Roller body mounting structure on steel belt processing line

A technology of installation structure and processing line, which is applied in metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problem of low roll changing efficiency, and achieve the effect of improving efficiency and quickly changing rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific embodiments of the present invention in conjunction with the accompanying drawings are further described in detail. It should be understood that the specific embodiments described herein are used only to illustrate and explain the present invention and are not intended to limit the present invention.

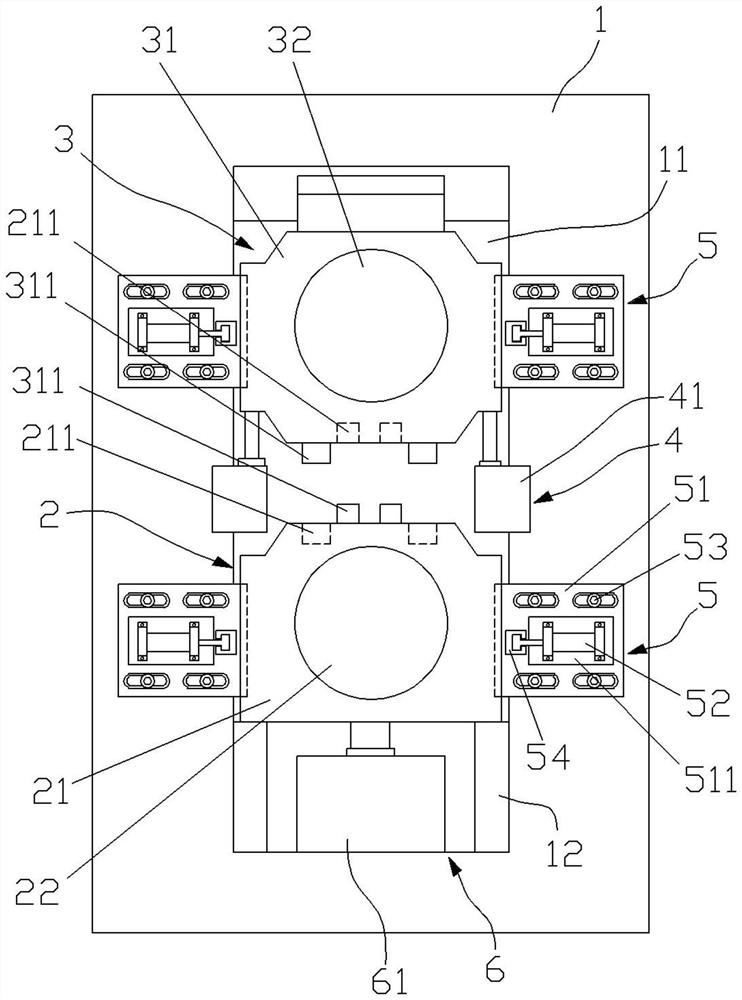

[0015] See Figure 1 , a roll body mounting structure on the steel belt processing line, comprising two support arms 1, the lower roller assembly 2, the upper roller assembly 3 and the first lifting mechanism 4, the two support arms 1 are relatively disposed on both sides of the steel belt conveying direction, each support arm 1 along the vertical direction of the opening of the tolerance groove 11, the capacitive groove 11 in the axis direction of the roller body through the support arm 11, correspondingly support arm 1 above the capacitive groove 11 to form a top wall, the capacity groove 11 below the formation of the bottom wall, the capacity groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com