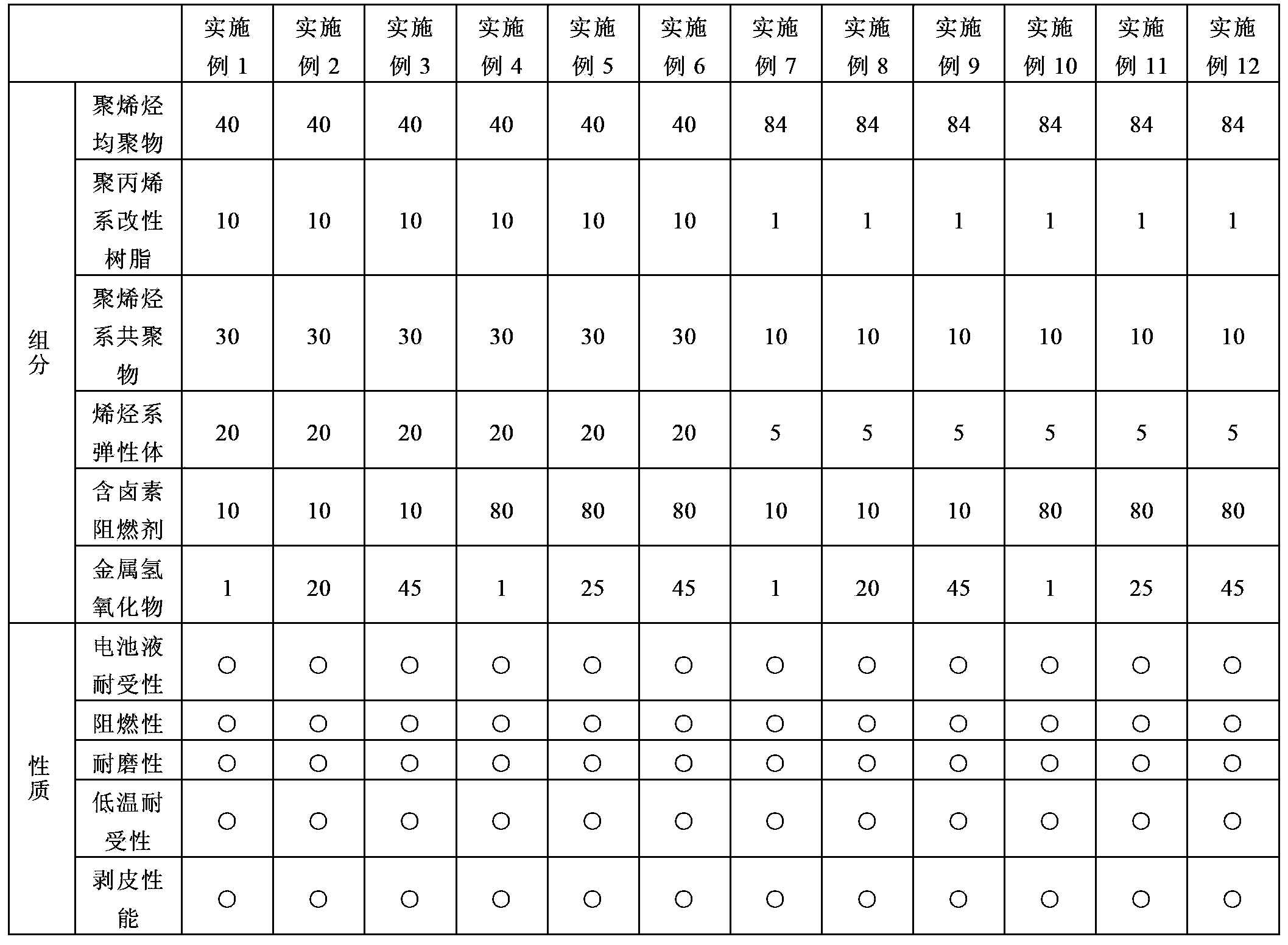

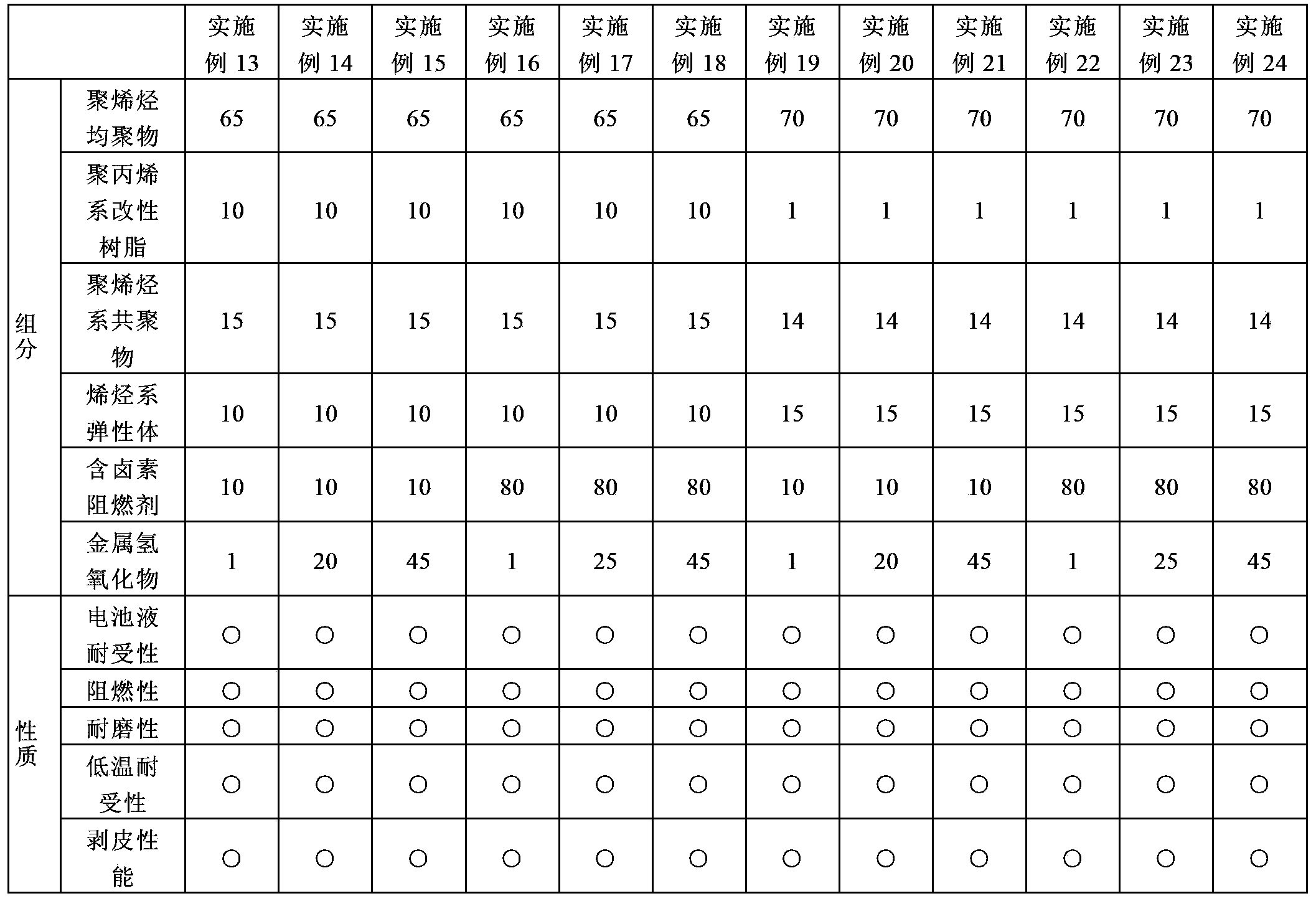

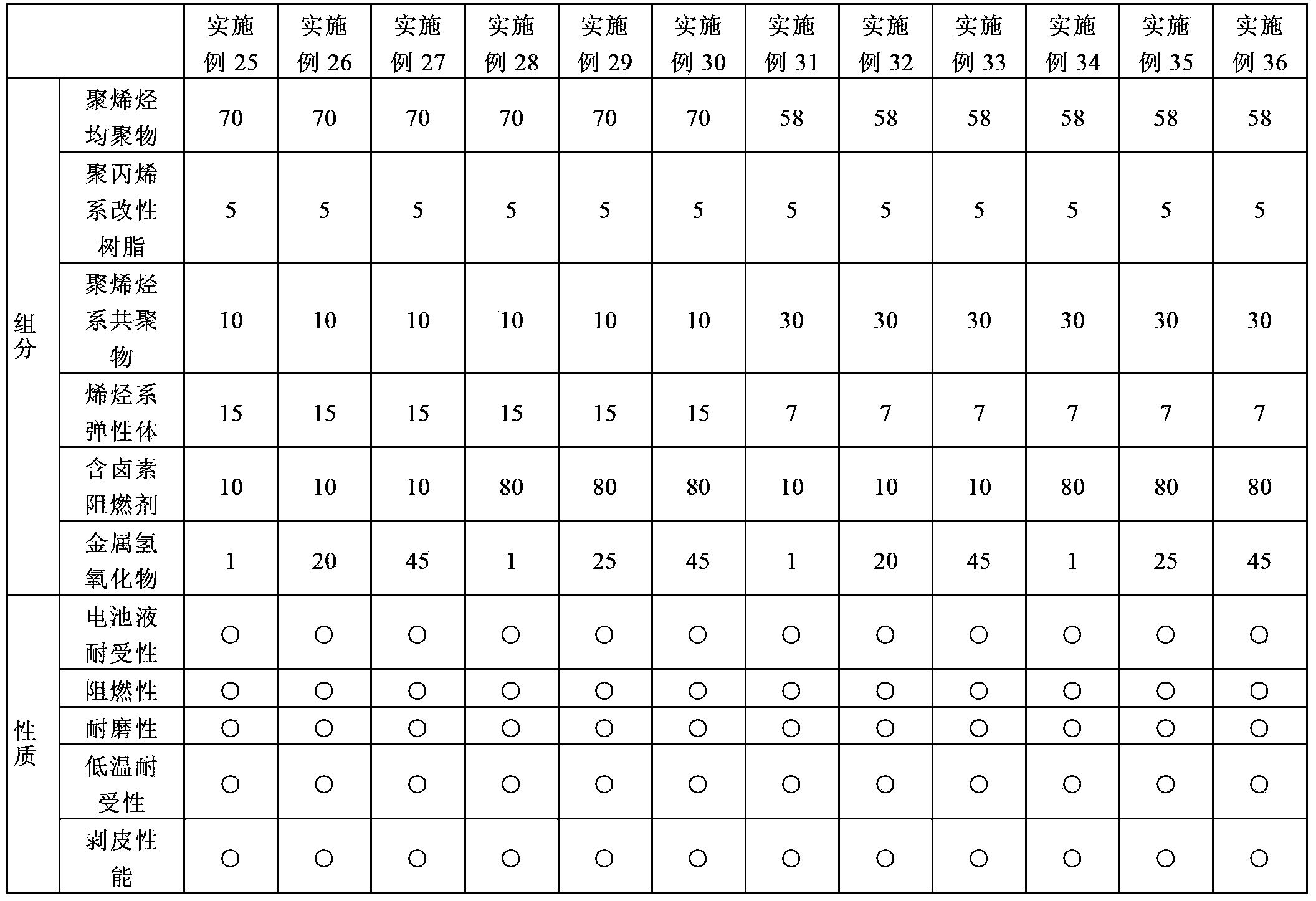

[0053] (Examples 1 to 48, Comparative Examples 1 to 9)

[0054] (Production of electric wires (cables) for automobiles)

[0055] The compositions used in Examples were prepared by kneading the respective components in the blending amounts (parts by mass) given in Tables 1 to 5 using a kneader or a screw type kneader, and then by using these compositions, Load them into an extruder (diameter 60mm, L / D=24.5, FF screw) and extrude them onto conductors at an extrusion rate of 500m / min and an extrusion temperature of 230°C to produce automotive electric wire. The respective components in Tables 1 to 5 are as follows:

[0056] Polypropylene homopolymer: Q100f produced by SunAllomer Ltd.

[0057] Polypropylene-based modified resin: YOUMEX 1001 manufactured by Sanyo Chemical Industries, Ltd.

[0058] Polyolefin-based copolymer: E185GK produced by Prime Polymer Co., Ltd.

[0059] Olefin-based elastomer: Tuftec H1062 produced by Asahi Kasei Corporation

[0060] Metal hydroxide: KI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com