Roll changing device of horizontal and vertical rolling mill

A technology of roll changing device and vertical rolling, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of changing the roll changing device to the horizontal rolling mill and vertical rolling mill, and achieve the reduction of spare parts specifications, Effects of fast roll change and convenient spare parts management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

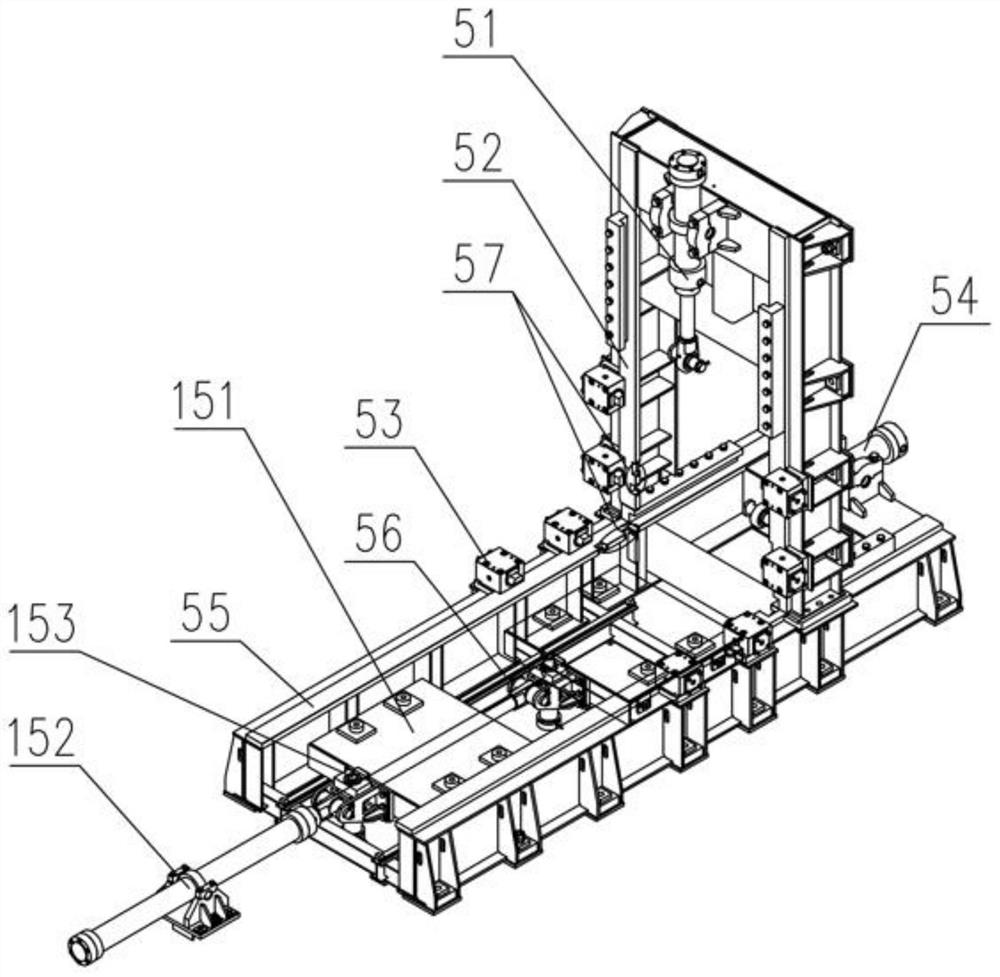

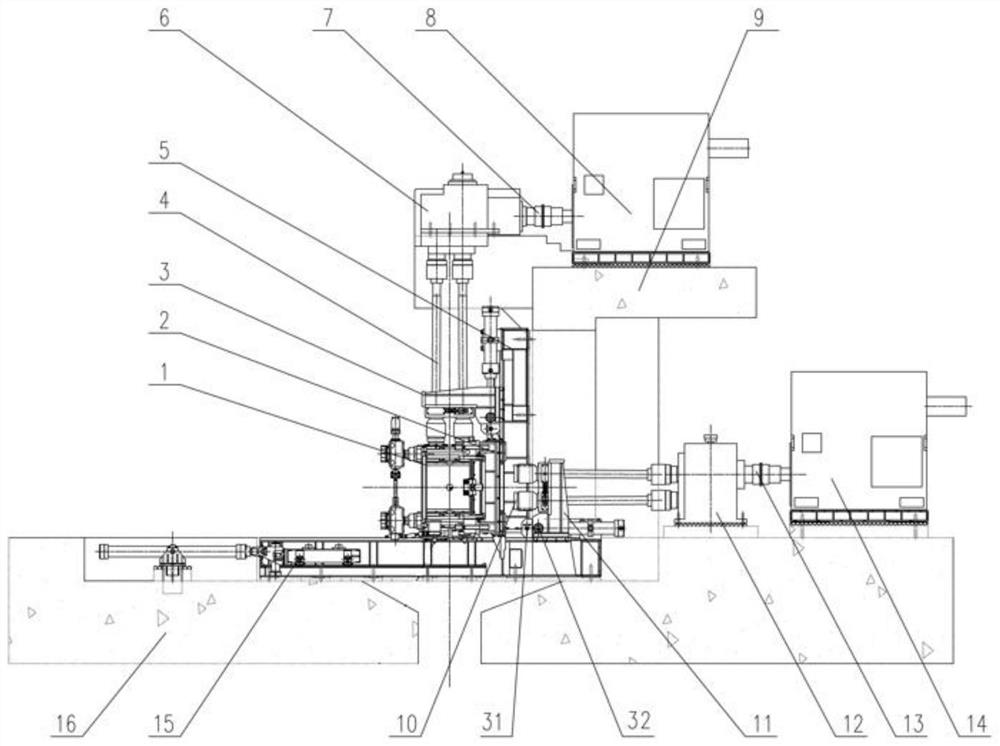

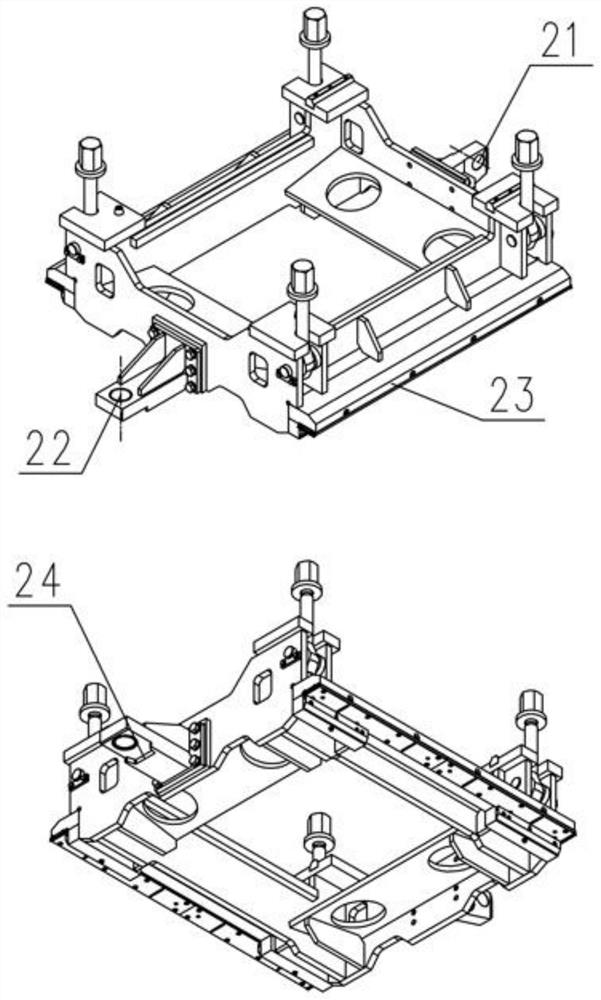

[0036] from Figure 1-7 It can be seen that a roll changing device for a vertical rolling mill in this embodiment includes a roll changing device 15 and a moving base 2. The roll changing device 15 is composed of a trolley 151, a roll changing hydraulic cylinder 152, and a pin mechanism 153. The cylinder 152 piston rod is connected with the latch mechanism 153, and the front end of the latch mechanism 153 is connected with the dolly 151. The surface of the latch mechanism 153 is provided with a roll-changing latch cylinder 154 and a plunger rod 155, and the surface of the latch mechanism 153 is also provided with a guide positioning block 156. It can be smoothly introduced and positioned with the guide positioning groove 24 of the connecting seat 2 on the mobile base 2, and one end of the latch mechanism 153 is connected with the mobile base 2, and the surface of the mobile base 2 is equipped with the rolling mill body 1.

[0037] When vertical rolling and horizontal rolling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com