Rapid supporting roller changing mechanism for plate strip rolling mill

A roll changing mechanism and technology for supporting rolls, applied in the direction of metal rolling mill stands, metal rolling stands, metal rolling, etc. The effect of convenient maintenance, reduction of auxiliary rolling time, and saving of roll change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

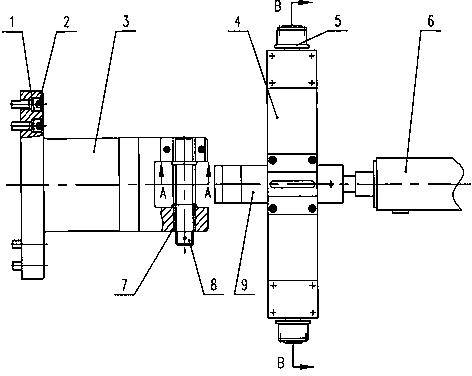

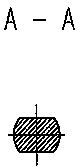

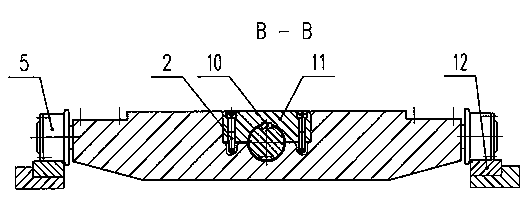

[0018] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] combine figure 1 , image 3 , Figure 4 , The present invention provides a fast roll changing mechanism for back-up rolls used in strip mills, the device includes a back-up roll hook 3 and a connecting shaft 8, and is driven by an oil cylinder 6. The support roller hook 3 is detachably connected to the support roller bearing housing 13 . Connecting shaft 8 is fixed on the support roller hook 3 by bearing 7 and bearing gland 14, and described bearing 7 can select high-intensity self-lubricating bearing for use, can install fastening device 16 and fix at its end, prevents from coming off. The cross-section of the middle part of the connecting shaft 8 is a flat shape symmetrically cut off on both sides, which is convenient for entering the shaft hole 18 of the oil cylinder joint 9 . One end of connecting shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com