Liquid-cooled plate for battery, preparation method of liquid-cooled plate, battery module, battery pack and electric vehicle

A battery module and liquid cold plate technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of insufficient welding seam connection and sealing strength, increase the manufacturing cost of the liquid cold plate, and affect the use of the liquid cold plate. Achieve the effects of saving stamping and forming steps, reducing forming costs, good connection strength and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a battery liquid cold plate, the method comprising: placing the upper liquid cold plate and the lower liquid cold plate in parallel at intervals; welding the upper liquid cold plate and the lower liquid cold plate by electromagnetic pulse welding, welding The upper liquid cold plate deforms and connects with the lower liquid cold plate to form a connecting portion, and a flow channel is formed between two adjacent connecting portions.

[0038] According to the present invention, preferably, the distance between the two adjacent connecting parts is 3-30 mm.

[0039] According to the present invention, preferably, the gap between the intervals is 0.3-2mm.

[0040] According to the present invention, preferably, the two adjacent connecting parts are parallel.

[0041] According to the present invention, preferably, the welding energy of the electromagnetic pulse welding is 16-64KJ.

[0042] The invention also pro...

Embodiment 1

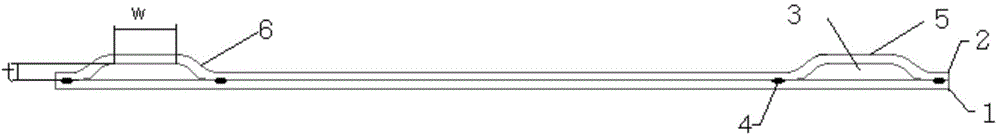

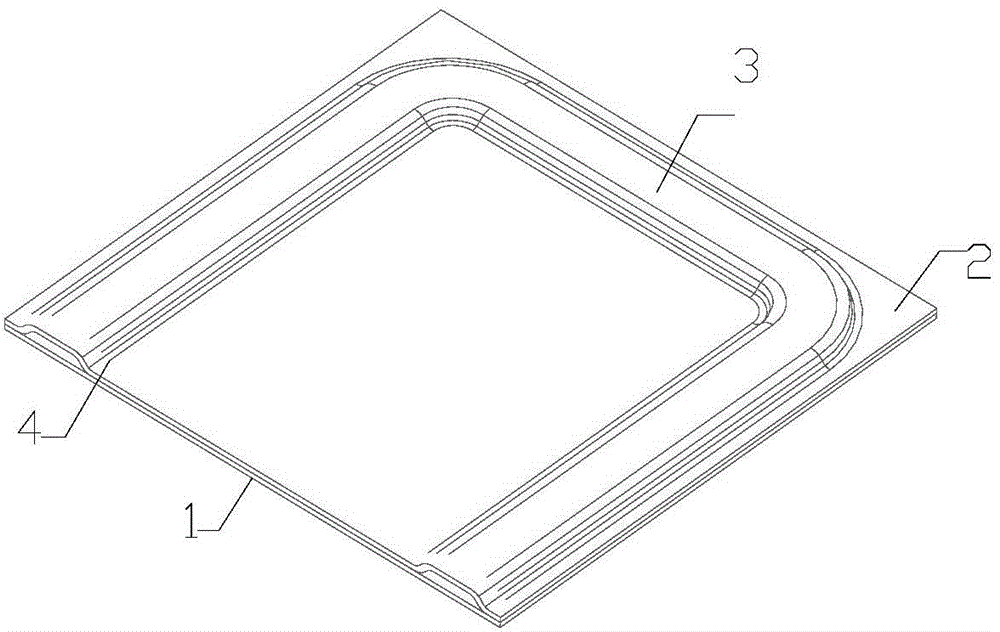

[0050] Put the upper liquid cold plate (copper material) and the lower liquid cold plate (aluminum alloy material) as figure 1Placed in parallel as shown in , with a gap of 2 mm, electromagnetic pulse welding (welding equipment model PS48-16 / 25, PST company) is applied on the upper liquid cold plate, and the welding energy is 16KJ to obtain the battery liquid cold plate. The structure after welding is as follows figure 2 , 3 As shown, the width of the connected part is 8mm, the width of the flow channel is 15mm, and the height is 2mm. The shape of the formed flow channel is Figure 4 As shown, the weight is 150g.

[0051] The obtained battery liquid cold plate was tested for connection strength and sealing performance, the connection strength was 400MPa, and the sealing strength was 0.01MPa.

[0052] Use a metallographic microscope to observe the structural morphology of the edge of the deformed part of the upper liquid cold plate and the part connected to the lower liquid...

Embodiment 2

[0054] Put the upper liquid cold plate (copper alloy material) and the lower liquid cold plate (aluminum material) as figure 1 Placed in parallel as shown in , with a gap of 1.5 mm, electromagnetic pulse welding is applied on the upper liquid cooling plate, and the welding energy is 20KJ to obtain a battery liquid cooling plate. The structure after welding is as follows figure 2 As shown, the width of the connected part is 10mm, the width of the flow channel is 20mm, and the height is 1.5mmm. The shape of the formed flow channel is Figure 5 As shown, the weight is 150g.

[0055] The obtained battery liquid cold plate was tested for connection strength and sealing performance, the connection strength was 300MPa, and the sealing strength was 0.02MPa.

[0056] Use a metallographic microscope to observe the structural morphology of the edge of the deformed part of the upper liquid-cooled plate and the part connected to the lower liquid-cooled plate. Figure 7 Similar as shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com