Real-time refrigerating capacity calculation method of electric vehicle power battery liquid cooling system and control thereof

A power battery and electric vehicle technology, which is applied in the real-time cooling capacity calculation method and control field of the liquid cooling system of the electric vehicle power battery, and can solve the problems of poor adaptability of the battery heat dissipation load and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

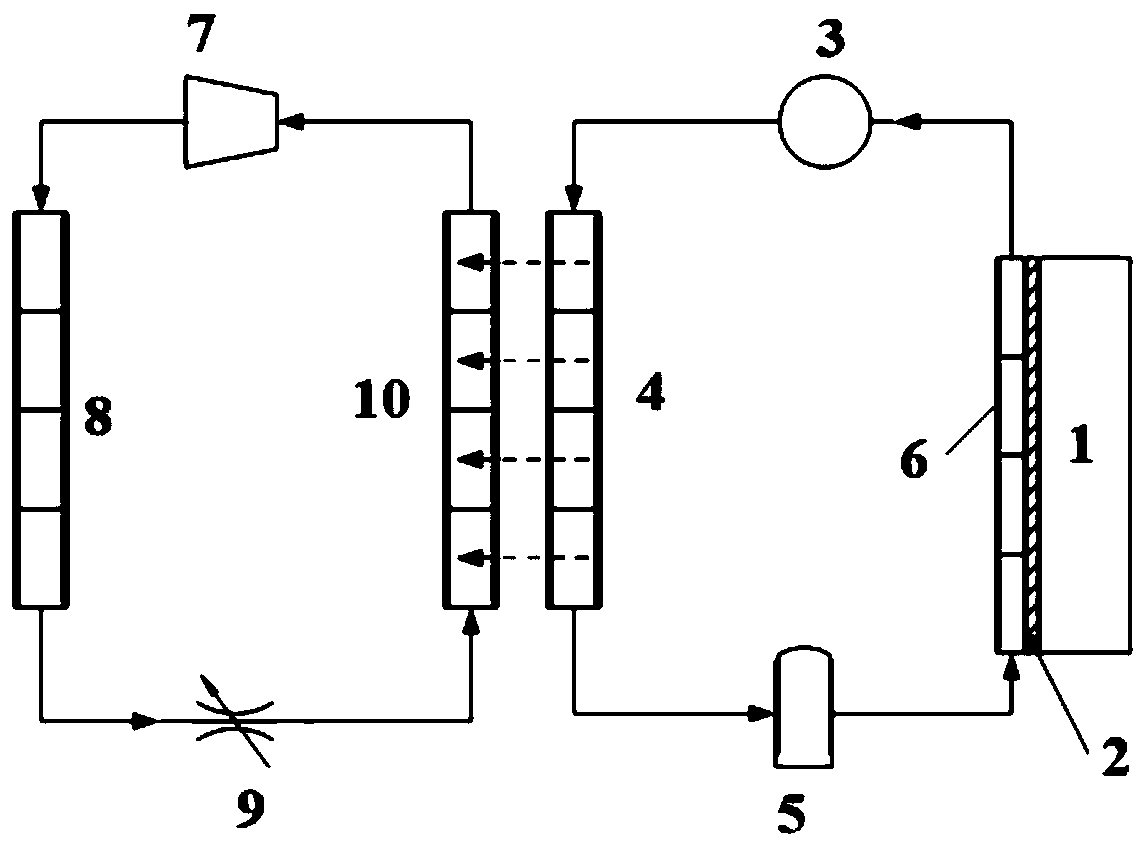

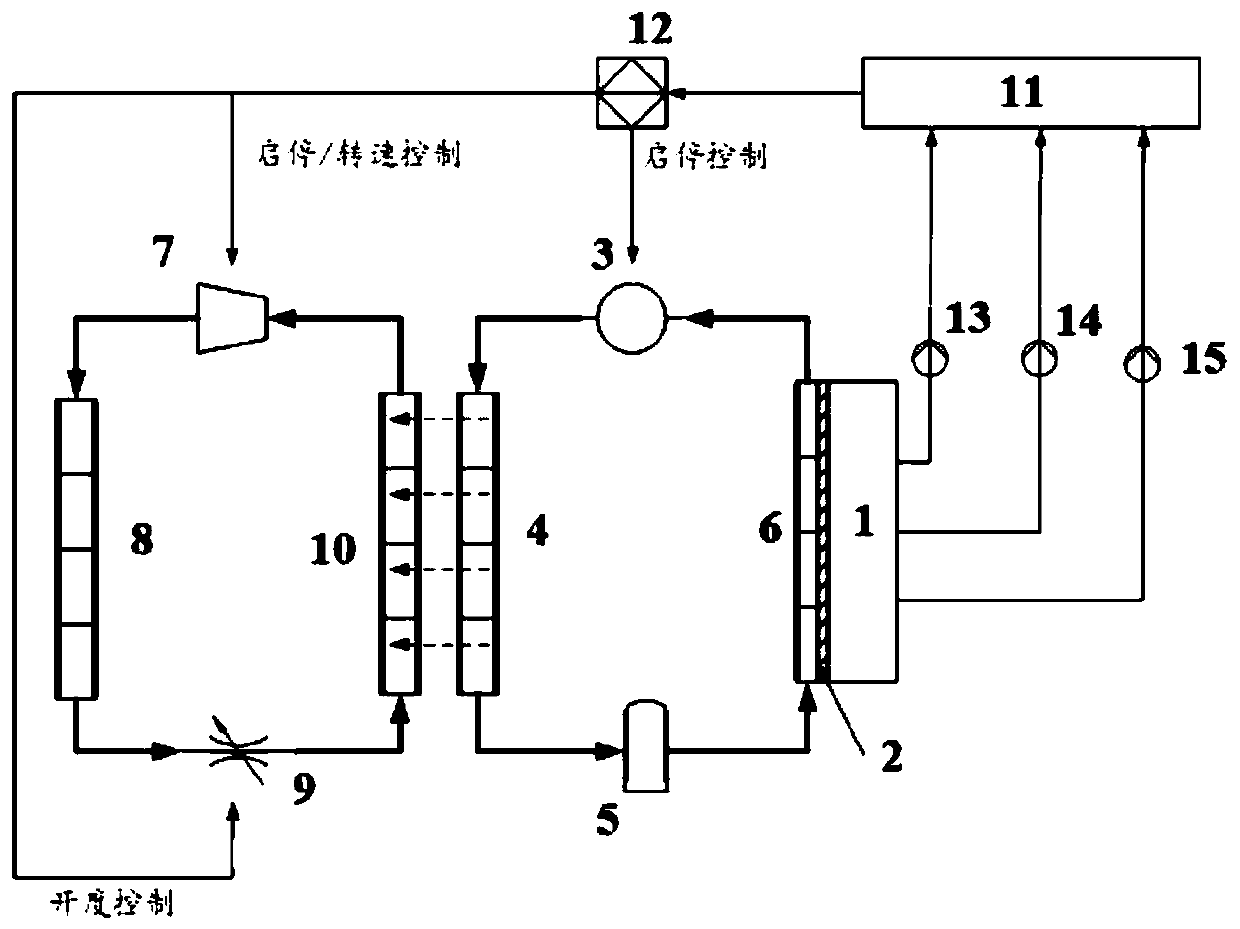

[0099] Such as image 3 As shown, the liquid cooling system of the present invention includes a power lithium-ion battery pack 1, a thermal insulation pad 2, a cooling liquid circulation circuit, and a refrigeration circulation circuit. The cooling liquid circulation circuit includes a circulation pump 3, a heat exchanger 4, and an expansion kettle 5. And the liquid cold plate 6, the refrigeration cycle circuit includes a compressor 7, a condenser 8, an electronic expansion valve 9 and an evaporator 10. A liquid cooling plate 6 is arranged between the lithium ion cells in the power lithium ion battery pack 3, and a thermally conductive and insulating pad 2 is arranged between the liquid cooling plate 6 and the surface of the lithium ion battery; the thermally conductive and insulating pad 2 can not only prevent external short circuits The risk of accidents (because the liquid-cooling plate 6 is usually a metal conductor) can also enhance the heat transfer rate between the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com