Composite flexible transparent electrode of copper nanowires and poly (3, 4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) and manufacturing method thereof

A technology of copper nanowires and transparent electrodes, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as poor adhesion, large roughness, and easy oxidation of copper nanowire films, and achieve good application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

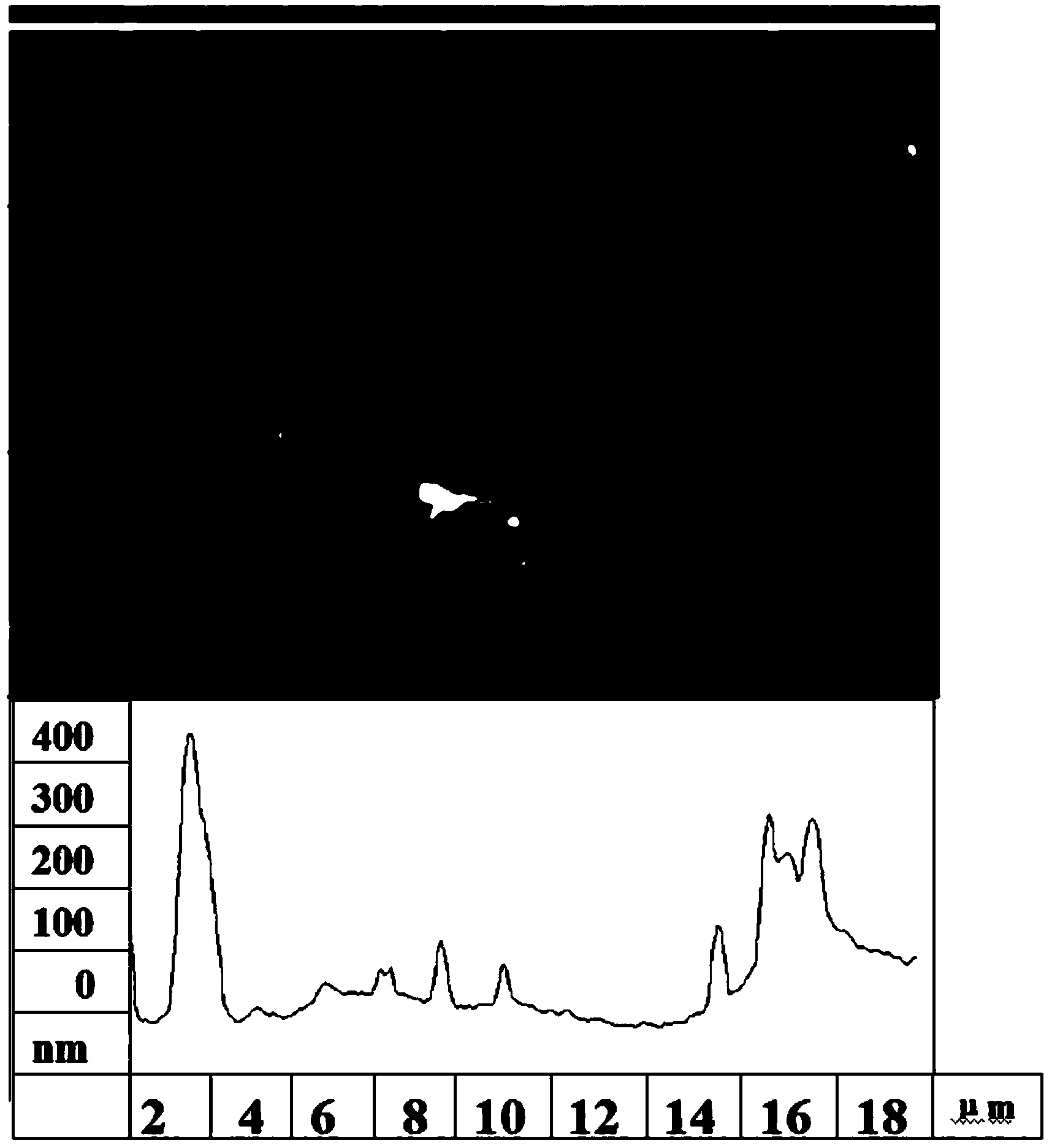

Image

Examples

Embodiment 1

[0020] (1) Remove the PET outer protective film.

[0021] (2) Copper nanowires are evenly dispersed in a solvent, and a copper nanowire film is prepared on a clean substrate by spin coating.

[0022] (3) The PEDOT:PSS film was transferred by spin coating to be superimposed on the copper nanowire film, wherein the mass ratio of copper nanowires and PEDOT:PSS was 80 / 20. Place the substrate in an environment at 120°C for 30 minutes to remove the residual solvent in the overlay.

[0023] (4) Carry out thermal curing and pressure treatment on the laminated flexible substrate and conductive layer. Form substrates (flexible electrodes) for flexible optoelectronic devices.

[0024] (5) The light transmittance of the substrate (flexible electrode) for testing flexible optoelectronic devices is 85%, and the square resistance of the film is 30Ω / sq.

Embodiment 2

[0026] (1) Remove the PET outer protective film.

[0027] (2) Copper nanowires are evenly dispersed in a solvent, and a copper nanowire film is prepared on a clean substrate by spin coating.

[0028] (3) The PEDOT:PSS film was transferred by spraying method, so that it was superimposed on the copper nanowire film, and the mass ratio of copper nanowire and PEDOT:PSS was 83 / 17. Place the substrate in an environment at 120°C for 30 minutes to remove the residual solvent in the overlay.

[0029] (4) Carry out thermal curing and pressure treatment on the laminated flexible substrate and conductive layer. Form substrates (flexible electrodes) for flexible optoelectronic devices.

[0030] (5) The light transmittance of the substrate (flexible electrode) for testing flexible optoelectronic devices is 83%, and the film resistance is 50Ω / sq.

Embodiment 3

[0032] (1) Remove the PET outer protective film.

[0033] (2) Copper nanowires are evenly dispersed in a solvent, and a copper nanowire film is prepared on a clean substrate by spin coating.

[0034] (3) The PEDOT:PSS film was transferred by the self-assembly method to be superimposed on the copper nanowire film, wherein the mass ratio of copper nanowires and PEDOT:PSS was 90 / 10. Place the substrate in an environment at 120°C for 30 minutes to remove the residual solvent in the overlay.

[0035] (4) Carry out thermal curing and pressure treatment on the laminated flexible substrate and conductive layer. Form substrates (flexible electrodes) for flexible optoelectronic devices.

[0036] (5) The light transmittance of the substrate (flexible electrode) for testing flexible optoelectronic devices is 90%, and the film resistance is 700Ω / sq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com