Fireproof material of housing of storage battery

A shell material and battery technology, applied in the field of materials, can solve the problems affecting the sintering resistance, oxygen penetration, and low density of ceramic silicon rubber, and achieve the effects of small thermal expansion, high heat resistance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

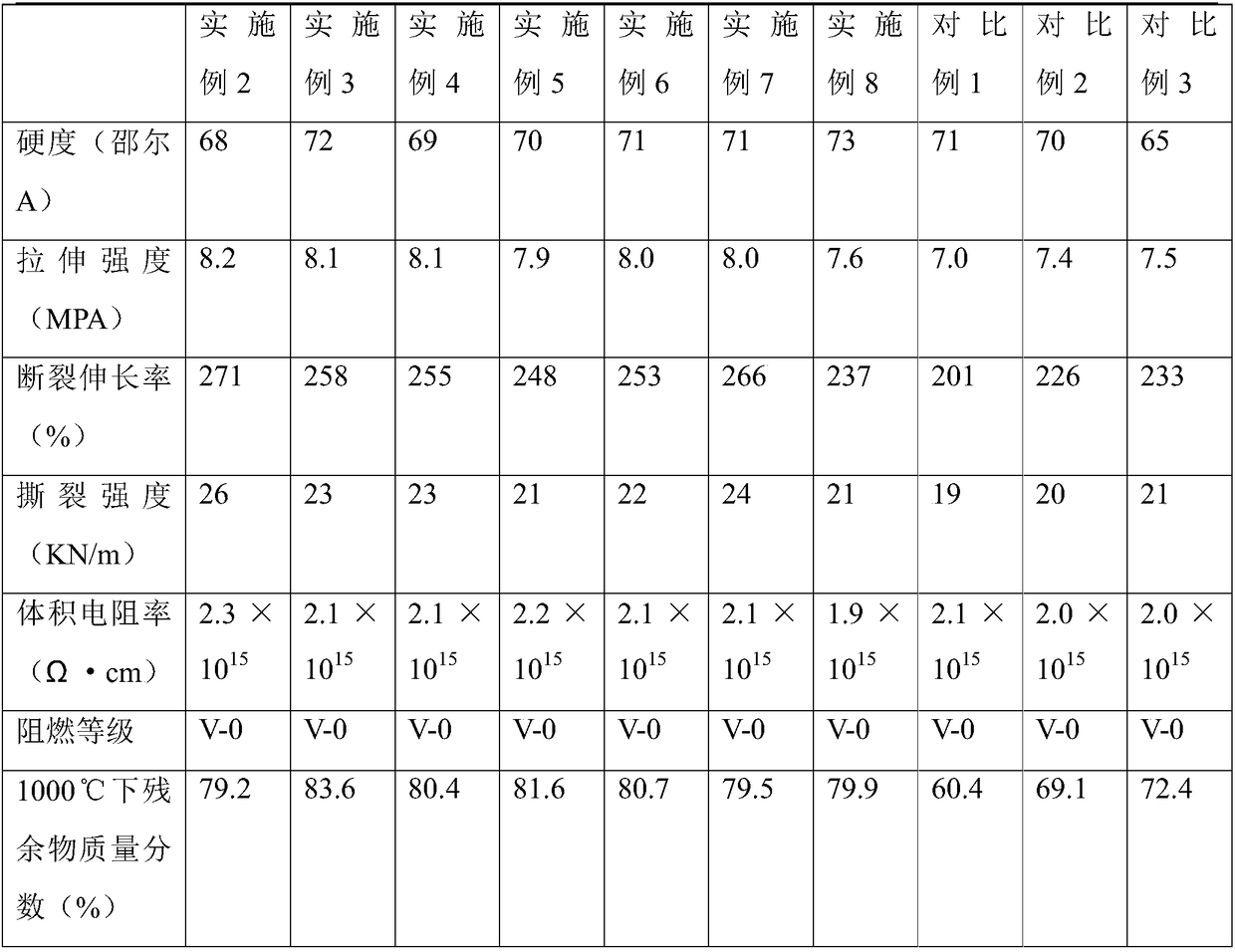

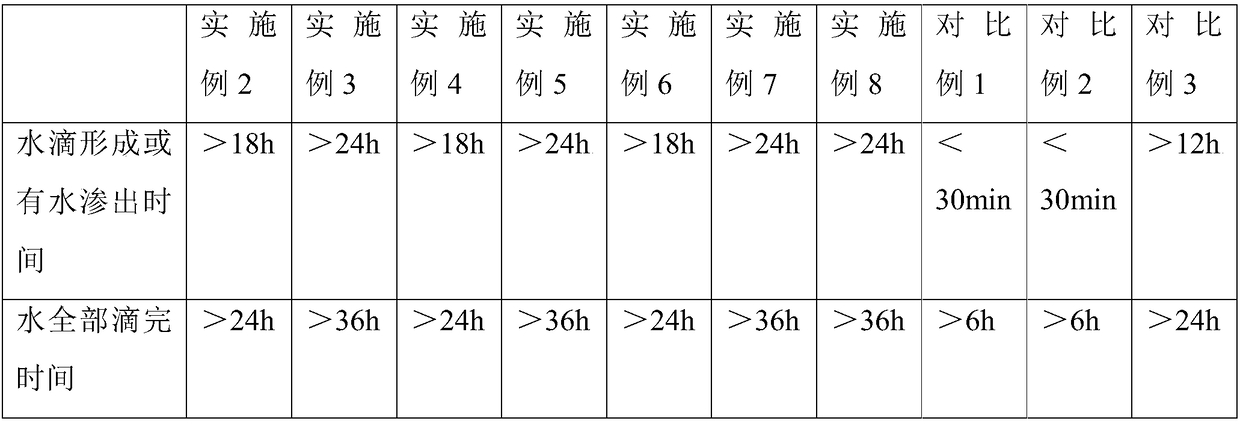

Examples

Embodiment 1

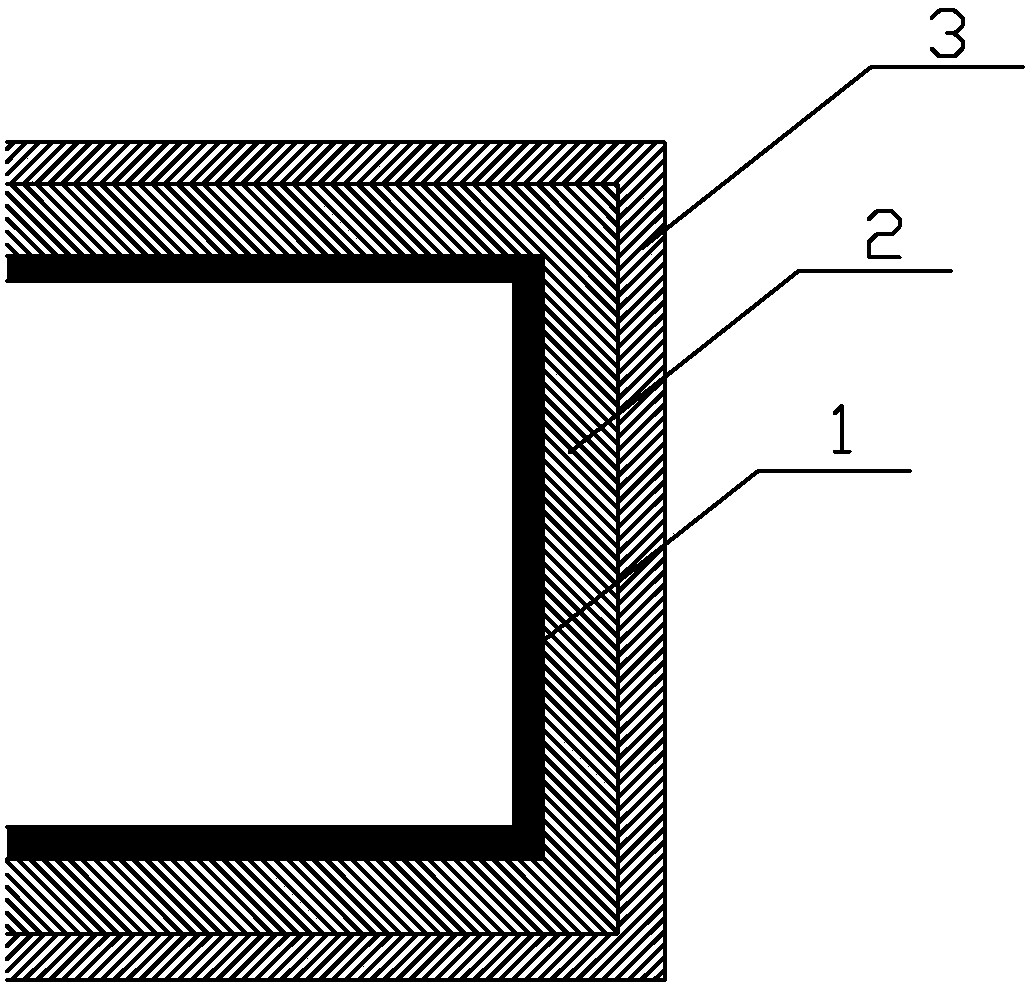

[0025] A battery shell material with fireproof performance, the shell includes a metal layer 1, a polypropylene plastic layer 2, and a vitrified silicon rubber layer 3 sequentially from the inside to the outside.

Embodiment 2

[0027] The ceramized silicone rubber layer in Example 1 is prepared from the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 30 parts of porcelain-forming filler, and the melting point range of 350-650°C as the flux. 5 parts of low-melting point glass powder, 1 part of chloroplatinic acid-octanol complex as catalyst, 5 parts of hydroxyl silicone oil, 3 parts of bis(2,4-dichlorobenzoyl) as vulcanizing agent, wherein, porcelain The filler is a mixture of aluminum silicate fiber and acicular wollastonite, wherein the mass ratio of aluminum silicate fiber and acicular wollastonite is 15:30.

[0028] To prepare, proceed as follows:

[0029] (1) Mix silicone rubber, ceramic filler, flux, platinum catalyst, and hydroxy silicone oil in a kneader with a vacuum degree of 0.01MPa, a temperature of 130°C, and a time of 120 minutes;

[0030] (2) After the above-mentioned rubber material is cooled to room temperature, add a vulcanizing agent into the ...

Embodiment 3

[0032] The ceramized silicone rubber layer in Example 1 is prepared from the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 50 parts of ceramic filler, and the melting point range of 350-650°C as the flux. 10 parts of low-melting point glass powder, 1 part of chloroplatinic acid-octanol complex as the catalyst, 5 parts of hydroxyl silicone oil, 3 parts of bis(2,4-dichlorobenzoyl) peroxide as the vulcanizing agent. The filler is a mixture of aluminum silicate fiber and acicular wollastonite, wherein the mass ratio of aluminum silicate fiber and acicular wollastonite is 17:33.

[0033] Prepare with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com