Roll changing device of multi-roll mill

A roll changing device and rolling mill technology, applied in the field of spreaders, can solve the problems of low position control precision, complicated operation, poor safety, etc., and achieve the effect of solving the high frequency of roll changing, efficient roll changing and increasing production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

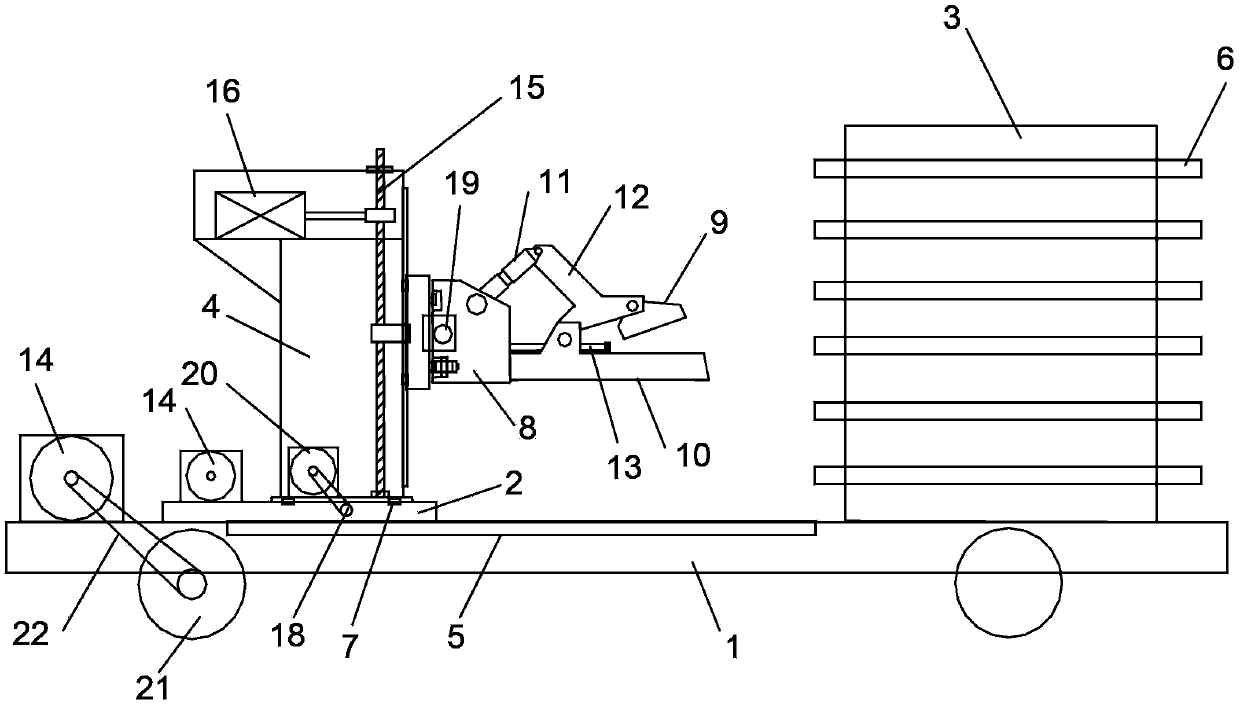

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] Please combine figure 1 As shown, the roll changing device for a multi-roll rolling mill of the present invention includes a traveling trolley 1, a clamp trolley 2 and a roll frame 3 arranged on the traveling trolley 1, a lifting frame 4 disposed on the clamp trolley 2, a lifting frame 4 located at one end of the lifting frame 4 Roller clamp, the driving trolley 1 is provided with a horizontal horizontal track 5 for the fixture trolley 2 to travel, the roll frame 3 is fixed on one end of the traveling trolley 1 to store spare rolls 6, and the fixture trolley 2 is provided with a lifting frame 4 The horizontal longitudinal track 7 that moves sideways, the roll clamp includes a clamp seat 8 located on the lifting frame 4, upper and lower clamps 9, 10 located on the clamp base 8, and a clamp cylinder 11, the clamp cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com